Optimizing Redox Initiation Catalysts: From Foundational Mechanisms to Advanced Biomedical Applications

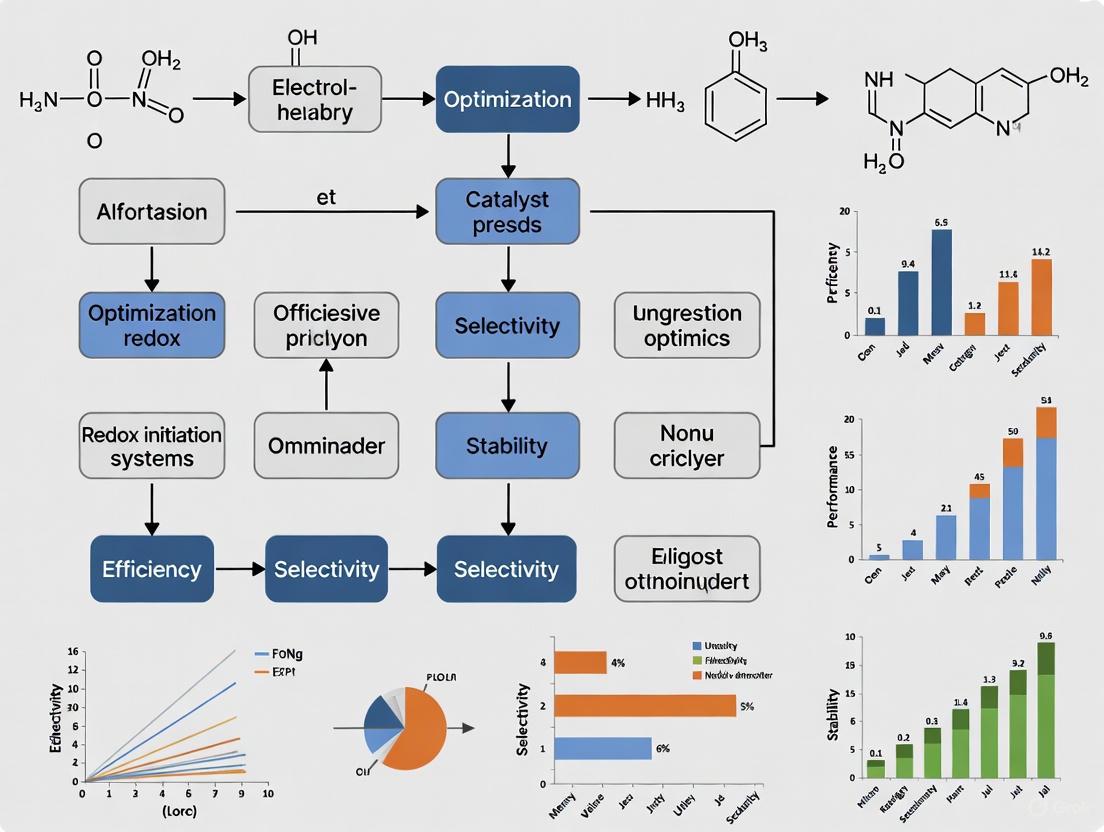

This comprehensive review explores the strategic optimization of catalysts for redox initiation systems, addressing critical needs in biomedical and pharmaceutical development.

Optimizing Redox Initiation Catalysts: From Foundational Mechanisms to Advanced Biomedical Applications

Abstract

This comprehensive review explores the strategic optimization of catalysts for redox initiation systems, addressing critical needs in biomedical and pharmaceutical development. We examine foundational mechanisms of metal-support interactions and redox cycling, evaluate high-performance metal complex systems like Mn(acac)2 and Cu(AAEMA)2 with silane reducing agents, and detail methodological approaches for controlled polymerization under mild conditions. The article provides systematic troubleshooting frameworks for overcoming oxygen inhibition, stability challenges, and selectivity control, while presenting robust validation protocols through electrochemical analysis, kinetic profiling, and comparative performance assessment. This resource equips researchers with practical strategies for developing next-generation redox catalysts tailored for drug delivery systems, biomaterials, and clinical applications.

Redox Catalyst Fundamentals: Unraveling Mechanisms and Metal-Support Interactions

Principles of Looping Metal-Support Interactions (LMSI) in Heterogeneous Catalysis

FAQ: What are Looping Metal-Support Interactions (LMSI)?

Answer: Looping Metal-Support Interactions (LMSI) describe a dynamic, self-sustaining cycle at the interface between a metal nanoparticle and its oxide support during redox reactions. Unlike static interactions, LMSI involves continuous, coordinated migration of the metal nanoparticle across the support surface, coupled with sacrificial reduction and re-oxidation of the support itself. This process creates a spatially separated yet intrinsically coupled reaction pathway, enhancing catalytic activity and stability under high-temperature redox conditions [1].

FAQ: How was LMSI discovered and what techniques are used to study it?

Answer: The LMSI phenomenon was uncovered using advanced operando transmission electron microscopy (ETEM), which allows for real-time, atomic-scale observation of catalyst structural evolution during reactions. This technique was pivotal in visualizing the looping interaction in a model NiFe-Fe₃O₄ catalyst during the hydrogen oxidation reaction. The experimental setup often includes a gas cell within the ETEM and a quadrupole mass spectrometer to correlate structural changes with catalytic activity [1].

Core Mechanism and Experimental Observation

FAQ: What is the fundamental mechanism behind LMSI?

Answer: The mechanism is a dual-site redox cycle that separates the oxidation and reduction half-reactions across a single nanoparticle [1]:

- Interface Reduction: At the NiFe-Fe₃O₄ interface, hydrogen atoms activated by the NiFe nanoparticle react with lattice oxygen from the Fe₃O₄ support. This sacrificial reaction releases water, reduces the support, and causes the interface to migrate dynamically [1].

- Metal Migration: Reduced iron (Fe⁰) adatoms migrate from the interface across the Fe₃O₄ support surface to specific facet edges [1].

- Surface Re-oxidation: At the {111} facets of the Fe₃O₄ support, the migrated Fe⁰ adatoms activate oxygen molecules, leading to the re-oxidation of the support and completion of the loop [1].

This mechanism is intrinsically coupled with the hydrogen oxidation reaction, which is driven by the dynamic migration of the metal-support interfaces [1].

Diagram 1: The LMSI dual-site redox cycle.

Experimental Protocol: Observing LMSI with Operando TEM

Objective: To directly visualize the LMSI phenomenon in a NiFe-Fe₃O₄ catalyst during hydrogen oxidation.

Synthesis:

- Precursor Preparation: Synthesize NiFe₂O₄ (NFO) nanoparticles as the catalyst precursor.

- Pre-treatment/Activation: Reduce the NFO precursor in a 10% H₂/He atmosphere at 400°C. This transforms it into the active NiFe-Fe₃O₄ structure, confirmed by Selected Area Electron Diffraction (SAED) [1].

Operando Measurement:

- Setup: Utilize a gas-celled ETEM. Introduce a reactant gas mixture (e.g., 2% O₂, 20% H₂, 78% He) into the cell.

- Observation: Heat the system above 500°C to initiate the LMSI.

- Data Collection:

- Record high-resolution TEM (HRTEM) image sequences to capture interface migration and support etching/reconstruction [1].

- Perform Fast Fourier Transform (FFT) analysis to determine the epitaxial relationship between the metal and support. For NiFe-Fe₃O₄, this is typically: NiFe (1̄12) // Fe₃O₄ (1̄1̄1̄) and NiFe [110] // Fe₃O₄ [110] [1].

- Use mass spectrometry to correlate observed structural dynamics with catalytic activity (H₂O production) [1].

Critical Parameters & Data

Key Quantitative Observations from LMSI Studies

Table 1: Experimental parameters and observations of LMSI in NiFe-Fe₃O₄.

| Parameter | Observation / Value | Significance / Explanation |

|---|---|---|

| Reaction Temperature | > 500 °C | Distinctive LMSI dynamic behavior emerges above this threshold [1]. |

| Lattice Spacing | NiFe (1̄11): ~0.20 nm | Approx. 15% lattice mismatch with the Fe₃O₄ support, leading to interfacial strain and void formation [1]. |

| Lattice Spacing | Fe₃O₄ (2̄24): ~0.17 nm | The support plane involved in the epitaxial interface with the metal nanoparticle [1]. |

| Interface Migration | Layer-by-layer dissolution of Fe₃O₄ along (111) plane | Driven by a Mars-van Krevelen-like mechanism where activated hydrogen spills over, releasing lattice oxygen [1]. |

| Oxygen Activation Site | Fe₃O₄ {111} facets | Location for O₂ molecule activation by migrated Fe⁰ adatoms, away from the metal-support interface [1]. |

| Metal Nanoparticle State | Single-crystalline, shape-changing | Maintains crystallinity while deforming like a liquid droplet to maintain lattice matching during migration [1]. |

Troubleshooting Common Experimental Issues

FAQ: Why is no dynamic LMSI behavior observed in my experiment?

Possible Causes and Solutions:

- Insufficient Temperature: Ensure the reaction temperature exceeds 500°C, as the looping behavior is a high-temperature phenomenon [1].

- Incorrect Redox Environment: Verify the partial pressures of H₂ and O₂ in the reactant gas mixture. The dynamic interaction is driven by the specific chemical potential of the redox environment [1].

- Missing Synergistic Pair: Control experiments on pure Ni and Fe₃O₄ showed no comparable dynamics. Confirm that you are using a synergistic metal-support pair like NiFe-Fe₃O₄ [1].

- Encapsulation Layer: The initial catalyst may be in a Classical Strong Metal-Support Interaction (SMSI) state with the metal nanoparticle encapsulated by an oxide layer. Ensure this layer is destabilized and retracts upon introduction of the redox-active gas mixture [1].

FAQ: How can I ensure my catalytic activity data is reliable and reproducible?

Answer: Adherence to standardized measurement protocols is critical. Inconsistent data generation is a major hurdle in catalysis research. To ensure reliability [2]:

- Document Catalyst History: Record the complete history of the catalyst, including all pre-treatment and activation steps. The catalyst is not a static material and its history profoundly impacts its state and performance [2].

- Control the Experiment Workflow: Kinetic values are not state functions and depend heavily on how the measurement is performed. Use consistent and documented workflows for activity and selectivity measurements [2].

- Report Comprehensive Metadata: Along with conversion and selectivity, report details on materials synthesis, shaping, and all characterization data to provide context for the results [2].

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential materials and their functions in LMSI experiments.

| Reagent / Material | Function in Experiment | Specific Example / Note |

|---|---|---|

| NiFe₂O₄ (NFO) Precursor | Starting material to synthesize the active NiFe-Fe₃O₄ catalyst via controlled reduction [1]. | Confirmed by SAED analysis pre- and post-reduction [1]. |

| Reducing Gas (H₂/He) | Used for the initial activation of the catalyst precursor to form the metal-support interface [1]. | Typical condition: 10% H₂/He at 400°C [1]. |

| Redox Reaction Gas Mixture | Creates the environment to initiate and sustain the LMSI cycle [1]. | Example: 2% O₂, 20% H₂, 78% He [1]. |

| Operando TEM with Gas Cell | Enables real-time, atomic-scale observation of structural dynamics under reaction conditions [1]. | Key equipment for direct visualization of interface migration [1]. |

| Mass Spectrometer (MS) | Coupled with ETEM to correlate structural changes with catalytic activity (e.g., H₂O production) [1]. | Provides quantitative activity data during visual observation [1]. |

Workflow for LMSI Experimentation

Diagram 2: Comprehensive workflow for an LMSI study.

Dual-site redox cycles represent an advanced catalytic strategy where oxidation and reduction processes are physically separated at distinct active sites. This spatial separation enhances catalytic efficiency by preventing cross-reactions, minimizing product recombination, and enabling specialized optimization of each site. This approach has demonstrated significant success across diverse fields including electrocatalysis, photocatalysis, and environmental remediation.

The fundamental principle involves designing catalyst architectures where electron transfer chains connect spatially isolated oxidation and reduction centers. This separation allows incompatible redox reactions to proceed simultaneously without interference, significantly boosting overall system performance and stability. Researchers have successfully implemented this concept in material systems ranging from metal-organic frameworks to transition metal catalysts and biochar composites.

Frequently Asked Questions (FAQs)

Q1: What are the primary advantages of spatially separating redox sites in catalytic systems? Spatial separation prevents cross-reactions between reactive intermediates, reduces product recombination, enables independent optimization of active sites for specific half-reactions, and enhances electron-hole separation in photocatalytic systems. This approach has demonstrated performance improvements across multiple metrics including conversion efficiency, product selectivity, and catalyst stability.

Q2: How can I determine if my catalyst system has achieved effective spatial separation? Effective spatial separation can be confirmed through techniques like controlled poisoning experiments, site-directed mutagenesis in enzymatic systems, advanced spectroscopy methods tracking specific intermediates, and electrochemical characterization showing distinct redox waves for oxidation and reduction processes. Performance metrics such as reduced charge recombination rates and improved quantum yields also indicate successful separation.

Q3: What are common characterization techniques for verifying spatial separation in redox catalysts? Common techniques include electrochemical impedance spectroscopy to measure charge separation efficiency, electron paramagnetic resonance (EPR) to detect radical species at specific sites, X-ray photoelectron spectroscopy (XPS) to determine elemental distribution, and transient absorption spectroscopy to track electron transfer pathways. Computational modeling can further predict and verify spatial arrangements.

Q4: How does spatial separation impact the scalability of redox catalytic systems? Proper spatial separation often enhances scalability by preventing deactivation pathways and improving catalyst longevity. However, fabricating precisely controlled nanostructures may present manufacturing challenges. Recent advances in self-assembly techniques and template-assisted synthesis have significantly improved the scalability of these sophisticated catalyst architectures.

Troubleshooting Common Experimental Issues

Problem 1: Poor Charge Separation Efficiency

Observed Symptoms: Low quantum yields, high electron-hole recombination rates, minimal potential difference between redox sites.

Possible Causes and Solutions:

| Cause | Diagnostic Tests | Solution Approaches |

|---|---|---|

| Insufficient spatial distance | Electrochemical impedance spectroscopy, transient absorption | Increase linker length between sites; implement stronger electronic barriers |

| Mismatched energy levels | UV-Vis spectroscopy, cyclic voltammetry | Modify donor-acceptor components to optimize energy alignment |

| Defective interfacial connections | TEM imaging, XPS analysis | Improve synthesis protocols for cleaner interfaces; reduce defect density |

Experimental Protocol Verification:

- Perform electrochemical impedance spectroscopy measurements from 100,000 Hz to 0.1 Hz with 10 mV amplitude

- Calculate charge separation efficiency using the formula: ηseparation = (1/τrecombination) / (1/τseparation + 1/τrecombination)

- Target charge separation efficiency >80% for optimal performance

Problem 2: Unbalanced Reaction Rates at Redox Sites

Observed Symptoms: Accumulation of intermediates, decreased overall reaction rate, side product formation.

Possible Causes and Solutions:

| Cause | Diagnostic Tests | Solution Approaches |

|---|---|---|

| Differential site activity | Kinetic analysis, Tafel plots | Independently optimize each site through targeted functionalization |

| Mass transport limitations | Rotating disk electrode studies | Modify catalyst porosity; implement hierarchical pore structures |

| Insufficient electron transfer | Electrochemical rate constant measurement | Incorporate conductive bridges; enhance electronic coupling |

Quantitative Assessment Method:

- Measure individual site turnover frequencies using selective inhibitors

- Calculate rate balance ratio: TOFoxidation/TOFreduction

- Target ratio between 0.8-1.2 for optimal system performance

- Adjust catalyst loading or surface area of the limiting site to rebalance rates

Problem 3: Catalyst Deactivation During Operation

Observed Symptoms: Progressive activity loss, changing product distribution, physical degradation.

Possible Causes and Solutions:

| Cause | Diagnostic Tests | Solution Approaches |

|---|---|---|

| Site crosstalk contamination | XPS, in-situ Raman spectroscopy | Implement stronger spatial barriers; add selective membranes |

| Structural degradation | XRD, SEM/TEM time-series | Enhance structural stability through cross-linking or support interactions |

| Fouling or poisoning | BET surface area, elemental analysis | Introduce protective functional groups; optimize reaction conditions |

Accelerated Stability Testing Protocol:

- Conduct extended operation at elevated temperature (50-60°C)

- Perform cyclic stress testing (rapid potential cycling for electrochemical systems)

- Characterize catalyst after 100 hours operation using XRD, XPS, and surface area analysis

- Target <10% activity loss after standardized stability testing

Experimental Protocols for Dual-Site Systems

Protocol 1: Electrochemical Activation for Enhanced OER Performance

This protocol adapts the Fe-redox oriented electrochemical activation strategy for creating heterojunctions with mixed metal surface components [3].

Materials:

- Fe-containing precatalyst (e.g., Fe3O4@NiO, NiFe2O4/C, or electrodeposited Ni(OH)2/Fe3O4/C)

- Alkaline electrolyte (1M KOH recommended)

- Standard three-electrode electrochemical cell

- Potentiostat with cycling capabilities

Procedure:

- Prepare catalyst ink and deposit on working electrode (glassy carbon recommended)

- Assemble electrochemical cell with Hg/HgO reference electrode and Pt counter electrode

- Perform electrochemical activation by cycling 20-30 times between -0.37 V to 0.66 V vs. RHE at 50 mV/s

- Characterize activated catalyst using CV in OER region (1.0-1.8 V vs. RHE)

- Verify heterojunction formation through XPS analysis of Ni-Fe surface components

Expected Outcomes: 40+ mV overpotential reduction at 100 mA cm⁻², formation of mixed Ni-Fe surface phase, improved charge transfer kinetics.

Protocol 2: MOF-Based Photocatalyst with Facet-Dependent Cocatalyst Separation

This protocol creates spatially separated redox sites on MOF structures for coupled H₂O₂ production and biomass oxidation [4].

Materials:

- MIL-125-NH₂ MOF crystals

- Palladium precursor (Na₂PdCl₄ recommended)

- Cobalt precursor (Co(NO₃)₂·6H₂O recommended)

- Methanol and deionized water

- Photoreactor with visible light source (λ ≥ 420 nm)

Synthesis Procedure:

- Synthesize MIL-125-NH₂ according to literature procedures

- Perform facet-selective photodeposition of Pd on {100} facets using methanol scavenger

- Deposit CoOₓ cocatalyst on {001} facets via controlled impregnation-calcination

- Characterize spatial distribution using TEM-EDS mapping

- Evaluate photocatalytic performance in H₂O₂ production coupled with vanillyl alcohol oxidation

Performance Metrics: Target H₂O₂ production rate >74.8 mM g⁻¹ h⁻¹ and vanillic acid production >80.9 mM h⁻¹ g⁻¹ with conversion >96% and selectivity >91%.

Protocol 3: Thermally Initiated Redox Cycles with Azo-Formate System

This protocol implements a scalable thermal initiation system for reductive radical chain reactions using azo initiators with formate salts [5].

Materials:

- Azo initiator (ACVA recommended for safety)

- Potassium formate or sodium formate

- Substrate (aryl halides for C-C bond formation)

- Nucleophiles (enolates for SRN1 reactions)

- Anhydrous DMSO solvent

- Schlenk line for inert atmosphere operations

Procedure:

- Prepare reaction mixture with substrate (1 equiv), nucleophile (4 equiv), Cs₂CO₃ (4.5 equiv)

- Add ACVA (0.25 equiv) and potassium formate (0.5 equiv)

- Degass using three freeze-pump-thaw cycles or argon sparging

- Heat at 80°C for 4 hours with stirring

- Quench with ammonium chloride solution

- Analyze products via GC-MS or HPLC

Key Applications: C(sp²)-C(sp³) bond formation, C(sp²)-S, C(sp²)-H, C(sp²)-B, and C(sp²)-P bond formations from complex (hetero)aryl halides.

The Scientist's Toolkit: Essential Research Reagents

| Reagent/Category | Function in Dual-Site Systems | Example Applications |

|---|---|---|

| Azo Initiators (ACVA) | Thermal generation of radicals for reductive initiation | Electron-catalyzed SRN1 reactions, polymerizations [5] |

| Formate Salts | Hydrogen atom transfer to generate CO₂•⁻ radical anions | Strong one-electron reductant (E° = -2.22 V vs. SCE) [5] |

| Manganese-doped Biochar | Multiple redox cycles (Mn(II)/Mn(III)/Mn(IV)) for PMS activation | Antibiotic degradation, water treatment [6] |

| Palladium-Cobalt Cocatalysts | Facet-dependent spatial separation on MOF surfaces | Photocatalytic H₂O₂ production coupled with biomass oxidation [4] |

| Fe-containing Precatalysts | Formation of heterojunctions under electrochemical activation | Oxygen evolution reaction enhancement [3] |

| Redox Mediators | Electron and proton transfer assistance in molecular systems | Alcohol oxidation reaction enhancement [7] |

| N-doped Carbon Materials | Electron transfer enhancement through modified electronic states | Peroxymonosulfate activation, environmental remediation [6] |

Table 1: Performance Metrics for Spatially Separated Redox Systems

| Catalyst System | Primary Reaction | Performance Metrics | Reference |

|---|---|---|---|

| Pd/{100}-CoOₓ/{001}-MIL-125-NH₂ | H₂O₂ production + vanillyl alcohol oxidation | H₂O₂: 74.8 mM g⁻¹ h⁻¹Vanillic acid: 80.9 mM h⁻¹ g⁻¹Conversion: 96.8%Selectivity: 91.1% | [4] |

| Fe-redox activated Fe₃O₄@NiO | Oxygen evolution reaction | Overpotential reduction: >40 mVStability: Maintained after activation | [3] |

| Mn-N-TS biochar | CIP degradation via PMS activation | Removal efficiency: 91.9% in 120 minTOC removal: 51%pH range: Wide applicability | [6] |

| ACVA-Formate Initiation | C(sp²)-C(sp³) bond formation | Yield: 30-85% rangeSubstrate scope: Broad heteroaryl compatibility | [5] |

Table 2: Optimization Parameters for Common Dual-Site Systems

| System Parameter | Optimization Range | Characterization Methods | Impact on Performance |

|---|---|---|---|

| Spatial Distance | 0.5-5.0 nm (system dependent) | TEM, EPR, electrochemical probing | Optimal distance balances electron transfer vs. site isolation |

| Site Balance Ratio | 0.8-1.2 (TOFox/TOFred) | Selective poisoning, kinetic analysis | Prevents intermediate accumulation, maximizes efficiency |

| Electronic Coupling | Moderate to weak coupling preferred | DFT calculation, electronic spectroscopy | Enables sufficient electron transfer while maintaining separation |

| Activation Protocol | 20-30 cycles (electrochemical) | XPS, CV, performance testing | Creates optimal surface structures without degradation |

Diagnostic Diagrams

Spatial Charge Separation Mechanism

Experimental Troubleshooting Decision Tree

Frequently Asked Questions (FAQs)

FAQ 1: What are the main electron transfer mechanisms in metal complexes, and how can I distinguish them experimentally?

Metal complexes primarily undergo electron transfer via two distinct mechanisms: inner-sphere and outer-sphere electron transfer [8] [9].

- Inner-Sphere Electron Transfer (IS ET): This process requires the formation of a covalent bridge between the oxidant and reductant. A ligand (e.g., a halide) simultaneously coordinates to both metal centers, creating a direct pathway for the electron [9]. A key experimental signature is the transfer of a bridging ligand from the oxidant to the reductant in the product. This was definitively demonstrated in Henry Taube's Nobel-prize winning experiment where a chloride ligand transferred from a cobalt complex to a chromium complex during reduction [8] [9].

- Outer-Sphere Electron Transfer (OS ET): This mechanism occurs without the formation of a chemical bridge. The coordination spheres of both complexes remain intact, and the electron tunnels through the outer electron shells of the complexes [8] [10]. This is the assumed mechanism unless evidence points to inner-sphere.

To distinguish them, you can design experiments to detect ligand transfer or measure reaction rates. The presence of a bridging ligand in the product, especially an inert one, strongly indicates an inner-sphere mechanism. Furthermore, inner-sphere reactions often proceed much faster than outer-sphere reactions when a good bridging ligand is present, as seen in the dramatic rate increase when a chloride ligand is involved [8].

FAQ 2: What roles can redox-active ligands play in catalytic cycles and radical generation?

Redox-active ligands are more than just spectators; they actively participate in electron transfer processes, enabling novel reactivity and radical generation pathways [11]. Their functions can be summarized as follows:

- Electron Reservoirs: They can store and release electrons, effectively mediating multi-electron transformations that might be challenging for the metal center alone.

- Radical Generators: They can form stable ligand-centered radicals, which can then directly engage in single-electron transfer (SET) or hydrogen atom transfer (HAT) with substrates [11].

- Spin-State Modulators: They can influence the spin state of the metal center, potentially accessing lower-energy reaction pathways through multistate reactivity [11].

- Lewis Acidity/Basicity Modifiers: Their redox state can alter the electron density at the metal center, changing its Lewis acidity or basicity.

FAQ 3: What are common precursors for generating aryl radicals in modern synthesis, and what are their advantages?

The field has moved beyond traditional stoichiometric methods toward more efficient, catalytic systems. The table below summarizes contemporary aryl radical precursors [12].

Table 1: Common Aryl Radical Precursors in Modern Synthesis

| Precursor | Key Feature | Advantage | Example Application |

|---|---|---|---|

| Diazonium Salts | Very low reduction potential (~ -0.16 V vs SCE) [12]. | High reactivity; wide availability of aniline precursors. | Photoredox-catalyzed C–H arylation of heteroarenes [12]. |

| Aryl Halides | Classic precursors, often activated by tin hydrides. | Well-established chemistry; many commercially available. | Traditional radical dehalogenation and cyclizations. |

| * (Emerging) Others* | E.g., aryl boronic acids, iodonium salts. | Offering complementary reactivity and functional group tolerance. | Various new C–C and C–heteroatom bond-forming reactions. |

Troubleshooting Guide

Problem 1: Low Catalytic Activity in Electrochemical Alcohol Oxidation

| Observed Issue | Potential Cause | Recommended Solution |

|---|---|---|

| Low conversion / poor catalytic current in CV. | High overpotential due to inefficient electron/proton transfer. | Incorporate a redox mediator (RM) such as TEMPO. The RM acts as a co-catalyst, shuttling electrons and protons, often resulting in lower overpotentials and faster rates [7]. |

| Catalyst decomposition or poor selectivity. | Unstable metal-hydride intermediate or unproductive reaction pathways. | Optimize the catalyst's ligand environment. For example, using a Ni-based catalyst with a diphosphine ligand framework (P₂N₂) with pendent amine groups can stabilize key intermediates and improve reactivity for alcohol oxidation [7]. |

| Sluggish kinetics. | The reaction is limited to a single-site catalyst mechanism. | Explore co-catalytic systems that combine a transition metal catalyst with a redox mediator. This can create synergistic effects and lower energy pathways for the reaction [7]. |

Problem 2: Poor Yields in Aryl Radical Generation and Trapping

| Observed Issue | Potential Cause | Recommended Solution |

|---|---|---|

| Low yield in photoredox reactions with diazonium salts. | Decomposition of diazonium salt or catalyst under irradiation. | Optimize electronic properties. Diazonium salts with electron-withdrawing groups (e.g., NO₂, CN) typically perform better in radical reactions. Use a photocatalyst with a suitable excited-state potential [12]. |

| Unwanted by-products from stoichiometric reductants. | Use of stoichiometric reagents like tributyltin hydride. | Switch to photoredox catalysis or use nucleophilic bases (e.g., formate). These methods generate radicals catalytically, minimizing toxic by-products [12]. |

| Inefficient radical trapping. | The radical is not sufficiently electrophilic/nucleophilic or the trap is unreactive. | Understand the radical character. Aryl radicals are relatively ambiphilic. For nucleophilic alkyl radicals, use an electrophilic trap like a diazonium salt. For electrophilic radicals, use electron-rich alkenes [12]. |

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Reagents and Materials for Redox Catalysis Experiments

| Reagent/Material | Function/Application | Key Example |

|---|---|---|

| Aminoxyl Radicals (e.g., TEMPO) | Redox Mediator; Co-catalyst for electrochemical oxidations. | Acts as an electron/proton shuttle in alcohol oxidation reaction (AOR), improving conversion and selectivity [7]. |

| Diazonium Salts | Aryl Radical Precursor. | Used in Meerwein arylation and modern photoredox catalysis for C–H functionalization and C–C bond formation [12]. |

| Redox-Active Ligands | Ligands that undergo reversible redox changes; enable multi-electron chemistry and radical pathways. | Ligands like diazabutadienes or o-aminophenols can store electrons or generate ligand-centered radicals for substrate activation [11]. |

| Cerium-Cobalt Composites | Dual-redox catalyst for oxidative degradation. | Ce–Co@γ-Al₂O₃ catalyst used in catalytic ozonation; synergistic Ce³⁺/Ce⁴⁺ and Co²⁺/Co³⁺ cycles promote reactive oxygen species (ROS) generation [13]. |

Experimental Protocols

Protocol 1: Investigating Electron Transfer Mechanism via a Classic Test Tube Experiment

This procedure is inspired by the experiments of Henry Taube that led to the discovery of the inner-sphere mechanism [8].

Objective: To determine if the reduction of [Co(NH₃)₅Cl]²⁺ by [Cr(H₂O)₆]²⁺ proceeds via an inner-sphere mechanism.

Materials:

[Co(NH₃)₅Cl]Cl₂(oxidant)CrCl₂or another source of[Cr(H₂O)₆]²⁺(reductant)- 1 M HClO₄ (reaction medium)

- Radioactive

³⁶Cl⁻(as a tracer) - Test tubes, pipettes, analytical equipment (e.g., ion chromatography).

Method:

- Prepare a solution of

[Co(NH₃)₅Cl]²⁺where the chloride ligand is radiolabeled with³⁶Cl. - In a test tube, mix the radiolabeled cobalt complex with

[Cr(H₂O)₆]²⁺in a 1 M HClO₄ medium. - Allow the redox reaction to proceed to completion. The overall reaction will yield

[Co(H₂O)₆]²⁺and[Cr(H₂O)₅Cl]²⁺. - Isolate the chromium(III) product.

- Measure the radioactivity of the isolated

[Cr(H₂O)₅Cl]²⁺complex and compare it to the radioactivity of the chloride in the original solution.

Expected Outcome and Interpretation: If the isolated chromium complex contains the radiolabeled chloride, it confirms a inner-sphere mechanism. The chloride bridge was directly transferred from cobalt to chromium, indicating that the electron was transferred through the bridge. If the chromium product's chloride is non-radioactive (i.e., it exchanged with chloride in the solution), it suggests an outer-sphere mechanism [8] [9].

Protocol 2: Characterizing a Complex with a Redox-Active Ligand

Objective: To determine the locus of oxidation (metal- or ligand-centered) in a paramagnetic complex bearing a redox-active ligand.

Materials:

- Paramagnetic metal complex (e.g., Cobalt-Porphyrin with a redox-active ligand).

- Solvent for spectroscopic studies.

- Cyclic Voltammetry (CV) setup.

- Electron Paramagnetic Resonance (EPR) Spectrometer.

- X-ray Crystallography setup.

- UV-Vis-NIR Spectrophotometer.

Method:

- Electrochemical Analysis: Perform Cyclic Voltammetry (CV) to identify the redox potentials of the complex. Combine with UV-Vis-NIR in a spectro-electrochemical (SEC) cell. A significant shift in the UV-Vis spectrum upon a redox event indicates a change in the electronic structure [11].

- Electronic Structure Analysis: Record a continuous-wave X-band EPR spectrum at low temperature.

- A g-value close to 2.003 (the free electron value) suggests the unpaired electron is primarily located on a light atom (C, N, O), indicating a ligand-centered radical.

- A g-value deviating significantly from 2.003 suggests significant spin-orbit coupling, indicating the unpaired electron is located on the metal center [11].

- Structural Analysis: Grow single crystals of the complex in different redox states. Determine their structures using Single-Crystal X-ray Diffraction (SC-XRD). Compare bond lengths within the ligand framework to known structures in databases like the Cambridge Structural Database (CSD). Characteristic bond distortions (lengthening/shortening) upon oxidation/reduction are a clear sign of redox activity at the ligand [11].

Interpretation: Correlate data from all three techniques. For example, a reversible redox wave in CV accompanied by a large spectral change in SEC, an EPR signal at g ~ 2.00, and ligand bond distortions in XRD collectively provide strong evidence for a redox-active ligand.

Experimental Workflow and Mechanism Diagrams

Diagram 1: Electron Transfer Mechanism Decision Workflow

This flowchart outlines the experimental thought process for determining the electron transfer mechanism between two metal complexes.

Diagram 2: Looping Metal-Support Interaction (LMSI) in NiFe-Fe₃O₄

This diagram illustrates the dynamic looping metal-support interaction observed in a NiFe-Fe₃O₄ catalyst during redox conditions [1].

Dynamic Interface Migration and Reconstruction Under Redox Conditions

In the field of catalyst optimization for redox initiation systems, the active, working state of a catalyst is often not its static, as-synthesized form. Under operating electrochemical or reactive conditions, catalysts undergo dynamic reconstruction, where their interface, composition, and structure evolve in response to the applied chemical potential [3] [14]. This dynamic process, which includes phenomena like phase transitions and surface migration, is crucial for catalytic activity but also presents common challenges in experimental reproducibility and stability. This technical support guide addresses these specific issues to help researchers reliably study and harness these dynamic interfaces.

Frequently Asked Questions (FAQs)

1. What does "dynamic reconstruction" mean in the context of redox catalysis? Dynamic reconstruction refers to the in-situ transformation of a catalyst's structure and composition under operating reaction conditions, which are often harsh and oxidizing/reducing. A pre-catalyst (or precatalyst) transforms into the true, active phase during the reaction. For instance, various transition metal-based precatalysts evolve into amorphous oxides or (oxy)hydroxides under the harsh conditions of the oxygen evolution reaction (OER) [3]. Identifying this true active phase is critical for understanding reaction mechanisms and designing better catalysts.

2. Why is the active state of my catalyst difficult to characterize and maintain? The active state is highly sensitive to the chemical potential of the gas or electrolyte environment. For example, Palladium (Pd) nanoparticles under methane oxidation conditions dynamically change their size, phase composition (metallic Pd vs. PdO), and surface structure in response to changes in temperature and gas-phase composition [15]. The state observed under ex-situ conditions (after reaction) does not represent the true active state under reactive conditions, making it challenging to characterize and stabilize.

3. Can I deliberately pre-treat a catalyst to improve its performance? Yes, deliberate activation outside the standard operational potential window is a viable strategy. An "Fe-redox-oriented electrochemical activation" method involves pre-cycling Fe-containing catalysts within a specific Fe-redox potential range (approximately -0.3 V to 0.7 V vs. RHE) to significantly enhance their OER performance. This process modifies the interfacial and surface structures, leading to the formation of more active phases like heterojunctions and mixed metal components [3].

4. What causes oscillatory behavior and instability in my nanoparticle catalyst? Oscillatory behavior, such as periodic transitions between metal and oxide phases, emerges from the dynamic interplay between oxidizing and reducing agents at a comparable chemical potential. In situ TEM studies of Pd nanoparticles during methane oxidation have shown that this coexistence of phases and their periodic transitions are linked to the catalytic activity itself. The resulting strained interfacial phases can have more favorable reaction energetics [15].

Troubleshooting Guides

Problem: Inconsistent Catalytic Performance After Synthesis

Possible Causes and Solutions:

- Cause: Uncontrolled Pre-Activation. The catalyst may not have been consistently transformed into its active state before performance evaluation.

- Solution: Implement a standardized electrochemical activation protocol. For Fe-based OER catalysts, use a controlled pre-cycling procedure within the Fe-redox potential range (e.g., -0.37 V to 0.66 V vs. RHE in alkaline solution) to ensure a consistent and optimized surface structure [3].

- Cause: Unidentified Active Phase.

Problem: Rapid Performance Degradation During Redox Cycling

Possible Causes and Solutions:

- Cause: Destructive Phase Transitions. Large volume changes during redox-induced phase transitions (e.g., between metal and oxide) can cause particle fracturing, sintering, or loss of electrical contact.

- Solution: As observed in Pd systems, the particle size will stabilize within a certain range under a given set of redox conditions [15]. Engineering the catalyst with a tailored initial particle size and strong interaction with the support can help accommodate strain and mitigate degradation.

- Cause: Unstable Phase Coexistence.

- Solution: Note that phase coexistence can be a marker of the active state [15]. The goal is not to eliminate it but to stabilize it. This can be achieved by using catalyst supports that strongly interact with the dynamic particles or by operating within a specific "sweet spot" in the gas/electrolyte composition where dynamics are stable.

Problem: Inability to Correlate Catalyst Structure with Activity

Possible Causes and Solutions:

- Cause: Ex-Situ Characterization. Analyzing the catalyst before or after the reaction provides no information about its state during catalysis.

- Solution: Integrate online mass spectrometry (MS) with operando characterization techniques like environmental TEM or XPS. This allows for the direct correlation of nanoscale structural dynamics (e.g., phase coexistence, surface reconstruction) with real-time catalytic activity data [15].

Experimental Protocols

Protocol 1: Fe-Redox Electrochemical Activation for OER Enhancement

This protocol is adapted from studies on Fe-containing OER precatalysts such as core-shell Fe₃O₄@NiO, spinel NiFe₂O₄/C, and electrodeposited Ni(OH)₂/Fe₃O₄/C [3].

1. Key Research Reagent Solutions

| Item | Function in the Experiment |

|---|---|

| Fe-containing precatalyst (e.g., Fe₃O₄/C) | The material to be electrochemically activated into a more active form. |

| Alkaline electrolyte (e.g., KOH solution) | Provides the alkaline medium for the Fe redox reactions and OER. |

| Working electrode (e.g., Glassy Carbon) | Support for the catalyst ink. |

| Counter electrode (e.g., Pt wire) | Completes the electrical circuit in the electrochemical cell. |

| Reference electrode (e.g., RHE) | Accurately controls and measures the applied potential. |

2. Step-by-Step Methodology

- Step 1: Electrode Preparation. Prepare a catalyst ink by dispersing the Fe-containing powder in a mixture of solvent (e.g., water/isopropanol) and Nafion binder. Deposit a known loading of the ink onto the polished surface of the working electrode and allow it to dry.

- Step 2: Electrochemical Setup. Assemble a standard three-electrode cell with the prepared working electrode, a counter electrode, and a reference electrode, filled with the deaerated alkaline electrolyte (e.g., 0.1 M or 1 M KOH).

- Step 3: Activation Procedure. Perform cyclic voltammetry (CV) by sweeping the potential repeatedly within the Fe-redox-rich window, typically between -0.37 V and 0.66 V vs. RHE. The number of cycles may be optimized but is often in the range of 10-50 cycles.

- Step 4: Performance Evaluation. After activation, switch to measuring the OER activity by performing CV or linear sweep voltammetry (LSV) in the OER potential region (typically >1.3 V vs. RHE). The enhancement is primarily attributed to the formation of heterojunctions and a mixed Ni-Fe surface component with a more favorable electronic structure [3].

Protocol 2: Monitoring Dynamic Reconstruction viaOperandoMass Spectrometry and Electron Microscopy

This protocol outlines the general principle of linking structural dynamics to catalytic activity, as demonstrated for Pd nanoparticle catalysts during methane oxidation [15].

1. Step-by-Step Methodology

- Step 1: Sample Preparation. Disperse catalyst nanoparticles on an electron-transparent membrane within a specially designed MEMS-based gas cell or nanoreactor that is compatible with TEM.

- Step 2: System Calibration. Connect the outlet of the gas cell to a Mass Spectrometer (MS). Calibrate the MS signals for reactants and products (e.g., CH₄, O₂, CO₂, H₂O).

- Step 3: Operando Experiment.

- Introduce the reactive gas mixture (e.g., CH₄ and O₂ in He) into the cell at the desired temperature and pressure.

- Simultaneously:

- Acquire real-time TEM images or videos to monitor changes in particle size, shape, and crystal phase (via SAED or HRTEM).

- Record the MS data to track reactant consumption and product formation (catalytic activity).

- Step 4: Data Correlation. Correlate the temporal evolution of the nanostructure (e.g., the onset of particle fragmentation or oscillation) with changes in the catalytic activity (e.g., rate of CO₂ production). This direct correlation helps identify the active state and the origin of performance oscillations [15].

The Scientist's Toolkit

Essential Materials and Reagents

| Item | Typical Function / Application |

|---|---|

| Fe-containing Precatalysts (e.g., Fe₃O₄, NiFe₂O₄) | Model systems for studying electrochemical activation and reconstruction in OER [3]. |

| Pd-based Nanoparticles | Benchmark catalysts for studying redox dynamics and phase oscillations in gas-phase oxidation reactions (e.g., CH₄ oxidation) [15]. |

| Azo Initiators (e.g., ACVA) | Used in thermal radical initiation systems; can generate strong reductants like CO₂•− in the presence of formate salts [5]. |

| Formate Salts (e.g., HCO₂K) | Act as a source of the carbon dioxide radical anion (CO₂•−), a potent one-electron reductant, in thermal initiation systems [5]. |

| Redox Mediators (e.g., TEMPO) | Small molecules that aid in proton and electron transfer, improving conversion and selectivity in molecular catalyst systems [7]. |

Core Diagnostic and Characterization Techniques

| Technique | Key Application in Troubleshooting |

|---|---|

| Cyclic Voltammetry (CV) | Identifying redox features of catalyst components and applying controlled activation protocols [3]. |

| Operando TEM | Directly visualizing nanoscale dynamics (migration, fragmentation, phase transitions) under reaction conditions [15]. |

| Operando / NAP-XPS | Probing the chemical state and composition of the catalyst surface in near-ambient pressure environments [15]. |

| Online Mass Spectrometry (MS) | Quantifying catalytic activity and selectivity in real-time, simultaneously with other operando measurements [15]. |

| Electrochemical Impedance Spectroscopy (EIS) | Assessing charge transfer and ionic transport resistances at the electrode-electrolyte interface [16]. |

Process Visualization

Diagram: Dynamic Interplay in a Working Redox Catalyst

The following diagram illustrates the feedback loop between a catalyst's structure and its environment that drives dynamic reconstruction and oscillatory behavior, as observed in systems like Pd during methane oxidation.

Diagram Title: Feedback Loop in Catalyst Dynamics

Diagram: Electrochemical Activation Workflow

This flowchart outlines the key steps for the successful electrochemical activation of a precatalyst.

Diagram Title: Precatalyst Activation Process

The Role of Epitaxial Relationships in Catalyst Stability and Performance

Troubleshooting Guide: Common Epitaxial Catalyst Challenges

FAQ: Why does my core-shell catalyst deactivate rapidly despite a high initial activity? Rapid deactivation in core-shell catalysts often results from insufficient epitaxial matching or shell instability under reaction conditions.

- Problem: Metal leaching from the core material due to a non-protective shell.

- Solution: Dynamically construct a dense epitaxial hydroxide layer. For instance, a dense epitaxial Ni(OH)₂ layer on nickel molybdate effectively prevented molybdenum leaching, enabling stable operation for 1400 hours at high current density [17].

- Prevention: Ensure the epitaxial shell is continuous and fully covers the core. Verify using STEM mapping at various magnifications to confirm a uniform, coherent relationship between the core and shell [17].

FAQ: How can I confirm an epitaxial relationship has been successfully achieved in my catalyst? Epitaxial growth is confirmed through a combination of structural and chemical analysis.

- Techniques to Use:

- Electron Microscopy: Use SEM and TEM to observe morphological changes and lattice fringes. Aberration-corrected STEM can clearly illustrate the epitaxial relationship [17].

- X-ray Absorption Spectroscopy: Analyze XANES and EXAFS spectra to detect changes in the oxidation state and local coordination environment that confirm the formation of a new epitaxial layer [17].

- Elemental Mapping: Perform EDS-lining across particles to confirm the desired elemental distribution, such as a high-silica core and low-silica outer layer in zeolites [18].

FAQ: My catalyst's performance is unstable under oxidizing conditions. What could be wrong? Instability under oxidizing conditions is frequently caused by elemental leaching from the catalyst surface.

- Problem: Halogen (e.g., F, Cl) leaching from iron oxyhalide catalysts, identified as a primary cause of catalytic activity loss [19].

- Solution: Implement spatial confinement. Intercalating catalysts, like iron oxyfluoride (FeOF), between layers of graphene oxide can mitigate deactivation by physically confining leached ions and protecting the catalyst structure [19].

Experimental Protocols for Epitaxial Catalyst Synthesis

Protocol 1: Two-Step Hydrothermal Synthesis for Zeolites

This protocol is adapted from the synthesis of SAPO-34 with a low-acidity outer layer [18].

- Objective: To synthesize a zeolite catalyst with a high-acidity core and a low-acidity epitaxial shell for improved MTO performance and stability.

Materials:

- Aluminium iso-propoxide (Aluminum source)

- Phosphoric acid, 85 wt% (Phosphorus source)

- Colloidal silica, 20 wt% (Silicon source)

- Tetraethylammonium hydroxide (TEAOH) solution, 25 wt% (Structure Directing Agent, SDA)

- Deionized water

Procedure:

- First-Step Synthesis (Core Formation):

- Prepare a precursor solution with molar composition: 1.0 Al₂O₃ : 4.0 P₂O₅ : 0.60 SiO₂ : 8.0 TEAOH : 212 H₂O.

- Mix aluminium iso-propoxide, TEAOH, and colloidal silica. Stir for 1 hour at room temperature.

- Add phosphoric acid dropwise to the mixture with stirring. Stir for an additional hour.

- Transfer the solution to a Teflon-lined stainless-steel autoclave for hydrothermal growth at 180°C for 72 hours with stirring.

- Recover the solid product (core) via centrifugation, wash with deionized water, and dry overnight at 90°C.

- Remove the SDA by calcination in air at 600°C for 4 hours.

- Second-Step Synthesis (Epitaxial Shell Growth):

- Prepare a second precursor solution with a lower silica content (e.g., molar composition: 1.0 Al₂O₃ : 4.0 P₂O₅ : 0.10 SiO₂ : 8.0 TEAOH : 218 H₂O).

- Add the calcined core from the first step to this solution in a weight ratio of 1.0 SAPO-34 : 74.0 precursor solution.

- Perform a second hydrothermal treatment at 180°C for 24 hours.

- Recover, wash, dry, and calcine the final core-shell product as in the first step.

- First-Step Synthesis (Core Formation):

Validation: Characterize the final product using EDS-lining to confirm a silica gradient and measure the thickness of the low-silica outer layer [18].

Protocol 2: Electrochemical Synthesis of an Epitaxial Hydroxide Layer

This protocol is adapted from the dynamic construction of a durable epitaxial catalytic layer on nickel molybdate [17].

- Objective: To electrochemically construct a dense epitaxial hydroxide layer on a pre-synthesized core material to enhance stability and performance.

Materials:

- Pre-synthesized core material (e.g., NiMoO₄ precursor microrods)

- KOH electrolyte

- Nickel chloride (Additional nickel source)

- Sodium citrate (Chelating agent)

- Standard electrochemical cell setup

Procedure:

- Synthesize a robust three-dimensional substrate (e.g., NiMoO₄ microrods) via a hydrothermal method [17].

- Prepare a tailored KOH electrolyte containing nickel chloride and sodium citrate.

- Use the core material as the working electrode in a cathodic electrochemical synthesis.

- Optimize the synthesis by adjusting the applied cathodic potential, duration, and other electrochemical parameters for different electrode sizes [17].

- Recover the resulting material (e.g., e-NiMoO₄) for analysis and use.

Validation: Use XPS and XAFS (XANES/EXAFS) to analyze the bonding states and confirm the lower oxidation state of the metal in the epitaxial layer compared to the core [17].

Quantitative Data on Epitaxial Catalyst Performance

The following table summarizes performance data for catalysts featuring epitaxial layers, demonstrating their enhanced stability and activity.

Table 1: Performance Metrics of Epitaxial Catalysts

| Catalyst System | Synthesis Method | Key Performance Improvement | Stability Assessment |

|---|---|---|---|

| e-NiMoO₄ (Epitaxial Ni(OH)₂ on NiMoO₄) [17] | Two-step: Hydrothermal + Electrochemical | Low Tafel slope of 45.7 mV/dec; Overpotential (η₁₀) of 32 mV for HER. | Stable operation for >1400 h at 0.45 A cm⁻² in an industrial electrolyzer. |

| SAPO-34 (Low-silica outer layer on high-silica core) [18] | Two-step Hydrothermal | Improved product selectivity and prolonged catalyst lifetime in MTO reaction. | Enhanced hydrothermal stability compared to one-step synthesized zeolite. |

| RuO₂/TiO₂ Core-Shell (Theoretical model) [20] | Epitaxial growth (DFT calculation) | Predicted enhanced OER activity and stability under operating conditions. | Increased stability predicted for lattice-matched, coherent shell layers. |

Table 2: Reagent Solutions for Epitaxial Catalyst Experiments

| Research Reagent | Function in Experiment | Example Application |

|---|---|---|

| Tetraethylammonium hydroxide (TEAOH) | Structure Directing Agent (SDA) | Directs the crystallization of specific zeolite frameworks (e.g., SAPO-34 CHA structure) [18]. |

| Colloidal Silica | Silicon source for zeolite framework | Incorporates silicon into the aluminophosphate framework, generating acid sites. Concentration controls acid site density in the shell [18]. |

| Sodium Citrate | Chelating Agent | In electrochemical synthesis, it helps tailor the electrolyte to effectively anchor the epitaxial hydroxide layer on the precursor [17]. |

| Nickel Chloride | Metal Ion Source | Provides the metal source (Ni²⁺) for the electrochemical deposition of the epitaxial hydroxide layer (e.g., Ni(OH)₂) [17]. |

Visualization of Experimental Workflows

Diagram: Two-Step Synthesis for Epitaxial Zeolite

Diagram: Electrochemical Epitaxial Layer Growth

High-Performance Catalyst Systems: Design Strategies and Biomedical Implementation

Performance Comparison of Redox Initiating Systems

The following table summarizes the key performance metrics of Mn(acac)₂, Cu(AAEMA)₂, and Fe(acac)₃ when used with diphenylsilane (DPS) as a reducing agent in free radical polymerization under air [21].

| Performance Parameter | Mn(acac)₂ / DPS | Cu(AAEMA)₂ / DPS | Fe(acac)₃ / DPS |

|---|---|---|---|

| Gel Time (1/1 wt%) | 110 s | 380 s | 900 s |

| Maximum Temperature | 140 °C | 130 °C | 45 °C |

| Final C=C Conversion | 98% | 90% | Not Determined |

| Surface Curing | Tack-free | Tack-free | Tacky |

| Reduction Potential (Ered) | -1.07 V | -0.65 V | Not Determined |

| Reaction Gibbs Energy (ΔG) | 2.47 eV | 2.05 eV | Not Determined |

| Storage Stability (at 50°C) | Excellent (7 days) | Excellent (7 days) | Data Not Available |

Troubleshooting FAQs and Guides

Q1: Why is my polymerization reaction proceeding too slowly or not initiating?

A: This is often related to the selection of an inefficient metal complex or incorrect concentrations for your application.

- Confirm Metal Complex Activity: Ensure you are using a complex with sufficient activity. Under identical conditions (1 wt% each of metal complex and DPS), Fe(acac)₃ shows significantly slower kinetics (900 s gel time) compared to Mn(acac)₂ (110 s) or Cu(AAEMA)₂ (380 s) [21].

- Adjust Concentrations: The gel time can be finely controlled by varying the concentrations of DPS and the metal complex. For a faster reaction, increase the DPS content (e.g., to 2% w/w), which can reduce gel time to 150-200 s. For a delayed curing and longer work time, use a higher metal complex content (~2 wt%) [21].

- Check for Oxygen Inhibition: While these RISs are designed to work under air, sample thickness can affect oxygen inhibition. If working with very thin films (<1 mm), consider the Cu(acac)₂/2dppba system, which is specifically reported to overcome oxygen inhibition effectively, even allowing for photoactivation [22].

Q2: How do I select the best metal complex for my specific needs?

A: The choice depends on the required reaction speed, storage stability, and desired properties of the final material.

- For Maximum Reactivity and High Conversion: Mn(acac)₂/DPS is the best choice. It offers the fastest gel time and the highest final methacrylate function conversion (98%) [21].

- For a Slower, More Controllable Reaction: Cu(AAEMA)₂/DPS is ideal. Its longer gel time (380 s) provides a larger processing window, while still achieving a high conversion (90%) and tack-free surface [21].

- For Long Shelf-Life and Stability: Both Mn(acac)₂ and Cu(AAEMA)₂ formulations show excellent stability. In accelerated aging experiments (50°C), they remained usable for 7 days without a significant change in gel time. Avoid Mn(acac)₃ if storage stability is a priority, as it degrades under these conditions [21].

Q3: The surface of my polymer remains tacky after curing. What is the solution?

A: A tacky surface indicates incomplete curing, often due to oxygen inhibition.

- Switch Metal Complex: Fe(acac)₃/DPS systems are known to produce tacky surfaces. Switching to Mn(acac)₂ or Cu(AAEMA)₂, which are proven to yield tack-free surfaces, will resolve this issue [21].

- Utilize Photoactivation: If your system allows, consider a photoactivatable RIS. The Cu(acac)₂/2dppba system can be activated with LED light (405 nm or 780 nm), which drives a faster and more complete surface cure, effectively overcoming oxygen inhibition [22].

The Scientist's Toolkit: Essential Research Reagents

| Reagent / Material | Function in the Experiment |

|---|---|

| Diphenylsilane (DPS) | Serves as the reducing agent in the two-component redox initiating system (RIS), replacing toxic aromatic amines [21]. |

| Mn(acac)₂, Cu(AAEMA)₂, Fe(acac)₃ | Act as the oxidizing agent in the RIS. They react with DPS to generate free radicals that initiate polymerization [21]. |

| Methacrylate Monomers | Benchmark monomers (e.g., in "resin 1") used for evaluating the performance of the redox systems, often formulated for polymerization under air [21]. |

| Tri-n-propylamine (TPrA) | A common sacrificial coreactant used in electrochemical studies and electrochemiluminescence (ECL) to generate strong reducing radicals [23]. |

| Acetonitrile (MeCN) | A common polar aprotic solvent used in electrochemical measurements and for computational modeling of solvent effects [24]. |

Experimental Protocol: Evaluating RIS Performance via Optical Pyrometry

This protocol outlines the methodology for assessing the performance of redox initiating systems by monitoring the reaction exothermicity [21].

1. Principle: The polymerization reaction is exothermic. Optical pyrometry is used to non-invasively monitor the temperature rise of the sample, from which key parameters like gel time and maximum temperature are determined.

2. Materials:

- Metal complex (e.g., Mn(acac)₂, Cu(AAEMA)₂, Fe(acac)₃)

- Reducing agent (Diphenylsilane - DPS)

- Methacrylate resin monomer formulation

- Two-cartridge mixing system or equivalent

- Optical pyrometer

- Sample molds (~4 mm thickness)

3. Procedure:

- Step 1: Solution Preparation. Prepare two separate solutions. Solution A: Metal complex dissolved in the monomer. Solution B: DPS dissolved in the monomer.

- Step 2: Mixing. Mix solutions A and B in a 1:1 ratio to initiate the redox reaction. Ensure homogeneous mixing.

- Step 3: Data Acquisition. Quickly transfer the mixture into a mold and place it under the optical pyrometer. Start recording the temperature immediately.

- Step 4: Data Analysis.

- Gel Time: Record the time from the start of mixing until a sharp, sustained increase in temperature is observed.

- Maximum Temperature ((T_{max})): Record the peak temperature reached during the polymerization.

- Final Conversion: Correlate the results with conversion data obtained via complementary techniques like Real-Time FTIR [21].

Mechanism and Experimental Workflow

The following diagram illustrates the general mechanism of redox-initiated free radical polymerization and the experimental workflow for catalyst evaluation.

The optimization of catalysts for redox initiation systems is a cornerstone of advanced materials research. Traditional Redox Initiating Systems (RIS) for Free Radical Polymerization (FRP) have predominantly relied on the interaction of aromatic amines with peroxides, such as dibenzoyl peroxide (BPO). However, these components are increasingly recognized for their inherent toxicity and instability, presenting significant safety and handling challenges in both research and industrial settings [25]. In response, a paradigm shift towards safer, peroxide-free, and amine-free initiating systems is underway. This technical support document outlines the use of diphenylsilane (DPS) as a robust, non-toxic reducing agent and a cornerstone for modern, high-performance redox systems [26] [25]. Its application offers researchers a pathway to conduct FRP under mild conditions (at room temperature and in the presence of air) while enabling precise control over reaction kinetics, such as gel time [25]. This guide provides detailed methodologies, troubleshooting, and resource information to facilitate the successful integration of DPS into your catalyst optimization research.

Core Concept: The Diphenylsilane Advantage

Diphenylsilane (DPS), with the chemical formula C12H12Si, is a clear, colorless liquid at room temperature [26]. It serves as a highly effective hydride donor in its role as a reducing agent. In the context of redox initiating systems, its primary function is to act as the reducing component in a two-component (2K) system, where it is paired with an oxidizing metal complex [25].

The fundamental advantage of DPS lies in its molecular structure and properties. Silicon possesses an electronegativity and ionization potential similar to boron, the key element in traditional reducing agents like borane, which reasonably suggests its utility as a reducing reagent [27]. Furthermore, the useful reducing properties of silanes like DPS can be enhanced by activating the acceptor (e.g., a metal complex) to increase its cationic character or by using activators like fluoride anions that form hypervalent silicon species, thereby strengthening the hydride-donating capability [27]. This makes DPS a versatile and powerful reagent for facilitating reduction reactions without the dangers associated with peroxides.

Experimental Protocols and Workflows

Key Redox Initiating System Formulation

The following protocol details the preparation of a high-performance, peroxide-free RIS based on DPS and metal complexes for the free radical polymerization of methacrylate monomers [25].

Materials and Reagents:

- Reducing Agent: Diphenylsilane (DPS) (Purity ≥ 97%) [26].

- Oxidizing Agents: Metal complexes such as: Manganese(II) acetylacetonate (Mn(acac)₂), Copper(II) (AAEMA)₂ (Cu(AAEMA)₂), or Iron(III) acetylacetonate (Fe(acac)₃).

- Monomer: Benchmark methacrylate monomers (e.g., methyl methacrylate).

- Solvent: An appropriate anhydrous solvent, if required by the specific experimental design.

Procedure:

- Preparation: In an appropriate reaction vessel, charge the methacrylate monomer. For reactions performed under air, no degassing is required [25].

- Mixing: Add the selected metal complex oxidizer to the monomer and stir until fully dissolved.

- Initiation: Introduce diphenylsilane (DPS) into the reaction mixture to initiate the free radical polymerization. The order of addition can be varied, but adding DPS last is standard.

- Reaction Monitoring: Conduct the polymerization at room temperature. The reaction progress can be monitored using techniques such as:

- Optical Pyrometry: To track reaction exotherms.

- Real-Time FTIR Spectroscopy: To measure the consumption of the monomer's carbon-carbon double bond and quantify conversion rates [25].

- Termination: The reaction can be terminated by removing the reaction vessel from the stimulus or by adding a termination agent as needed.

Experimental Workflow for Redox Optimization

The diagram below outlines the logical workflow for developing and optimizing a DPS-based redox initiating system, from hypothesis to analysis.

Troubleshooting Common Experimental Issues

FAQ 1: My polymerization reaction is proceeding too slowly. What could be the cause?

- A: Slow polymerization kinetics can be attributed to several factors. First, verify the choice of metal complex; different metals (Mn, Cu, Fe) exhibit varying redox potentials and catalytic activities with DPS [25]. Second, ensure the concentration of the DPS/metal complex redox pair is optimized, as insufficient initiator will lead to a low radical flux. Finally, if the reaction is not proceeding well under air, ensure that the DPS/metal complex system you are using is one of the formulations specifically reported to be effective in the presence of oxygen [25].

FAQ 2: I am observing inconsistent gel times between experimental replicates. How can I improve reproducibility?

- A: Inconsistent gel times often stem from improper mixing or variations in component purity. Ensure that all reagents, particularly DPS and the metal complex, are of high and verified purity (e.g., ≥97% for DPS) [26]. Standardize the mixing procedure (speed, duration, and order of addition) to ensure homogeneous distribution of the redox components immediately upon initiation. Using freshly prepared solutions of the metal complex can also prevent decomposition that might alter reactivity.

FAQ 3: What safety precautions are critical when handling diphenylsilane?

- A: While DPS is generally more stable and less toxic than peroxide-based alternatives, it should still be handled with care. Consult its Safety Data Sheet (SDS) for specific hazards. Standard laboratory safety practices are essential: wear appropriate personal protective equipment (PPE) including gloves and safety glasses, and work in a well-ventilated fume hood. Although DPS is not classified as hazardous mater in some commercial specifications, always treat laboratory chemicals with respect for potential risks [26].

FAQ 4: Can diphenylsilane be used to reduce other functional groups besides initiating polymerization?

- A: Yes, silanes as a class, including DPS, are versatile reducing agents. They can be employed in transition metal-catalyzed hydrogenations of alkenes and alkynes, as well as in the reduction of carbonyl groups when activated by Lewis acids or fluoride anions [27]. The specific reactivity will depend on the silane structure and the reaction conditions.

The Scientist's Toolkit: Key Research Reagents

The following table details essential materials used in DPS-based redox initiating systems and their primary functions within the research context.

| Research Reagent | Function/Explanation | Key Characteristics |

|---|---|---|

| Diphenylsilane (DPS) | Primary reducing agent in the 2K redox system; donates a hydride to activate the metal catalyst [25]. | Clear, colorless liquid; air & moisture stable; ≥97% purity [26]. |

| Mn(acac)₂, Fe(acac)₃ | Metal complex oxidizers; accept electrons from DPS to generate free radicals for initiation [25]. | Manganese and iron acetylacetonate salts; act as oxidizing components. |

| Cu(AAEMA)₂ | Copper-based metal complex oxidizer; an alternative for generating active radicals with DPS [25]. | Copper(II) complex; provides a different redox potential for reaction tuning. |

| Methacrylate Monomers | Benchmark substrates for free radical polymerization (FRP) to test redox system efficacy [25]. | e.g., Methyl methacrylate; contain polymerizable C=C bonds. |

| Tetrabutylammonium Fluoride (TBAF) | An activator for silane-based reductions; fluoride ions form hypervalent silicon, enhancing hydride donation [27]. | Organic salt; used in non-protic solvents to boost reducing power. |

Mechanism of Action: The Redox Pathway

The high performance of DPS/metal complex systems stems from a efficient redox mechanism that generates free radicals. The diagram below illustrates this proposed chemical pathway.

Controlled Gel Time and Curing Optimization for Biomedical Hydrogels

Troubleshooting Guides and FAQs

Frequently Asked Questions

Q1: Why is my hydrogel gelling too quickly, leaving insufficient time for processing? A fast gel time can compromise your ability to mix, pour, or mold the hydrogel effectively. This is often due to an excessively high concentration of initiators or catalysts. For example, in a ferrous sulfate (Fe+2) based redox system, the initial polymerization rate exhibits a square root dependence on the Fe+2 concentration. Increasing the Fe+2 concentration from 1.0 × 10⁻⁴M to 5.0 × 10⁻⁴M will increase the rate, but excess beyond this range can also reduce final conversion [28]. Alternatively, high ambient temperature can accelerate the reaction kinetics. Ensure the reaction is performed at a controlled, specified temperature (e.g., 25°C) [28].

Q2: What could be causing inconsistent gel times between batches? Inconsistent gel times are frequently traced to variations in initiator or catalyst preparation and handling. Redox initiators like ferrous salts can oxidize if stored improperly or for extended periods. To ensure consistency, prepare fresh stock solutions of initiators and catalysts for each use and standardize their method of addition to the monomer solution [28]. Also, verify that the monomer solution itself is consistent, as inhibitors (e.g., MEHQ) can vary between batches and cause induction period fluctuations [28].

Q3: My hydrogel does not form at all. What are the potential causes? The most common cause is the omission of a critical component in the redox initiation system. For a glucose oxidase (GOX)-mediated system, the reaction will not proceed if GOX, glucose, or Fe+2 is absent [28]. Similarly, for an APS/FS (Ammonium Persulfate/Ferrous Sulfate) system, both components are essential. Another major inhibitor is atmospheric oxygen, which can quench free radicals. While the GOX system consumes oxygen and provides some tolerance, other systems may require a controlled atmosphere or oxygen-scavenging additives [28].

Q4: How can I achieve a gel time of under two minutes for rapid prototyping? Ultrafast gelation can be achieved using robust redox initiator pairs. A system utilizing Ammonium Persulfate (APS) and Ferrous Sulfate (FS) as a redox pair has been demonstrated to achieve gelation in approximately two minutes at room temperature for an acrylamide and alkali-lignin based hydrogel [29]. The key is optimizing the concentrations of the initiator pair relative to the monomer and crosslinker to achieve instant, homogeneous gelation.

Q5: How do I measure gel time accurately in a laboratory setting? Several standardized methods exist [30]:

- Manual Stirring (Fishell Method): A simple method involving stirring the resin with a stick or probe and recording the time until the material becomes stringy and offers strong resistance.

- Automated Gel Timer: Instruments with a rotating spindle that automatically stop and record the time when increased viscosity from gelation stalls the motor. This offers high consistency and reduces operator error.

- Rheometer Modulus Method: A high-precision method where the gel point is defined as the moment the storage modulus (G', elasticity) and loss modulus (G", viscosity) intersect during a time sweep experiment.

Common Gelation Problems and Solutions

| Problem | Potential Causes | Recommended Solutions |

|---|---|---|

| Overly Rapid Gelation | High initiator/catalyst concentration; High temperature; Incorrect reactant ratios. | Reduce initiator/catalyst loadings; Perform reactions at lower temperatures; Review and adjust stoichiometry based on kinetic data [28] [29]. |

| Slow or No Gelation | Missing redox component; Oxygen inhibition; Expired or deactivated initiators; Presence of inhibitors. | Verify all system components are present and fresh; Use oxygen-scavenging systems or inert atmosphere; Use purified monomers to remove inhibitors [28]. |

| Inconsistent Gel Times | Poor storage of initiators; Variable ambient conditions; Inconsistent mixing or sample preparation. | Use fresh initiator stock solutions; Control reaction temperature and environment; standardize mixing protocols and container shapes [30] [28]. |

| Low Cell Viability (for cell-laden gels) | Cytotoxic initiator concentrations; Excessive heat generation during exothermic cure; Fast gelation causing mechanical stress. | Use cytocompatible initiators like GOX/Fe²⁺; Optimize initiator levels to minimum required; Ensure gelation rate allows for even cell distribution without damage [28]. |

Experimental Protocols and Data

Detailed Methodology: Glucose Oxidase-Mediated Redox Initiation

This protocol describes the encapsulation of fibroblasts using a cytocompatible redox initiation system, achieving high cell viability (96% ± 3%) [28].

Reagents and Materials

- Poly(ethylene glycol) tetra-acrylate (PEGTA, Mn ~20,000)

- Glucose Oxidase (GOX) from Aspergillus niger

- Iron (II) Sulfate (FeSO₄)

- D-Glucose

- CRGDS Peptide

- Dulbecco's Phosphate Buffered Saline (PBS), pH=7.2-7.4

- NIH3T3 Fibroblast cells

- Cell culture media (DMEM with 25mM glucose)

Procedure

- Preparation: Synthesize and characterize PEGTA to confirm acrylation (e.g., ~95% via ¹H-NMR). Synthesize and purify the CRGDS peptide to facilitate cellular adhesion.

- Monomer Formulation: Prepare the monomer solution in PBS to a final concentration of 15 wt% PEGTA20000 and 1mM CRGDS peptide.

- Initiator Addition: To the monomer solution, add the redox initiator components to achieve the following final concentrations: 2.5 × 10⁻⁵ M GOX, 1.25 mM Fe+2, and 4 mM glucose.

- Cell Suspension: Gently suspend NIH3T3 fibroblasts in the complete formulation at a density of 30 × 10⁶ cells/mL. Keep the solution on ice until polymerization to slow reaction kinetics.

- Polymerization: Transfer the cell-precursor mixture to a cylindrical mold (e.g., 4mm diameter). Allow it to polymerize at room temperature for approximately 5 minutes.

- Post-Processing: After polymerization, incubate the hydrogel constructs for 30 minutes in PBS at 37°C before transferring them to complete cell culture media.

Quantitative Data on Initiation System Kinetics

The following table summarizes key kinetic parameters for the GOX/Fe+2 initiation system, enabling tailored polymerization rates [28].

| Factor | Concentration Range Studied | Effect on Polymerization Rate (Rₚ) | Observation / Plateau |

|---|---|---|---|

| Glucose | Varying concentrations | Increased Rₚ with increasing [Glucose] | Rate plateau above ~1 × 10⁻³ M Glucose |

| Fe²⁺ | 1.0 × 10⁻⁴ M to 5.0 × 10⁻⁴ M | Square root dependence of Rₚ on [Fe²⁺] | Excess Fe²⁺ (beyond range) reduced final acrylate conversion |

Workflow Diagram: Hydrogel Synthesis via Redox Initiation

The Scientist's Toolkit: Research Reagent Solutions

Essential Materials for Redox-Initiated Hydrogel Formation

| Reagent / Material | Function in Hydrogel Formation | Example from Literature |

|---|---|---|

| Ammonium Persulfate (APS) | Oxidizing agent in redox pairs; generates sulfate radical anions to initiate polymerization. | Used with Ferrous Sulfate for ultrafast synthesis of lignin-based hydrogels [29]. |

| Ferrous Sulfate (FS) | Reducing agent in redox pairs; reacts with persulfate to rapidly produce free radicals. | Paired with APS for room-temperature gelation in ~2 minutes [29]. |

| Glucose Oxidase (GOX) | Enzyme that consumes glucose and oxygen to produce H₂O₂ in situ for a secondary redox reaction. | Creates a cytocompatible, O₂-tolerant initiation system with Fe²⁺ for cell encapsulation [28]. |

| Tetramethylethylenediamine (TEMED) | Catalyst that accelerates the decomposition of persulfate radicals, speeding up initiation. | Often used in combination with APS for polymerizing acrylamide hydrogels [28]. |

| Poly(ethylene glycol) di/tetra-acrylate | Macromeric monomer and crosslinker; provides the backbone structure for the hydrogel network. | PEG-diacrylate (Mn~575) used in kinetic studies; PEG-tetra-acrylate (Mn~20k) for cell encapsulation [28]. |

| Fe²⁺ ions (e.g., from FeSO₄) | Reductive component in Fenton-like reactions; reacts with H₂O₂ to generate hydroxyl radicals. | Critical component in both GOX-mediated and APS/FS initiation systems [28] [29]. |

Composite Material Fabrication for Drug Delivery Scaffolds and Implants

Frequently Asked Questions (FAQs)

FAQ 1: What are the key properties of an ideal scaffold for bone tissue engineering and drug delivery?

An ideal scaffold must balance several critical properties to be effective for both bone regeneration and controlled drug release. These include excellent biocompatibility to avoid adverse immune reactions, suitable biodegradability that matches the rate of new tissue formation, and adequate mechanical strength to support the defect site. Structurally, it requires a highly porous and interconnected pore network to facilitate vascular ingrowth, cell migration, and nutrient/waste exchange. Furthermore, the material must allow for efficient drug encapsulation and provide a controlled release profile for therapeutic agents [31] [32] [33].

FAQ 2: Which materials are most commonly used for creating composite drug delivery scaffolds?

Materials are typically chosen from synthetic polymers, natural polymers, and inorganic compounds, often combined to form composites that leverage the benefits of each.

- Synthetic Polymers: Poly(lactic-acid) (PLA), poly(glycolic-acid) (PGA), poly(caprolactone) (PCL), and their copolymer PLGA. These offer excellent control over mechanical properties and degradation rates but may lack bioactivity [31] [33].

- Natural Polymers: Collagen, chitosan, alginate, and gelatin. These are highly biocompatible and resemble the native extracellular matrix but can have variable properties and lower mechanical strength [31] [33].

- Inorganic Materials: Hydroxyapatite (HA) and tricalcium phosphates. These are osteoconductive (guide bone growth) and mimic the mineral component of bone, improving integration and mechanical compression strength [31] [33].

- Advanced Composites: Zeolitic imidazolate framework–polymer (ZIF-polymer) composites are emerging for their high drug loading efficiency and controlled release capabilities [34].

FAQ 3: What are the advantages of 3D printing for fabricating these scaffolds?

3D printing, also known as additive manufacturing, provides unparalleled precision in controlling the scaffold's internal and external architecture. It allows for the creation of customized, patient-specific designs with complex, hierarchical pore structures. This technology enables precise manipulation of pore size, geometry, and porosity, which are critical for cell attachment, tissue ingrowth, and vascularization. Compared to traditional methods like freeze-drying or gas foaming, 3D printing ensures enhanced reproducibility and can create structures that closely mimic the natural bone microenvironment [32].

FAQ 4: How can I improve the drug loading capacity and control the release kinetics from a scaffold?

Several strategies can be employed:

- Material Selection: Use materials with inherent high surface area and porosity, such as ZIF-polymer composites or mesoporous silica nanoparticles, which offer high drug loading efficiency [35] [34].

- Structural Design: Fabricate scaffolds with an interconnected microporous structure (including macro-, micro-, and nano-pores) to increase the surface area for drug entrapment [35] [32].

- Functionalization: Incorporate stimuli-responsive polymers (e.g., thermosensitive polymers) that change their structure in response to physiological cues (like temperature or pH), thereby triggering or modulating drug release [33].

- Composite Approach: Blend polymers with ceramic materials like hydroxyapatite, which can also act as a carrier for therapeutic molecules, creating a more complex release profile [31] [33].

Troubleshooting Common Experimental Issues

Problem 1: Scaffold has poor mechanical strength and collapses under load.

- Potential Causes and Solutions:

- Cause: Inadequate material selection for load-bearing applications.

- Cause: Excessively high porosity or overly large pore sizes compromising structural integrity.

- Solution: Optimize the trade-off between porosity and strength. Design a hierarchical pore structure that maintains interconnected pores for bioactivity while ensuring some regions have sufficient density to bear load. Utilize 3D printing to precisely control these parameters [32].