Polarographic Analysis of Heavy Metals: Advanced Techniques for Environmental and Biomedical Research

This comprehensive article details the principles and modern applications of polarography for the sensitive detection and quantification of heavy metals in environmental and biomedical samples.

Polarographic Analysis of Heavy Metals: Advanced Techniques for Environmental and Biomedical Research

Abstract

This comprehensive article details the principles and modern applications of polarography for the sensitive detection and quantification of heavy metals in environmental and biomedical samples. We begin by exploring the fundamental electrochemical concepts, including the evolution from classical DC polarography to advanced techniques like Differential Pulse (DPP) and Square Wave Polarography (SWP). The core of the guide provides a step-by-step methodological framework for sample preparation, instrument calibration, and analysis of key contaminants such as lead, cadmium, mercury, and arsenic. To ensure reliable data, we systematically address common troubleshooting scenarios, interference challenges, and optimization strategies for sensitivity and selectivity. Finally, we validate polarography's role by comparing its performance metrics—detection limits, accuracy, and cost-effectiveness—against established techniques like ICP-MS and AAS. This resource equips researchers and drug development professionals with the knowledge to implement robust, reproducible heavy metal analysis critical for environmental monitoring and safety assessment in pharmaceutical development.

What is Polarographic Analysis? Core Principles and Electrochemical Foundations for Heavy Metal Detection

Thesis Context: Polarographic Analysis of Heavy Metals in Environmental Samples

This article details the application of polarography and its modern voltammetric descendants for the detection and quantification of heavy metals (e.g., Pb, Cd, Hg, As, Cu, Zn) in complex environmental matrices like water, soil leachates, and biological tissues. The evolution from Heyrovský's classical dropping mercury electrode (DME) to contemporary techniques provides the sensitivity, selectivity, and multi-element capability required for environmental monitoring and regulatory compliance.

Historical Evolution & Key Principles

Jaroslav Heyrovský's invention of polarography in 1922, for which he received the Nobel Prize in 1959, involved measuring current as a function of applied voltage using a DME. The resulting sigmoidal current-voltage curve (polarogram) provides qualitative (via half-wave potential, E₁/₂) and quantitative (via limiting current, iₗ) information.

Modern voltammetry has replaced constant-potential polarography with pulsed potential waveforms (e.g., Differential Pulse, Square Wave) applied to static mercury drop electrodes (SMDE) or mercury-film electrodes (MFE). This dramatically enhances sensitivity by minimizing capacitive charging current.

Core Quantitative Parameters from a Modern Voltammetric Analysis:

| Parameter | Symbol | Significance in Heavy Metal Analysis |

|---|---|---|

| Peak Current | iₚ | Proportional to analyte concentration (quantitative basis). |

| Peak Potential | Eₚ | Identifies the metal species (qualitative basis). |

| Supporting Electrolyte | - | Minimizes migration current; controls pH and complexation. |

| Deposition Potential | E_dep | Potential for pre-concentrating metal ions onto/into electrode. |

| Deposition Time | t_dep | Controls amount of metal pre-concentrated; enhances sensitivity. |

Application Notes: Heavy Metal Analysis in Water Samples

Note 1: Stripping Voltammetry for Ultra-Trace Analysis. Anodic Stripping Voltammetry (ASV) is the pre-eminent method for trace (ppb to ppt) heavy metals. Metals are first electroplated (reduced) onto the working electrode during a deposition step, then oxidized (stripped) during a positive potential sweep. The resulting sharp peak currents provide high sensitivity.

Note 2: Addressing Interferences in Complex Matrices. Environmental samples contain organic matter (fouling agents) and other metals that can interfere. Protocols include:

- UV Digestion: Destruction of organic complexes using UV light in the presence of persulfate.

- pH Adjustment & Buffering: Essential for reproducible complexation and deposition.

- Standard Addition Method: Mandatory for quantification to compensate for matrix effects.

Note 3: Comparative Analytical Figures of Merit. The following table summarizes capabilities of key voltammetric techniques for Cd and Pb analysis:

| Technique | Typical LOD (for Cd/Pb) | Key Advantage | Key Disadvantage |

|---|---|---|---|

| Classic DC Polarography | ~10⁻⁵ M (~1 ppm) | Robust, simple waveform | Poor sensitivity |

| Differential Pulse Polarography (DPP) | ~10⁻⁷ M (~10 ppb) | Better sensitivity than DC | Slower than SWV |

| Differential Pulse ASV (DPASV) | ~10⁻¹⁰ M (~0.01 ppb) | Extremely high sensitivity | Longer analysis time |

| Square Wave ASV (SWASV) | ~10⁻¹⁰ M (~0.01 ppb) | Fast, excellent sensitivity | More complex waveform optimization |

Detailed Experimental Protocols

Protocol 1: Analysis of Trace Lead and Cadmium in River Water by SWASV

Objective: Determine concentrations of Pb²⁺ and Cd²⁺ in a filtered water sample.

I. Materials & Reagents (The Scientist's Toolkit)

| Item | Function/Description |

|---|---|

| Voltammetric Analyzer | Instrument for applying potential and measuring current (e.g., Metrohm, CH Instruments). |

| Static Mercury Drop Electrode (SMDE) or Mercury Film Electrode (MFE) | Working Electrode. SMDE offers renewable surface; MFE offers superior resolution for some metals. |

| Ag/AgCl (3M KCl) Reference Electrode | Provides stable, known reference potential. |

| Platinum Wire Counter Electrode | Completes the electrical circuit. |

| High-Purity Nitrogen Gas (N₂) | Deoxygenates solution for 5-10 minutes prior to analysis. |

| Acetate Buffer (0.1 M, pH 4.5) | Supporting Electrolyte. Provides optimal pH for deposition of many heavy metals. |

| Heavy Metal Standard Solutions (1000 ppm) | For calibration (use standard addition). |

| Ultrapure Water (18.2 MΩ·cm) | For preparing all solutions. |

| UV Digestion System (with quartz vials) | For sample pre-treatment to destroy organic metal complexes. |

II. Procedure

- Sample Pre-treatment: Acidify 10 mL of filtered (0.45 µm) river water to pH ~2 with ultrapure HNO₃. Irradiate in a UV digester with 50 µL of H₂O₂ (30%) for 60 minutes to destroy organic matter. Cool and adjust pH to 4.5 using acetate buffer and dilute NaOH.

- Instrument Setup: Configure the voltammeter for Square Wave Anodic Stripping Voltammetry (SWASV). Typical parameters:

- Deposition Potential (Edep): -1.2 V vs. Ag/AgCl

- Deposition Time (tdep): 60-180 s (with stirring)

- Equilibration Time: 15 s (without stirring)

- Potential Scan: -1.2 V to -0.1 V

- Square Wave Amplitude: 25 mV

- Frequency: 25 Hz

- Step Potential: 5 mV

- Deaeration: Transfer the sample to the electrochemical cell. Purge with N₂ for 8 minutes to remove dissolved oxygen. Maintain an N₂ blanket over the solution during analysis.

- Initial Run: Perform the SWASV scan. Record the voltammogram.

- Standard Additions: Add a known volume (e.g., 50 µL) of a mixed Cd/Pb standard solution (e.g., 10 ppm). Deoxygenate briefly (1 min). Repeat the SWASV scan. Perform at least 3 standard additions.

- Data Analysis: Plot peak current (iₚ) for Cd (~-0.6 V) and Pb (~-0.4 V) against added concentration. Extrapolate the linear plot to the x-intercept to determine the original sample concentration.

Protocol 2: Classic DC Polarography Demonstration

Objective: To illustrate the fundamental principle using a simple system (e.g., Cd²⁺ in KCl).

- Prepare a 0.1 mM Cd(NO₃)₂ solution in 0.1 M KCl.

- Use a DME, SCE reference, and Pt counter.

- Set the instrument to apply a linear ramp from -0.2 V to -1.0 V vs. SCE at a slow scan rate (e.g., 2 mV/s).

- Deoxygenate with N₂.

- Record the polarogram. Observe the S-shaped wave. Measure the half-wave potential (E₁/₂) and limiting current (iₗ).

Visualizations

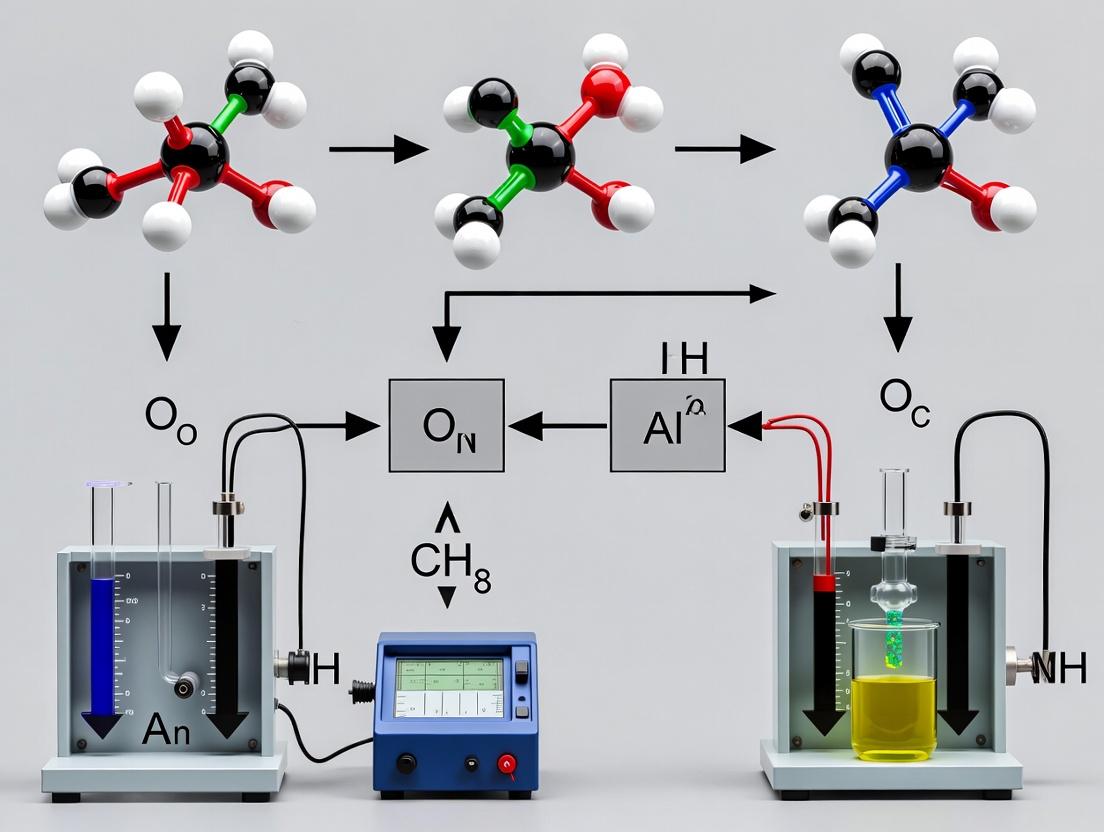

Workflow for Voltammetric Heavy Metal Analysis

Three-Step Principle of Anodic Stripping Voltammetry (ASV)

This application note details the core components of an electrochemical cell within the framework of a doctoral thesis investigating the polarographic analysis of heavy metals (e.g., Cd, Pb, Hg, As) in environmental water and soil samples. Precise understanding and implementation of the three-electrode system is critical for achieving accurate, reproducible, and sensitive voltammetric measurements, which are the foundation of modern electroanalytical techniques like Differential Pulse Polarography (DPP) and Square Wave Anodic Stripping Voltammetry (SWASV).

Electrode Functions & Selection Criteria

A standard three-electrode cell separates the current-carrying (counter electrode) and potential-sensing (reference electrode) functions to allow precise control of the potential at the working electrode surface.

Table 1: Core Electrodes in Analytical Electrochemistry

| Electrode | Primary Function | Key Characteristics for Heavy Metal Analysis | Common Types |

|---|---|---|---|

| Working Electrode (WE) | Site of the redox reaction of interest (e.g., reduction/oxidation of metal ions). Potential is controlled relative to the RE. | Material dictates the potential window, sensitivity, and reproducibility. Must have a renewable or stable surface. | Static Mercury Drop Electrode (SMDE), Hanging Mercury Drop Electrode (HMDE), Mercury Film Electrode (MFE), Boron-Doped Diamond (BDD), Glassy Carbon (GC). |

| Reference Electrode (RE) | Provides a stable, known, and constant potential against which the WE potential is measured and controlled. | Must be non-polarizable. Stable potential is unaffected by sample composition. Junction potential must be minimized. | Saturated Calomel Electrode (SCE), Ag/AgCl (in saturated KCl), Double-Junction Ag/AgCl. |

| Counter Electrode (CE) | Completes the electrical circuit by supplying the current required by the WE reaction. | Inert material to prevent introduction of contaminants. High surface area to avoid current limitations. | Platinum wire or coil, Graphite rod, Glassy Carbon rod. |

Table 2: Electrode Selection for Specific Heavy Metal Analysis Protocols

| Analysis Target | Recommended WE | Rationale | Supporting Electrolyte |

|---|---|---|---|

| Simultaneous Cd²⁺, Pb²⁺, Cu²⁺, Zn²⁺ | HMDE or MFE on GC | High hydrogen overpotential of Hg allows analysis of metals at negative potentials. Excellent renewal for stripping analysis. | 0.1 M Acetate Buffer (pH 4.5) |

| As(III) and As(V) | Gold Ultramicroelectrode or BDD | Hg forms amalgams; Au allows for As deposition. BDD offers wide window and low background. | HCl or H₂SO₄ medium |

| Hg(II) | Gold Film Electrode | Au forms amalgam with Hg, enabling its pre-concentration and stripping. | HCl or HNO₃ with added chloride |

Experimental Protocols

Protocol 3.1: Cell Setup & Electrode Preparation for SWASV of Pb and Cd

Aim: To prepare a standard three-electrode cell for the determination of trace lead and cadmium in filtered river water samples.

Materials:

- Potentiostat/Galvanostat with software control

- Electrochemical cell (15-20 mL)

- WE: Mercury Film Electrode (MFE) on a glassy carbon substrate

- RE: Double-junction Ag/AgCl (3M KCl inner, 0.1 M KNO₃ outer)

- CE: Platinum wire coil

- Nitrogen gas (Oxygen-free, ≥99.99%)

- Supporting electrolyte: 0.1 M Acetate Buffer, pH 4.5 (prepared from CH₃COOH and CH₃COONa)

- Standard solutions: 1000 mg/L Cd²⁺ and Pb²⁺

- Ultrapure water (18.2 MΩ·cm)

Procedure:

- Electrode Preparation:

- Polish the glassy carbon electrode surface successively with 1.0 µm, 0.3 µm, and 0.05 µm alumina slurry on a microcloth. Rinse thoroughly with ultrapure water.

- Electrochemically clean the surface in 0.1 M H₂SO₄ by cycling the potential between -1.0 V and +1.5 V (vs. Ag/AgCl) at 100 mV/s until a stable cyclic voltammogram is obtained.

- Form the mercury film in situ by adding Hg(NO₃)₂ to the cell (final conc. ~10 mg/L) and depositing at -1.0 V for 300 s with stirring in the acetate buffer.

Cell Assembly & Deaeration:

- Place 10 mL of the sample (or standard) into the clean electrochemical cell.

- Add 1.0 mL of 1.0 M acetate buffer (pH 4.5) to provide a consistent ionic strength and pH.

- Assemble the three electrodes, ensuring the RE junction is immersed and the Pt CE is fully submerged.

- Purge the solution with nitrogen gas for 10 minutes to remove dissolved oxygen, which interferes via reduction. Maintain a nitrogen blanket over the solution during analysis.

SWASV Measurement:

- Pre-concentration/Deposition: Hold the WE at -1.2 V vs. Ag/AgCl for 60-180 s with constant stirring (e.g., 400 rpm). Metal ions are reduced and form amalgams with the Hg film.

- Equilibration: Stop stirring and allow the solution to become quiescent for 15 s.

- Stripping Scan: Apply a square wave potential scan from -1.2 V to -0.1 V.

- Frequency: 25 Hz

- Amplitude: 25 mV

- Step Potential: 5 mV

- The resulting current peaks are proportional to concentration. Identify Cd and Pb peaks at approximately -0.6 V and -0.4 V, respectively.

Calibration & Quantification:

- Perform a standard addition by spiking the sample with known volumes of Cd²⁺ and Pb²⁺ standard solution.

- Plot peak current vs. added concentration. Extrapolate to the x-intercept to determine the sample concentration.

Protocol 3.2: Maintenance of a Double-Junction Reference Electrode

Aim: To ensure stable potential and prevent contamination of the sample by the inner filling solution (e.g., Cl⁻ leakage into samples where Cl⁻ is an interferent).

Procedure:

- Regularly check the level of the inner filling solution (e.g., 3M KCl for Ag/AgCl). Refill if below 2/3 full.

- The outer compartment (second junction) should be filled with an inert electrolyte compatible with the sample (e.g., 0.1 M KNO₃ for heavy metal analysis). Replace this solution before each analytical session.

- Ensure the porous ceramic frit or sleeve is not clogged. Soak in warm ultrapure water if the flow rate is too slow.

Diagrams & Workflows

The Scientist's Toolkit: Key Research Reagents & Materials

Table 3: Essential Reagents for Polarographic Heavy Metal Analysis

| Item | Specification / Preparation | Primary Function in Analysis |

|---|---|---|

| Supporting Electrolyte | 0.1 M Acetate Buffer (pH 4.5): Mix 0.1 M CH₃COOH and 0.1 M CH₃COONa to desired pH. | Provides conductive medium, controls pH (critical for metal speciation and deposition efficiency), minimizes migration current. |

| Mercury Film Precursor | 1000 mg/L Hg(II) standard solution (e.g., as Hg(NO₃)₂ in 1% HNO₃). Handle with extreme toxicity controls. | Source of Hg for forming the in-situ MFE on a glassy carbon or carbon paste electrode substrate. |

| Oxygen Scavenging Gas | High-purity Nitrogen (N₂) or Argon (Ar), passed through an oxygen trap. | Removes dissolved O₂ from solution, eliminating its interfering reduction currents (-0.1 V to -0.8 V vs. SCE). |

| Metal Stock Standards | 1000 mg/L certified single- or multi-element standards in 2% HNO₃. | Used for calibration via standard addition method, ensuring matrix-matched conditions for accurate quantification. |

| Electrode Polishing Kit | Alumina or diamond polishing suspensions (1.0 µm, 0.3 µm, 0.05 µm) and microcloth pads. | Provides a clean, reproducible, and active surface on solid working electrodes (GC, Au, BDD), essential for baseline stability and reproducibility. |

| Ultrapure Water | Resistivity ≥18.2 MΩ·cm at 25°C (Type I). | Used for all solution preparation and rinsing to minimize contamination from trace ionic impurities. |

| Chelating Agent (Optional) | 0.01 M Dimethylglyoxime or 8-Hydroxyquinoline. | Used in some protocols for adsorptive stripping voltammetry (AdSV) to selectively complex and pre-concentrate specific metals (e.g., Ni, Co). |

Application Notes

Polarography, a voltammetric technique using a dropping mercury electrode (DME), remains a fundamental tool for the quantitative and qualitative analysis of electroactive species, particularly in environmental heavy metal analysis. Within the broader thesis on the polarographic analysis of heavy metals in environmental samples, interpreting the polarogram's key features is critical for method development and data validation.

The signature polarogram (current vs. applied voltage) reveals two paramount features for each reducible ion:

- Limiting Current (iₗ): The plateau current, which is diffusion-controlled and directly proportional to the concentration of the analyte in the bulk solution. This is the basis for quantitative analysis.

- Half-Wave Potential (E₁/₂): The potential at which the current is half of the limiting current. This is characteristic of the specific ion and the supporting electrolyte matrix, providing qualitative identification.

In complex environmental matrices (e.g., soil leachates, wastewater), these features can be influenced by organic matter, competing ions, and adsorption phenomena. Modern advancements in pulse polarographic techniques (e.g., Differential Pulse Polarography) enhance sensitivity and resolution for trace-level heavy metal detection.

Quantitative Data Summary

Table 1: Characteristic Half-Wave Potentials (vs. SCE) for Selected Heavy Metals in Common Supporting Electrolytes

| Metal Ion | Supporting Electrolyte (0.1 M) | Half-Wave Potential, E₁/₂ (V) | Notes |

|---|---|---|---|

| Cd²⁺ | KCl | -0.64 | Well-defined wave, ideal for calibration. |

| Pb²⁺ | KNO₃ | -0.40 | Subject to hydrolysis; often done in acidic medium. |

| Zn²⁺ | KCl | -1.00 | Overlaps with hydrogen discharge in acidic media. |

| Cu²⁺ | NH₃/NH₄Cl | -0.24, -0.50 | Two distinct waves for Cu(II)→Cu(I)→Cu(0). |

| In³⁺ | HCl | -0.60 | Sharp wave in chloride medium. |

Table 2: Comparative Analytical Figures of Merit for Polarographic Techniques

| Parameter | Classic DC Polarography | Differential Pulse Polarography (DPP) |

|---|---|---|

| Typical Detection Limit | ~10⁻⁵ M | ~10⁻⁷ - 10⁻⁸ M |

| Resolution of E₁/₂ | ~100 mV | ~50 mV |

| Influence of Capacitive Current | High | Significantly Reduced |

| Primary Use in Thesis | Preliminary screening, fundamental studies | Trace analysis in complex environmental matrices |

Experimental Protocols

Protocol 1: Standard Calibration for Cadmium in Simulated Water Samples via DC Polarography

Objective: To establish a linear relationship between limiting current (iₗ) and Cd²⁺ concentration.

Reagent & Solution Preparation:

- Prepare 1.0 M KCl stock solution (supporting electrolyte).

- Prepare 1000 ppm Cd²⁺ stock solution from Cd(NO₃)₂.

- Generate standard solutions of 1, 2, 5, and 10 ppm Cd²⁺ by dilution in 0.1 M KCl final concentration.

Deaeration:

- Pipette 10 mL of the lowest concentration standard into the polarographic cell.

- Bubble high-purity nitrogen or argon through the solution for 10-15 minutes to remove dissolved oxygen, which produces interfering reduction waves.

Polarographic Run:

- Set the DME parameters: drop time ~2-5 s.

- Initiate the potential scan from 0.0 V to -1.0 V vs. the reference electrode (e.g., Saturated Calomel Electrode, SCE).

- Record the polarogram. Identify the Cd²⁺ wave with E₁/₂ ≈ -0.64 V vs. SCE.

- Measure the limiting current (iₗ), typically as the average current on the plateau.

Calibration Curve:

- Repeat steps 2-3 for each standard solution.

- Plot iₗ (µA) vs. Cd²⁺ concentration (ppm). Perform linear regression. The slope gives the calibration sensitivity.

Protocol 2: Analysis of Lead in Soil Leachate Using Differential Pulse Polarography (DPP)

Objective: To quantify trace levels of Pb²⁺ in a complex matrix with enhanced sensitivity.

Sample Pre-treatment:

- Digest 1.0 g of soil with 10 mL of 2 M HNO₃ at 95°C for 2 hours.

- Filter, neutralize with NaOH, and dilute to 50 mL with 0.1 M KNO₃ as supporting electrolyte.

Instrumental Parameters (DPP Mode):

- Set pulse amplitude: 50 mV.

- Set pulse duration: 50 ms.

- Set scan rate: 2-5 mV/s.

- Maintain deaeration with N₂ throughout.

Standard Addition Method:

- Record the DPP polarogram of the unknown sample.

- Note the peak current (iₚ) at E~-0.4 V for Pb.

- Add three known aliquots (e.g., 0.1 mL each) of a standard Pb²⁺ solution to the cell.

- Record the DPP polarogram after each addition.

Calculation:

- Plot iₚ vs. concentration of added Pb²⁺ standard.

- Extrapolate the linear plot to zero current. The absolute value of the x-intercept gives the concentration of Pb²⁺ in the cell, which is used to back-calculate the concentration in the original soil sample.

Visualizations

Polarogram Key Features and Their Analytical Meaning

Workflow for Polarographic Heavy Metal Analysis

The Scientist's Toolkit: Essential Research Reagents & Materials

| Item | Function in Polarographic Analysis |

|---|---|

| Dropping Mercury Electrode (DME) | The working electrode. Provides a renewable, clean surface and a high overpotential for hydrogen evolution. |

| Saturated Calomel Electrode (SCE) | A common reference electrode to provide a stable, known potential against which the DME is measured. |

| Platinum Wire Auxiliary Electrode | The counter electrode to complete the electrochemical circuit. |

| High-Purity Nitrogen/Argon Gas | For deaeration of solutions to remove interfering dissolved oxygen. |

| Supporting Electrolyte (e.g., KCl, KNO₃) | To carry current and minimize migration current; defines the medium for E₁/₂. |

| Maximum Suppressor (e.g., Triton X-100) | A surface-active agent added in trace amounts to suppress polarographic maxima (false current peaks). |

| Standard Metal Ion Solutions | High-purity stock solutions for calibration and standard addition methods. |

| Polarographic Cell | A dedicated, sealed glass vessel with ports for electrodes and gas purging. |

Application Notes: Toxicity Profiles & Relevance

Heavy metals such as Lead (Pb), Cadmium (Cd), Mercury (Hg), and Arsenic (As) persist in the environment and bioaccumulate, posing significant risks to ecosystems and human health. Within the context of polarographic analysis research for environmental samples, understanding their distinct toxicity profiles is paramount for developing accurate detection and quantification methods to inform remediation and biomedical intervention.

Table 1: Comparative Toxicity Profiles of Critical Heavy Metals

| Metal | Primary Environmental Sources | Key Toxicological Targets & Mechanisms | Major Health Effects (Chronic Exposure) | WHO Guideline Value (Drinking Water) |

|---|---|---|---|---|

| Lead (Pb) | Old paint, contaminated soil, plumbing, industrial emissions. | Mimics Ca2+, inhibits δ-aminolevulinic acid dehydratase (ALAD), disrupts neurotransmission. | Neurodevelopmental deficits (children), anemia, nephropathy, cardiovascular effects. | 0.01 mg/L |

| Cadmium (Cd) | Phosphate fertilizers, industrial waste, Ni-Cd batteries, tobacco smoke. | Accumulates in kidneys, induces oxidative stress, disrupts Zn2+/Ca2+ homeostasis. | Osteomalacia (Itai-Itai disease), renal tubular dysfunction, pulmonary injury, carcinogen. | 0.003 mg/L |

| Mercury (Hg) | Artisanal gold mining, coal combustion, seafood (MeHg). | Binds to sulfhydryl groups, disrupts selenium homeostasis, induces oxidative stress. | Neurological (Minamata disease), prenatal developmental toxicity, renal damage. | 0.006 mg/L (inorganic) |

| Arsenic (As) | Geogenic groundwater contamination, pesticides, smelting. | Inhibits mitochondrial respiration, induces oxidative stress, alters DNA methylation. | Skin lesions, peripheral neuropathy, cardiovascular disease, multi-site carcinogen. | 0.01 mg/L |

Table 2: Polarographic Analysis Parameters for Target Metals

| Metal | Common Electrolyte/Supporting Medium | Typical Reduction Potential (vs. SCE, approx.) | Key Interferences in Environmental Samples | Recommended Polarographic Mode |

|---|---|---|---|---|

| Pb(II) | 0.1 M HCl or acetate buffer (pH 4.5) | -0.4 V | Sn(II), Tl(I), Bi(III). Use complexing agents. | Differential Pulse Polarography (DPP) |

| Cd(II) | 0.1 M KCl (neutral) or ammonia buffer | -0.6 V | Zn(II), Ni(II) in some media. | Square Wave Voltammetry (SWV) |

| Hg(II) | 0.1 M HNO3 or HCl | +0.1 to -0.1 V | Cu(I/II), Ag(I). Requires careful potential control. | Anodic Stripping Voltammetry (Hg-film electrode) |

| As(III) | 1-2 M HCl or H2SO4 | -0.3 to -0.5 V | Cu(II), Sb(III). Often co-plated with Cu. | Cathodic Stripping Voltammetry (on Au electrode) |

Experimental Protocols

Protocol 1: Differential Pulse Polarography (DPP) for Simultaneous Determination of Pb(II) and Cd(II) in Soil Leachate

Principle: DPP enhances sensitivity by applying small amplitude potential pulses and measuring the current difference just before and at the end of each pulse, minimizing capacitive background current.

Materials & Reagents:

- Polarograph with three-electrode system (DME or SMDE as WE, Ag/AgCl RE, Pt CE).

- Supporting electrolyte: 0.1 M ammonium acetate buffer, pH 4.6.

- Standard stock solutions: 1000 mg/L Pb(NO3)2 and Cd(NO3)2.

- Ultrapure water (18.2 MΩ·cm).

- Soil sample.

Procedure:

- Sample Preparation: Digest 0.5 g of air-dried soil with 10 mL of 2 M HNO3 at 95°C for 2 hours. Filter, dilute to 50 mL with ultrapure water.

- Instrument Setup: Deoxygenate all solutions by purging with high-purity N2 for 10 minutes. Set DPP parameters: Pulse amplitude = 50 mV, Pulse duration = 50 ms, Scan rate = 5 mV/s, Drop time = 0.5 s.

- Calibration: To 10 mL of supporting electrolyte, add increasing volumes of mixed Pb/Cd standard. After each addition, deoxygenate, record DPP polarogram from -0.2 V to -0.8 V. Plot peak current vs. concentration.

- Sample Analysis: Mix 1 mL of digested sample with 9 mL of supporting electrolyte. Deoxygenate and record the polarogram under identical conditions.

- Quantification: Use the standard addition method. Spike the sample solution with known concentrations of Pb and Cd standards, record polarograms, and extrapolate to determine original concentration.

Protocol 2: Anodic Stripping Voltammetry (ASV) for Trace Hg(II) in Water Samples using a Gold Nanoparticle-Modified Electrode

Principle: Hg is first electroplated (reduced) onto the Au electrode surface at a controlled potential and time, concentrating the analyte. The deposited Hg is then oxidized (stripped) back into solution during an anodic potential sweep, producing a quantifiable current peak.

Materials & Reagents:

- Voltammetric analyzer with Au working electrode, Ag/AgCl RE, Pt CE.

- Au nanoparticle modification solution.

- Supporting electrolyte: 0.1 M HNO3 + 0.01 M HCl.

- N2 gas for deaeration.

Procedure:

- Electrode Modification: Clean Au electrode. Cycle potential in 0.5 M H2SO4 until a stable CV is obtained. Electrodeposit Au nanoparticles from a HAuCl4 solution at -0.4 V for 30 s.

- Pre-concentration: In a stirred solution containing 10 mL of acidified sample (pH <2) and supporting electrolyte, apply a deposition potential of +0.1 V (vs. Ag/AgCl) for 120-300 s.

- Stripping Analysis: After a 15-second equilibration period, initiate an anodic square-wave scan from +0.1 V to +0.6 V. Record the stripping peak current near +0.25 V.

- Calibration: Perform analysis on a series of standard Hg(II) solutions under identical conditions. Construct a calibration curve of peak current vs. concentration.

Visualizations

Diagram Title: Heavy Metal Toxicity Pathways in Humans

Diagram Title: Polarographic Analysis Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Polarographic Heavy Metal Analysis

| Item/Category | Specific Example/Product | Function & Relevance |

|---|---|---|

| Supporting Electrolytes | High-purity KCl, NH4Ac buffers, HCl, HNO3 | Provides ionic conductivity, fixes pH, influences metal speciation and reduction potential. |

| Standard Reference Materials | NIST SRM 1640a (Trace Elements in Water), CRM soils | Validates analytical accuracy and method recovery for quality assurance. |

| Complexing/Masking Agents | Sodium tartrate, EDTA, Cyanide (careful use) | Selectively binds interfering ions, improving analytical selectivity for target metals. |

| Electrode Conditioning Solutions | 0.5 M H2SO4 (for Au), HNO3 dil. (for Hg-film), polishing alumina | Cleans and activates electrode surface, ensuring reproducibility and sensitivity. |

| Oxygen Scavengers | High-purity Nitrogen (N2) or Argon (Ar) gas | Removes dissolved O2 which interferes by producing reduction waves in the analyte window. |

| Chelating Resins | Chelex 100, iminodiacetate-based resins | Pre-concentrates trace metals from large volume samples, lowering detection limits. |

| pH Buffers | Acetate (pH ~4.5), Ammonia (pH ~9.2), Phosphate buffers | Maintains consistent chemical form of analyte, crucial for reproducible peak potentials. |

| Electrode Materials | Static Mercury Drop Electrode (SMDE), Gold Ultramicroelectrode, Carbon Paste | Working electrode choice dictates sensitivity, potential window, and applicable technique (e.g., ASV vs. DPP). |

Within the context of a thesis on the polarographic analysis of heavy metals in environmental samples, the evolution from Direct Current (DC) to advanced pulse techniques like Differential Pulse (DPP) and Square Wave Polarography (SWP) represents a critical trajectory in analytical electrochemistry. This progression is driven by the need for lower detection limits, superior resolution of analytes with close reduction potentials, and faster analysis times to accurately quantify trace heavy metals (e.g., Pb²⁺, Cd²⁺, Zn²⁺, Cu²⁺) in complex matrices like water, soil, and biological tissues.

Principles and Comparative Performance

The core principle involves applying a controlled potential to a working electrode (typically a dropping or static mercury electrode) and measuring the resulting current from the reduction of metal ions. The key evolution lies in the waveform of the applied potential and the current sampling method, which dramatically enhances sensitivity and selectivity.

Table 1: Comparative Overview of Polarographic Techniques

| Feature | DC Polarography | AC Polarography | Differential Pulse Polarography (DPP) | Square Wave Polarography (SWP) |

|---|---|---|---|---|

| Applied Potential | Linear ramp | Linear ramp + small sinusoidal wave | Linear staircase + small amplitude pulses | Square wave superimposed on staircase |

| Current Measurement | Continuous | In-phase AC component | Difference just before & at end of pulse | Forward minus Reverse current |

| Key Advantage | Simplicity, wide potential window | Rejection of capacitive current | High sensitivity, low detection limits | Very fast scan, excellent sensitivity & background rejection |

| Limitation | High capacitive current, poor sensitivity | Moderate sensitivity | Slower than SWP | More complex instrumentation |

| Typical LOD (for Cd²⁺) | ~10⁻⁵ M | ~10⁻⁶ M | ~10⁻⁸ M | ~10⁻⁸ M |

| Resolution (ΔEp) | ~100 mV | ~50 mV | ~50 mV | ~50 mV |

| Analysis Speed | Slow (minutes) | Moderate | Slow-Moderate | Very Fast (seconds) |

| Primary Use in Thesis | Historical reference, basic behavior | Studying electrode kinetics | Quantitative trace analysis (e.g., river water) | High-throughput screening (e.g., soil leachates) |

Application Notes

- DC Polarography: Serves as a foundational technique for identifying approximate reduction potentials of heavy metals in a new supporting electrolyte. Its use in quantitative environmental analysis is now limited due to poor detection limits.

- AC Polarography: Useful for studying the reversibility of metal ion reduction processes, which can be influenced by organic complexes in environmental samples.

- DPP: The workhorse for precise, quantitative determination of trace heavy metals. Its superior sensitivity allows for direct measurement in moderately contaminated samples after minimal pretreatment (e.g., filtration, acidification).

- SWP: Ideal for high-throughput analysis and for samples where speed is essential. Its effective background suppression is valuable for analyzing metals in samples with high organic content (e.g., soil extracts, wastewater).

Experimental Protocols

Protocol 1: Standard Calibration for Cd²⁺ and Pb²⁺ in Simulated Water Using DPP

Objective: To establish a calibration curve for the simultaneous determination of cadmium and lead. Materials: See "The Scientist's Toolkit" below. Procedure:

- Deoxygenation: Purge the supporting electrolyte (0.1 M acetate buffer, pH 4.5) in the electrochemical cell with high-purity nitrogen or argon for 10 minutes. Maintain an inert atmosphere blanket during analysis.

- Blank Run: Record a DPP polarogram from -0.2 V to -1.0 V (vs. Ag/AgCl) to confirm a clean baseline. Parameters: Pulse amplitude 50 mV, pulse duration 50 ms, scan rate 5 mV/s.

- Standard Addition: Sequentially add known volumes of a mixed Cd²⁺/Pb²⁺ standard solution (e.g., 10 ppm each) to the cell. After each addition, mix, purge briefly (30 sec), and record the polarogram.

- Data Analysis: Measure the peak heights (current) at approximately -0.6 V (Cd) and -0.4 V (Pb). Plot peak current vs. concentration for each metal to create calibration curves. Determine the slope (sensitivity) and correlation coefficient (R² > 0.995).

Protocol 2: Rapid Screening of Heavy Metals in Soil Leachate Using SWP

Objective: To quickly identify and semi-quantify multiple heavy metals in an acidic soil extract. Materials: Soil leachate (0.1 M HNO₃ extract, filtered), 0.1 M KNO₃ supporting electrolyte, pH 2. Procedure:

- Sample Preparation: Mix 5 mL of filtered soil leachate with 5 mL of 0.2 M KNO₃ supporting electrolyte in the cell.

- Deoxygenation: Purge the sample mixture for 8 minutes.

- SWP Analysis: Record a square wave polarogram from -0.3 V to -1.2 V. Parameters: Frequency 25 Hz, step potential 5 mV, square wave amplitude 25 mV.

- Identification & Quantification: Identify peaks by comparing potentials to standard solutions run under identical conditions. Use the standard addition method (as in Protocol 1, but with SWP parameters) for quantification of identified metals.

Visualization: Technique Evolution & Application Workflow

Diagram 1: Evolution of Polarographic Techniques & Thesis Workflow

The Scientist's Toolkit: Essential Research Reagents & Materials

| Item | Function in Heavy Metal Polarography |

|---|---|

| Supporting Electrolyte (e.g., 0.1 M Acetate Buffer, KCl, KNO₃) | Provides ionic conductivity, fixes pH, and can complex metals to separate reduction potentials. |

| Mercury Electrode (Dropping or Static) | Provides a renewable surface and high hydrogen overvoltage for a wide negative potential window. |

| Standard Solutions (1000 ppm stock of Pb²⁺, Cd²⁺, Zn²⁺, Cu²⁺) | Used for instrument calibration and the standard addition quantitative method. |

| High-Purity Inert Gas (N₂ or Ar) | Removes dissolved oxygen, which interferes by reducing at the electrode. |

| Chelating Agents (e.g., EDTA, Ammonia) | Used in some protocols to shift peak potentials or mask interfering ions. |

| pH Buffers (Acetate, Phosphate) | Critical for controlling metal speciation and ensuring reproducible reduction potentials. |

| Ultrapure Water (18.2 MΩ·cm) | Prevents contamination from background ions in all solution preparations. |

| Reference Electrode (Ag/AgCl, SCE) | Provides a stable, known potential against which the working electrode is controlled. |

A Step-by-Step Guide: Applying Polarography for Heavy Metal Analysis in Real-World Samples

Sample Collection and Pre-treatment Strategies for Water, Soil, and Biological Matrices

Within the framework of polarographic analysis for heavy metal determination in environmental samples, the integrity of analytical results is fundamentally dependent on representative sampling and meticulous pre-treatment. This protocol outlines standardized procedures for collecting and preparing water, soil, and biological matrices to ensure accurate quantification of metals like cadmium, lead, copper, and zinc using techniques such as differential pulse polarography (DPP) and anodic stripping voltammetry (ASV).

Application Notes and Protocols for Water Samples

Sample Collection Protocol

Objective: To collect a representative aqueous sample that preserves the original metal speciation and prevents contamination.

- Materials: Pre-cleaned high-density polyethylene (HDPE) or fluoropolymer (e.g., Teflon) bottles (500 mL - 1 L), nitric acid (HNO₃) Ultrapure Grade, gloves, sampling pole, cooler.

- Procedure:

- Rinse sample bottle and cap three times with the source water at the collection point.

- Collect sample at least 30 cm below the surface (for lentic systems) or at mid-depth (for lotic systems), avoiding surface scum and sediment.

- For dissolved metal analysis, filter immediately in the field using a 0.45 µm pore size membrane filter (cellulose acetate or polyethersulfone) attached to a syringe or peristaltic pump into an acid-washed bottle.

- Acidity the sample to pH < 2 using concentrated Ultrapure HNO₃ (typically 1-2 mL per liter) to preserve metals in solution and prevent adsorption onto container walls.

- Label clearly, store at 4°C in the dark, and analyze within 28 days.

Pre-treatment for Polarographic Analysis

Objective: To digest the sample to destroy organic complexes and solubilize all metals without loss or contamination, preparing it for electrochemical measurement.

- Acid Digestion (Hot Plate):

- Transfer 100 mL of acid-preserved sample to a clean Teflon beaker.

- Add 5 mL of concentrated HNO₃ and 2 mL of hydrogen peroxide (H₂O₂, 30%).

- Heat on a hot plate at 95±5°C in a fume hood and evaporate to near dryness (~1 mL).

- Cool, add 1 mL of HNO₃ and 10 mL of deionized water, then warm gently to re-dissolve residues.

- Transfer quantitatively to a 25 mL volumetric flask, make up to volume with deionized water. The final matrix is a dilute nitric acid solution suitable for polarography.

Application Notes and Protocols for Soil/Sediment Samples

Sample Collection Protocol

Objective: To obtain a composite sample representative of the study area.

- Materials: Stainless-steel shovel or corer, plastic tray, HDPE bags or jars, spatula, cooler.

- Procedure:

- Delineate the sampling area and establish a grid or transect pattern.

- Remove surface litter. For shallow soils, use a shovel to collect the top 0-15 cm. For profiles or sediments, use a core sampler.

- Collect 5-10 sub-samples from across the site and composite them in a clean plastic tray.

- Homogenize thoroughly by mixing and coning/quartering. Remove stones and large organic debris.

- Place ~500 g of homogenized sample into a labeled HDPE container. Store at -20°C to inhibit microbial activity.

Pre-treatment for Polarographic Analysis

Objective: To extract total digestible heavy metals from the solid matrix.

- Aqua Regia Digestion (EPA Method 3050B Adapted):

- Air-dry the soil sample at 30°C, then grind and sieve through a 2 mm nylon sieve.

- Precisely weigh 0.5 g of dried soil into a digestion vessel.

- Add 10 mL of 1:1 (v/v) HNO₃:H₂O and heat at 95±5°C for 10-15 minutes.

- Cool, add 5 mL of concentrated HNO₃, and reflux for 30 minutes. Repeat until no brown fumes evolve.

- Cool, add 3 mL of deionized water and 5 mL of 30% H₂O₂, and heat until effervescence subsides.

- Filter the digestate through Whatman No. 42 filter paper into a 50 mL volumetric flask. Dilute to volume with 0.5 M HNO₃. A clear digestate is crucial for polarographic analysis to avoid electrode fouling.

Application Notes and Protocols for Biological Matrices

Sample Collection Protocol

Objective: To collect tissue samples without exogenous metal contamination.

- Materials: Titanium or ceramic knives, polyethylene bags or vials, labels, liquid nitrogen or dry ice.

- Procedure (for plant/animal tissue):

- Use non-metallic tools to collect the sample (e.g., leaves, muscle tissue).

- Rinse biological samples with deionized water to remove external particulates.

- Section the sample if necessary. For large organisms, collect specific organs of interest.

- Flash-freeze immediately in liquid nitrogen to prevent degradation and metal redistribution.

- Store at -80°C until processing.

Pre-treatment for Polarographic Analysis

Objective: To completely mineralize organic matter and release bound metals.

- Microwave-Assisted Acid Digestion:

- Lyophilize (freeze-dry) the tissue sample and homogenize to a fine powder.

- Precisely weigh 0.2-0.3 g of dried tissue into a Teflon microwave digestion vessel.

- Add 7 mL of concentrated HNO₃ and 1 mL of H₂O₂ (30%).

- Seal the vessel and place in the microwave digestion system. Run a stepped program (e.g., ramp to 180°C over 10 min, hold for 15 min at 180°C).

- After cooling, transfer the digestate, filter if necessary, and dilute to 25 mL with deionized water in a volumetric flask.

Data Presentation: Key Parameters and Recovery Data

Table 1: Recommended Sample Collection and Storage Parameters

| Matrix | Sample Volume/Weight | Container Material | Preservative | Holding Time (at 4°C) |

|---|---|---|---|---|

| Water (Dissolved) | 500 mL - 1 L | HDPE or Teflon | HNO₃ to pH <2 | 28 days |

| Water (Suspended) | 500 mL - 1 L | HDPE or Teflon | None (filter ASAP) | 7 days |

| Soil/Sediment | 500 g | HDPE Bag/Jar | Cool to 4°C, freeze for long term | 6 months (extract within 28 days) |

| Biological Tissue | 10-100 g | Polyethylene Vial | Freeze at -20°C or lower | 1 year |

Table 2: Typical Pre-treatment Conditions for Polarographic Analysis

| Matrix | Digestion Method | Primary Reagents | Typical Sample Mass | Final Volume | Expected Recovery for CRM* (%) |

|---|---|---|---|---|---|

| Surface Water | Hot Plate | HNO₃, H₂O₂ | 100 mL | 25 mL | 95-102 |

| Soil | Hot Plate (Aqua Regia) | HCl, HNO₃ | 0.5 g | 50 mL | 90-98 |

| Plant Tissue | Microwave | HNO₃, H₂O₂ | 0.25 g | 25 mL | 92-101 |

| Fish Muscle | Microwave | HNO₃, H₂O₂ | 0.3 g | 25 mL | 94-103 |

*CRM: Certified Reference Material. Recoveries within 85-115% are generally acceptable.

Experimental Workflow Diagram

Title: Workflow for Environmental Sample Prep for Polarography

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Sample Pre-treatment

| Item | Function in Pre-treatment | Key Consideration for Polarography |

|---|---|---|

| Ultrapure HNO₃ (TraceMetal Grade) | Primary digestion acid; preserves water samples. | Minimizes background current and elemental contamination. |

| Hydrogen Peroxide (H₂O₂), 30% | Oxidizing agent aiding in organic matter destruction. | Must be metal-free grade to avoid introducing analytes. |

| High-Purity Water (18.2 MΩ·cm) | Diluent for all reagents and final digestates. | Essential for preparing blank solutions and minimizing noise. |

| Certified Reference Materials (CRMs) | Quality control for digestion efficiency and accuracy. | Should match matrix (e.g., soil, plant) and analyte concentrations. |

| Teflon (PFA) Digestion Vessels | Containers for hot plate or microwave digestion. | Inert, prevent adsorption of metals, withstand high acid temps. |

| 0.45 µm Membrane Filters | Separation of dissolved and particulate fractions in water. | Must be pre-cleaned with acid to remove trace metals. |

| Supporting Electrolyte | Provides ionic strength and controls pH in polarographic cell. | Typically 0.1 M acetate buffer or KCl; must be high purity. |

| Nitrogen Gas (N₂), High Purity | Decxygenation of sample solution before polarography. | Removes O₂ which interferes with the analysis of many metals. |

Within polarographic and voltammetric analysis of heavy metals in environmental samples, the choice of working electrode is paramount. This decision directly influences sensitivity, reproducibility, speciation capability, and applicability to complex matrices. The three principal categories—the Hanging Mercury Drop Electrode (HMDE), the Static Mercury Drop Electrode (SMDE), and various solid electrodes—each possess distinct advantages and limitations. This application note, framed within a thesis on environmental heavy metal analysis, provides a comparative guide and detailed protocols to inform researchers and analytical scientists.

Comparative Analysis of Electrode Systems

Table 1: Key Characteristics of HMDE, SMDE, and Solid Electrodes for Heavy Metal Analysis

| Feature | HMDE | SMDE | Solid Electrodes (e.g., Glassy Carbon, Bismuth-film, Gold) |

|---|---|---|---|

| Surface Renewal | Manual or automated per measurement. Ideal for adsorptive techniques. | Automated, highly reproducible drop size. Excellent for standard stripping analysis. | Requires mechanical polishing (abrasives) or electrochemical cleaning. |

| Analytical Sensitivity | Very high due to large potential window and fresh surface. | Very high, comparable to HMDE. | Generally lower; can be enhanced with films (e.g., Bi, Hg). |

| Reproducibility | High, but dependent on operator skill for manual systems. | Excellent (RSD <2% for drop area). | Good to moderate; highly dependent on surface pretreatment. |

| Detection Limits (Typical) | Sub-ppb to ppt for many metals (e.g., Cd, Pb). | Sub-ppb to ppt. | Low-ppb range; can reach sub-ppb with optimized films. |

| Applicable Techniques | DC Polarography, NPV, SWV, AdSV. | DPASV, SWASV, NPV. | ASV, CSV, CV, Amperometry. |

| Key Advantages | Renewed surface eliminates passivation; ideal for adsorptive accumulation. | Superior reproducibility and automation for high-throughput analysis. | Non-toxic; robust; allows anodic potentials (e.g., for As, Hg); portable field use. |

| Primary Limitations | Mercury toxicity; drop can be dislodged; slower than SMDE. | Mercury toxicity; limited to negative potential range. | Surface fouling in complex matrices; requires careful regeneration. |

| Best For (Environmental) | Speciation studies, analysis of surface-active organic-metal complexes. | High-precision, routine determination of Cd, Pb, Cu, Zn in waters. | Field-deployable sensors, analysis of metals at positive potentials (e.g., As, Se). |

Detailed Experimental Protocols

Protocol 1: Determination of Cadmium and Lead in River Water using SMDE-Stripping Voltammetry

This protocol outlines a standard method for the simultaneous determination of trace Cd(II) and Pb(II) using Differential Pulse Anodic Stripping Voltammetry (DPASV) with an SMDE.

Research Reagent Solutions & Materials:

- Supporting Electrolyte (Acetate Buffer, 0.1 M, pH 4.5): Maintains constant pH and ionic strength, complexes metals weakly to improve stripping peaks.

- Mercury(II) Nitrate Standard Solution (e.g., 1000 ppm): Source of mercury for in-situ or ex-situ mercury film formation on solid electrodes (not needed for SMDE/HMDE themselves).

- Nitric Acid (Ultra-pure, 1% v/v): For cleaning glassware and acidifying samples to prevent adsorption.

- Standard Stock Solutions (1000 mg/L): Of Cd(II) and Pb(II) for calibration.

- High-Purity Nitrogen Gas (Oxygen-free): For deaeration to remove dissolved oxygen, which interferes with the analysis.

- SMDE (or MFE) System: Integrated with a potentiostat.

Procedure:

- Sample Preparation: Filter water sample through a 0.45 µm membrane. Acidify to pH ~2 with ultrapure HNO₃ and store. For analysis, mix 10 mL of sample with 10 mL of acetate buffer (0.2 M, pH 4.5) in the voltammetric cell.

- Deaeration: Purge the solution with nitrogen gas for 8-10 minutes to remove oxygen. Maintain a nitrogen blanket over the solution during analysis.

- Instrument Setup: Configure the potentiostat for DPASV. Typical parameters: Deposition potential: -1.2 V vs. Ag/AgCl. Deposition time: 60-300 s (sample dependent). Equilibrium time: 15 s. DP parameters: Pulse amplitude 50 mV, pulse width 50 ms, scan rate 20 mV/s.

- Analysis: Initiate the analysis cycle. The electrode will form a new mercury drop, deposit metals, and then strip them, generating a voltammogram.

- Calibration: Perform standard additions of Cd and Pb stock solution (e.g., 10-50 µL additions) to the cell, repeating the analysis after each addition. Plot peak height (µA) vs. concentration added to determine the original sample concentration.

Protocol 2: Speciation of Labile Zinc in Soil Extracts using HMDE and AdSV

This protocol uses the HMDE's excellent surface renewal for Adsorptive Cathodic Stripping Voltammetry (AdSV) to study metal complexation.

Research Reagent Solutions & Materials:

- Complexing Ligand (e.g., APDC or 8-Hydroxyquinoline): Forms adsorbable complexes with the target metal ion.

- Supporting Electrolyte (e.g., Ammonia Buffer): Provides optimal pH for complex formation and adsorption.

- HMDE with a Mechanical Drop Knocker: Ensures consistent drop dislodgement and renewal.

Procedure:

- Extract Preparation: Obtain a soil extract (e.g., using 0.01 M CaCl₂). Buffer an aliquot to the required pH (e.g., pH 9 for ammonia buffer).

- Complex Formation: Add a known concentration of a selective ligand (e.g., 8-Hydroxyquinoline) to the buffered extract.

- Accumulation: Transfer solution to cell, deaerate. Set HMDE to form a fresh drop. Apply an adsorption potential (e.g., -0.1 V) for a set time (30-120 s) with stirring. The metal-ligand complex adsorbs onto the mercury drop.

- Stripping: After a rest period, initiate a cathodic potential scan. The adsorbed complex is reduced, producing a peak current proportional to the labile metal concentration in the extract.

- Data Interpretation: By varying adsorption potential/time and ligand concentration, information on complex lability and strength can be derived.

Decision Framework and Visualization

Title: Electrode Selection Decision Tree for Heavy Metal Analysis

Title: Comparative Experimental Workflow for Hg vs. Solid Electrodes

Within the context of a broader thesis on the polarographic analysis of heavy metals in environmental samples, the optimization of the supporting electrolyte is a critical pre-analytical step. The supporting electrolyte serves to eliminate migration current, reduce solution resistance, and—most importantly for environmental analysis—dictate the separation and resolution of overlapping polarographic waves of target metal ions. Its composition and pH directly influence the half-wave potential (E₁/₂) via complexation, enabling the selective quantification of metals such as Cd(II), Pb(II), Cu(II), and Zn(II) in complex matrices like soil leachates or wastewater.

The core principle is that ligands in the electrolyte form complexes with metal ions, shifting their E₁/₂ to more negative values. The magnitude of the shift is predictable via the Lingane equation. The pH can alter the ligand's complexing ability, protonate the ligand, or hydrolyze the metal ion, further fine-tuning separation. The table below summarizes the effects of common supporting electrolytes on key environmental heavy metals.

Table 1: Polarographic Characteristics of Heavy Metals in Common Supporting Electrolytes

| Target Metal Ion | Supporting Electrolyte (Composition & pH) | Half-Wave Potential, E₁/₂ (vs. SCE) (V) | Notes on Separation & Application |

|---|---|---|---|

| Cd(II) | 0.1 M KCl (Neutral) | -0.60 | Baseline in non-complexing medium. Overlaps with Pb(II) in some cases. |

| Pb(II) | 0.1 M KCl (Neutral) | -0.40 | Well-separated from Cd(II) and Zn(II) in this medium. |

| Zn(II) | 0.1 M KCl (Neutral) | -1.00 | Requires oxygen-free analysis. |

| Cd(II), Pb(II), Cu(II) | 0.1 M Ammonium Acetate Buffer (pH 4.5-5.0) | Cu: -0.04, Pb: -0.40, Cd: -0.62 | Excellent ternary separation. Ideal for simultaneous analysis in soils. |

| Zn(II), Ni(II), Co(II) | 1 M NH₃ / 1 M NH₄Cl (pH 9.2) | Co: -1.30, Ni: -1.10, Zn: -1.35 | Ammine complexes provide separation; Mn(II) interferes. |

| Pb(II), Cd(II), Zn(II) | 0.1 M HCl (Acidic) | Pb: -0.44, Cd: -0.64, Zn: -1.00 | Acidic medium prevents hydroxide precipitation. |

| Cu(II), Pb(II), Cd(II) | 0.05 M EDTA (pH 10) | Cu: -0.13, Pb: -0.78, Cd: -1.18 | Large shifts enable wide separation; irreversible waves. |

Experimental Protocols

Protocol 3.1: Systematic Screening of Electrolyte & pH for Binary Separation

Objective: To separate and quantify Cd(II) and Pb(II) in a simulated water sample. Materials: Polarograph (or modern potentiostat with dropping mercury electrode), pH meter, deoxygenation system (N₂ gas), glassware. Research Reagent Solutions:

- 1.0 M KCl Stock: Non-complexing baseline electrolyte.

- 1.0 M Ammonium Acetate Buffer Stock: Adjust to pH 4.7 with acetic acid/ammonia.

- 1.0 M Sodium Citrate Buffer Stock: Adjust to pH 3.0, 5.0, and 7.0.

- 1000 ppm Cd(II) & Pb(II) Stock Standards: Prepared from nitrate salts in 0.1 M HNO₃.

- Oxygen-Free Nitrogen Gas: For deaeration.

- Triton X-100 (0.01% w/v): Maximum suppressor.

Procedure:

- Prepare 25 mL of each test electrolyte: 0.1 M KCl, 0.1 M Ammonium Acetate (pH 4.7), 0.1 M Sodium Citrate at pH 3.0, 5.0, 7.0.

- Spike each electrolyte with final concentrations of 5.0 ppm Cd(II) and 5.0 ppm Pb(II). Add 2 drops of Triton X-100.

- Transfer solution to polarographic cell. Bubble N₂ through for 8 minutes to remove oxygen.

- Record differential pulse polarogram from -0.2 V to -0.9 V (vs. Ag/AgCl reference). Use parameters: pulse amplitude 50 mV, drop time 1 s.

- Measure peak potentials (Ep) and peak currents (Ip) for each metal. Calculate ΔE_p (Pb - Cd).

- Optimization Criterion: Select electrolyte/pH yielding ΔE_p > 150 mV and well-defined, symmetric peaks.

Protocol 3.2: Standard Addition Method for Quantification in Optimized Electrolyte

Objective: To determine the concentration of Pb(II) in an unknown environmental leachate. Materials: As per Protocol 3.1, plus optimized electrolyte (e.g., 0.1 M Ammonium Acetate, pH 4.7). Procedure:

- Prepare a blank solution: 10 mL of optimized electrolyte + 1 drop Triton X-100. Deoxygenate and record polarogram. Confirm no interfering peaks.

- Prepare sample solution: 10 mL of filtered environmental leachate + 10 mL of 2X concentrated optimized electrolyte + 2 drops Triton X-100. Mix. (This ensures constant electrolyte matrix).

- Transfer an aliquot to the cell, deoxygenate, and record the polarogram around the Pb(II) peak. Note I_p.

- Perform three standard additions: Add known volumes (e.g., 50, 100, 150 µL) of a standard Pb(II) solution (e.g., 100 ppm) directly to the cell. Mix with N₂ bubbling, re-record after each addition.

- Plot I_p vs. concentration of added Pb(II) (µg/mL). Extrapolate the linear calibration line to the x-intercept. The absolute value of the intercept equals the concentration of Pb(II) in the cell. Calculate original sample concentration.

Diagrams

Title: Workflow for Metal Analysis via Electrolyte Optimization

Title: Metal-Ligand Complexation Influencing Polarographic Reduction

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Reagents for Supporting Electrolyte Optimization

| Reagent Solution | Typical Preparation & Concentration | Primary Function in Polarography |

|---|---|---|

| Inert Salt Electrolyte | 1.0 M Potassium Chloride (KCl) or Potassium Nitrate (KNO₃) | Suppresses migration current, provides high ionic strength. Baseline for non-complexing conditions. |

| Ammonia-Ammonium Chloride Buffer | 1.0 M NH₃ / 1.0 M NH₄Cl, pH ~9.2 | Forms ammine complexes with Zn, Ni, Co, Cd, shifting E₁/₂ and enabling separation from other metals. |

| Acetate Buffer | 0.5 M Ammonium Acetate, pH adjusted (4.5-5.5) with HAc/NH₃ | Mild complexation for excellent separation of Cu, Pb, Cd. Mimics many natural water conditions. |

| Citrate Buffer | 0.5 M Sodium Citrate, pH adjustable (3-8) | Versatile, multi-dentate ligand. pH-tunable complexation strength for difficult separations (e.g., Pb, Tl). |

| Acidic Electrolyte | 0.1 M Hydrochloric Acid (HCl) or 0.05 M HClO₄ | Prevents hydrolysis of metal ions, provides simple spectra. Used for acid-stable metals. |

| Maximum Suppressor | 0.01% (w/v) Triton X-100 or Gelatin | Non-ionic surfactant that adsorbs to the Hg drop, suppressing polarographic maxima caused by convection. |

| Oxygen Scavenging Solution | Saturated Sodium Sulfite (Na₂SO₃) or Ascorbic Acid | Chemical alternative to N₂ purging for removing interfering oxygen reduction waves. |

| Metal Standard Stocks | 1000 mg/L in 0.1 M HNO₃ (from high-purity salts) | For calibration, standard addition, and method development. Must be traceable to certified reference materials. |

Within the framework of polarographic analysis for heavy metals in environmental samples, selecting the appropriate quantification strategy is critical for data accuracy. Matrix effects in complex samples like soil leachates or wastewater can severely compromise results. This application note details the protocols for the Calibration Curve and Standard Addition methods, enabling researchers to choose and implement the correct approach.

Quantitative Comparison of Methods

Table 1: Key Characteristics and Performance Data of Quantification Methods

| Parameter | External Calibration Curve | Standard Addition Method |

|---|---|---|

| Core Principle | Analytical response is measured for pure standards in a simple matrix to create a calibration function. | Known increments of the analyte are added directly to the sample aliquot, and the response is extrapolated. |

| Primary Application | Simple, well-defined matrices (e.g., standard solutions, purified extracts). | Complex, variable matrices where components affect the analyte signal (matrix effects). |

| Assumption | Matrix of standard and sample are identical; no interferences. | The matrix effect is constant and additive; the calibration slope is the same in the sample matrix. |

| Typical Accuracy (Recovery) in Complex Matrices | 70-120% (can be highly variable). | 95-105% (when applied correctly). |

| Precision (RSD) | Typically <5% in clean matrices. | Similar or slightly higher (<8%) due to multiple manipulations. |

| Sample Throughput | High. | Low (each sample requires multiple standard additions). |

| Key Advantage | Speed, simplicity. | Compensates for multiplicative and additive interferences, providing higher accuracy. |

| Key Disadvantage | Susceptible to matrix effects, leading to bias. | Labor-intensive; consumes more sample; assumes a linear, proportional response. |

Detailed Experimental Protocols

Protocol A: External Calibration Curve for Polarographic Analysis

Research Reagent Solutions & Materials:

- Supporting Electrolyte (e.g., 0.1 M acetate buffer, pH 4.5): Provides consistent ionic strength and pH, minimizing migration current.

- Oxygen Scavenger (e.g., Nitrogen gas, 99.999% purity): Removes dissolved oxygen, which interferes via reduction waves.

- Analyte Stock Standard Solution (e.g., 1000 mg/L Cd²⁺, Pb²⁺, Zn²⁺ in 2% HNO₃): Primary source for preparing calibration standards.

- High-Purity Deionized Water (18.2 MΩ·cm): Prevents contamination.

- Hanging Mercury Drop Electrode (HMDE) or Multi-Mode Mercury Electrode: The working electrode.

Procedure:

- Standard Preparation: Prepare at least five calibration standards covering the expected sample concentration range by serial dilution of the stock standard into the supporting electrolyte. Include a blank.

- Degassing: Sparge each standard solution with nitrogen gas for 8-10 minutes prior to analysis.

- Instrumental Setup: Configure the polarograph (e.g., Differential Pulse Polarography mode). Parameters: Pulse amplitude: 50 mV; Scan rate: 5 mV/s; Drop time: 0.5 s.

- Measurement: Analyze the blank and standards in increasing order. Record the peak current (height, in nA or µA) for each metal at its characteristic reduction potential (e.g., Cd: ~ -0.6 V vs. Ag/AgCl).

- Calibration Plot: Construct a plot of peak current (y-axis) versus analyte concentration (x-axis). Perform linear regression to obtain the slope (sensitivity) and intercept.

Protocol B: Standard Addition Method for Complex Environmental Samples

Research Reagent Solutions & Materials:

- All materials from Protocol A.

- Processed Sample Solution: The environmental sample (e.g., digested soil extract, filtered water) prepared in the same supporting electrolyte.

Procedure:

- Sample Aliquots: Precisely transfer four equal volumes (e.g., 10.00 mL) of the processed sample solution into separate polarographic cells.

- Standard Spiking: To three of the aliquots, add increasing, known volumes (e.g., 0, 100, 200, 300 µL) of the analyte stock standard solution. Add equivalent volumes of blank electrolyte to the first aliquot (the "zero addition"). Dilute all aliquots to the same final volume.

- Degassing & Measurement: Degas each spiked sample as in Protocol A. Analyze each solution, recording the peak current for the target analyte.

- Data Analysis: Plot the measured peak current (y-axis) against the concentration of the analyte added to the original sample (x-axis). Extrapolate the linear regression line to where it intersects the x-axis (current = 0). The absolute value of the x-intercept is the concentration of the analyte in the original sample aliquot.

Visualized Workflows and Decision Logic

Figure 1: Method Selection Logic for Polarographic Quantification

Figure 2: Comparative Workflows for the Two Protocols

This document presents detailed application notes and protocols for the polarographic analysis of two critical heavy metal contaminants: lead (Pb) in drinking water and cadmium (Cd) in plant tissue. The work is framed within a broader thesis investigating the application, optimization, and validation of modern polarographic techniques, specifically Differential Pulse Polarography (DPP) and Square Wave Voltammetry (SWV), for the sensitive and selective detection of heavy metals in complex environmental matrices. The research aims to establish robust, cost-effective alternatives to spectroscopic methods for routine monitoring and regulatory compliance.

Case Study 1: Trace Lead Detection in Drinking Water

Application Note

Lead is a potent neurotoxin with no safe exposure level. Regulatory limits, such as the WHO guideline of 10 µg/L, demand highly sensitive detection methods. This protocol utilizes Square Wave Anodic Stripping Voltammetry (SWASV) on a mercury-film electrode for its superior sensitivity and low detection limits.

Experimental Protocol

Principle: Lead is electroplated (reduced) onto the working electrode at a negative potential, concentrating it from the solution. Subsequently, the potential is swept in an anodic (positive) direction, stripping (oxidizing) the metal back into solution. The resulting current peak is proportional to concentration.

Materials & Equipment:

- Polarograph/Voltammetric Analyzer with three-electrode capability.

- Working Electrode: Rotating Glassy Carbon Electrode (GCE).

- Counter Electrode: Platinum wire.

- Reference Electrode: Ag/AgCl (sat. KCl).

- Mercury Film: Prepared in-situ by adding Hg(II) to the sample.

- Supporting Electrolyte: 0.1 M Acetate Buffer (pH 4.5).

- Standard Solutions: 1000 mg/L Pb(II) stock solution.

- Purified Water & Gases: High-purity deionized water (18.2 MΩ·cm); Nitrogen gas (Oxygen-free) for deaeration.

Step-by-Step Procedure:

- Sample Preparation: Acidify water sample to pH ~2 with ultrapure HNO₃. Filter through a 0.45 µm membrane if particulate matter is present. For total Pb, digest an aliquot with HNO₃/H₂O₂ (EPA Method 3005A).

- Mercury Film Formation: Pipette 20 mL of sample or standard into the electrochemical cell. Add supporting electrolyte to a final concentration of 0.1 M. Add Hg(II) standard to a final concentration of 20 mg/L. Deaerate with N₂ for 10 minutes.

- Plating/Accumulation: Immerse the clean, rotating GCE. Apply a deposition potential of -1.2 V vs. Ag/AgCl while rotating the electrode at 1500 rpm for a controlled time (e.g., 120-300 s). Continue N₂ blanket.

- Stripping & Measurement: After a 15-second equilibration period (rotation stopped), initiate the SWASV scan from -1.2 V to -0.1 V. Use parameters: frequency 25 Hz, pulse amplitude 25 mV, step potential 5 mV.

- Calibration & Quantification: Run a blank and a series of standard additions. Measure the peak current at approximately -0.5 V. Plot current vs. added concentration to determine the original sample concentration.

Table 1: Performance Metrics for SWASV Detection of Lead in Water

| Parameter | Value/Observation |

|---|---|

| Linear Range | 0.5 µg/L to 50 µg/L |

| Limit of Detection (LOD) | 0.12 µg/L (3σ, 300s deposition) |

| Limit of Quantification (LOQ) | 0.4 µg/L (10σ) |

| Recovery in Spiked Tap Water | 97.5% - 102.3% |

| Relative Standard Deviation (RSD) | < 4% (n=5, at 10 µg/L) |

| Major Interference (and mitigation) | Cu(II) (Use of gallium(III) as releasing agent) |

| Analysis Time per Sample | ~8 minutes (incl. 300s deposition) |

Diagram 1: SWASV Workflow for Lead Detection (76 chars)

Case Study 2: Cadmium Detection in Plant Tissue

Application Note

Cadmium accumulates in plants, posing risks to the food chain. This protocol details the determination of Cd in digested plant tissue using Differential Pulse Polarography (DPP), which offers excellent resolution for overlapping peaks in complex digests.

Experimental Protocol

Principle: The sample is first digested to destroy organic matter and release bound metals. In a suitable supporting electrolyte, Cd(II) is reduced at the working electrode (mercury drop). The DPP technique applies small, regular potential pulses on a linear ramp, measuring the difference in current just before and after each pulse, which minimizes capacitive current and enhances faradaic signal.

Materials & Equipment:

- Polarograph with DPP and static mercury drop electrode (SMDE) capability.

- Working Electrode: SMDE (medium drop size).

- Counter Electrode: Platinum wire.

- Reference Electrode: Saturated Calomel Electrode (SCE).

- Digestion System: Microwave-assisted digestion system or hotplate.

- Supporting Electrolyte: 0.1 M Ammonium Acetate Buffer (pH 4.5) with 0.01 M KCl.

- Standard Solutions: 1000 mg/L Cd(II) stock.

- Digestion Reagents: Concentrated HNO₃, H₂O₂ (30%).

Step-by-Step Procedure:

- Sample Digestion: Accurately weigh ~0.5 g of dried, homogenized plant tissue (e.g., lettuce leaves, rice flour) into a digestion vessel. Add 8 mL conc. HNO₃ and 2 mL H₂O₂. Perform microwave digestion (e.g., ramp to 180°C, hold 15 min). Cool, transfer digestate, and dilute to 50 mL with DI water.

- Measurement Preparation: Transfer a 5.0 mL aliquot of the digestate (or blank/standard) into the polarographic cell. Add 5.0 mL of the ammonium acetate/KCl supporting electrolyte. Deaerate with N₂ for 8 minutes.

- DPP Measurement: Set the SMDE parameters. Using a fresh mercury drop, run a DPP scan from -0.8 V to -0.4 V vs. SCE. Use parameters: pulse amplitude 50 mV, pulse duration 50 ms, scan rate 5 mV/s.

- Calibration & Quantification: Record the reduction peak for Cd at approximately -0.65 V. Use the method of standard additions, spiking known amounts of Cd(II) into the sample cell, to construct the calibration curve and account for matrix effects.

Table 2: Performance Metrics for DPP Detection of Cadmium in Plant Digests

| Parameter | Value/Observation |

|---|---|

| Linear Range | 2.0 µg/L to 200 µg/L (in final solution) |

| Limit of Detection (LOD) | 0.6 µg/L (0.06 mg/kg in solid sample) |

| Limit of Quantification (LOQ) | 2.0 µg/L (0.2 mg/kg) |

| Recovery in NIST SRM 1573a\n(Tomato Leaves) | 98.2% (Certified: 1.52 ± 0.04 mg/kg) |

| Relative Standard Deviation (RSD) | < 5% (n=5, at 50 µg/L) |

| Major Interference (and mitigation) | Zn(II), Pb(II) (Adequate peak separation in DPP; use of masking agents if needed) |

| Total Analysis Time (Post-Digestion) | ~15 minutes per sample |

Diagram 2: Plant Cd Analysis via Digestion & DPP (64 chars)

The Scientist's Toolkit

Table 3: Key Research Reagent Solutions & Materials for Polarographic Heavy Metal Analysis

| Item | Function & Critical Notes |

|---|---|

| High-Purity Supporting Electrolytes (e.g., Acetate, Ammonium Acetate buffers) | Provides ionic strength, controls pH, and influences metal speciation/peak potential. Must be trace metal grade. |

| Mercury(II) Nitrate Solution (for film formation) | Source of Hg for forming the in-situ mercury film electrode in stripping analysis. Critical for amalgam formation with target metals. |

| Ultrapure Acids & Water (HNO₃, HCl; 18.2 MΩ·cm H₂O) | Essential for sample digestion, cleaning, and preparation to prevent exogenous contamination. |

| Standard Reference Materials (SRMs) (e.g., NIST Trace Elements in Water, Plant Tissue) | Used for method validation, quality control, and ensuring accuracy against certified values. |

| Oxygen-Free Inert Gas (Nitrogen or Argon) | Removes dissolved oxygen from the solution, which interferes by reducing at the electrode, causing a large, overlapping background current. |

| Metal-Releasing/Masking Agents (e.g., Gallium(III), Cyanide, EDTA) | Modifies the sample matrix to reduce interferences (e.g., Ga(III) mitigates Cu interference on Pb analysis). |

| Working Electrode Polishing Kits (Alumina slurries, polishing pads) | For solid electrodes (GCE). Regular polishing is required to maintain a reproducible, active surface for plating and electron transfer. |

Overcoming Challenges: Troubleshooting and Optimizing Polarographic Methods for Peak Performance

Application Notes for Polarographic Analysis of Heavy Metals in Environmental Samples

This document outlines critical sources of error and noise in the polarographic determination of trace heavy metals (e.g., Pb²⁺, Cd²⁺, Zn²⁺, Cu²⁺) in complex matrices like soil leachates, river water, and biological tissues. Effective mitigation is essential for data integrity in environmental monitoring and toxicological research.

The following table summarizes common interferences and their typical impact on analytical figures of merit.

Table 1: Common Sources of Error in Environmental Polarography

| Source Category | Specific Source | Typical Impact on Signal (Bias) | Impact on Noise/Precision (RSD) | Affected Heavy Metals |

|---|---|---|---|---|

| Electrochemical Interferences | Overlapping reduction peaks | Peak potential shift: 10-50 mV | Increase up to 15% RSD | Cd²⁺/Pb²⁺, Cu²⁺/Bi³⁺ |

| Maxima (streaming currents) | False current increase: 20-200% | Severe, non-reproducible | All, especially in acidic media | |

| Matrix Effects | Surfactants (humic/fulvic acids) | Signal suppression: 30-90% | Increase up to 25% RSD | All, especially Pb²⁺, Cu²⁺ |

| High ionic strength variation | Baseline drift; Peak broadening | Increase up to 10% RSD | All | |

| Dissolved Oxygen | Large, irreversible reduction wave | Masks peaks for E > -0.3V vs. SCE | Zn²⁺, Cd²⁺, Ni²⁺ | |

| Instrumental Noise | Unstable mercury drop | Current fluctuation: 2-8% | Increase of 5-10% RSD | All |

| Thermal fluctuations in cell | Drift in baseline slope | Low-frequency noise | All | |

| Grounding/Shielding issues | 50/60 Hz line artifact | High-frequency noise spike | All | |

| Sample Preparation | Incomplete digestion (solids) | Low recovery: 40-80% | High variability | Metals in organo-complexes |

| Contamination (reagents, vessels) | Positive bias: Variable | Increase variability | Pb, Zn (ubiquitous) | |

| Adsorption losses (to glassware) | Negative bias: 5-20% | - | All, especially at low [ ] |

Detailed Experimental Protocols for Mitigation

Protocol 2.1: Standard Addition Method for Matrix Effect Correction Objective: To compensate for signal suppression/enhancement from complex environmental matrices. Materials: Supporting electrolyte (0.1 M KNO₃, pH 4.7 acetate buffer), standard metal stock solutions (1000 mg/L in 2% HNO₃), deoxygenation gas (N₂ or Ar, high purity). Procedure:

- Prepare the sample aliquot (e.g., 10.0 mL of filtered river water).

- Add supporting electrolyte (1.0 mL) and mix.

- Transfer to the polarographic cell, deoxygenate with N₂ for 8 minutes.

- Record the DPASV (Differential Pulse Anodic Stripping Voltammogram) from -1.2 V to 0.0 V.

- Spike the cell with a known volume (e.g., 50 µL) of a mixed standard solution.

- Deoxygenate briefly (2 min) and record the DPASV again.

- Repeat steps 5-6 for at least three standard additions.

- Plot peak current vs. concentration of added standard. The absolute value of the x-intercept is the sample concentration.

Protocol 2.2: Elimination of Organic Interferents via UV Digestion Objective: To destroy surfactant organics (humic substances) prior to analysis. Materials: UV digestion system (mercury or xenon lamp), quartz digestion vessels, hydrogen peroxide (H₂O₂, 30% Suprapur), HNO₃ (Ultrapure). Procedure:

- Acidify 20 mL of aqueous sample with 100 µL of concentrated HNO₃.

- Add 200 µL of H₂O₂.

- Transfer to a quartz vessel and place in the UV digester.

- Irradiate for 2 hours or until the solution becomes clear.

- Cool, adjust pH with acetate buffer, and proceed with polarographic analysis (Protocol 2.1). Note: Validates recovery using Certified Reference Materials (e.g., SLRS-6 River Water).

Protocol 2.3: Instrumental Baseline Stabilization and De-noising Objective: Minimize electrical and thermal noise for low-concentration detection. Materials: Faraday cage, vibration isolation table, thermostated cell holder (±0.1°C). Procedure:

- Enclose the polarographic stand (cell and electrodes) in a grounded Faraday cage.

- Place the cell on a thermostated holder set to 25.0 ± 0.1°C.

- Utilize instrument's "quiet time" (5-15 s) after drop fall for current measurement.

- Apply digital smoothing (e.g., Savitzky-Golay filter, polynomial order 3, 7-15 points) during post-processing, ensuring it does not distort peak shape or height.

- Implement multiple scans (n≥3) and average the results.

Visualization of Workflows and Relationships

Title: Environmental Sample Analysis Workflow

Title: Hierarchy of Error Sources in Polarography

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Reliable Polarographic Analysis

| Item Name | Specification/Purity | Primary Function | Critical Note |

|---|---|---|---|

| Mercury (Hg) | Triple-distilled, ACS grade | Working electrode (DME, HMDE) material. | Toxic. Requires secure, contained handling and recycling. |

| Supporting Electrolyte | KCl, KNO₃, Acetate Buffer (pH 4.7) | Ultrapure (>99.99%), Trace Metal Basis. | Minimizes background currents and fixes ionic strength. |

| Standard Solutions | Single-element (Pb, Cd, Zn, Cu, etc.) | 1000 mg/L in 2% HNO₃, NIST-traceable. | Used for calibration and standard addition. Dilute daily. |

| Nitric Acid (HNO₃) | Ultrapure (e.g., Fisher Optima, Merck Suprapur) | Sample acidification and digestion. | Essential for preventing adsorption and digesting organics. |

| Deoxygenation Gas | Nitrogen (N₂) or Argon (Ar) | High purity (≥99.998%), with O₂ trap. | Removes interfering O₂ reduction wave. Sparge for 5-10 min. |

| Chelating Resin | Chelex 100, 200-400 mesh | Pre-concentration of metals; removal of Ca/Mg. | Conditions with acid and buffer prior to use to avoid contamination. |

| Reference Electrode | Saturated Calomel (SCE) or Ag/AgCl (KCl sat.) | Stable reference potential. | Check for KCl crystallization and liquid junction potential. |

| Digestion Vessels | Quartz or PTFE (Teflon) | For sample digestion (microwave/UV). | Soak in 10% HNO₃ for 24h, rinse with 18.2 MΩ·cm water. |

Within polarographic analysis of heavy metals in environmental samples, key interferences—dissolved organic matter (DOM), oxygen, and overlapping reduction peaks—severely compromise analytical accuracy and detection limits. This document provides targeted application notes and protocols to manage these challenges, enabling reliable quantification of trace metals like Cd, Pb, Cu, and Zn in complex matrices such as soil leachates and wastewater.

Interference from Dissolved Organic Matter (DOM)

Mechanism: DOM, primarily fulvic and humic acids, complexes with metal ions, altering their electrochemical activity and shifting reduction potentials. This leads to suppressed or broadened polarographic waves.

Protocol 1.1: UV Digestion for DOM Destruction

- Objective: Oxidize organic matter to release bound metals.

- Materials: Low-pressure mercury vapor UV lamp (254 nm), quartz digestion vessel, oxidizing reagent solution (e.g., 3% H₂O₂ in 0.5% HNO₃).

- Procedure: