Performance Evaluation of Nanostructured Electrode Materials: From Fundamentals to Advanced Biomedical Applications

This article provides a comprehensive performance evaluation of nanostructured electrode materials, tailored for researchers and professionals in scientific and drug development fields.

Performance Evaluation of Nanostructured Electrode Materials: From Fundamentals to Advanced Biomedical Applications

Abstract

This article provides a comprehensive performance evaluation of nanostructured electrode materials, tailored for researchers and professionals in scientific and drug development fields. It systematically explores the fundamental properties that define material performance, details advanced synthesis methods and their applications in biosensing and energy storage, addresses key challenges and optimization strategies for real-world use, and establishes rigorous validation and comparative analysis frameworks. By integrating the latest research, this review serves as a critical resource for selecting, developing, and validating nanostructured electrodes for cutting-edge biomedical and clinical applications.

Unlocking the Potential: Fundamental Properties and Performance Metrics of Nanostructured Electrodes

The pursuit of advanced energy storage technologies has positioned nanostructured electrode materials at the forefront of materials science research. The performance of these materials in applications ranging from supercapacitors to metal-ion batteries is governed by a complex interplay of key physicochemical properties. Among these, specific surface area, electrical conductivity, and structural stability form the fundamental triumvirate controlling electrochemical efficiency, energy density, and cycle life. This guide provides an objective comparison of major nanostructured electrode material classes, examining their performance through experimental data and methodologies, framed within the broader context of performance evaluation research for next-generation energy storage systems.

Performance Comparison of Nanostructured Electrode Materials

The table below summarizes key physicochemical properties and electrochemical performance metrics for major classes of nanostructured electrode materials, synthesized from recent experimental studies.

Table 1: Comparative Performance of Nanostructured Electrode Materials

| Material Class | Specific Surface Area (SSA) | Electrical Conductivity | Structural Stability (Cycle Life) | Specific Capacitance/Capacity | Key Advantages |

|---|---|---|---|---|---|

| 3D Graphene Foams | Ultra-high SSA from porous network [1] | Excellent conductive continuous network [1] | Good (enhanced by porous network) [1] | High (synergistic EDLC + pseudocapacitance) [1] | Large active surface area; fast charge transfer [1] |

| MXenes (e.g., Ti3C2Tx) | High (2D layered morphology) [2] | Metallic conductivity [2] | Excellent (>92.4% retention after 100 cycles) [2] | Very High (~1500 F/cm³ reported) [2] | Tunable surface chemistry; hydrophilic nature [2] |

| Metal Oxides (RuO2, NiO) | Moderate (varies with nanostructuring) [2] | Moderate to Low (often requires composites) [2] | Variable (NiO: good; others may degrade) [2] | Very High (high theoretical capacitance) [2] | Multiple oxidation states; rich redox chemistry [2] |

| Intercalation-type (Nb2O5, TiO2) | Moderate [2] | Moderate [2] | Excellent (fast, reversible ion insertion) [2] | Moderate [2] | Minimal phase transitions during cycling [2] |

| Activated Carbon (AC) Composites | Very High (e.g., >1500 m²/g) [3] | Moderate (requires conductive additives) [3] | Excellent (hundreds of thousands of cycles) [3] | Moderate (EDLC mechanism) [3] | Well-developed porosity; cost-effective [3] |

Table 2: Sodium-Ion Battery Electrode Material Performance

| Material | Specific Energy Density | Average Voltage | Capacity Retention | Key Findings |

|---|---|---|---|---|

| Na2Ti3O7 Nanotubes / VOPO4 Nanosheets (Full Cell) | 220 Wh/kg [4] | ~0.55 V (safe operation) [4] | 92.4% after 100 cycles [4] | Higher energy density than most SIBs; comparable to some Li-ion cells [4] |

| Na2Ti3O7 Nanotubes (Anode) | N/A (Anode material) | Low voltage (prevents Na plating) [4] | Good [4] | Safer alternative to hard carbon anodes [4] |

| VOPO4 Nanosheets (Cathode) | N/A (Cathode material) | N/A | Good [4] | High capacity; excellent rate capability [4] |

Experimental Protocols and Methodologies

Electrochemical Performance Evaluation

Standard experimental protocols for evaluating electrode materials involve a combination of structural characterization and electrochemical testing.

- Structural and Chemical Characterization: Techniques include Transmission Electron Microscopy (TEM) for nanoscale morphology, gas sorption analysis (e.g., BET) for specific surface area and porosity, and streaming potential and elemental analysis (EDX) for surface chemistry [3].

- Electrochemical Testing: This is typically performed using a three-electrode cell or a two-electrode coin cell configuration. Key tests include:

- Cyclic Voltammetry (CV): Used to study charge storage mechanisms (EDLC vs. pseudocapacitive) and rate capability. A rectangular-shaped CV curve indicates ideal capacitive behavior [2].

- Galvanostatic Charge-Discharge (GCD): Measures specific capacitance, energy density, and power density. The linear voltage-time profile is characteristic of capacitor behavior [4].

- Electrochemical Impedance Spectroscopy (EIS): Reveals information about internal resistance, charge transfer resistance, and ion diffusion kinetics within the electrode [3].

- Long-term Stability Tests: Conducted via prolonged voltage floating (e.g., at 2.7 V for 100 hours) or continuous charge-discharge cycling (e.g., over 100 cycles) to assess capacity retention and structural degradation [3].

Material Fabrication Techniques

- Infiltration: A common method for fabricating nanocomposite electrodes, particularly for solid oxide cells. It involves injecting a precursor solution into a pre-sintered porous electrode scaffold, followed by calcination to form a composite structure. This technique enhances the triple-phase boundary (TPB) length and specific surface area, crucial for reaction kinetics [5].

- In Situ Exsolution: A process where metal nanoparticles are grown on a perovskite oxide surface under reducing conditions. This method produces highly active and stable nanoparticles, mitigating agglomeration at high temperatures—a significant challenge for traditional methods like atomic layer deposition or sol-gel techniques [5].

- Liquid-Phase Exfoliation: Used for producing two-dimensional materials, such as VOPOâ‚„ nanosheets, from their bulk counterparts. This scalable method involves breaking apart layers in a suitable solvent [4].

- Hydrothermal Synthesis: A common route for creating nanostructured materials like Na₂Ti₃O₇ nanotubes, involving a reaction in a sealed vessel at high temperature and pressure under alkaline conditions [4].

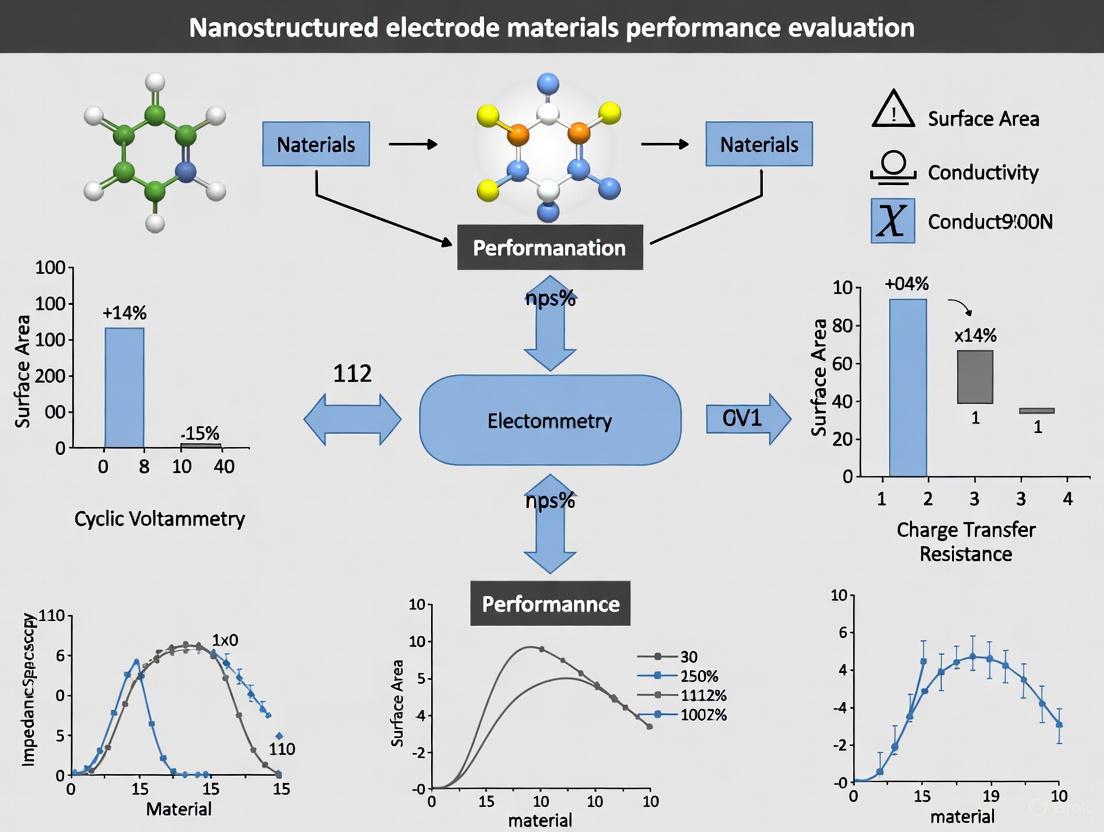

The following diagram illustrates the interconnected relationship between key properties, material engineering strategies, and the resulting electrochemical performance.

The Scientist's Toolkit: Essential Research Reagents and Materials

This table details key materials and their functions as commonly used in the development and testing of nanostructured electrodes.

Table 3: Essential Research Reagents and Materials for Electrode Development

| Material/Reagent | Function in Research | Application Context |

|---|---|---|

| Activated Carbon (AC) | High-surface-area active material for Electric Double-Layer Capacitors (EDLCs) [3]. | Supercapacitor electrodes [3]. |

| Carbon Black (CB) | Conductive additive to improve electrical conductivity and rate capability in composite electrodes [3]. | Mixed with AC or metal oxides in battery and supercapacitor electrodes [3]. |

| Carbon Onions | Conductive additive; alternative to CB with different particle morphology and dispersibility [3]. | Supercapacitor electrodes (research context) [3]. |

| Polymeric Binders (e.g., PVDF) | Mechanically bind active carbon particles and conductive additives to form a cohesive film electrode [3]. | Standard electrode fabrication for batteries and supercapacitors [3]. |

| Organic Electrolytes (e.g., TEA-BFâ‚„ in ACN) | Provide ionic conductivity within the electrochemical cell; wider voltage window than aqueous electrolytes [3]. | Performance testing of supercapacitors [3]. |

| Precursor Solutions (Metal Salts) | Source of active materials (e.g., metal oxides) for electrode fabrication via infiltration [5]. | Synthesis of nanocomposite electrodes for solid oxide cells [5]. |

| Perovskite Oxides | Host structures for in situ exsolution of catalytic metal nanoparticles [5]. | High-temperature fuel cell and electrolysis cell electrodes [5]. |

| Gra EX-25 | Gra EX-25, MF:C29H36F3N3O5, MW:563.6 g/mol | Chemical Reagent |

| Ido-IN-13 | Ido-IN-13, MF:C26H17F3N4O, MW:458.4 g/mol | Chemical Reagent |

The performance of nanostructured electrode materials is decisively governed by the synergistic optimization of specific surface area, electrical conductivity, and structural stability. As evidenced by experimental data, no single material class holds a universal advantage across all metrics. 3D graphene foams and MXenes demonstrate exceptional conductivity and surface area, leading to high power densities, while intercalation-type oxides and carefully designed sodium-ion materials excel in cycling stability. The future of electrode material research lies in the rational design of composite architectures, such as pseudocapacitive materials decorated on conductive scaffolds, which leverage synergistic effects to overcome the limitations of individual components. This approach, guided by standardized experimental protocols and a deep understanding of property-performance relationships, paves the way for the next generation of high-performance, durable, and scalable energy storage devices.

In the rapidly evolving field of energy storage, the performance of nanostructured electrode materials is quantitatively assessed through three critical metrics: specific capacitance, which measures the charge storage capacity per unit mass; energy density, which determines the amount of energy stored per unit volume or mass; and sensitivity, which reflects the material's consistent performance under varying operational conditions. These metrics form the fundamental trilogy for evaluating and comparing advanced electrode materials, driving innovation in supercapacitor technology [6] [7]. As global demand for efficient energy storage systems intensifies, researchers are increasingly focusing on nanostructured materials that offer high surface area, tailored porosity, and enhanced electrochemical properties [8]. The accurate measurement and standardization of these parameters are paramount for developing next-generation energy storage devices that bridge the gap between conventional capacitors and batteries [9] [10].

The significance of these metrics extends beyond laboratory research to commercial applications, where they dictate the suitability of materials for specific uses such as electric vehicles, portable electronics, and grid storage [11] [12]. For instance, while batteries offer higher energy density for long-term storage, supercapacitors provide substantially higher power density and faster charge-discharge cycles [7] [10]. This comparative landscape underscores the importance of a standardized framework for evaluating electrode materials, enabling researchers to make meaningful comparisons between different material systems and accelerate the development of high-performance energy storage solutions [11].

Experimental Protocols for Metric Evaluation

Measurement Standards and Methodologies

The evaluation of specific capacitance, energy density, and sensitivity requires standardized experimental protocols to ensure reproducibility and reliable comparison across different material systems. For supercapacitor electrodes, the primary measurement techniques include cyclic voltammetry (CV), galvanostatic charge-discharge (GCD), and electrochemical impedance spectroscopy (EIS) [7]. Each technique provides distinct insights into the electrochemical behavior of electrode materials.

Cyclic voltammetry involves sweeping the potential between defined limits and measuring the resulting current. The specific capacitance (C(s)) from CV data is calculated using the formula: C(s) = (∫IdV) / (2×m×ν×ΔV) where ∫IdV is the integrated area of the CV curve, m is the mass of the active material, ν is the scan rate, and ΔV is the potential window [7]. The shape of the CV curve provides additional information: rectangular curves indicate ideal electric double-layer capacitor (EDLC) behavior, while redox peaks signify pseudocapacitive contributions [7].

Galvanostatic charge-discharge measurements apply a constant current and monitor potential changes over time. The specific capacitance is derived from the discharge curve using: C(_s) = (I × Δt) / (m × ΔV) where I is the discharge current, Δt is the discharge time, m is the active mass, and ΔV is the voltage window [7]. The linear discharge profile typically indicates EDLC behavior, while plateaus suggest pseudocapacitive or battery-type behavior [7].

Electrochemical impedance spectroscopy measures the frequency response of the electrode, providing information about charge transfer resistance, series resistance, and the capacitive behavior through Nyquist plots [10].

Critical Considerations for Accurate Measurements

Recent comparative studies highlight significant discrepancies in energy density values obtained through different measurement methods [11]. For instance, research on NaNbO(_3) systems reported a hysteresis-derived energy density of 14.1 J/cm(^3), while discharge current measurements yielded only 5.94 J/cm(^3) for the same material [11]. Such inconsistencies underscore the need for method-specific standardization in the field.

The hysteresis loop integration method (Method A) is widely regarded as a reliable benchmark for evaluating energy density in dielectric capacitors [11]. This method calculates energy density using: Energy = -∫Q({max})Q(0)UdQ W({rec}) = Energy/Vol where Q, U, W({rec}), and Vol represent charge, voltage, recoverable energy density, and capacitor volume, respectively [11].

In contrast, the discharge current method (Method B) tends to overestimate energy density due to unaccounted energy losses, while the equivalent capacitance method (Method C) often underestimates it because of nonlinear dielectric behavior [11]. The UI integration method (Method D) and resistive consumption method (Method E) generally provide consistent results with Method A but require precise time-resolved measurements [11].

For flexible supercapacitors, additional testing protocols assess mechanical stability under bending, folding, and stretching conditions, ensuring that performance metrics remain consistent across various deformations [12].

Comparative Performance of Nanostructured Electrode Materials

Quantitative Comparison of Material Classes

Table 1: Specific Capacitance and Energy Density of Different Electrode Material Classes

| Material Class | Specific Examples | Specific Capacitance (F/g) | Energy Density (Wh/kg) | Key Advantages |

|---|---|---|---|---|

| Carbon-Based EDLC | Activated Charcoal, CNTs, Graphene | 100-300 [7] | 4-10 [10] | High power density, Excellent cycling stability (>100,000 cycles) [7] |

| Metal Oxides | MnO(2), Fe(2)O(3), RuO(2) | 200-1000 [12] [10] | 7-41.8 [12] | Rich redox activity, High theoretical capacitance [10] |

| MXenes | Ti(3)C(2)T(_x) | 300-1500 [13] | 10-50 [13] | High electrical conductivity, Hydrophilic surfaces, Tunable chemistry [13] |

| Hybrid Composites | Metal Oxide/Graphene, MOF-derived | 500-2000 [8] | 20-100 [8] | Synergistic effects, Combined EDLC and pseudocapacitance [8] |

Table 2: Asymmetric vs. Symmetric Supercapacitor Configuration Performance

| Configuration | Electrode Materials | Voltage Window (V) | Specific Capacitance (F/g) | Energy Density (Wh/kg) | Cycling Stability (%) |

|---|---|---|---|---|---|

| Symmetric | MnO(2)//MnO(2) [12] | 0-1.0 | ~46 | ~20.9 | 83 (after 3,000 cycles) [12] |

| Asymmetric | MnO(2)//Fe(2)O(_3) [12] | 0-2.0 | 92 | 41.8 | 91 (after 3,000 cycles) [12] |

| Hybrid | MOF-derived composites [8] | 0-2.5-3.0 | 300-1200 | 50-100 | >90 (after 10,000 cycles) [8] |

Analysis of Performance Trends

The data reveals clear performance advantages for asymmetric configurations over symmetric designs, primarily due to their expanded voltage windows [12]. The MnO(2)//Fe(2)O(3) asymmetric system demonstrates approximately double the specific capacitance and energy density compared to its symmetric MnO(2)//MnO(_2) counterpart, while also exhibiting superior cycling stability [12]. This performance enhancement stems from the complementary operational potential windows of the two different electrode materials, allowing the full device to operate at a significantly higher voltage than either electrode could achieve individually [12].

Among material classes, MXenes and hybrid composites consistently outperform conventional carbon-based materials and single-component metal oxides [13] [8]. MXenes, such as Ti(3)C(2)T(x), benefit from high electrical conductivity (≈6.76 × 10(^5) S/m for single-layer Ti(3)C(2)T(x)), rich surface chemistry, and fast ion transport pathways [13]. Hybrid composites leverage synergistic effects between components, such as combining the high conductivity of carbon materials with the rich redox activity of metal oxides [8]. For instance, graphene-metal oxide composites demonstrate enhanced conductivity, structural integrity, and increased charge storage capacity due to the combination of EDLC and pseudocapacitive mechanisms [8].

The sensitivity of these materials—their ability to maintain performance under varying conditions—is influenced by structural stability, electrical conductivity, and ionic accessibility [8]. Materials with robust nanostructures that maintain integrity during repeated charge-discharge cycles demonstrate higher sensitivity metrics, as evidenced by their capacity retention over thousands of cycles [12].

Interrelationship of Critical Metrics

The diagram above illustrates the fundamental interrelationship between the three critical performance metrics and their connection to underlying material properties. Specific capacitance serves as the foundational parameter, directly dependent on material characteristics such as surface area, electrical conductivity, and redox activity [7] [10]. This relationship explains why nanostructured materials with high specific surface areas, such as MXenes and porous metal oxides, demonstrate superior specific capacitance compared to bulk materials [13] [8].

Energy density exhibits a quadratic relationship with operating voltage (E=½CV²), making voltage window expansion the most effective strategy for enhancing this parameter [12]. This explains the significant performance advantage of asymmetric configurations, which leverage complementary electrode materials to achieve wider operational voltage windows than symmetric designs [12]. The mathematical relationship also highlights why modest increases in operating voltage can dramatically improve energy density, making electrolyte development and asymmetric device engineering crucial research directions [12] [10].

Sensitivity encompasses the material's ability to maintain performance across varying conditions, including cycling stability, rate capability, and mechanical flexibility [8] [12]. This metric is strongly influenced by structural stability and conductivity, with composite materials often demonstrating enhanced sensitivity due to synergistic effects between components [8]. For instance, the incorporation of graphene into metal oxide composites significantly improves structural integrity and cycling stability while maintaining high capacitance [8].

Research Reagent Solutions for Energy Storage Studies

Table 3: Essential Research Reagents and Materials for Electrode Evaluation

| Category | Specific Examples | Function/Application | Performance Relevance |

|---|---|---|---|

| Electrode Materials | MXenes (Ti(3)C(2)T(x)) [13], Metal Oxides (MnO(2), RuO(2), Fe(2)O(_3)) [12] [10], Carbon Allotropes (Graphene, CNTs) [7] | Active charge storage components | Determine specific capacitance through surface area and redox activity |

| Synthesis Reagents | HF, LiF/HCl, NH(_4)F [13], Hydrazine Monohydrate [13] | Etching and delamination of MXenes from MAX phases | Influence material morphology, surface chemistry, and conductivity |

| Electrolytes | Aqueous (K(2)SO(4), Na(2)SO(4)) [12], Organic, Ionic Liquids [10] | Ion transport medium between electrodes | Determine voltage window, conductivity, and overall energy density |

| Binders & Additives | Carboxymethyl Cellulose (CMC) [12], PVDF, Carbon Black | Structural integrity and conductivity enhancement | Affect electrode stability, internal resistance, and cycling performance |

| Substrates | Flexible Stainless Steel [12], Carbon Fabric, Foams | Current collection and mechanical support | Enable flexible devices, influence mass loading and power characteristics |

The selection of appropriate research reagents is critical for accurate performance evaluation of nanostructured electrode materials. MXene synthesis typically requires selective etching agents such as hydrofluoric acid (HF) or mixtures of lithium fluoride and hydrochloric acid (LiF/HCl) to remove aluminum layers from MAX phase precursors like Ti(3)AlC(2) [13]. Less corrosive alternatives include bifluorides (KHF(2), NH(4)HF(2)) or hydrothermal routes using NH(4)F, which gradually hydrolyzes to generate HF in situ [13]. Subsequent delamination often employs intercalants like hydrazine monohydrate to separate multilayer MXenes into individual flakes [13].

For metal oxide electrodes, synthesis methods include electrodeposition, successive ionic layer adsorption and reaction (SILAR), hydrothermal treatment, and sol-gel processes [12]. These methods allow precise control over nanostructure morphology, which significantly influences electrochemical performance. For example, MnO(2) electrodes with nanosheet morphology and Fe(2)O(_3) electrodes with nanoparticle structures demonstrate optimized electrochemical performance due to their porous architectures that foster ion transport and diffusion [12].

Electrolyte selection represents another critical consideration, with aqueous electrolytes offering higher conductivity and safety, while organic and ionic liquid electrolytes enable wider voltage windows and consequently higher energy densities [12] [10]. Recent research has also explored gel polymer electrolytes such as Na(2)SO(4)/carboxymethyl cellulose (CMC) for flexible solid-state supercapacitors, providing both ionic conductivity and mechanical separation [12].

The critical evaluation of specific capacitance, energy density, and sensitivity provides a comprehensive framework for assessing nanostructured electrode materials for advanced energy storage applications. The comparative analysis presented in this guide demonstrates that hybrid composite materials in asymmetric configurations currently deliver the most favorable balance of these performance metrics, leveraging synergistic effects between components to overcome the limitations of individual material systems [8] [12].

Future research directions should address several key challenges identified in this analysis. First, standardization of measurement methodologies is urgently needed to resolve discrepancies between different evaluation techniques and enable reliable comparison of material performance [11]. Second, scalable synthesis approaches must be developed to transition laboratory-scale achievements to commercially viable production while maintaining performance characteristics [13] [8]. Third, continued innovation in nanostructure engineering will further enhance specific capacitance by optimizing surface area, porosity, and redox activity while maintaining high conductivity and structural stability [8] [10].

The integration of computational modeling with experimental research presents a promising pathway for accelerating materials discovery and optimization [13]. Similarly, the development of in situ and operando characterization techniques will provide deeper insights into charge storage mechanisms and degradation processes, enabling rational design of more durable and efficient electrode materials [11] [8]. As these advancements mature, the performance metrics outlined in this guide will continue to serve as the fundamental criteria for evaluating progress toward next-generation energy storage technologies that meet the demanding requirements of emerging applications from portable electronics to grid-scale storage.

The relentless pursuit of advanced energy storage solutions has propelled the development of various nanostructured materials, each offering unique physicochemical properties that cater to specific electrochemical requirements. Electrode materials serve as the fundamental building blocks of energy storage devices, directly governing key performance metrics including specific capacitance, energy and power density, cycling stability, and rate capability. Within this landscape, carbon nanotubes (CNTs), graphene, metal-organic frameworks (MOFs), MXenes, and metal oxides have emerged as frontrunning material classes, each exhibiting distinct charge storage mechanisms and architectural advantages.

The performance evaluation of these materials extends beyond intrinsic properties to encompass their synergistic behavior in composite structures, where interfacial interactions and hierarchical design unlock enhanced functionality. This comparative guide objectively analyzes these material classes based on empirical data, synthesizing experimental findings to provide researchers with a rigorous foundation for material selection and innovation. By examining synthesis protocols, electrochemical performance metrics, and application-specific suitability, this review establishes a structured framework for the ongoing optimization of nanostructured electrodes in energy storage research.

Material Class Fundamentals and Charge Storage Mechanisms

Individual Material Characteristics

Each material class exhibits inherent characteristics derived from its atomic structure and chemical composition, which directly influence its electrochemical behavior and suitability for specific energy storage applications.

Carbon Nanotubes (CNTs) are characterized by their tubular nanostructure with sp² orbital hybridization, endowing them with high specific surface area, exceptional mechanical elasticity, and superior electrical conductivity. However, structural defects inherent in CNTs can decelerate electron migration rates, impairing their electrochemical performance [14]. Graphene consists of a single layer of carbon atoms arranged in a hexagonal lattice, offering exceptional electrical conductivity (6000 S·cmâ»Â¹) and theoretical surface area (2675 m²·gâ»Â¹). Its derivatives, graphene oxide (GO) and reduced graphene oxide (rGO), feature oxygen-containing functional groups that enable facile functionalization and composite formation, though often at the expense of reduced conductivity [15].

Metal-Organic Frameworks (MOFs) are crystalline porous materials formed through coordination bonds between metal ions/clusters and organic linkers, exhibiting exceptional specific surface area, tunable pore size distributions, and programmable porosity. However, most pristine MOFs suffer from limited electrical conductivity, restricting their direct application in energy storage devices [16] [17]. MXenes, a family of two-dimensional transition metal carbides, nitrides, and carbonitrides with general formula Mnâ‚Šâ‚XnTâ‚“, possess metallic conductivity, tunable surface chemistry, and abundant functional groups (-O, -OH, -F). These properties facilitate rapid ion transport and efficient charge storage, though MXenes are prone to oxidation in aqueous environments [16] [18]. Metal Oxides, particularly transition metal oxides, exhibit redox activity that enables pseudocapacitive charge storage through Faradaic reactions. They offer abundant active sites, exceptional mechanical strength, and robust chemical stability, though their electrical conductivity is typically lower than carbonaceous materials [8].

Charge Storage Mechanisms

The fundamental charge storage mechanisms vary significantly across material classes, dictating their performance in different electrochemical configurations:

- Electrical Double-Layer Capacitance (EDLC): CNTs, graphene, and MXenes primarily store charge electrostatically at the electrode-electrolyte interface through non-Faradaic processes, resulting in high power density and exceptional cycling stability [15] [17].

- Pseudocapacitance: Metal oxides and some functionalized MXenes/store charge through reversible surface or near-surface Faradaic redox reactions, leading to higher specific capacitance but often reduced cycling stability due to structural changes during redox processes [8] [15].

- Hybrid Behavior: Many advanced composites combine EDLC and pseudocapacitive mechanisms to achieve synergistic performance enhancements, balancing high energy and power density [17].

Table 1: Fundamental Properties and Charge Storage Mechanisms

| Material Class | Primary Charge Storage Mechanism | Theoretical Specific Surface Area (m²/g) | Electrical Conductivity | Key Advantages |

|---|---|---|---|---|

| CNTs | EDLC | 500-1300 [14] | High (∼10³-10ⵠS/m) | High mechanical strength, aligned ion channels |

| Graphene/rGO | EDLC | 2675 (theoretical) [15] | Very high (pristine graphene: 6000 S/cm) [15] | Excellent conductivity, tunable functionality |

| MOFs | Varies (often limited) | Up to 10,000 [17] | Very low (10â»â¸-10â»â¶ S/m) [17] | Ultrahigh porosity, tunable pore architectures |

| MXenes | EDLC/Pseudocapacitive | Varies by composition | High (∼10³ S/cm) [16] | Hydrophilicity, tunable surface chemistry |

| Metal Oxides | Pseudocapacitive | Varies significantly | Typically low to moderate | Multiple oxidation states, rich redox chemistry |

Comparative Performance Analysis

Electrochemical Performance Metrics

Direct comparison of electrochemical performance across material classes reveals distinct strengths and limitations, particularly when evaluated in composite configurations that mitigate individual weaknesses.

Specific Capacitance values vary significantly across material classes, with metal oxides often demonstrating superior values due to Faradaic processes, while carbonaceous materials provide exceptional rate capability and cycling stability. For instance, transition metal oxides like (NiMn)Coâ‚‚Oâ‚„ when composited with CNTs and N-doped graphene quantum dots achieve specific capacitances of 2172 F·gâ»Â¹ at 1 A·gâ»Â¹ [14]. MXene-based electrodes in organic electrolytes demonstrate capacitances up to 130 F·gâ»Â¹ (276 F·cmâ»Â³) with exceptional retention over wide scan rates [19].

Energy and Power Density represent critical metrics for practical applications. MXene-knotted CNT composite electrodes achieve an energy density of 59 Wh·kgâ»Â¹ with a power density of 9.6 kW·kgâ»Â¹ at -30°C, representing some of the highest reported values for 2D materials at low temperatures [19]. Asymmetric supercapacitors incorporating ZIF-67 derived electrodes reach 42.3 Wh·kgâ»Â¹ at 476 W·kgâ»Â¹ [20], while CNT/P-(NiMn)Coâ‚‚Oâ‚„@NGQD composites paired with activated carbon achieve 94.4 Wh·kgâ»Â¹ at 800 W·kgâ»Â¹ [14].

Cycling Stability remains a particular strength of carbon-based materials, with MXene-CNT composites demonstrating no capacitance loss after 10,000 cycles in organic electrolytes [19]. The CNT/P-(NiMn)Coâ‚‚Oâ‚„@NGQD composite maintains 86.41% of its initial specific capacitance with coulombic efficiency of 97.92% after 10,000 charge-discharge cycles [14].

Table 2: Experimental Electrochemical Performance Comparison

| Material System | Specific Capacitance | Energy Density | Power Density | Cycling Stability | Test Conditions |

|---|---|---|---|---|---|

| CNT/P-(NiMn)Coâ‚‚Oâ‚„@NGQD [14] | 2172 F·gâ»Â¹ @ 1 A·gâ»Â¹ | 94.4 Wh·kgâ»Â¹ | 800 W·kgâ»Â¹ | 86.41% retention after 10,000 cycles | 3-electrode system, 6 M KOH |

| MXene-knotted CNT [19] | 130 F·gâ»Â¹ @ 10 mV·sâ»Â¹ | 59 Wh·kgâ»Â¹ | 9.6 kW·kgâ»Â¹ | No loss after 10,000 cycles | Organic electrolyte, -30°C |

| ZIF-67 Derived Electrode [20] | Not specified | 42.3 Wh·kgâ»Â¹ | 476 W·kgâ»Â¹ | Not specified | Asymmetric supercapacitor |

| rGO/Metal Oxide Composites [15] | Varies widely (200-1200 F·gâ»Â¹) | Moderate-high | High | Generally >80% after 5000 cycles | Varies by specific composition |

Composite Material Synergies

The integration of multiple material classes creates synergistic effects that address individual limitations while amplifying strengths. These interactions occur through several mechanisms:

Conductive Scaffolding: MXenes and graphene provide high-conductivity networks that enhance charge transport in metal oxide and MOF-based composites. For instance, MXene's 2D layers form interconnected conductive pathways that improve electron transfer to MOF-derived active materials [16]. Morphological Control: CNTs with knot-like structures prevent restacking of MXene flakes, creating 3D electrolyte-accessible architectures that maximize ion accessibility and reduce tortuosity in ion transport pathways [19]. Interfacial Polarization: In hybrids like Ti₃C₂Tₓ MXene@CoFe-MOF, heterogeneous interfaces between components stimulate polarization relaxation effects that enhance charge storage capabilities [21]. Stability Enhancement: MOF derivatives obtained through controlled pyrolysis inherit porous frameworks while achieving significantly enhanced electrical conductivity and structural stability via carbon-based matrix formation [16].

Experimental Methodologies and Synthesis Protocols

Material Synthesis and Fabrication Techniques

Reproducible synthesis of nanostructured electrode materials requires precise control over reaction parameters, with techniques tailored to specific material classes and desired morphologies.

Hydrothermal/Solvothermal Synthesis represents a widely employed approach for metal oxides, MOFs, and their composites. A typical protocol for CNT/(NiMn)Co₂O₄ composite involves dissolving Ni(NO₃)₂·6H₂O (0.0625 mmol), Co(NO₃)₂·6H₂O (0.26 mmol), Mn(NO₃)₂·4H₂O (0.14 mmol), and CNTs in deionized water with stirring, then transferring to a Teflon-lined autoclave and maintaining at 120°C for 6 hours. The resulting precursor is collected, washed, and annealed at 350°C for 2 hours [14].

In Situ Growth Strategy for MXene/MOF composites involves adding MXene to a solution containing dissolved metal ions and organic ligands, allowing spontaneous nucleation and growth of MOFs on MXene surfaces. For ZIF-67@MXene aerogel, Co(NO₃)₂·6H₂O and 2-methylimidazole are introduced into aqueous MXene dispersion, forming a hydrogel through coordination-driven self-assembly, followed by freeze-drying and thermal treatment at 600°C for 2 hours under argon atmosphere [16].

Electrochemical Synthesis of MOFs offers advantages including precise control over reaction parameters, mild operating conditions (typically room temperature and atmospheric pressure), and direct deposition onto conductive substrates. This method eliminates the need for harsh chemicals and facilitates faster synthesis compared to traditional approaches, though it requires careful optimization to ensure uniform MOF formation [22].

Mechanical Milling employs mechanical forces to reduce bulk materials to nanoscale particles. In a typical process, bulk materials are placed in a milling vessel with milling media (e.g., stainless steel balls or ceramic beads) and rotated to induce collisions that gradually breakdown the material. Factors such as milling time, speed, and media choice must be optimized to achieve desired particle size distributions while avoiding contamination or unintended structural changes [8].

Electrode Fabrication and Device Assembly

Standardized electrode preparation ensures consistent performance evaluation across material systems. A common approach involves mixing active materials with conductive additives (e.g., carbon black) and binders (e.g., PVDF) in a mass ratio of 80:10:10 in an appropriate solvent (e.g., NMP) to form a homogeneous slurry. This slurry is then coated onto current collectors (typically nickel foam or carbon paper) and dried under vacuum at elevated temperatures (e.g., 80-120°C) for 12-24 hours [14].

For freestanding electrodes, alternative fabrication techniques including vacuum-assisted filtration, electrospinning, and 3D printing eliminate the need for binders and conductive additives, reducing inactive material mass and enhancing electrochemical performance. These approaches are particularly advantageous for MXene and graphene-based electrodes, leveraging their inherent conductivity and mechanical properties [20].

Three-electrode configurations using platinum counter electrodes and standard reference electrodes (e.g., Ag/AgCl, Hg/HgO) enable rapid material screening, while two-electrode symmetric or asymmetric devices provide performance data relevant to practical applications. Electrolyte selection (aqueous, organic, or ionic liquid) significantly influences operating voltage window and overall energy density, with organic electrolytes extending voltage windows to 3-4V despite lower conductivity compared to aqueous systems [19] [15].

Research Reagent Solutions and Essential Materials

Table 3: Key Research Reagents and Their Functions in Nanostructured Electrode Research

| Reagent/Material | Function | Application Examples | Key Considerations |

|---|---|---|---|

| Metal Precursors (e.g., Ni(NO₃)₂·6H₂O, Co(NO₃)₂·6H₂O) [14] | Provide metal ions for MOF formation, metal oxides, or composite synthesis | Hydrothermal synthesis of metal oxides, MOF construction | Purity affects crystallinity; concentration controls nucleation rate |

| Organic Linkers (e.g., 2-methylimidazole, 1,3,5-benzenetricarboxylic acid) [16] [22] | Coordinate with metal ions to form MOF structures | ZIF-8, ZIF-67, and various MOF syntheses | Determines pore size and functionality; affects stability |

| MXene Precursors (e.g., Ti₃AlC₂ MAX phase) [16] | Source for MXene synthesis through selective etching | Production of Ti₃C₂Tₓ MXene | Etching conditions (e.g., HF, LiF+HCl) control surface terminations |

| Carbon Nanotubes [14] | Conductive additive, structural spacer, active material | Composite electrodes, conductive networks | Diameter, length, and functionalization affect dispersion and interaction |

| Graphene Oxide/RGO [15] | 2D conductive scaffold, active material | Composite formation with metal oxides, polymer hybrids | Degree of oxidation/reduction impacts conductivity and functionality |

| Structure-Directing Agents (e.g., CTAB, PVP) [8] | Control morphology and particle size during synthesis | Shape-controlled nanoparticle synthesis | Concentration and type influence crystal growth kinetics |

| Dopant Precursors (e.g., melamine, ammonium dihydrogen phosphate) [14] | Introduce heteroatoms (N, P, S) to modify electronic properties | Enhancing conductivity of carbon materials | Dopant type and concentration tailor electronic structure |

Material Synergy in Energy Storage Composites

The comparative analysis of carbon nanotubes, graphene, MOFs, MXenes, and metal oxides reveals a complex performance landscape where each material class offers distinct advantages while facing particular challenges. Carbonaceous materials (CNTs, graphene) provide exceptional electrical conductivity and cycling stability, while MXenes combine metallic conductivity with tunable surface chemistry. MOFs offer unparalleled porosity and structural tunability, and metal oxides deliver high theoretical capacitance through Faradaic processes.

Future research directions should focus on optimizing composite architectures that leverage synergistic effects between material classes, with particular emphasis on interfacial engineering, morphology control, and scalability of synthesis approaches. The development of standardized testing protocols will enable more rigorous comparative analyses across material systems. Additionally, advancing our understanding of charge storage mechanisms at nanoscale interfaces, particularly in hybrid systems, will inform the rational design of next-generation electrode materials with enhanced performance characteristics for specific application requirements.

As the field progresses, considerations of sustainability, cost-effectiveness, and environmental impact will become increasingly important in materials selection and synthesis route development. The integration of computational screening with experimental validation presents a promising pathway for accelerated discovery and optimization of novel nanostructured electrode materials tailored to the evolving demands of energy storage technologies.

The Impact of Nanostructuring on Ion Diffusion Pathways and Electron Transfer Kinetics

The performance of electrochemical energy storage systems, such as batteries and supercapacitors, is fundamentally governed by the efficiency of two coupled processes: ion diffusion within the electrode and electron transfer at the electrode-electrolyte interface. Nanostructuring of electrode materials has emerged as a powerful strategy to enhance both these processes by fundamentally altering the material's physical and electronic properties. This guide provides a comparative analysis of how different nanostructuring approaches impact ion transport dynamics and electron transfer kinetics, framing the discussion within the broader context of performance evaluation for next-generation energy storage materials. We synthesize experimental data and mechanistic insights to offer researchers a foundation for rational electrode design.

Nanostructuring Approaches and Their Fundamental Mechanisms

Nanostructuring modifies electrode materials primarily by increasing the specific surface area, reducing the solid-state ion diffusion distances, and creating a higher density of electrochemically active sites. The dimensionality and spatial arrangement of the nanostructures play a critical role in determining the efficiency of charge transport.

- One-Dimensional (1D) Nanostructures: Materials like nanowires and nanotubes facilitate fast electron transport along their longitudinal axis while shortening the radial ion diffusion pathways. This architecture helps in accommodating volume changes during charge-discharge cycles, improving cycling stability [23].

- Two-Dimensional (2D) Nanomaterials: Graphene-family nanomaterials (GFNs) and MXenes offer exceptionally high surface areas and unique electronic properties. Their basal planes and edge sites can be engineered with defects and dopants to dramatically enhance electron transfer kinetics [24].

- Three-Dimensional (3D) Porous Networks: Interconnected nano-porous structures, such as carbon nano-skyscrapers and aerogels, provide a continuous pathway for electrons while decoupling and optimizing ion transport routes. The uniform distribution of pores is key to minimizing ion transport resistance [25].

The working principle of these materials in a device like a lithium-ion battery involves lithium ions shuttling between the cathode and anode. During charging, lithium ions are extracted from the cathode, diffuse through the electrolyte, and are inserted into the anode, with a corresponding flow of electrons through the external circuit. The reverse occurs during discharge. Nanostructuring directly optimizes the kinetics of these ion and electron transfer processes [26].

Comparative Performance of Nanostructured Electrodes

The following tables summarize the electrochemical performance of various nanostructured electrodes, highlighting the direct impact of their design on key metrics such as capacitance, energy density, and rate capability.

Table 1: Performance Comparison of Composite Nanostructured Electrodes

| Material System | Specific Capacitance | Energy Density | Power Density | Cycle Life / Retention | Key Nanostructuring Feature |

|---|---|---|---|---|---|

| NiWOâ‚„/MXene [27] | 1545.42 F gâ»Â¹ @ 1.5 A gâ»Â¹ | 107.32 Wh kgâ»Â¹ | 199.9 W kgâ»Â¹ | 95.80% after 2000 cycles | Hydrothermally synthesized composite; enhanced cation mobility. |

| Nitrogen-Doped Graphene [28] | N/A | N/A | N/A | N/A | Doped sheets for flow batteries; estimated 30x lower manufacturing cost than Li-ion. |

| Laser-Induced Graphene [24] | N/A | N/A | N/A | N/A | 3D porous network; Stone–Wales defects; high electrical conductivity. |

Table 2: Ion Transport Dynamics in 3D Carbon Nano-Architectures [25]

| Electrode Variant | Specific Capacitance @ 100 mV sâ»Â¹ | Specific Capacitance @ 10,000 mV sâ»Â¹ | Capacitance Retention | Key Structural Insight |

|---|---|---|---|---|

| C-AAO-0 (No transverse pores) | Baseline (100%) | 1.87 mF cmâ»Â² | 42.6% | Baseline with straight nanopores only. |

| C-AAO-150 (Dense transverse pores) | 95.4% of baseline | 2.32 mF cmâ»Â² | 54.2% | Uniform transversal pores act as "overpasses" for rapid ion transport, prioritizing minimal-time paths. |

The data in Table 2 demonstrates a critical principle: at low scan rates, performance is dominated by total surface area, which is slightly reduced by introducing transversal pores. However, at ultra-high scan rates, where ion dynamics become the bottleneck, the architecture with the highest density of interconnected pores (C-AAO-150) significantly outperforms the others. This confirms that a uniformly distributed porous network mitigates ion concentration gradients and reduces transport resistance, enabling faster charging [25].

Experimental Protocols for Key Studies

To ensure reproducibility and provide a clear framework for performance evaluation, this section outlines the detailed methodologies from several key studies cited in this guide.

- Synthesis of MXene: Ti₃AlC₂ MAX powder (0.1 g) and KOH (0.35 g) were ground for 2 hours with dropwise addition of DI water to form a paste. The paste was subjected to hydrothermal treatment in a Teflon-lined autoclave at 180°C for 24 hours. The resulting product was washed with DI water and ethanol until neutral pH, then dried at 60°C for 12 hours.

- Synthesis of NiWO₄: Solutions of Ni(NO₃)₂·6H₂O and Na₂WO₄·2H₂O were dissolved in 60 mL DI water and stirred for 50 minutes. The pH was adjusted to 10 using KOH solution. The mixture was transferred to an autoclave and heated at 160°C for 4 hours. The precipitate was collected, washed, dried, and finally annealed at 450°C for 4 hours.

- Preparation of Composite: NiWOâ‚„ and MXene were combined in a 75:25 weight ratio, dispersed in DI water, and stirred for 50 minutes to form the homogeneous NiWOâ‚„/MXene composite.

- Electrochemical Testing: The electrochemical performance was evaluated using cyclic voltammetry (CV) and galvanostatic charge-discharge (GCD) in a standard three-electrode setup with a potassium hydroxide (KOH) electrolyte.

- Electrode Fabrication: Various GFNs, including pristine graphene, chemically/electrochemically reduced graphene oxide (rGO), and laser-induced graphene (LIG), were prepared as working electrodes.

- Kinetics Measurement: Scanning Electrochemical Microscopy (SECM) operating in feedback mode was used to quantify the standard electron transfer rate constant ((k^0)). A solution containing outer-sphere redox probes, such as potassium hexacyanoferrate (III/IV) or ferrocene methanol, was used.

- Correlative Characterization: The electrochemical activity was co-located with spectroscopic techniques to correlate the measured (k^0) with surface properties.

- Theoretical Modeling: Density Functional Theory (DFT) calculations were performed to parameterize the influence of defects and dopants on the electronic structure (density of states near the Fermi level) and quantum capacitance.

- Template Fabrication: A pulse anodization technique was used to create a 3D anodic aluminum oxide (AAO) template with controlled density and spatial arrangement of transversal nanopores. Variants like C-AAO-0, C-AAO-515, C-AAO-225, and C-AAO-150 were synthesized with varying transverse pore spacings.

- Carbon Coating: Chemical Vapor Deposition (CVD) was used to coat the 3D AAO template with a conformal carbon layer, creating a robust 3D C-AAO electrode.

- Structural Analysis: Cross-sectional SEM and TEM imaging were used to confirm uniform pore distribution and structural integrity. ImageJ software was used for quantitative nanopore size distribution analysis.

- Electrochemical Analysis: Cyclic voltammetry (CV) at scan rates from 100 mV sâ»Â¹ to 10,000 mV sâ»Â¹ was performed in both aqueous and ionic liquid electrolytes to evaluate capacitance and capacitance retention, directly probing ion dynamics.

Visualization of Ion Transport and Electron Transfer Mechanisms

Ion Transport Optimization in 3D Nano-Architectures

The following diagram illustrates how transversal nanopores in a 3D electrode create efficient ion transport pathways, minimizing time resistance even over longer spatial distances.

Electron Transfer Enhancement at Nanomaterial Surfaces

This diagram summarizes the key factors that govern electron transfer kinetics at the interface of graphene-family nanomaterials, as revealed by combined experimental and theoretical studies.

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Key Reagents and Materials for Nanostructured Electrode Research

| Item | Function in Research | Example Application / Rationale |

|---|---|---|

| Transition Metal Precursors (e.g., Ni(NO₃)₂·6H₂O) | Active material source for pseudocapacitive or battery-type electrodes. | Provides Ni²⺠ions for synthesis of NiWO₄, which undergoes Faradaic redox reactions [27]. |

| MXenes (e.g., Ti₃AlC₂) | Conductive 2D support material with high surface area and functionalizable surface. | Enhances electron transport in composites; contributes to double-layer capacitance [27]. |

| Polyimide Film | Precursor for direct-laser writing of 3D graphene electrodes. | Used to fabricate Laser-Induced Graphene (LIG) via photothermal conversion [24]. |

| Anodic Aluminum Oxide (AAO) | Templating material for creating highly ordered, tunable nanoporous structures. | Serves as a scaffold for synthesizing 3D carbon nano-skyscraper electrodes with defined pore geometries [25]. |

| Potassium Hydroxide (KOH) | Common aqueous electrolyte for alkaline energy storage systems. | Used in electrochemical testing of NiWOâ‚„/MXene and other electrodes to provide high ionic conductivity [27]. |

| Redox Probes (e.g., [Fe(CN)₆]³â»/â´â», Fcâº/â°) | Well-characterized molecules for quantifying electron transfer kinetics. | Used in SECM studies to measure standard rate constant ((k^0)) on GFN surfaces without specific adsorption [24]. |

| Nitrogen Dopant | Modifies the electronic structure of carbon nanomaterials. | Incorporated into graphene to improve its charge carrier density and electrocatalytic activity [24] [28]. |

| GSK2801 | GSK2801, MF:C20H21NO4S, MW:371.5 g/mol | Chemical Reagent |

| Lp-PLA2-IN-1 | Lp-PLA2-IN-1, MF:C21H17F5N4O3, MW:468.4 g/mol | Chemical Reagent |

The systematic comparison presented in this guide unequivocally demonstrates that nanostructuring is a critical lever for enhancing the performance of electrochemical electrodes. The design of the nanostructure—whether 1D, 2D, or 3D—directly controls ion diffusion pathways and electron transfer kinetics, which in turn dictate the device's power density, energy density, and cycling stability. Key findings indicate that uniformly distributed porous networks optimize ion transport by providing minimal-time pathways, while the introduction of defects and dopants in carbon nanomaterials tailors their electronic structure for faster electron transfer. For researchers, the future direction lies in the precise, atomic-level control of these nanostructures and a deeper, multi-scale understanding of the coupled ion-electron transport phenomena to unlock further gains in electrochemical energy storage.

Synthesis and Implementation: Advanced Fabrication Techniques and Application-Specific Performance

This guide provides an objective comparison of four advanced synthesis routes—electrospinning, anodization, sol-gel, and chemical vapor deposition (CVD)—for fabricating nanostructured electrode materials. The performance evaluation is contextualized within energy storage and conversion applications, supported by experimental data and detailed methodologies to aid researchers in selecting and optimizing synthesis protocols.

The development of nanostructured electrode materials is a cornerstone of emerging electrochemical technologies, providing clean and sustainable solutions to address global energy demand and environmental pollution. The unique features of these materials, arising from the ability to tailor their structural and functional properties at the nanoscale, are key to optimizing the performance, durability, and efficiency of energy storage devices like lithium-ion batteries (LIBs), fuel cells, and supercapacitors [29]. Synthesis routes that enable precise control over morphology, composition, and architecture are critical. Electrospinning produces nanofibers with high surface areas, anodization creates highly ordered oxide nanotube arrays, sol-gel allows for versatile chemical synthesis of thin films and powders, and chemical vapor deposition enables high-purity, conformal coatings. Understanding the capabilities, experimental parameters, and performance outcomes of each method is essential for advancing nanostructured electrode research.

Synthesis Route Comparison

The following sections detail each synthesis method, its underlying principles, and its application in producing electrode materials. A comparative summary of their characteristics is provided in Table 1.

Table 1: Comparison of Advanced Synthesis Routes for Nanostructured Electrodes

| Synthesis Route | Typical Morphologies | Key Control Parameters | Common Electrode Materials | Typical Applications in Energy Storage |

|---|---|---|---|---|

| Electrospinning [30] [31] | Nanofibers (solid, core-shell, hollow), porous mats | Applied voltage, solution flow rate & viscosity, spinneret-collector distance [31] [32] | LiCoO₂, LiFePO₄, Si/C, CNFs, Metal Oxides (e.g., TiO₂, Co₃O₄) [30] [31] | LIB cathodes & anodes, supercapacitors, fuel cells [30] [31] |

| Anodization | Nanotube arrays, porous layers | Applied voltage/current, electrolyte composition & temperature, anodization time [33] | TiO₂, Al₂O₃, Ni nanowire arrays [33] | Photoanodes, catalyst supports, templates for nanostructures [33] |

| Sol-Gel [34] | Thin films, powders, monoliths | pH, temperature, water/alkoxide ratio, precursor type & concentration [34] | SiOâ‚‚, TiOâ‚‚, mixed metal oxides (e.g., NiCo-, NiFe-oxides) [34] [29] | Catalyst coatings (e.g., for OER), protective layers, composite electrodes [34] [29] |

| Chemical Vapor Deposition (CVD) [35] [33] | Conformal thin films, 2D materials, nanowires | Precursor vapor pressure, substrate temperature, chamber pressure, carrier gas flow [35] [33] | Graphene, carbon nanotubes, polymeric carbon nitride (PCN) films [35] [33] [29] | Conductive coatings, active catalyst layers, separator modification [35] [33] |

Electrospinning

1. Principle and Process: Electrospinning is a versatile, low-cost technique for producing continuous polymer or composite nanofibers with diameters ranging from tens of nanometers to several micrometers [31] [32]. A basic setup consists of a high-voltage power supply, a syringe with a metallic needle (spinneret), and a grounded conductive collector [30]. The process begins when a high voltage electrostatic field charges the surface of a polymer solution droplet at the needle tip, forming a Taylor cone. Once the electrostatic force overcomes the solution's surface tension, a liquid jet is ejected and accelerated toward the collector. The jet undergoes stretching and whipping, during which the solvent evaporates, depositing solid nanofibers on the collector [31]. The morphology and diameter of the fibers are highly dependent on parameters such as applied voltage, solution flow rate, spinning distance, polymer molecular weight, and solution properties like viscosity and conductivity [30] [32].

2. Experimental Protocol for a Li-Ion Battery Anode (Si/C Composite):

- Precursor Solution Preparation: A typical solution might involve dispersing silicon nanoparticles and a carbon precursor (e.g., polyacrylonitrile (PAN)) in a suitable solvent like DMF [36].

- Electrospinning Parameters: The solution is loaded into a syringe. A voltage of 27.5 kV [37] and a spinneret-to-collector distance of 12 cm [37] can be used, with the solution feed rate controlled by a syringe pump (e.g., between 0.3 and 1 ml/h) [37].

- Post-processing: The collected fibrous mat is first stabilized in air at a moderate temperature (e.g., 280°C) and then carbonized at high temperature (e.g., 750°C) in an inert atmosphere (Ar or N₂) to convert the polymer into amorphous carbon, forming a Si/C composite nanofiber network [30] [29].

3. Key Advantages for Electrodes: Electrospun nanofibers exhibit high specific surface areas and high porosities, which are significant for decreasing the length of Li+ diffusion pathways in batteries, providing more active sites for reactions, and facilitating electrolyte penetration [30] [31]. This structure is beneficial for improving rate capability and kinetic properties.

Anodization

1. Principle and Process: Anodization is an electrochemical method for growing oxide layers on valve metals (e.g., Al, Ti, Zr). It involves making the metal the anode in an electrochemical cell. Under an applied voltage in a suitable electrolyte, the metal oxidizes, and the interplay between oxide growth and dissolution leads to the self-organized formation of highly ordered nanoporous or nanotubular structures. For instance, anodized aluminum oxide (AAO) is widely used as a template for synthesizing other nanostructures like nanowires [33].

2. Experimental Protocol for Ni Nanowire Array Electrode:

- Template Preparation: A two-step anodization process is often used to create a highly ordered porous AAO template on a substrate [33].

- Electrodeposition: The porous AAO template is then used as a nanochannel scaffold. A potentiostatic electrodeposition technique is employed to electrodeposit Ni into the nanochannels, forming Ni nanowire arrays [33] [29].

- Template Removal: The AAO template can be selectively dissolved using a chemical etchant, leaving behind a free-standing array of Ni nanowires [33].

3. Key Advantages for Electrodes: This method produces electrodes with an extremely large surface area and a highly ordered, one-dimensional structure. The Ni nanowire array electrodes fabricated this way showed a textured structure and exhibited a lower overpotential and higher current density towards the hydrogen evolution reaction (HER) compared to electrodeposited Ni films [29].

Sol-Gel

1. Principle and Process: The sol-gel process is a wet-chemical technique for producing ceramic and glass materials in various forms, including thin films, powders, and monoliths [34]. It involves the transition of a system from a liquid "sol" (a colloidal suspension of solid particles in a liquid) into a solid "gel" phase. This transition is achieved through hydrolysis and polycondensation reactions of metal alkoxide or inorganic salt precursors (e.g., Si(OCâ‚‚Hâ‚…)â‚„ for silica) [34]. The process is influenced by parameters such as pH, temperature, water-to-precursor ratio, and the nature of the catalyst [34].

2. Experimental Protocol for a Bimetallic Oxide Electrocatalyst Film:

- Sol Preparation: Dissolve metal precursors (e.g., nitrates of Ni and Co or Fe) in water or alcohol. A complexing agent (e.g., citric acid) is often added to control hydrolysis and form a homogeneous sol [29].

- Coating: The sol can be deposited on a substrate (e.g., Ni foam) using dip-coating, spin-coating, or spray-coating [34]. For dip-coating, the withdrawal speed is a key parameter determining film thickness [34].

- Gelation and Calcination: The coated substrate is dried, during which gelation occurs. Subsequently, the film is calcined (e.g., in air at different temperatures) to crystallize the bimetallic oxide (e.g., NiCo-oxide or NiFe-oxide) [29].

3. Key Advantages for Electrodes: The sol-gel method is economical and straightforward, allows for excellent stoichiometry control and homogeneous doping, and can be used to coat large and complex surfaces [34]. It enables the synthesis of highly pure and finely grained electrocatalysts, which have been shown to yield higher current densities at lower overpotentials in water electrolysis [29].

Chemical Vapor Deposition (CVD)

1. Principle and Process: CVD is a vacuum deposition method where a substrate is exposed to volatile precursors, which react and/or decompose on the substrate surface to produce the desired deposit [35] [33]. It is widely used for creating high-quality, high-performance solid materials and thin films. In a typical process, precursor gases are fed into a reaction chamber and undergo a chemical reaction on a heated substrate, forming a solid layer. A related technique, Atomic Layer Deposition (ALD), involves sequential, self-limiting surface reactions for ultra-thin, highly conformal films [33].

2. Experimental Protocol for a Polymeric Carbon Nitride (PCN) Film:

- Precursor and Substrate Loading: A solid precursor like melamine is placed in the chamber along with a porous substrate like Ni foam [29].

- Chemical Vapor Infiltration (CVI): The chamber is heated under controlled conditions. The melamine sublimates, and the vapor infiltrates the Ni foam, undergoing condensation and polymerization to form a PCN film directly on the substrate. The reaction temperature and precursor amount are key to controlling the polymerization degree and morphology [29].

- Cooling and Collection: The system is cooled, and the Ni foam with the deposited PCN is removed, ready for use as a self-standing electrode [29].

3. Key Advantages for Electrodes: CVD allows for the deposition of high-purity, dense, and adherent films with good conformality over complex shapes [35] [33]. It is particularly suitable for creating dense carbon shells on active materials (e.g., for core-shell structures) and for directly synthesizing complex structures like PCN films on 3D substrates, which show promising catalytic performances [36] [29].

Performance Data and Comparison

The performance of electrode materials is directly influenced by the synthesis method. Table 2 summarizes quantitative electrochemical data from the literature for materials created via these routes.

Table 2: Electrochemical Performance of Select Nanostructured Electrodes

| Synthesis Route | Electrode Material | Specific Capacity / Current Density | Performance Metric | Stability / Cycle Life | Ref. |

|---|---|---|---|---|---|

| Electrospinning | LiCoOâ‚‚ Nanofibers | 182 mAh/g (1st cycle) | Discharge Capacity | Poor cyclability (not quantified) | [31] |

| Electrospinning | Core-shell LiCoOâ‚‚-MgO NFs | ~163 mAh/g (20 mA/g) | Discharge Capacity | 90% capacity retention after 40 cycles | [31] |

| Electrospinning | Si/C composite (theoretical) | ~4200 mAh/g | Theoretical Specific Capacity | Challenges with volume expansion (>300%) | [30] [36] |

| Sol-Gel | Low-cost bimetallic oxide (e.g., NiCo-oxide) | N/A | OER performance in AEMWE | High current densities at low overpotentials | [29] |

| CVD (CVI) | Polymeric Carbon Nitride (PCN) on Ni foam | N/A | OER Catalytic Performance | Promising performance as OER electrode | [29] |

| Anodization + Electrodeposition | Ni Nanowire Arrays | N/A | HER Overpotential & Current Density | Lower overpotential, higher current density vs. Ni film; stable | [29] |

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Key Reagents and Materials for Nanostructured Electrode Synthesis

| Reagent/Material | Typical Function | Example Synthesis Route |

|---|---|---|

| Polyacrylonitrile (PAN) | Polymer matrix and carbon precursor for electrospinning | Electrospinning [31] |

| Poly(vinylpyrrolidone) (PVP) | Polymer matrix for electrospinning; stabilizer | Electrospinning, Sol-Gel [31] [32] |

| Metal Alkoxides (e.g., TEOS) | Precursor for metal oxides in sol-gel process | Sol-Gel [34] |

| Metal Nitrates/Salts (e.g., Ni(NO₃)₂, Co(NO₃)₂) | Inorganic precursors for sol-gel and electrospinning | Sol-Gel, Electrospinning [29] |

| Formic Acid / Acetic Acid | Solvent for electrospinning polyamide solutions | Electrospinning [37] |

| N, N-Dimethylformamide (DMF) | Common solvent for electrospinning and sol-gel | Electrospinning [32] |

| Melamine | Precursor for vapor-deposited carbon nitride films | CVD (CVI) [29] |

| Porous Ni Foam | 3D conductive substrate for direct electrode synthesis | Sol-Gel, CVD [29] |

| GSK2837808A | GSK2837808A, CAS:1445879-21-9, MF:C31H25F2N5O7S, MW:649.6258 | Chemical Reagent |

| GSK467 | GSK467, MF:C17H13N5O2, MW:319.32 g/mol | Chemical Reagent |

Synthesis Route Selection Workflow

The following diagram illustrates a decision-making workflow for selecting an appropriate synthesis route based on research goals and material requirements.

The choice of synthesis route is a fundamental decision in the design of nanostructured electrode materials. Electrospinning excels in creating high-surface-area fiber mats ideal for facilitating ion diffusion. Anodization is unparalleled for fabricating highly ordered, one-dimensional nanostructures on specific metal substrates. The sol-gel method offers superior compositional control and versatility for thin films and doped oxides at a lower cost. Chemical Vapor Deposition provides the highest purity and conformality for coatings, essential for complex architectures and 2D materials. The optimal path depends on a careful balance of the target electrode architecture, material composition, performance requirements, and practical constraints like scalability and cost. Future developments will likely focus on hybrid approaches that combine the strengths of these individual methods to create next-generation electrode materials with unprecedented performance.

The evaluation of nanostructured electrode materials is pivotal for advancing electrochemical biosensors. Within this field, enzyme-mimicking sensors have emerged as a transformative technology for glucose monitoring and biomarker detection. Unlike traditional biosensors that rely on natural enzymes, these systems utilize nanomaterial-based catalysts (nanozymes) to overcome inherent limitations of biological components, such as poor stability and stringent storage requirements [38] [39]. This guide provides a comparative analysis of sensor performance based on material composition, detection methodology, and operational characteristics, offering researchers a framework for selecting and developing next-generation sensing platforms.

Performance Comparison of Glucose Sensing Technologies

The table below summarizes the key performance metrics of different glucose sensor types, highlighting the advantages of nanozyme-based approaches.

Table 1: Performance comparison of enzymatic and non-enzymatic glucose sensors

| Sensor Type | Detection Mechanism | Linear Range | Sensitivity | Limit of Detection (LOD) | Key Advantages | Key Challenges |

|---|---|---|---|---|---|---|

| First-Generation Enzymatic (GOx) [40] | Measures O₂ consumption or H₂O₂ production | Varies by design | Varies by design | ~3.1 μM (in advanced designs) [40] | High specificity, well-established | Oxygen dependence, interferent susceptibility |

| Second-Generation Enzymatic (GOx with mediator) [40] | Uses redox mediators for electron transfer | 0.6–26.3 mM (example) [40] | Improved over first-gen | - | Reduced oxygen dependence | Potential mediator toxicity, added complexity |

| Third-Generation Enzymatic (GOx) [40] | Direct electron transfer from GOx to electrode | - | - | - | No mediator required, simpler design | Challenging electron transfer due to buried FAD center |

| Copper Oxide Nanozyme (Cuâ‚‚O/ITO) [41] | Direct glucose oxidation on Cuâ‚‚O surface | R² = 0.989 (linearity) | 1214.33 μA mMâ»Â¹ cmâ»Â² | 1.297 μM | High stability, low cost, enzyme-free | Requires alkaline conditions |

| Copper Oxide Nanozyme (Cuâ‚‚O/PET) [41] | Direct glucose oxidation on Cuâ‚‚O surface | R² = 0.997 (linearity) | 1188.14 μA mMâ»Â¹ cmâ»Â² | 1.824 μM | Flexible substrate potential | Slightly lower performance than ITO version |

| Gold Nanoparticle Nanozyme (PEC) [39] | Photoelectrochemical detection via AuNP catalysis | 1.0 μM – 1.0 mM | - | 0.46 μM | High sensitivity, novel mechanism | Complex fabrication |

Experimental Protocols for Key Sensor Fabrication and Evaluation

Fabrication of Copper Oxide Nanozyme Electrodes via LIFT

The Laser-induced Forward Transfer (LIFT) technique represents a single-step, maskless fabrication method for creating highly sensitive non-enzymatic glucose sensors [41].

Materials and Equipment:

- Substrates: Indium Tin Oxide (ITO) glass or Polyethylene terephthalate (PET)

- Donor film: Copper metal film (1000 nm thickness)

- LIFT system: Pulsed laser system capable of focusing through a glass substrate

Procedure:

- LIFT Processing: A pulsed laser passes through a glass substrate, focusing on the donor copper thin film to locally melt and eject microdroplets onto the target substrate (ITO or PET).

- Material Transfer: The process is conducted at ambient pressure and room temperature, transferring the copper coating onto the substrates at different laser power levels.

- Oxide Formation: During transfer, Cuâ‚‚O phases form on both PET and ITO electrode surfaces, with an additional Cuâ‚‚O (110) phase observed on ITO.

- Characterization: Field Emission Scanning Electron Microscopy (FESEM) reveals that ITO surfaces exhibit denser and more uniform nanoparticle distribution compared to PET surfaces [41].

Photoelectrochemical Glucose Sensor Construction

The photoelectrochemical (PEC) sensor demonstrates an alternative approach using gold nanoparticles as glucose oxidase mimics [39].

Materials:

- Electrode substrate: Indium Tin Oxide (ITO) coated glass

- Quantum dots: Thioglycolic acid-capped PbS QDs

- Insulating layer: Thiol-modified SiO₂ nanospheres (∼50 nm)

- Nanozyme: Small gold nanoparticles (∼4 nm)

- Assembly aids: Poly-(diallyldimethylammonium chloride) (PDDA)

Procedure:

- PbS Layer Formation: ITO electrodes are alternately immersed in PDDA solution and TGA-capped PbS QDs solution to create multilayers through electrostatic interaction.

- SiO₂ Insulation: Thiol-modified SiO₂ nanospheres (50 μL) are applied to the PbS-modified ITO electrode and dried naturally.

- AuNP Immobilization: Gold nanoparticle solution (50 μL) is dropped onto the ITO/PbS/SiO₂ electrode and dried at 50°C to form the complete ITO/PbS/SiO₂/AuNPs electrode.

- Glucose Detection: The fabricated electrode is immersed in Tris–HCl buffer (pH 7.4) saturated with oxygen. The decrease in cathodic photocurrent upon glucose addition is measured for quantification [39].

Signaling Pathways and Electron Transfer Mechanisms

The fundamental operating principles of these sensors revolve around distinct electron transfer pathways, which can be visualized through the following diagram.

The diagram illustrates the fundamental difference in detection mechanisms. Enzymatic sensors rely on the glucose oxidase (GOx) catalytic cycle, where flavin adenine dinucleotide (FAD) is reduced to FADH₂ during glucose oxidation, subsequently transferring electrons to the electrode [40]. In contrast, non-enzymatic sensors utilizing copper oxide nanozymes facilitate direct glucose oxidation through the electrochemical transition of Cu²⺠to Cu³⺠species (CuOOH) in alkaline conditions, with accompanying electron transfer generating the detection signal [41].

Experimental Workflow for Sensor Development and Testing

The complete process from material synthesis to sensor performance evaluation follows a systematic workflow, as illustrated below.

This workflow encompasses two primary fabrication routes: LIFT processing for non-enzymatic copper oxide sensors [41] and layer-by-layer assembly for photoelectrochemical sensors [39]. Critical characterization techniques include structural analysis (FESEM, EDS, XRD) and electrochemical testing (cyclic voltammetry, chronoamperometry) to validate sensor performance and selectivity against common interferents like ascorbic acid (AA), uric acid (UA), dopamine (DA), and NaCl [41].

The Scientist's Toolkit: Essential Research Reagents and Materials

The table below catalogues essential materials and their functions in developing and testing enzyme-mimicking glucose sensors.

Table 2: Key research reagents and materials for glucose sensor development

| Material/Reagent | Function | Application Example |

|---|---|---|

| Glucose Oxidase (GOx) | Biological recognition element for glucose | Traditional enzymatic biosensors [40] |

| Copper Oxide (Cuâ‚‚O) | Nanozyme for direct glucose oxidation | Non-enzymatic sensors via LIFT fabrication [41] |

| Gold Nanoparticles (AuNPs) | GOD-mimicking nanozyme | Photoelectrochemical glucose sensing [39] |

| Indium Tin Oxide (ITO) | Conductive transparent electrode substrate | Working electrode base material [41] [39] |

| Polyethylene Terephthalate (PET) | Flexible substrate | Flexible electrode applications [41] |

| PbS Quantum Dots | Photoelectrochemical active probe | Oxygen-sensitive PEC sensor component [39] |

| SiOâ‚‚ Nanospheres | Insulating layer | Reduces base current in PEC sensors [39] |

| Ascorbic Acid (AA), Uric Acid (UA), Dopamine (DA) | Interferents for selectivity testing | Validating sensor specificity [41] |

| GSK583 | GSK583 | |

| GSK6853 | GSK6853, MF:C22H27N5O3, MW:409.5 g/mol | Chemical Reagent |

The performance evaluation of nanostructured electrode materials for enzyme-mimicking glucose sensors reveals distinct advantages of nanozyme-based approaches, particularly in stability, sensitivity, and cost-effectiveness. Copper oxide-based sensors fabricated via LIFT processing demonstrate exceptional sensitivity (1214.33 μA mMâ»Â¹ cmâ»Â²) and low detection limits (1.297 μM), while gold nanoparticle-based PEC sensors offer alternative detection mechanisms with high sensitivity [41] [39]. As research progresses, the integration of these materials with advanced manufacturing techniques and multimodal detection platforms will further enhance their applicability in biomedical sensing, potentially expanding beyond glucose monitoring to multiplexed biomarker detection for comprehensive diagnostic applications.

The advancement of medical technology is inextricably linked to the evolution of portable, reliable, and safe power sources. Energy storage systems power a wide spectrum of medical devices, from life-sustaining implantable cardioverter defibrillators (ICDs) and insulin pumps to critical portable diagnostic equipment and emergency medical devices. The performance requirements for these power sources are exceptionally stringent, demanding high energy density, long cycle life, absolute safety, and reliable operation across diverse environmental conditions. For decades, lithium-ion batteries (LIBs) have dominated this landscape, prized for their high energy density and proven performance. However, the emerging class of sodium-ion batteries (SIBs) presents a compelling alternative with distinct advantages in safety, cost, and supply chain resilience. This guide provides an objective, data-driven comparison of these two technologies within the specific context of medical device applications, framed by the ongoing research in nanostructured electrode materials that is pivotal to enhancing their performance.

Technical Comparison: Sodium-Ion vs. Lithium-Ion Batteries

The core difference between these batteries lies in the chemistries of their active ions: lithium (Li+) for LIBs and sodium (Na+) for SIBs. While their fundamental operating principles are similar, the larger ionic radius and higher atomic weight of sodium lead to significant variations in electrochemical performance [42]. The selection of electrode materials is critical, as they must host these ions while maintaining structural integrity over repeated charge-discharge cycles.

Table 1: Core Electrochemical and Material Properties

| Property | Sodium-Ion Battery (SIB) | Lithium-Ion Battery (LIB) |

|---|---|---|

| Working Ion | Sodium (Na+) | Lithium (Li+) |

| Ionic Radius | ~1.02 Ã… | ~0.76 Ã… [42] |

| Anode Material | Hard Carbon, Alloys | Graphite, Lithium Titanate |

| Cathode Material | Layered Oxides, Prussian Blue Analogs, Polyanionic Compounds | Lithium Cobalt Oxide (LCO), Lithium Iron Phosphate (LFP), NMC |

| Nominal Voltage | ~2.8-3.5 V [43] | ~3.0-4.5 V [43] |

| Abundance | Sodium is the 6th most abundant element [42] | Lithium is ~0.0017% of Earth's crust [44] |

Quantitative Performance Metrics for Medical Applications

The suitability of a battery for a specific medical device is determined by a set of key performance indicators. The data below, drawn from recent commercial and research findings, provides a direct comparison.

Table 2: Performance Comparison for Medical Device Application

| Performance Metric | Sodium-Ion Battery (SIB) | Lithium-Ion Battery (LIB) |

|---|---|---|