Potentiometric Titration for Acid-Base Analysis: A Comprehensive Guide for Pharmaceutical Professionals

This comprehensive article explores potentiometric titration for acid-base analysis, addressing the critical needs of researchers, scientists, and drug development professionals.

Potentiometric Titration for Acid-Base Analysis: A Comprehensive Guide for Pharmaceutical Professionals

Abstract

This comprehensive article explores potentiometric titration for acid-base analysis, addressing the critical needs of researchers, scientists, and drug development professionals. Covering foundational principles to advanced applications, it details methodological approaches for Active Pharmaceutical Ingredients (APIs) and excipients, aligned with USP-NF monographs and Quality by Design initiatives. The content provides practical troubleshooting guidance for common electrode and method errors, validation protocols following ICH guidelines, and explores innovative adaptations like microtitration for material-limited early development. With the potentiometric titrators market projected to grow at 7.0% CAGR through 2035, this resource offers essential knowledge for implementing robust, accurate analytical methods in pharmaceutical quality control and research.

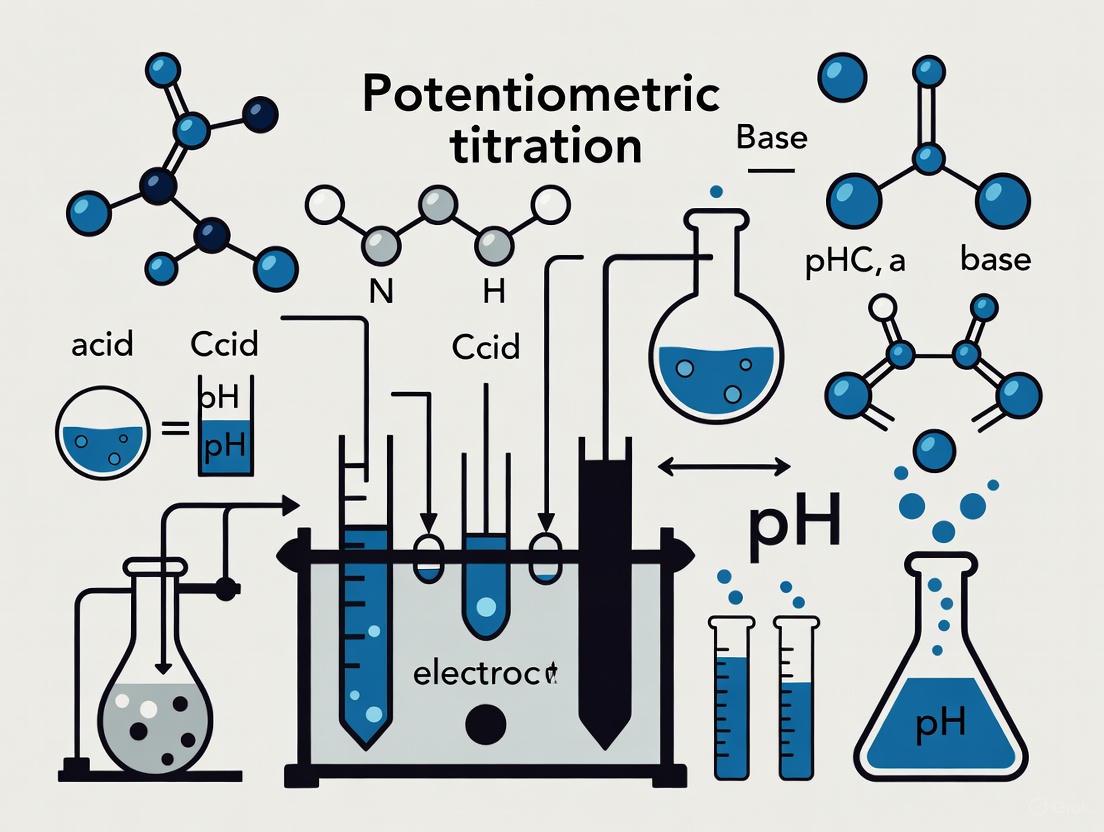

Principles and Pharmaceutical Relevance of Potentiometric Acid-Base Titration

Potentiometric titration is an electroanalytical technique used to determine the concentration of an analyte by measuring the electric potential across an electrochemical cell as a titrant is added. Unlike direct titration methods that rely on visual indicators, potentiometric titration uses an indicator electrode and a reference electrode to monitor the change in potential, which corresponds to the progress of the chemical reaction [1]. This method is particularly valuable for analyzing colored, turbid, or complex samples where visual endpoint detection is impractical or unreliable [2] [3].

The fundamental principle is based on the Nernst equation, which relates the electrode potential to the concentration (activity) of ions in solution. For a half-reaction of the form: [ \ce{M^{n+} + n e^{-} -> M} ] the Nernst equation is expressed as: [ E = E^⦵ - \frac{RT}{nF} \ln \frac{1}{[M^{n+}]} ] where E is the electrode potential, E⦵ is the standard electrode potential, R is the gas constant, T is the temperature, n is the number of electrons transferred, F is the Faraday constant, and [Mⁿ⁺] is the concentration of the ion of interest [4] [1]. The overall cell potential is calculated as: [ E{\rm{cell}} = E{\rm{ind}} - E{\rm{ref}} + E{\rm{sol}} ] where ( E{\rm{ind}} ) is the potential of the indicator electrode, ( E{\rm{ref}} ) is the potential of the reference electrode, and ( E_{\rm{sol}} ) is the potential drop over the test solution [1].

Electrode Systems and Potential Measurement

Electrode Configuration and Function

A potentiometric titration cell consists of two primary electrodes, each serving a distinct function in measuring the potential difference.

- Indicator Electrode: This electrode responds selectively to the activity (concentration) of the specific ion involved in the titration reaction. Its potential changes as the concentration of the target ion changes during the titration. Common types include:

- Metal Electrodes: Used for redox titrations (e.g., platinum electrode) [1].

- Glass Membrane Electrodes: Standard for pH measurement in acid-base titrations [2].

- Metal/Metal Oxide Electrodes (MMO): Such as RuO₂, IrO₂, or stainless steel electrodes, which can also provide a Nernstian response to pH and are advantageous for their mechanical robustness and lower cost [3].

- Reference Electrode: This electrode provides a stable, fixed potential against which the change in the indicator electrode's potential is measured. It is designed to maintain a constant ionic composition. Common reference systems include:

- Combined Electrodes: For convenience, combined sensors that integrate both the measuring and reference electrode into a single body are often used in automated systems [2].

The Electrochemical Cell and Potential Measurement

The core of the measurement is the electrochemical cell formed by the indicator and reference electrodes immersed in the analyte solution. The potential difference (( E_{\rm{cell}} )) is monitored continuously as the titrant is added. A high-impedance voltmeter is used to ensure minimal current draw, preventing electrolysis and ensuring the measurement reflects the equilibrium potential [4] [1]. The setup and the flow of information in this system can be visualized as follows:

Endpoint Detection Methodologies

The endpoint of a potentiometric titration is not a single volume reading but is derived from the characteristic shape of the titration curve—a plot of the measured cell potential (E or pH) versus the volume of titrant added. The endpoint is marked by a sharp change in potential occurring at the equivalence point [4] [1]. In automated systems, the titrator can detect this change and slow down the titrant addition to improve accuracy [2].

Primary Detection Methods

Several analytical methods are used to precisely determine the endpoint from the acquired data.

- First Derivative Method: This method plots the rate of change of potential with respect to volume (ΔE/ΔV) against the volume of titrant. The endpoint is identified as the volume at which this derivative curve reaches a maximum, corresponding to the steepest point of the titration curve [5].

- Second Derivative Method: This method plots the rate of change of the first derivative (Δ²E/ΔV²) against volume. The endpoint is the volume where the second derivative crosses zero, precisely locating the inflection point of the original titration curve [5].

- Gran Plot Analysis: This is a linearization method used particularly for titrations with a small potential jump. It plots an antilog function of the potential against volume, resulting in a straight line that sharply deviates at the endpoint. This method is useful for determining endpoints in weak acid-base systems or for very dilute solutions [5].

Comparison of Endpoint Detection Techniques

While potentiometry is a common endpoint detection method, other physical property changes can be utilized, each with distinct advantages and applications as summarized in the table below.

Table 1: Comparison of Endpoint Detection Techniques in Titration

| Determination Principle | Description | Key Applications & Advantages |

|---|---|---|

| Potentiometric | Measures the concentration-dependent potential (mV) against a reference potential [2]. | Versatile for acid-base, redox, precipitation, and complexometric titrations; robust and widely applicable [2] [6]. |

| Photometric | Measures the change in intensity of a light beam at a specific wavelength as the solution's color changes [2]. | Ideal for titrations using color indicators; objective replacement for subjective visual determination [2]. |

| Conductometric | Measures the change in the electrical conductivity of the solution during titration [2]. | Useful for acid-base titrations in dilute solutions or when no suitable indicator is available. |

| Thermometric | Records the temperature change (ΔT) resulting from the molar heat of reaction (ΔHr) [2]. | Applicable to any reaction with a significant enthalpy change, does not require specific chemical properties. |

| Amperometric | Measures the concentration-dependent current (μA) at a constant applied voltage [2]. | Used for titrations involving electroactive species. |

Experimental Protocol: Acid-Base Potentiometric Titration

This protocol details the steps for a general acid-base titration using a potentiometric endpoint, adaptable for various electrode types.

Research Reagent Solutions and Essential Materials

Table 2: Essential Materials and Reagents for Potentiometric Titration

| Item | Function/Description |

|---|---|

| Burette | Precision dispenser for the titrant solution. |

| Indicator Electrode | e.g., Glass pH electrode, metal/metal oxide (MMO) electrode. Sensitive to H⁺ ion activity [2] [3]. |

| Reference Electrode | e.g., Ag/AgCl electrode. Provides a stable, fixed reference potential [4] [2]. |

| pH/mV Meter | High-impedance instrument for accurate potential difference measurement. |

| Magnetic Stirrer & Stir Bar | Provides homogeneous mixing of the solution during titrant addition. |

| Titrant Solution | Standardized solution of known concentration (e.g., NaOH for acid titration). |

| Analyte Solution | The solution containing the unknown concentration of acid or base. |

| Buffer Solutions | Used for the calibration of the electrode system prior to titration. |

| Redox Mediators | Used in redox titrations to facilitate equilibrium and a stable potential reading [6]. |

Step-by-Step Procedure

- Electrode Setup and Calibration: Connect the indicator and reference electrodes (or a combined electrode) to the pH/mV meter. Calibrate the system using standard buffer solutions (e.g., pH 4.01, 7.00, and 10.01) to ensure accurate potential/pH measurement [3].

- Sample Preparation: Pipette a known, precise volume of the analyte solution (e.g., HCl) into a clean titration beaker. Add a magnetic stir bar.

- Titration Assembly: Place the beaker on the magnetic stirrer and immerse the electrodes into the solution, ensuring they are sufficiently submerged and not interfered with by the stir bar. Position the burette tip above the solution.

- Initial Measurement: Record the initial potential (or pH) and volume reading on the burette (V₀).

- Titrant Addition and Data Collection:

- Begin stirring the solution.

- Add the titrant (e.g., NaOH) in small, incremental volumes. Initially, additions can be larger (e.g., 1.0 mL) when the potential is changing slowly.

- After each addition, allow the potential to stabilize and record both the volume added and the corresponding potential.

- As the potential begins to change more rapidly (approaching the endpoint), decrease the volume increments (e.g., to 0.1 mL or smaller) to capture the inflection point accurately [2].

- Post-Endpoint Data Collection: Continue adding titrant for several milliliters after the major potential jump, resuming larger increments once the potential change stabilizes again. This ensures a well-defined titration curve.

- Data Analysis: Plot the measured potential (E) versus the volume of titrant added. Determine the equivalence point volume using the first or second derivative method as described in Section 3.1.

The following workflow summarizes the key experimental stages:

Advanced Applications and Considerations

Potentiometric titration is a robust technique that extends beyond simple acid-base analysis. It is widely used in redox titrations, such as determining the concentration of Fe²⁺ by titration with permanganate (MnO₄⁻) [4], and in complexometric titrations like the determination of metal ions with EDTA [2] [1]. Furthermore, it is a critical tool in biochemical research for determining the reduction potentials of redox-active cofactors in metalloproteins, providing insights into electron transfer processes in respiration and photosynthesis [6].

A key consideration in potentiometric measurements is that the Nernst equation is written in terms of ion activity, not concentration. Activity accounts for non-ideal behavior in electrolyte solutions and is influenced by the ionic strength of the medium [4]. For precise thermodynamic studies, this distinction is critical. A limitation to consider, especially in biochemical contexts, is that EPR-based potentiometric titrations can typically only detect steady-state radicals and may not capture fleeting paramagnetic intermediates formed during enzyme catalysis [6].

The United States Pharmacopeia-National Formulary (USP-NF) monographs and the Food and Drug Administration (FDA) Quality by Design (QbD) requirements represent two complementary pillars of the modern pharmaceutical quality framework. USP-NF provides legally enforceable standards for drug products, ingredients, and dosage forms, while QbD embodies a systematic, science-based, and risk-informed approach to pharmaceutical development and manufacturing [7] [8]. The integration of robust analytical methodologies, such as potentiometric titration for acid-base analysis, within this converged framework enables the generation of high-quality data essential for demonstrating compliance and ensuring product quality throughout the lifecycle.

USP is transitioning to a new bimonthly publication model effective July 2025, consolidating official publications from 15 to six issues per year to provide a more regular distribution cadence and expedited publishing timelines [9]. Furthermore, USP has implemented updated procedures for monograph modernization, where redesign-only revisions are now published with a "To Be Official" status and become official six months after posting [10]. These updates reflect a dynamic regulatory environment aimed at enhancing efficiency while maintaining quality standards.

Fundamental Principles: QbD and Compendial Standards

Core Elements of Quality by Design

QbD, as defined by ICH Q8(R2), is "a systematic approach to development that begins with predefined objectives and emphasizes product and process understanding and process control, based on sound science and quality risk management" [7]. This represents a paradigm shift from traditional quality control methods that primarily relied on end-product testing toward proactively building quality into pharmaceutical products from the design phase [8].

The core principles of QbD include [7] [8]:

- Quality Target Product Profile (QTPP): A prospective summary of the quality characteristics of a drug product that ideally will be achieved to ensure the desired quality, considering safety and efficacy.

- Critical Quality Attributes (CQAs): Physical, chemical, biological, or microbiological properties or characteristics that should be within an appropriate limit, range, or distribution to ensure the desired product quality.

- Critical Process Parameters (CPPs): Process parameters whose variability impacts CQAs and therefore should be monitored or controlled to ensure the process produces the desired quality.

- Design Space: The multidimensional combination and interaction of input variables (e.g., material attributes) and process parameters that have been demonstrated to provide assurance of quality.

- Control Strategy: A planned set of controls, derived from current product and process understanding, that ensures process performance and product quality.

Table 1: QbD Implementation Stages and Outputs

| Stage | Description | Key Outputs | Applications/Notes |

|---|---|---|---|

| Define QTPP | Establish prospectively defined summary of quality characteristics | QTPP document listing target attributes | Foundation for all subsequent QbD steps (ICH Q8) |

| Identify CQAs | Link product quality attributes to safety/efficacy using risk assessment | Prioritized CQAs list | CQAs vary by product type (biologics vs. small molecules) |

| Risk Assessment | Systematic evaluation of material attributes and process parameters | Risk assessment report, CPPs/CMAs identification | Tools: Ishikawa diagrams, FMEA |

| Design of Experiments | Statistically optimize process parameters through multivariate studies | Predictive models, optimized CPP/CMA ranges | Identifies interactions between variables |

| Establish Design Space | Define multidimensional combination of input variables ensuring quality | Validated design space model with Proven Acceptable Ranges | Regulatory flexibility: Changes within design space don't require re-approval |

| Develop Control Strategy | Implement monitoring and control systems | Control strategy document | Combines procedural controls and analytical tools |

| Continuous Improvement | Monitor process performance and update strategies using lifecycle data | Updated design space, refined control plans | Tools: Statistical process control, Six Sigma |

Studies indicate that QbD implementation can reduce development time by up to 40% by optimizing formulation parameters before full-scale manufacturing and reduce material wastage by up to 50% through fewer batch failures [8]. The FDA's initiative on Pharmaceutical Quality for the 21st Century and ICH guidelines (Q8-Q12) position QbD as a foundational standard for modern pharmaceutical development [11].

Role and Structure of USP-NF Monographs

USP-NF monographs provide legally recognized standards for the identity, strength, quality, and purity of drug substances, excipients, and finished drug products. These standards are enforceable under the Federal Food, Drug, and Cosmetic Act and are utilized by regulators, manufacturers, and researchers to ensure consistent product quality [9] [10].

Each monograph typically includes [10]:

- Definition: Description of the substance or product, including packaging and storage requirements.

- Identification: Specific tests to confirm identity.

- Assay: Procedures to quantify the active ingredient.

- Impurity Tests: Limits and methods for detecting and quantifying impurities.

- Performance Tests: For dosage forms, tests demonstrating proper drug release or delivery.

The recent update to USP's publication model, effective with the first issue of USP-NF 2026 in July 2025, transitions from 15 to six official publications annually, published bimonthly on the last Friday of each month [9]. This consolidation aims to streamline the standardization process while maintaining timely updates to compendial standards.

Analytical Methodology: Potentiometric Titration in Pharmaceutical Analysis

Principles and Applications of Potentiometric Titration

Potentiometric titration is an analytical technique that measures the potential difference between a reference electrode and an indicator electrode during a titration to determine the endpoint. This method provides significant advantages for pharmaceutical analysis, including high accuracy, applicability to colored or turbid solutions, minimal sample preparation, and the ability to automate [12].

In pharmaceutical development and quality control, potentiometric titration serves multiple critical functions [13] [12]:

- Acid-base characterization of active pharmaceutical ingredients (APIs) and excipients

- Quantification of ionic components in drug formulations

- Determination of protonation constants (pKa values) essential for predicting API behavior

- Quality control testing for compendial methods referenced in USP monographs

The technique is particularly valuable for determining acid dissociation constants (pKa), which profoundly influence a drug's pharmacokinetic properties, including absorption and bioavailability [12]. As noted in recent research, "pH/potentiometric titration remains the gold standard method for determining acid/base constants" for soluble and stable compounds in aqueous media [12].

Comparative Analytical Techniques

While potentiometric titration serves as the reference method for acid-base characterization, orthogonal techniques provide complementary approaches for challenging analytical scenarios:

Table 2: Comparison of Analytical Methods for Acid-Base Characterization

| Parameter | Potentiometry | NMR/pH Titration | Spectrophotometric Titration |

|---|---|---|---|

| Principle | Measurement of electrode potential | Measurement of chemical shifts with pH | Measurement of absorbance changes with pH |

| Accuracy | High, especially with clear ion selectivity | High, particularly for complex molecules | Medium to high, depending on chromophores |

| Sample Requirements | Pure (>95%), sufficient concentration (0.1-10 mmol/L) | Sufficient concentration (>1 mmol/L) for NMR detection | Requires UV-active moieties |

| Throughput | Medium to high with automation | Low to medium | Medium to high |

| Cost | Low to moderate | High (instrumentation and maintenance) | Moderate |

| Multiprotic Molecules | Characterizes molecule as a whole | Provides site-specific protonation information | May resolve multiple protonation sites |

| Key Applications | pKa determination (pH 2-12), quantification | pKa determination, structural information, site-specific data | pKa determination for UV-active compounds |

Recent meta-analyses demonstrate excellent agreement between potentiometric and NMR-based pKa determinations, validating both methods for reliable acid-base characterization in drug development [12].

Integrated Application: QbD-Driven Analytical Method Development

QbD Principles in Analytical Methodology

The application of QbD principles to analytical method development, known as Analytical Quality by Design (AQbD), ensures that methods are robust, reproducible, and fit-for-purpose throughout the product lifecycle. AQbD aligns with ICH Q14 guidelines and establishes a Method Operable Design Region (MODR) to define the parameter space within which method performance remains acceptable [8].

Key stages in implementing AQbD for potentiometric titration methods include [7] [8]:

- Define Analytical Target Profile (ATP): Specify requirements for the method, including accuracy, precision, and robustness.

- Identify Critical Method Attributes (CMAs): Determine measurable characteristics critical to method performance.

- Risk Assessment: Systematically evaluate factors that could impact method performance using tools like Failure Mode Effects Analysis (FMEA).

- Method Development and Design of Experiments: Statistically optimize method parameters through multivariate studies.

- Establish MODR: Define the combination of input variable ranges where method performance is guaranteed.

- Control Strategy: Implement procedures to ensure method performance over time.

Experimental Protocol: Potentiometric Titration for Acid-Base Analysis

Materials and Equipment:

- Potentiometer with high-impedance input

- Combined pH glass electrode or separate reference and indicator electrodes

- Magnetic stirrer with temperature control

- Burette (automated or manual) for titrant delivery

- Thermostated titration vessel

- Standardized titrant solution (e.g., 0.1 M NaOH or HCl)

- Ionic strength adjuster (e.g., 0.1 M NaCl or KNO₃)

- Standard buffer solutions (pH 4.01, 7.00, 10.01) for electrode calibration

Sample Preparation:

- Accurately weigh the sample and transfer to the titration vessel.

- Dissolve in appropriate solvent (typically water or water-cosolvent mixtures).

- Add ionic strength adjuster to maintain constant ionic strength (typically 0.1-0.15 M).

- Purge with inert gas (e.g., nitrogen) if dissolved oxygen interference is anticipated.

- Thermostate to desired temperature (typically 25.0 ± 0.1°C).

Titration Procedure:

- Calibrate electrodes using standard buffer solutions.

- Immerse electrodes in sample solution, ensuring complete immersion of sensing elements.

- Begin stirring at constant rate to ensure homogeneity without vortex formation.

- Record initial potential/pH reading.

- Add titrant in increments, allowing stabilization between additions (typically 30-60 seconds).

- Reduce increment size in regions of rapid potential change near endpoints.

- Continue titration until sufficient data beyond all equivalence points is collected.

- Perform replicate determinations (typically n=3) to establish precision.

Data Analysis:

- Plot potential (E) versus titrant volume (V).

- Identify equivalence points using first (ΔE/ΔV) or second derivatives (Δ²E/ΔV²).

- For pKa determination, apply the Henderson-Hasselbalch equation or nonlinear regression.

- Calculate analyte concentration using stoichiometric relationships at equivalence points.

- Determine method precision, accuracy, and detection limits through statistical analysis.

Method Validation Parameters:

- Accuracy through standard addition or comparison with reference materials

- Precision (repeatability and intermediate precision)

- Linearity and range

- Robustness to deliberate variations in method parameters

- Specificity in presence of potential interferents

Integrated Regulatory Strategy: Connecting QbD and Compendial Standards

Strategic Implementation Framework

Successfully navigating the integrated landscape of QbD and compendial standards requires a systematic approach that connects development activities with regulatory expectations. The following framework visualizes this integrated strategy:

Diagram 1: QbD-USP Integration Framework (79 characters)

This framework demonstrates how QbD principles and USP-NF requirements intersect throughout the product lifecycle. Compendial standards inform CQA identification, method validation approaches support control strategy development, and ongoing monograph updates necessitate proactive lifecycle management.

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Essential Research Reagents and Materials for Potentiometric Analysis

| Item | Function | Application Notes |

|---|---|---|

| Standard Buffer Solutions | Electrode calibration and performance verification | pH 4.01, 7.00, 10.01 at specified temperature; traceable to NIST standards |

| Ionic Strength Adjusters | Maintain constant ionic medium | NaCl, KNO₃ (0.1-0.15 M); minimizes activity coefficient variations |

| Standardized Titrants | Quantitative reagent delivery | NaOH, HCl (0.01-0.1 M); standardized against primary standards |

| Primary Standards | Titrant standardization and method validation | Potassium hydrogen phthalate (KHP), sodium carbonate; high purity (>99.95%) |

| Reference Electrodes | Stable potential reference | Ag/AgCl, calomel; regular inspection and maintenance required |

| Indicator Electrodes | pH/potential response | Glass membrane, hydrogen, quinhydrone; selection based on application |

| Inert Gases | Oxygen exclusion in redox systems | Nitrogen, argon; degassing solutions when oxygen interference anticipated |

The strategic integration of USP-NF monograph requirements with QbD principles represents the contemporary paradigm for pharmaceutical quality assurance. This converged framework enables manufacturers to develop robust processes and analytical methods that consistently produce products meeting their quality attributes while maintaining compliance with compendial standards. Potentiometric titration, as a gold standard for acid-base characterization, provides critical data supporting both QbD implementation and monograph compliance.

As regulatory landscapes evolve with initiatives like the USP's new bimonthly publication model and updated monograph implementation procedures, pharmaceutical scientists must maintain vigilance regarding compendial updates [9] [10]. Similarly, the ongoing adoption of QbD principles across development and manufacturing operations continues to demonstrate significant benefits in efficiency, quality, and regulatory flexibility [7] [8]. Through the thoughtful application of this integrated framework and robust analytical methodologies, pharmaceutical professionals can advance product quality while ensuring regulatory compliance throughout the product lifecycle.

Within pharmaceutical and chemical research, quantitative acid-base analysis is fundamental to drug development and quality control. Titration serves as a cornerstone technique, with traditional visual methods historically employed for endpoint detection. However, the subjective nature of visual indicator interpretation introduces significant variability, potentially compromising data integrity. This application note delineates the definitive advantages of potentiometric titration over visual methods, with a specific focus on its enhanced objectivity, superior accuracy, and seamless automation compatibility, thereby supporting the broader thesis of its superiority for rigorous acid-base analysis research [14] [15].

Comparative Analysis: Potentiometric vs. Visual Titration

Potentiometric titration eliminates the reliance on human vision to detect a color change, instead utilizing an electrode pair to measure the potential difference across the analyte solution. This fundamental difference in endpoint detection translates into several key performance advantages, quantitatively summarized in Table 1.

Table 1: Quantitative Comparison of Visual and Potentiometric Titration Methods [14] [16]

| Factor | Visual Titration | Potentiometric Titration |

|---|---|---|

| Endpoint Detection | Subjective color change | Objective potential (mV) measurement |

| Accuracy | Lower in colored/turbid samples | High, even in complex matrices |

| Precision (RSD) | Subject to higher variability (< 1% possible with automation) [15] | Consistently high (< 1% RSD achievable) [15] |

| Data Objectivity | Low (analyst-dependent) | High (instrument-generated) |

| Automation Potential | Low, manual intensive | High, easily integrated |

| Sample Versatility | Limited to clear, colorless solutions | High; suitable for colored, turbid, and viscous samples [14] |

| Labor Requirement | High | Minimal post-setup |

| Regulatory Compliance | Challenging for data integrity | Simplified with full data traceability [15] |

Core Advantages in Research and Development

Objectivity in Endpoint Detection

Potentiometry replaces the subjective interpretation of a color change with an objective, instrument-based measurement of a voltage shift at the equivalence point [14]. This removes analyst-to-analyst variability, a significant source of error in visual methods, especially when the endpoint is subtle or ambiguous. In practice, the endpoint is determined from a sharp inflection in a potential-versus-volume curve, which is precisely defined by the instrument's software, ensuring consistent and unbiased results across all analyses [15].

Enhanced Accuracy and Precision

The accuracy of potentiometric titration is superior, particularly for non-ideal samples. Colored, turbid, or suspensions that would obscure a visual indicator's color change pose no challenge to an electrode [14]. Furthermore, the method provides a full titration curve, allowing for the analysis of mixtures with multiple buffering components or the identification of weak acid/base pairs that a single visual endpoint would fail to reveal [14]. The precision, expressed as Relative Standard Deviation (RSD), is significantly improved, often achieving values below 1% with automated systems [15] [17].

Automation Compatibility

Potentiometric systems are inherently suited for automation. Automatic burets deliver titrant with high precision, while the electrode continuously monitors the reaction. This is governed by software that controls the entire process—from titrant addition and stirring to endpoint recognition and data calculation—minimizing human intervention and error [14] [15]. Automated systems can operate 24/7, dramatically increasing laboratory throughput and efficiency, and ensuring strict adherence to ALCOA+ (Attributable, Legible, Contemporaneous, Original, and Accurate) principles for data integrity, a critical requirement in regulated environments like pharmaceutical QC [15].

Experimental Protocol: Automated Potentiometric Titration of an Active Pharmaceutical Ingredient (API)

Scope

This protocol describes the general procedure for determining the acid or base value of a soluble API using an automated potentiometric titration system, compliant with principles outlined in USP general chapters <541> and <1225> [15] [17].

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials and Reagents [15] [17]

| Item | Function | Specification/Note |

|---|---|---|

| Automated Titrator | Precision delivery of titrant and data acquisition. | Must be qualified (IQ/OQ). |

| Combined pH Electrode | Indicator electrode; detects H+ ion activity. | e.g., Glass electrode with 3 mol/L KCl reference electrolyte. |

| Titrant (e.g., HClO₄ or NaOH) | Reacts stoichiometrically with the analyte. | Concentration precisely determined by standardization. |

| Primary Standard | Used for exact titrant concentration determination. | High purity, stable, low hygroscopicity (e.g., Potassium Hydrogen Phthalate). |

| Solvent System | Dissolves the sample and provides medium for reaction. | Chosen based on sample solubility (e.g., water, glacial acetic acid). |

| Software | Controls instrument, acquires data, calculates results. | 21 CFR Part 11 compliant for regulated environments [15]. |

Method Workflow

The following diagram illustrates the automated workflow for a potentiometric titration.

Step-by-Step Procedure

System Setup and Calibration:

- Install the appropriate combined pH electrode (e.g., a Solvotrode for non-aqueous titration) [15].

- Calibrate the electrode using at least two standard buffer solutions traceable to national standards. Verify calibration success per instrument specifications.

Titrant Standardization:

- Precisely weigh an appropriate primary standard (e.g., Potassium Hydrogen Phthalate for base titrants) into the titration vessel [17].

- Dissolve in the prescribed solvent and titrate using the automated method.

- Perform in triplicate. The software will calculate the exact titrant concentration (titer) based on the consumed volume. The Relative Standard Deviation (RSD) for the determined concentration must be within predefined limits (e.g., < 0.5%) [17].

Sample Analysis:

- Accurately weigh the test sample (API) and transfer to the titration vessel.

- Add the required solvent and ensure complete dissolution.

- Initiate the pre-defined automated titration method. The system will add titrant, record the potential, and identify the endpoint from the first or second derivative of the titration curve.

Data Analysis and Reporting:

- The software automatically calculates the result (e.g., acid value, content) based on the titrant consumption and sample weight.

- The full titration curve, all raw data, and calculated results are stored with a time-stamped audit trail for complete traceability [15].

Method Validation

For results to be acceptable in a pharmaceutical context, the method must be validated. Key parameters for titration are summarized below [17].

Table 3: Key Validation Parameters for Potentiometric Titration [17]

| Validation Parameter | Target | Protocol |

|---|---|---|

| Accuracy | Recovery of 98-102% | Compare results from spiked samples with known added standard. |

| Precision (Repeatability) | RSD < 1.0% | Perform at least six independent determinations of a homogeneous sample. |

| Linearity | R² ≥ 0.999 | Titrate at least five different sample masses across the range of 80-120% of the target concentration. |

| Specificity | No interference | Demonstrate that excipients or potential impurities do not interfere with the analyte's endpoint. |

Potentiometric titration definitively surpasses visual titration for acid-base analysis in research and quality control. By providing objective, instrument-driven endpoint detection, it delivers superior accuracy and precision, particularly for challenging sample matrices. Its inherent compatibility with automation streamlines workflows, enhances throughput, and ensures robust data integrity compliant with stringent regulatory standards. For these reasons, potentiometric titration represents the modern, reliable choice for scientists engaged in drug development and analytical research.

Current Market Landscape and Growth Projections in Pharmaceutical Analysis

The global pharmaceutical industry is navigating a period of profound transformation as it approaches 2025. Characterized by unprecedented scientific innovation alongside significant economic and regulatory pressures, the sector faces a pivotal moment where traditional business models are being fundamentally questioned. Industry leaders recognize that bold reinvention is no longer optional but essential for future survival and growth. With many CEOs doubting their current business models can survive another decade, pharmaceutical companies are placing strategic bets on new technologies and approaches to create value in an increasingly complex landscape [18]. This analysis examines the current market dynamics, growth projections, and strategic priorities shaping the industry, with particular focus on the role of advanced analytical techniques like potentiometric titration in ensuring quality and efficacy amid these transformative changes.

Current Market Dynamics and Performance Metrics

The pharmaceutical sector has demonstrated resilience in growth projections while facing significant challenges in delivering shareholder value relative to the broader market. Recent performance data reveals a complex picture of innovation alongside financial headwinds.

Financial Performance and Market Valuation

Recent analysis reveals the pharmaceutical sector has delivered lagging shareholder returns compared to the broader market. From 2018 through November 2024, a PwC equal-weight index of 50 pharma companies returned 7.6% to shareholders, compared with more than 15% for the S&P 500. This performance gap became even more pronounced over the most recent year, with the pharma index returning 13.9% compared to 28.7% for the S&P through November 2024 [18].

Compounding this challenge, value growth within the sector has become increasingly concentrated. Since 2018, just two companies accounted for nearly 60% of the increase in value growth among the 50 pharma companies analyzed by PwC, indicating significant performance disparity within the industry [18]. This dynamic has led to declining market valuations, with the median enterprise-value-to-EBITDA multiple for pharma companies falling from 13.6X in 2018 to 11.5X in 2024, during a period of multiple expansion for the broader S&P index [18].

Global Sales Projections and Growth Areas

Despite these challenges, the industry demonstrates robust growth potential in specific therapeutic areas and technologies. The pharmaceutical industry is on track to surpass $1.75 trillion in prescription drug sales by the end of the decade, with several key segments driving this expansion [19].

Table 1: Pharmaceutical Market Growth Projections and Key Therapeutic Areas

| Category | Projection / Current Impact | Timeframe | Key Drivers/Examples |

|---|---|---|---|

| Global Prescription Drug Sales | > $1.75 trillion | By 2030 | Overall market expansion, innovative therapies [19] |

| GLP-1 Receptor Agonists | ~9% of global drug sales | By 2030 | Effectiveness in obesity, multiple conditions being evaluated [19] |

| AI-Driven Drug Discovery | 30% of new drugs discovered using AI | By 2025 | Reduced timelines/costs (25-50% in preclinical) [20] |

| Patent Expirations | > $300 billion sales at risk | Through 2030 | Loss of exclusivity for high-revenue products [19] |

| Chinese Biotech Assets | ~40% of global licensing deals | 2025 | Increasing innovation and global partnerships [19] |

The growth in GLP-1 receptor agonists is particularly noteworthy, with these medications projected to account for nearly 9% of global drug sales by 2030. Their application has expanded beyond diabetes to obesity treatment, with ongoing evaluations for conditions including sleep apnea, addiction, Alzheimer's disease, and nonalcoholic fatty liver disease [19]. This represents a significant shift toward addressing general medicines and common conditions after decades of focus on specialty and rare diseases.

Key Strategic Priorities for Pharmaceutical Companies

Evolving R&D and Portfolio Strategies

Research and development transformation represents a cornerstone of pharmaceutical strategy in 2025. Companies are fundamentally rethinking their approaches to R&D in response to declining productivity and high failure rates that can reach 90% for new drug candidates [21]. Several key trends are shaping R&D evolution:

- Novel Modalities and Mechanisms: Pharmaceutical companies are increasingly adopting new modalities including fusion proteins, oligonucleotide therapies, multispecific antibodies, antibody drug conjugates, radioligand therapies, and oncolytic viruses to redefine standards of care [22].

- Therapy Area Shifts: While oncology and immunology remain priorities, about half of the ten largest pharma companies are focusing on therapy areas beyond these core domains, including cardiovascular, renal and metabolic diseases [22].

- AI and Digital Integration: Eighty-five percent of biopharma executives plan to invest in data, digital and AI in R&D for 2025, with one top-10 pharma company expecting to save approximately $1 billion in drug development costs over five years through these technologies [22].

Digital Transformation and AI Adoption

Artificial intelligence has transitioned from experimental pilot projects to core strategic capability across the pharmaceutical value chain. Nearly 60% of executives plan to increase generative AI investments across their organizations, suggesting companies are beginning to realize substantial value from adopting these technologies at scale [21].

AI implementation is delivering measurable benefits in specific operational areas. Amgen has doubled its clinical trial enrollment speed using a multimodal, data-driven machine learning tool, while Sanofi is collaborating with OpenAI and Formation Bio to develop an AI tool that reduces patient recruitment timelines "from months to minutes" [22]. Beyond R&D, AI investments could generate up to 11% in value relative to revenue across functional areas for biopharma companies over the next five years, with some medtech companies potentially achieving cost savings of up to 12% of total revenue within two to three years [21].

Strategic Partnerships and M&A Activity

Mergers, acquisitions, and strategic partnerships continue to play a crucial role in pharmaceutical innovation strategies. An impressive 77% of surveyed executives expect M&A to increase in 2025, partly driven by the need to address portfolio gaps created by patent expirations on high-revenue products [21]. This trend is reflected in the market data, with M&A activity in the industry increasing by more than 100% in Q1 2024 compared to Q1 2023 [20].

Strategic collaborations are also expanding beyond traditional boundaries. Notable examples include a research alliance between the Broad Institute, MIT, Harvard, and Novo Nordisk to identify novel therapeutic targets for Type 2 diabetes and cardiometabolic diseases, and Pfizer's partnership with the American Cancer Society to address disparities in cancer care [22]. These partnerships reflect a growing recognition that solving complex healthcare challenges requires ecosystems of expertise rather than isolated efforts.

Analytical Techniques in Pharmaceutical Analysis: Potentiometric Titration

In the context of evolving pharmaceutical portfolios and increasingly complex molecules, robust analytical techniques like potentiometric titration remain essential for quality control and compound characterization. This method provides precise quantitative analysis crucial for pharmaceutical development and manufacturing.

Principles and Applications in Pharmaceutical Analysis

Potentiometric titration is a method of volumetric analysis where the endpoint is determined by measuring the electrical potential (voltage) between two electrodes as a titrant is added to the solution being analyzed [23]. This technique offers significant advantages for pharmaceutical analysis, particularly for colored, turbid, or opaque solutions where visual indicator-based methods are ineffective [23].

In pharmaceutical applications, potentiometric titration can be used to determine the effective content of active pharmaceutical ingredients (APIs), excipients, and to monitor reaction progress during synthesis. The method's precision and simplicity make it particularly valuable for quality control in drug manufacturing processes [24].

Table 2: Research Reagent Solutions for Potentiometric Titration in Pharmaceutical Analysis

| Reagent/Equipment | Function in Analysis | Pharmaceutical Application Examples |

|---|---|---|

| Indicator Electrode | Sensitive to the analyte; detects potential changes | Glass electrode (pH), Platinum electrode (redox) [23] |

| Reference Electrode | Maintains a constant, known potential | Silver/Silver Chloride, Calomel Electrode [23] |

| Standardized Titrant Solutions | Reacts with analyte of known concentration | Acid/Base solutions (HCl, NaOH), Redox agents (K₂Cr₂O₇) [24] [23] |

| High-Impedance Voltmeter | Measures potential difference between electrodes | Accurate detection of millivolt changes [23] |

| Ion Selective Electrodes | Targets specific ions in complex mixtures | Drug counter-ion analysis, impurity detection |

Experimental Protocol: Potentiometric Titration for Acid-Base Analysis

Objective: To determine the concentration of an unknown pharmaceutical compound (acid or base) using potentiometric titration.

Principles: This technique measures the potential difference between a reference electrode and an indicator electrode during the addition of titrant. The equivalence point is identified by a sharp change in potential, which corresponds to the point where the amount of titrant added is stoichiometrically equivalent to the analyte concentration [23]. For acid-base titrations, the potential is related to the pH of the solution through the Nernst equation [24].

Materials and Equipment:

- Potentiometer or high-impedance pH meter with millivolt capability

- Indicator electrode (glass pH electrode)

- Reference electrode (silver/silver chloride or calomel)

- Magnetic stirrer and stir bar

- Burette (25 or 50 mL)

- Standardized titrant solution (0.1 M HCl for bases or 0.1 M NaOH for acids)

- Analytical balance

- Sample solution of unknown concentration

Procedure:

Electrode Preparation: Calibrate the electrode system using standard buffer solutions (pH 4.00, 7.00, and 10.00). Rinse electrodes with deionized water between measurements.

Sample Preparation: Accurately weigh the pharmaceutical sample and dissolve in an appropriate solvent (typically deionized water). Transfer quantitatively to a clean beaker.

Titration Setup: Place the beaker on the magnetic stirrer and immerse the electrodes. Ensure the electrodes are properly positioned and not touching the stir bar. Begin gentle stirring.

Initial Measurement: Record the initial potential (mV) and corresponding pH reading before adding any titrant.

Incremental Titration: Add the titrant in 1.0 mL increments for the first 80% of the expected equivalence point, recording the potential after each addition. Allow the reading to stabilize before recording values.

Precise Endpoint Determination: As the potential begins to change more rapidly (typically a change of >20 mV between additions), decrease the titrant volume to 0.1 mL increments. Continue until the potential change reverses direction and begins to slow.

Post-Equivalence Point Measurements: Continue adding titrant in 1.0 mL increments for at least 5-6 additions beyond the equivalence point.

Data Recording: Record the volume of titrant added and the corresponding potential (mV) throughout the entire procedure.

Data Analysis and Endpoint Determination:

Titration Curve Plotting: Plot the measured potential (mV) against the volume of titrant added (mL).

First Derivative Method: Calculate ΔE/ΔV (the change in potential per change in volume) for each successive addition and plot these values against the average volume. The peak of this derivative curve corresponds to the equivalence point.

Second Derivative Method: For greater precision, calculate Δ²E/ΔV² and determine where it equals zero, which indicates the equivalence point.

Concentration Calculation: Using the volume at the equivalence point (Veq), calculate the concentration of the unknown sample using:

Quality Control Considerations:

- Perform all measurements at constant temperature (23±2°C)

- Use freshly prepared standardized solutions

- Run duplicate or triplicate determinations for statistical accuracy

- Verify electrode response with standard reference materials

Market Outlook and Future Projections

The pharmaceutical industry's trajectory through 2025 and beyond will be shaped by its response to several converging forces. While 75% of global life sciences executives express optimism about the year ahead, with 68% anticipating revenue increases and 57% predicting margin expansions, this optimism is tempered by significant headwinds [21].

Regulatory and pricing pressures represent substantial challenges, with nearly half (47%) of executives expecting pricing and access issues to significantly affect their strategies in 2025 [21]. The U.S. Inflation Reduction Act alone is projected to drive a 31% decrease in U.S. pharmaceutical company revenues through 2039 and lead to 135 fewer new asset approvals as provisions change the cost-benefit analysis of development [22]. Simultaneously, demographic shifts including the projected doubling of the world's population aged 60 and above to 2.1 billion by 2050 will create both market opportunities and healthcare system challenges [22].

The industry's future will likely be characterized by several defining features:

- Precision and Personalization: Value creation is moving toward prevention, personalization, prediction, and point-of-care delivery, with more focus on addressing health risk factors and creating data-driven, customized treatments based on genetics and behavior [18].

- Technology Integration: AI, real-world evidence, and digital health technologies will become embedded across the value chain from discovery to patient engagement.

- Portfolio Transformation: Companies will continue shifting from traditional blockbuster models to more targeted therapies and platform technologies, with increased focus on novel modalities and high-unmet-need areas.

- Geographic Rebalancing: Emerging markets, particularly China's growing innovation ecosystem, will play an increasingly important role in global pharmaceutical strategy.

As the industry navigates these changes, analytical techniques like potentiometric titration will maintain their critical role in ensuring product quality, safety, and efficacy, even as the therapeutic modalities and business models around them continue to evolve at an accelerating pace.

Practical Implementation: From API Quantification to Excipient Analysis

Sample Preparation Strategies for APIs and Complex Formulations

Within the framework of potentiometric titration method research for acid-base analysis, sample preparation is a critical foundational step that directly impacts the accuracy, reproducibility, and reliability of analytical results. Proper sample preparation ensures that the active pharmaceutical ingredient (API) is in a suitable form and environment for precise potentiometric determination while effectively isolating it from potentially interfering excipients in complex formulations. This document outlines standardized protocols and strategic approaches for preparing various sample types, from raw APIs to sophisticated drug products, ensuring alignment with Quality by Design (QbD) principles in pharmaceutical manufacturing [25].

The diversity of pharmaceutical dosage forms—including tablets, creams, ointments, and suspensions—presents unique challenges for analytical characterization. Sample preparation strategies must address variations in solubility, matrix effects, and potential chemical interactions to enable accurate quantification of both active ingredients and excipient components. potentiometric titration serves as a powerful tool in this context, with United States Pharmacopeia (USP) monographs recommending its application for approximately 630 APIs and 110 excipients [25].

Fundamental Principles of Potentiometric Titration in Pharmaceutical Analysis

Potentiometric titration is a laboratory method that determines the concentration of an analyte by measuring the potential difference between two electrodes (indicator and reference electrode) under conditions of controlled titrant addition [26]. Unlike titrations that use visual indicators, potentiometric titration relies on the measurement of electrochemical potential to identify the endpoint, making it particularly valuable for colored, turbid, or complex samples where visual endpoint detection is problematic [26].

The fundamental principle involves monitoring the change in electrochemical potential as a function of titrant volume added. The potential difference across the analyte solution is measured while maintaining thermodynamic equilibrium where the current passing through the electrodes does not disturb this equilibrium [26]. The overall cell potential can be represented as:

[E{cell} = E{ind} - E{ref} + E{sol}]

Where (E{cell}) is the total cell potential, (E{ind}) is the potential of the indicator electrode, (E{ref}) is the potential of the reference electrode, and (E{sol}) represents the potential drop over the electrolyte solution [26].

In pharmaceutical applications, four primary types of potentiometric titrations are employed: (1) acid-base titration for concentration determination of acids/bases through neutralization, (2) redox titration for analytes undergoing oxidation-reduction reactions, (3) complexometric titration involving metal-ligand complex formation, and (4) precipitation titration based on insoluble precipitate formation [26].

Sample Preparation for Active Pharmaceutical Ingredients (APIs)

General Considerations for API Analysis

Sample preparation for APIs must ensure complete dissolution of the active ingredient in a suitable solvent system while maintaining chemical stability throughout the analysis. The selection of dissolution media depends on the physicochemical properties of the API, particularly its solubility characteristics and stability profile. A key advantage of potentiometric titration is its ability to accommodate both aqueous and non-aqueous media, expanding its application to a wide range of pharmaceutical compounds [25].

For raw API substances, careful weighing and quantitative transfer to dissolution media are essential steps. The sample size should be calculated to ensure the measured analyte quantity falls within the optimal range for the titration system being used, typically consuming between 5-20 mL of 0.1 M titrant for satisfactory results. For hygroscopic or volatile compounds, special handling procedures may be necessary to prevent moisture absorption or decomposition during preparation.

Case Study: Sulfanilamide Purity Determination

Sulfanilamide, used in treating vaginal yeast infections, demonstrates a preparation approach for water-soluble APIs analyzed through redox titration [25].

Experimental Protocol:

- Accurately weigh approximately 0.5 g of sulfanilamide sample into a titration vessel

- Add 50 mL of deionized water to dissolve the API

- Introduce 10 mL of 20% hydrochloric acid solution to create acidic conditions

- Add 5 mL of 2.5 M potassium bromide solution; bromide ions act as catalysts for the diazotization titration [25]

- Titrate potentiometrically with 0.1 M sodium nitrite (NaNO₂) as titrant

- Use a Pt Titrode electrode system for endpoint detection

- Maintain solution temperature between 15-20°C throughout titration

The entire analysis, including electrode maintenance, requires approximately 3-5 minutes per sample. The acidic conditions and catalyst are essential for achieving a sharp, reproducible endpoint in this diazotization-based determination [25].

Case Study: Ketoconazole Concentration Analysis

Ketoconazole, an antifungal medication with low aqueous solubility (<1 mg/mL), exemplifies sample preparation for lipophilic APIs requiring non-aqueous titration [25].

Experimental Protocol:

- Precisely weigh approximately 0.4 g of ketoconazole sample into a clean, dry titration vessel

- Add 50 mL of glacial acetic acid to dissolve the API; gentle heating may be applied if necessary

- Add 10 mL of acetic anhydride to eliminate potential interference from water

- Titrate potentiometrically with 0.1 M perchloric acid (HClO₄) in acetic acid as titrant

- Use a Solvotrode easyClean electrode resistant to organic solvents

- Condition the electrode in non-aqueous media prior to analysis

The non-aqueous approach enables accurate determination of ketoconazole concentration despite its limited water solubility. The complete analysis, including electrode conditioning, requires 5-10 minutes per sample [25].

Sample Preparation for Complex Formulations

Strategy for Tablet Formulations

Tablets present unique challenges due to the presence of excipients such as binders, fillers, disintegrants, and lubricants that may interfere with analytical determination. Sample preparation focuses on extracting the API while minimizing co-extraction of interfering components.

General Protocol for Tablets:

- Weigh and finely powder not less than 20 tablets using a mortar and pestle or mechanical grinder

- Accurately weigh a portion of the powder equivalent to one dose of the API

- Transfer to an appropriate container with 30-50 mL of suitable solvent

- Extract the API using 15-30 minutes of mechanical shaking or sonication

- Centrifuge or filter the solution to remove insoluble excipients

- Wash the residue with additional solvent and combine the extracts

- Make up to a known volume with the same solvent

- Use an aliquot for potentiometric titration

For film-coated tablets, the coating should be removed prior to powdering when possible. Enteric-coated tablets may require initial treatment with acidic or alkaline solutions to simulate gastrointestinal conditions.

Strategy for Semisolid Formulations (Ointments and Creams)

Semisolid formulations like ointments and creams often contain the API dispersed in hydrophobic or emulsion bases, requiring specialized preparation to liberate the active compound for analysis.

Case Study: Lidocaine in Ointment Formulations

Lidocaine, a local anesthetic API in topical formulations, demonstrates the approach for analyzing drugs in emulsion bases [25].

Experimental Protocol:

- Weigh accurately approximately 2 g of the ointment preparation

- Transfer to a titration vessel and add 40 mL of methanol

- Apply moderate heat (approximately 40-50°C) with continuous stirring to destroy the emulsion and dissolve the API

- Cool the solution to room temperature

- Add 10 mL of glacial acetic acid to create appropriate conditions for titration

- Titrate potentiometrically with 0.1 M sodium tetraphenylborate as titrant

- Use a nonionic surfactant electrode for endpoint detection

The combination of methanol and heat effectively disrupts the semisolid matrix, releasing the lidocaine for accurate quantification while minimizing interference from the ointment base [25].

Strategy for Surfactant-Containing Formulations

Surfactants present in formulations as solubilizing agents, emulsifiers, or stabilizers require specific approaches based on their ionic character.

Anionic Surfactants:

- Prepare sample solutions in aqueous media with pH adjustment to 3.0

- Titrate with sodium dodecyl sulfate (sodium lauryl sulfate) as titrant

- Use surfactant-specific electrodes

Cationic Surfactants:

- Prepare sample solutions with methanol or formaldehyde solution as reagent

- Titrate with sodium dodecyl sulfate as titrant

Nonionic Surfactants:

- Prepare samples using sodium tetraphenylborate (STPB) as primary reagent

- Include polyvinyl alcohol as protective colloid to prevent precipitate deposition on electrodes

- Use papaverine hydrochloride, sodium hydroxide, boric acid, or hydrochloric acid as additional reagents based on specific surfactant properties

For complex matrices or samples with limited aqueous solubility, two-phase titration systems may be employed to improve accuracy [25].

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 1: Key Reagents for Sample Preparation and Potentiometric Titration of Pharmaceuticals

| Reagent/Chemical | Primary Function | Application Examples |

|---|---|---|

| Potassium Bromide (KBr) | Catalyst for diazotization reactions | Sulfanilamide purity determination [25] |

| Hydrochloric Acid (HCl) | Acidification agent for aqueous media | Creating acidic conditions for redox titrations [25] |

| Sodium Nitrite (NaNO₂) | Diazotizing titrant for primary amines | Sulfanilamide and other aromatic amine-containing APIs [25] |

| Perchloric Acid (HClO₄) | Strong acid titrant for non-aqueous titration | Ketoconazole and other weakly basic APIs in acetic acid [25] |

| Glacial Acetic Acid | Non-aqueous solvent for lipophilic compounds | Dissolving water-insoluble APIs [25] |

| Sodium Tetraphenylborate (STPB) | Titrant for cationic and nonionic surfactants | Lidocaine assay in ointments; surfactant quantification [25] |

| Methanol | Organic solvent for matrix disruption | Extraction of APIs from semisolid formulations [25] |

| Sodium Dodecyl Sulfate | Titrant for cationic surfactants | Determination of cationic surfactants in formulations [25] |

Analytical Workflows for Pharmaceutical Analysis

The following diagrams visualize key experimental workflows for sample preparation and analysis of different pharmaceutical forms using potentiometric titration.

Figure 1: API Analysis Workflow - This diagram outlines the decision process for selecting appropriate sample preparation methods based on API solubility characteristics, leading to either aqueous or non-aqueous titration approaches.

Figure 2: Formulation Analysis Workflow - This diagram illustrates the sample preparation pathways for different pharmaceutical dosage forms, highlighting the specific techniques required to liberate APIs from complex matrices.

Quality Control and Validation Parameters

Method Validation for Sample Preparation Protocols

Robust sample preparation methods must be validated to ensure reliability and reproducibility. Key validation parameters include:

Accuracy: Assessed through standard addition or comparison with reference materials, with recovery rates typically targeted between 98-102% for API assays.

Precision: Evaluated through repeatability (intra-day) and intermediate precision (inter-day) studies, with relative standard deviation (RSD) not exceeding 2.0% for API determinations.

Specificity: Demonstrated by analyzing placebo formulations containing all excipients except the API to confirm absence of interference.

Linearity and Range: Established by preparing and analyzing samples at different concentration levels across the expected working range.

Robustness: Tested by deliberate variations in sample preparation parameters such as extraction time, solvent volume, and temperature.

Troubleshooting Common Sample Preparation Issues

Table 2: Troubleshooting Guide for Sample Preparation Challenges

| Problem | Potential Causes | Solutions |

|---|---|---|

| Incomplete API Extraction | Insufficient solvent volume, inadequate mixing, inappropriate solvent selection | Increase solvent volume, extend extraction time with shaking/sonication, optimize solvent system |

| Endpoint Detection Issues | Electrode fouling, slow reaction kinetics, insufficient sample clarification | Filter sample solution, clean/condition electrode, add catalysts, adjust temperature |

| Poor Reproducibility | Inconsistent sample homogenization, variable weighing accuracy, environmental factors | Standardize powdering technique, use calibrated balances, control laboratory conditions |

| Excipient Interference | Co-extraction of interfering compounds, similar reactivity with titrant | Implement purification steps, adjust pH, change titration system, use masking agents |

| Low Recovery Rates | API degradation during preparation, adsorption to container walls, volatilization | Minimize preparation time, use appropriate container materials, maintain temperature control |

Strategic sample preparation is an indispensable component in the potentiometric titration analysis of pharmaceuticals, directly influencing the quality and reliability of analytical data. The protocols outlined in this document provide a systematic framework for preparing diverse sample types, from pure APIs to complex formulated products. By adhering to these standardized approaches and understanding the underlying principles, researchers can ensure accurate quantification of active ingredients while effectively managing matrix effects and potential interferences.

The application of these sample preparation strategies within potentiometric titration methodologies supports the pharmaceutical industry's commitment to Quality by Design, enabling robust analytical methods that provide critical data for formulation development, process optimization, and quality control throughout the drug manufacturing lifecycle.

Within the framework of acid-base analysis research, the selection of an appropriate sensing electrode is a fundamental determinant for the success of any potentiometric titration method. Potentiometric titration is a robust quantitative chemical analysis technique where the endpoint is monitored by an indicator electrode that records the change in potential as a function of the added titrant volume [6]. This technique is indispensable in pharmaceutical development for applications ranging from the assay of active pharmaceutical ingredients (APIs) and excipients to the determination of salt ratios and pKa values [25] [27]. The electrode serves as the primary interface between the chemical system under investigation and the analytical instrumentation. Its performance characteristics—including sensitivity, response time, and selectivity—directly impact the accuracy, precision, and reliability of the generated data. This application note provides a detailed guide for researchers and drug development professionals on selecting and implementing the correct electrode technology for specific analytical challenges in acid-base titration.

The core of potentiometric pH measurement lies in the electrochemical cell established by the electrode pair. The most common configuration is the combination electrode, which integrates both the sensing (indicator) and reference half-cells into a single, convenient probe [28] [29] [30].

Fundamental Working Principle

A typical glass pH electrode operates as an ion-selective electrode (ISE). Its operation is based on the development of an electrical potential across a thin, pH-sensitive glass membrane that separates the internal solution of known pH from the sample solution [28] [31]. The difference in hydrogen ion (H⁺) activity between these two solutions generates a potential difference, as described by the Nernst equation, which is measured against the stable potential of the reference electrode to determine the sample's pH [28] [31] [4]. The reference electrode, typically based on a silver/silver chloride (Ag/AgCl) system, completes the electrical circuit and provides a stable reference potential against which the indicator electrode's potential is measured [28] [29].

Table 1: Core Components of a Combination pH Electrode

| Component | Function | Common Types/Materials |

|---|---|---|

| Electrode Body | Houses internal components; determines durability and chemical resistance. | Glass (high temp, corrosive solvents), Epoxy/Polymer (durable, economical) [29] [30]. |

| Glass Membrane | pH-sensitive component that generates the potential; shape varies for different applications. | Spherical (general use), Conical (general use), Flat (surface measurements), Spear Tip (semi-solids) [28]. |

| Reference System | Provides a stable, constant potential for measurement. | Ag/AgCl (most common), Iodine/Iodide (metal-free, for proteins/Tris), Calomel (Hg/Hg₂Cl₂, less common) [28] [29]. |

| Reference Electrolyte | Closes the electrical circuit; must be chemically neutral with high conductivity. | 3 M KCl (most common); K₂SO₄ (chloride-free applications) [28]. |

| Reference Junction | Creates a controlled, low-flow electrical contact between reference electrolyte and sample. | Ceramic (general lab), PTFE (viscous samples), Flushable/Sure-Flow (dirty/viscous samples) [29] [30]. |

Electrode Selection Guide for Acid-Base Analysis

Choosing the optimal electrode requires matching the sensor's properties to the sample's chemical and physical characteristics. The following table provides a structured comparison of primary electrode technologies.

Table 2: Electrode Technology Selection Guide for Titration Applications

| Parameter | Glass Membrane Electrode | Stainless Steel/Metal Oxide | Microelectrode |

|---|---|---|---|

| Primary Use Case | Standard laboratory titrations; aqueous and non-aqueous media. | Rugged environments, miniaturized systems, in-vivo sensing, high solids content. | Early development with limited API; small volume vessels (e.g., 1 mL) [27]. |

| Measurement Range | 0 to 14 pH [32] | Varies with oxide layer; generally narrower than glass. | Same as base technology (typically glass). |

| Key Advantages | Well-understood, high accuracy, wide pH and temperature range, withstands sterilization [32]. | High mechanical strength, flexible, suitable for miniaturization, low cost [31]. | Enables accurate titration with 2-10 mg of material; uses standard titrators [27]. |

| Key Limitations | Fragile glass membrane; requires careful handling; prone to alkaline/acid errors [32] [31]. | Limited by the stability of the oxide layer; potential for interference. | Requires 1 mL burette and low-concentration titrant (e.g., 0.01 N) [27]. |

| Junction Selection | Double-junction for proteins, sulfides, Tris buffers, heavy metals [29]. | Not applicable (solid-state sensor). | Double-junction recommended for complex samples. |

| Pharma Application | Assay of ~630 APIs and ~110 excipients per USP-NF [25]; raw material QC. | Process Analytical Technology (PAT); in-line monitoring. | Salt ratio determination; quantification of APIs and intermediates in early development [27]. |

The following workflow diagram outlines the logical decision process for selecting the appropriate electrode based on the sample and application requirements.

Detailed Experimental Protocols

Protocol 1: Microtitration for Early-Phase API Quantification

Objective: To accurately determine the weight percent of a scarce API (5-10 mg) using acid-base microtitration [27].

Materials & Reagents:

- API Compound: 5-10 mg (e.g., weak base like Compound A, MW ~444 g/mol) [27].

- Titrant: 0.01 N HCl (for base) or 0.01 N NaOH (for acid), standardized [27].

- Diluent: 1 mL of solvent (e.g., 50:50 v/v Acetonitrile/Water), chosen for sample solubility [27].

- Equipment: Automated titrator, 1 mL burette, 3 mm diameter micro-pH electrode, microbalance (±0.02 mg) [27].

Procedure:

- Solution Preparation: Precisely weigh 5-10 mg of the API using a microbalance. Transfer quantitatively into a titration vessel and dissolve in exactly 1 mL of diluent.

- Instrument Setup: Mount the microelectrode and 1 mL burette on the automated titrator. Ensure the electrode is properly calibrated using standard pH buffers.

- Titration: Initiate the Dynamic Equivalence Titration (DET) method. The titrator will dynamically add the 0.01 N titrant while monitoring the potential.

- Endpoint Determination: The instrument's software will use the first derivative of the potential vs. volume curve to identify the endpoint (the point of maximum rate of change).

- Calculation:

- Weight Percent (%) = (V * N * MW * 100) / (w * n)

- Where: V = titrant volume at endpoint (L), N = titrant normality (eq/L), MW = molecular weight (g/mol), w = sample weight (g), n = number of equivalents per mole.

Validation Notes: This method has demonstrated a linear response (R² = 0.9999) over 40-120% of the target concentration, with reproducibility of %RSD < 0.6% and accuracy deviations within 1.1% compared to conventional titration [27].

Protocol 2: Electrode Calibration and Maintenance for cGMP Compliance

Objective: To ensure ongoing accuracy and prolong electrode lifespan through proper calibration and maintenance, critical for pharmaceutical quality control.

Materials & Reagents:

- Calibration Buffers: pH 4.00, 7.00, and 10.00 NIST-traceable buffer solutions.

- Cleaning Solutions: Selected based on contamination (e.g., 0.1 M HCl for protein deposits, enzymatic cleaners for organics, detergent for oils) [30].

- Storage Solution: pH 4.00 buffer or proprietary pH electrode storage solution [30].

- Equipment: pH meter/autotitrator, beakers, wash bottle with DI water.

Procedure:

- Calibration:

- Rinse the electrode thoroughly with deionized water and blot dry with a lint-free tissue.

- Immerse the electrode in the first buffer (e.g., pH 7.00). Stir gently and allow the reading to stabilize.

- Accept the calibration point on the meter. Repeat with the second (e.g., pH 4.00) and third (e.g., pH 10.00) buffers.

- Verify the obtained calibration slope is within the acceptable range (typically 95-105% of the theoretical Nernstian slope).

- Cleaning (Perform when response is slow or erratic):

- Identify the type of contamination.

- Immerse the electrode in the appropriate cleaning solution for 15-30 minutes.

- Rinse thoroughly with deionized water and re-calibrate.

- Storage:

- Never store an electrode in deionized water, as this will cause leaching of ions from the glass membrane and reference electrolyte.

- For short-term storage, keep the electrode immersed in a pH 4.00 or pH 7.00 buffer.

- For long-term storage or with refillable electrodes, ensure the filling port is closed and the protective cap containing storage solution is securely placed over the sensing module.

The experimental setup for a microtitration is illustrated below, highlighting the key components that differ from a conventional setup.

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Key Reagent Solutions and Materials for Potentiometric Titration

| Item | Function/Application | Technical Notes |

|---|---|---|

| Standardized Titrants (0.1 N or 0.01 N HCl/NaOH) | Reacts stoichiometrically with the analyte of interest. | Must be standardized against a primary standard for validation; lower concentration (0.01 N) is critical for microtitration [17] [27]. |

| Primary Standards (e.g., Potassium Hydrogen Phthalate) | High-purity materials used to determine the exact concentration (normality) of a titrant with high accuracy [17]. | Characterized by high purity, stability, low hygroscopicity, and high molecular weight to minimize weighing errors [17]. |

| Redox Mediators (e.g., Iodine/Iodide, Quinhydrone) | Facilitate electron transfer in redox titrations or in the reference system of specific electrodes [28] [6]. | Used to buffer the potential range and ensure equilibrium in redox potentiometric titrations; iodine/iodide system offers low temperature sensitivity [28] [6]. |

| Supporting Electrolyte (e.g., 3 M KCl) | Serves as the reference electrolyte in most electrodes, providing ionic conductivity and completing the circuit [28]. | For refillable electrodes, the fill level must be kept at least 2 cm above the sample solution level during measurement [28]. |

| Non-Aqueous Solvents (e.g., Methanol, Acetonitrile) | Dissolve poorly water-soluble APIs for titration; used in diluent mixtures [25] [27]. | Solvent selection is key to isolating APIs from interfering excipients and obtaining accurate, repeatable results [25]. |

| Potassium Bromide (KBr) Solution | Acts as a catalyst in specific titrations, such as the diazotization titration of sulfanilamide [25]. | Addition accelerates the reaction, reducing total analysis time to 3-5 minutes [25]. |

Potentiometric titration remains a cornerstone technique for quantitative analysis in research and industrial laboratories, valued for its precision, simplicity, and adaptability to both aqueous and non-aqueous systems. This application note provides a structured framework for developing and optimizing potentiometric titration methods, with a specific focus on acid-base analysis within pharmaceutical and chemical research contexts. The protocols outlined herein are designed to assist researchers in systematically selecting titrant concentrations, solvent systems, and critical parameters to ensure method robustness, accuracy, and compliance with analytical quality standards. As potentiometric titration does not require chemical indicators and can analyze colored or turbid solutions, it offers distinct advantages for complex sample matrices encountered in drug development and material science [33] [34].

A critical advancement in this field is the Gran method, a linearization technique that enhances equivalence point detection accuracy, particularly for weak acids, bases, or in low-ionic-strength solutions [35] [13]. Furthermore, the integration of automation and multivariate calibration techniques, such as Partial Least Squares (PLS), has expanded the method's capability to resolve complex mixtures with overlapping dissociation constants [36]. This note integrates these classical and modern approaches, providing a comprehensive guide from foundational principles to advanced applications for research scientists.