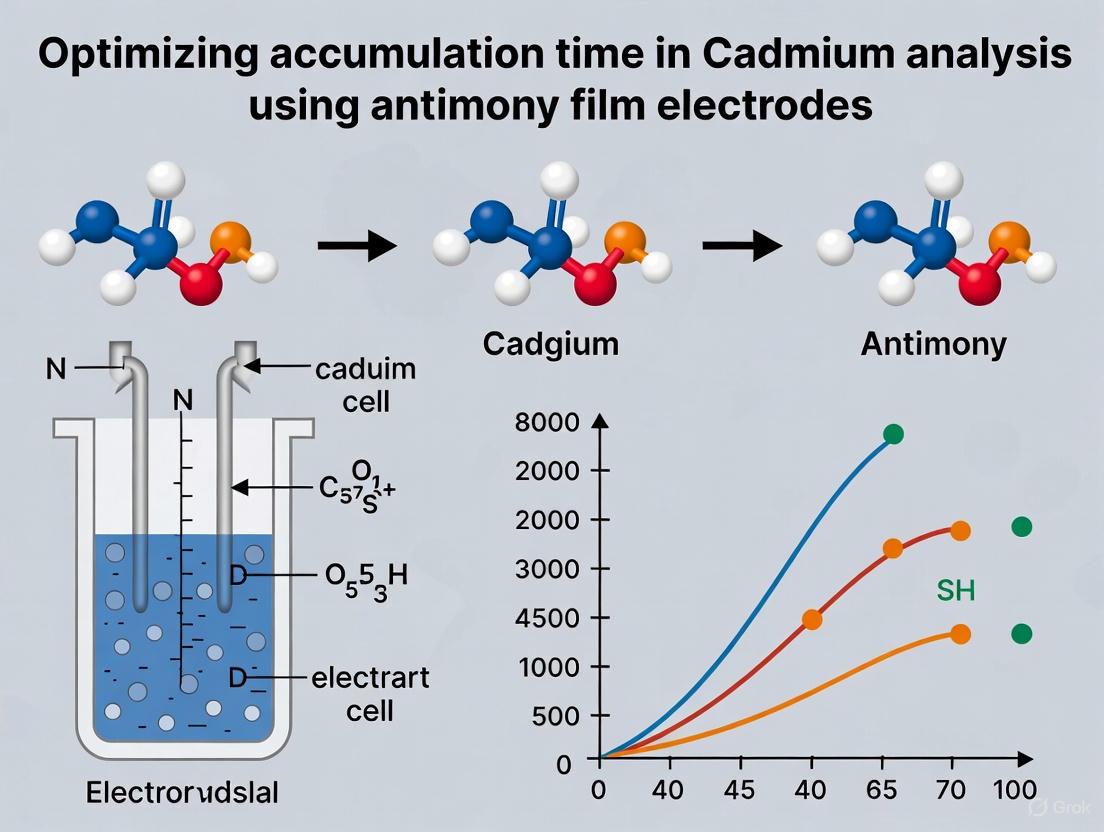

Optimizing Accumulation Time for Cadmium Analysis: A Comprehensive Guide to Antimony Film Electrode Performance

This article provides a systematic examination of accumulation time optimization for cadmium detection using antimony film electrodes (SbFEs), a critical mercury-free alternative in electrochemical analysis.

Optimizing Accumulation Time for Cadmium Analysis: A Comprehensive Guide to Antimony Film Electrode Performance

Abstract

This article provides a systematic examination of accumulation time optimization for cadmium detection using antimony film electrodes (SbFEs), a critical mercury-free alternative in electrochemical analysis. Tailored for researchers and analytical professionals, the content explores the foundational principles of anodic stripping voltammetry (ASV) and the unique advantages of SbFEs, including their performance in acidic media and insensitivity to dissolved oxygen. A detailed methodological framework covers electrode fabrication, from substrate selection to in-situ antimony film formation, and the establishment of standardized ASV protocols. The core focuses on a structured optimization strategy for accumulation time, analyzing its interplay with deposition potential and matrix effects to maximize sensitivity and minimize analysis time. Finally, the article outlines rigorous validation procedures for real-sample applications in biomedical and environmental monitoring, comparing SbFE performance with established spectroscopic techniques to underscore its reliability for trace cadmium determination.

Antimony Film Electrodes and Cadmium Detection: Principles and Advantages

Anodic Stripping Voltammetry (ASV) is a highly sensitive electrochemical technique renowned for its capability to detect heavy metals at sub-parts per billion (ppb) levels [1]. Its compatibility with portable, low-cost instrumentation makes it an ideal candidate for decentralized, "at-the-source" analysis, a significant advantage over traditional laboratory-based techniques like ICP-MS [1]. Despite its substantial potential, commercial adoption of ASV has been limited, partly due to the practical challenges associated with moving away from traditional mercury electrodes [1] [2]. This application note provides a foundational overview of ASV, framed within research focused on optimizing accumulation time for cadmium analysis using antimony film electrodes.

Fundamental Principles of ASV

ASV operates on a two-step process: an electrochemical pre-concentration step followed by a stripping step for measurement [1] [3].

The Two-Step Process

The first step involves the cathodic reduction of target metal ions (e.g., Cd²⁺) in the solution to their zero-valent metallic state (Cd⁰), which is deposited onto the working electrode surface. This deposition, or pre-concentration, occurs at a potential more negative than the formal potential of the Mⁿ⁺/M redox couple for a controlled time under stirred conditions to enhance mass transport [1]. The subsequent step, anodic stripping, involves re-oxidizing the deposited metal back into solution. The current generated during this oxidative dissolution is measured, and the resulting peak current or charge is proportional to the original concentration of the metal in the solution [1]. The pre-concentration step is key to the technique's high sensitivity, as it allows trace amounts of metal to be accumulated on the electrode before measurement [4].

Table 1: Core Steps in an Anodic Stripping Voltammetry Experiment.

| Step | Description | Key Parameters |

|---|---|---|

| 1. Pre-concentration / Deposition | Reduction of metal ions (Mⁿ⁺) from solution onto the electrode surface (M⁰). | Deposition potential, deposition time, mass transfer (stirring rate). |

| 2. Equilibration | cessation of stirring prior to the stripping step to establish quiet conditions. | Equilibration time. |

| 3. Stripping / Measurement | Oxidation of deposited metal (M⁰) back into solution (Mⁿ⁺) while measuring current. | Stripping technique (e.g., Linear Sweep, Square-Wave, Differential Pulse). |

The following workflow diagram illustrates the sequence of steps and key parameter choices in a typical ASV experiment:

Electrode Materials: From Mercury to Modern Alternatives

The choice of working electrode is critical in ASV. Historically, mercury electrodes were the material of choice due to their ability to form homogenous amalgams with many metals, providing well-defined stripping peaks and a wide cathodic potential window [1]. However, due to significant toxicity concerns, mercury electrodes have been largely phased out, driving the development of environmentally friendly "green" alternatives [1] [5].

Table 2: Common Mercury-Free Electrode Materials for ASV.

| Electrode Material | Key Advantages | Considerations / Performance |

|---|---|---|

| Bismuth Film Electrodes (BiFE) | Low toxicity, environmentally friendly, well-defined stripping signals, insensitivity to dissolved oxygen [6] [7]. | Performance can be affected by competition with copper ions in solution [7]. |

| Antimony Film Electrodes (SbFE) | Favorable performance in acidic media, wide potential window, good alternative for Cu(II) determination where BiFE struggles [5] [7]. | Softer and more soluble than bismuth; film stability can be a concern [5]. |

| Solid Bismuth Electrodes | No need to introduce bismuth ions into the sample solution, favorable signal-to-noise ratio (microelectrodes) [8]. | Requires an electrochemical activation step to reduce surface oxide before measurement [8]. |

For cadmium detection specifically, antimony film electrodes have demonstrated excellent performance. For instance, one study reported a linear range of 4.0–150.0 μg L⁻¹ for Cd(II) with a impressively low detection limit of 0.25 μg L⁻¹ using a square-wave ASV protocol [5].

Experimental Protocol: Cadmium Detection via ASV

This protocol outlines a detailed methodology for determining trace cadmium using an antimony film modified carbon paste electrode, based on optimized parameters from the literature [5].

Research Reagent Solutions

Table 3: Essential Reagents and Materials for ASV Cadmium Analysis.

| Item | Function / Description | Example / Specification |

|---|---|---|

| Supporting Electrolyte | Provides conductive medium and controls pH. | 0.1 M Acetate buffer, pH 4.5 [5] [7] or Hydrochloric acid, pH 3.0 [5]. |

| Antimony Film Precursor | Source of Sb(III) for in-situ or ex-situ film plating. | SbCl₃ or atomic absorption standard solution, e.g., 5.0 mg L⁻¹ in measurement solution [5]. |

| Cadmium Standard | For calibration and standard addition quantification. | Cd(NO₃)₂·4H₂O or CdCl₂ prepared in ultrapure water [5]. |

| Working Electrode | Surface for electrodeposition and stripping of cadmium. | Antimony film modified carbon paste electrode (SbF-CPE) [5] or screen-printed carbon electrode (SbSPCE) [7]. |

| Reference Electrode | Provides a stable, known potential for the cell. | Saturated Calomel Electrode (SCE) or Ag/AgCl [5] [6]. |

| Counter Electrode | Completes the electrical circuit in the three-electrode cell. | Platinum wire [6] or graphite rod. |

Step-by-Step Procedure

Electrode Preparation (Sb Film Plating): The antimony film can be formed in-situ by adding a known concentration of Sb(III) directly to the buffered sample solution, or ex-situ by plating the film from a separate Sb(III) solution prior to analysis [5] [7]. For ex-situ plating, immerse the polished bare carbon paste electrode into a plating solution of 1 M HCl containing 0.02 M Bi(NO₃)₃ (for bismuth) or a corresponding Sb(III) solution. Apply a constant deposition potential (e.g., -1.0 V vs. SCE for Sb) for a fixed time (e.g., 300 s) to electrodeposit a uniform metallic film on the substrate surface [6].

Sample Preparation and Deaeration (Optional): Dilute the water sample with the appropriate supporting electrolyte (e.g., acetate buffer pH 4.5) to maintain a consistent ionic strength and pH. A key advantage of antimony and bismuth film electrodes is that they can often be used without the need for prior removal of dissolved oxygen, simplifying and speeding up the analysis [5] [6].

Pre-concentration / Deposition Step: Transfer the prepared solution to the electrochemical cell. Insert the three electrodes (working, reference, counter). While stirring the solution, apply a carefully optimized deposition potential (e.g., -1.2 V vs. SCE for Cd) for a defined accumulation time. Accumulation time is a critical parameter that directly influences the amount of metal deposited and thus the analytical sensitivity; it must be optimized for the specific application and expected concentration range [5].

Equilibration: After the deposition time has elapsed, stop the stirring and allow the solution to become quiescent for a short period (typically 10-15 seconds) before initiating the stripping scan [6].

Stripping and Measurement: Initiate the anodic potential scan using a sensitive voltammetric technique such as Square-Wave Anodic Stripping Voltammetry (SWASV). A typical scan may run from -1.1 V to -0.6 V vs. SCE. The square-wave parameters (frequency, step potential, pulse amplitude) should be held constant [5] [6].

Calibration and Quantification: Record the stripping voltammogram, identifying the peak current for cadmium. Construct a calibration curve by repeating steps 3-5 with standard solutions of known cadmium concentration. The method of standard addition is highly recommended for analyzing complex sample matrices to account for potential interferences [1] [5].

Critical Parameters for Optimizing Accumulation Time

Within the context of thesis research on optimizing accumulation time for cadmium analysis, several interconnected factors must be considered:

- Target Concentration Range: For lower concentrations of cadmium, longer accumulation times are generally required to deposit a measurable amount of metal, thereby improving the signal-to-noise ratio and lowering the detection limit [1] [5].

- Electrode Substrate and Film Homogeneity: The nature of the substrate (e.g., carbon paste, glassy carbon) and the uniformity of the plated antimony film can influence the efficiency of metal deposition. A more homogeneous and reproducible surface allows for more predictable and reliable optimization of the deposition time [5] [7].

- Intermetallic Compound Formation: The formation of intermetallic compounds between different metals deposited simultaneously on the electrode can significantly alter stripping peaks. For example, copper and zinc are known to form intermetallic compounds in mercury amalgams. Understanding these interactions is crucial when designing experiments for complex samples [1] [4].

- Solution Matrix Effects: Real-world samples like groundwater or wastewater contain organic matter, surfactants, or other inorganic species that can adsorb to the electrode surface or complex with the target metal, reducing the fraction available for deposition. This can necessitate adjustments to the accumulation time compared to clean model solutions [1] [8].

Anodic Stripping Voltammetry represents a powerful and sensitive analytical tool for the detection of trace cadmium and other heavy metals. The transition to environmentally friendly electrode materials like antimony and bismuth has made ASV a greener and more practical technique. A central tenet of maximizing its performance, particularly for a specific analyte like cadmium, is the systematic optimization of experimental parameters, with accumulation time being one of the most critical for controlling sensitivity and detection limits. The protocols and considerations outlined in this note provide a solid foundation for research aimed at refining ASV methodologies for robust and reliable environmental monitoring.

Why Antimony? Key Properties of SbFEs for Cadmium Analysis

Antimony Film Electrodes (SbFEs) represent a significant advancement in the electrochemical detection of trace heavy metals, particularly cadmium. The development of SbFEs is situated within a broader research context focused on replacing traditionally used toxic mercury electrodes with environmentally friendly alternatives while maintaining high analytical performance [9] [10]. Antimony, a metalloid element related to bismuth, has emerged as a promising electrode material due to its unique electrochemical properties and favorable environmental profile.

The historical use of antimony in electrochemistry dates back to 1923 when it was first reported for pH measurements [9]. Recent research has expanded its application to stripping analysis for detecting trace heavy metals, with antimony nanoparticles and structured antimony films demonstrating exceptional capabilities for cadmium analysis [9]. This application note examines the fundamental properties of SbFEs that make them particularly suitable for cadmium detection, with specific emphasis on optimizing accumulation time to enhance analytical sensitivity within cadmium analysis research.

Key Properties of Antimony Film Electrodes

Comparative Electrode Performance

The selection of antimony as an electrode material is justified by several distinct properties that contribute to its effectiveness in cadmium analysis, especially when compared to other common electrode materials.

Table 1: Comparison of Electrode Materials for Cadmium Detection

| Electrode Type | Detection Limit for Cd(II) | Linear Range | Key Advantages | Limitations |

|---|---|---|---|---|

| Antimony Film Electrode (SbFE) | 0.15 µg·L⁻¹ [11] | 1.0-220.0 µg·L⁻¹ [11] | Environmentally friendly, well-defined stripping signals, reproducible [9] | Relatively newer technology |

| Bismuth Film Electrode (BiFE) | 0.38 µg·L⁻¹ [12] | 2-100 µg·L⁻¹ [12] | Low toxicity, high sensitivity [13] [6] | Electrode reactions involve adsorption phenomena [14] |

| Mercury Film Electrode (MFE) | Not specified in results | Not specified in results | Established history, excellent electrochemical properties [9] | High toxicity, regulatory restrictions [10] |

| Bi-Sb Film Electrode | 0.15 µg·L⁻¹ [11] | 1.0-220.0 µg·L⁻¹ [11] | Enhanced signal compared to single metal films [11] | More complex optimization required |

Fundamental Characteristics

Several fundamental characteristics establish SbFEs as superior platforms for cadmium analysis:

Environmental Compatibility: Antimony presents a more environmentally friendly alternative to mercury, addressing toxicity concerns and regulatory restrictions associated with traditional mercury electrodes [9] [10]. This property is particularly valuable for environmental monitoring and routine analysis applications.

Excellent Electrochemical Performance: SbFEs produce highly reproducible and well-defined stripping signals for cadmium, facilitating accurate quantification at trace levels [9]. The electrochemical behavior of antimony provides favorable electron transfer kinetics for cadmium detection.

Controlled Porosity and Surface Area: Macroporous antimony films fabricated using colloidal crystal templates exhibit increased internal electroactive area, significantly enhancing electrochemical performance [9]. The controlled porosity achieved through template replication improves analyte accessibility and deposition efficiency.

Adsorption-Independent Mechanisms: Unlike bismuth film electrodes where electrode reactions involve adsorption phenomena, antimony film electrodes operate free of adsorption effects, simplifying the electrochemical process and interpretation [14].

Enhanced Performance in Composite Films: The combination of antimony with bismuth in bismuth-antimony film electrodes (Bi-SbFEs) demonstrates synergistic effects, displaying higher stripping current response compared to single-metal film electrodes [11].

Experimental Protocols for Cadmium Analysis

Fabrication of Antimony Film Electrodes

Macroporous Antimony Film Electrode Fabrication

Table 2: Reagents and Materials for SbFE Fabrication

| Reagent/Material | Specification | Function | Source/Reference |

|---|---|---|---|

| Antimony (III) chloride | Reagent grade | Sb film precursor | Sigma-Aldrich [9] |

| Polystyrene spheres | 500 nm, monodisperse | Colloidal crystal template | Prepared by surfactant-free emulsion polymerization [9] |

| Gold coated glass plates | NiCr/Au, 0.3 μm | Electrode substrate | A.C.M. France [9] |

| Hydrochloric acid | 0.01 M | Supporting electrolyte | Prepared from reagent grade HCl [9] |

The fabrication protocol for macroporous SbFEs involves the following steps:

Template Preparation: Monodisperse polystyrene spheres (500 nm) are synthesized via surfactant-free emulsion polymerization of styrene initiated by potassium peroxodisulfate [9].

Template Assembly: Polystyrene spheres are assembled into artificial opal structures on gold-coated glass substrates, creating robust templates with excellent adhesion properties [9].

Electrochemical Deposition: Antimony is electrochemically deposited into the interstitial spaces of the colloidal crystal template using a solution of antimony(III) chloride in 0.01 M hydrochloric acid as the supporting electrolyte [9].

Template Removal: The polystyrene template is removed, resulting in a robust, mechanically stable macroporous antimony film with pore diameter determined by the original polystyrene sphere size [9].

Modified Glassy Carbon Electrode with Sb Film

An alternative approach for SbFE preparation involves modifying glassy carbon electrodes:

Electrode Pretreatment: Polish the glassy carbon electrode with alumina powder (0.1 mm and 0.005 mm) to a mirror-like surface to improve analytical performance [15].

Composite Modification (Optional): Modify the electrode surface with carboxylated multi-walled carbon nanotubes (CMWCNTs) and Nafion via drop-casting to enhance surface area and adsorption characteristics [12].

Antimony Deposition: Deposit antimony film onto the modified surface via potentiostatic deposition from an antimony(III) solution [12].

Cadmium Analysis Using Differential Pulse Stripping Voltammetry

The quantification of cadmium using SbFEs typically employs differential pulse anodic stripping voltammetry (DPASV) with the following optimized parameters:

Table 3: Optimized Parameters for Cd(II) Detection Using SbFEs

| Parameter | Optimal Condition | Effect |

|---|---|---|

| Supporting electrolyte | Hydrochloric acid (pH 2.0) [11] | Provides optimal ionic conductivity and pH environment |

| Deposition potential | -1.2 V vs. SCE [6] | Enables efficient Cd(II) reduction without co-reducing interfering species |

| Accumulation time | Optimized between 50-300 s [6] [12] | Critical parameter controlling analytical sensitivity |

| Pulse amplitude | 50 mV [6] | Balances sensitivity and resolution |

| Step potential | 5 mV [6] | Determines potential scan resolution |

The general analytical procedure consists of:

Sample Preparation: Dilute water samples in acetate buffer (pH 4.35) or prepare in hydrochloric acid (pH 2.0) [6] [11]. For complex matrices, appropriate sample pretreatment may be necessary.

Accumulation/Deposition Step: Apply the optimized deposition potential for a predetermined accumulation time to reduce Cd(II) ions to Cd(0) and deposit them onto the SbFE surface. The accumulation time represents a critical optimization parameter for maximizing cadmium detection sensitivity.

Stripping Step: Apply a positive-going potential scan using differential pulse or square-wave waveform to oxidize the deposited cadmium back to Cd(II) ions, generating the analytical signal.

Quantification: Measure the cadmium stripping peak current at approximately -0.8 V to -0.6 V (vs. Ag/AgCl) and correlate with calibration curves for quantification [6].

The Scientist's Toolkit: Essential Research Reagents

Table 4: Essential Research Reagents for SbFE-Based Cadmium Analysis

| Reagent/Material | Function | Application Notes |

|---|---|---|

| Antimony (III) chloride | Sb film precursor | Used for electrochemical deposition of antimony films; concentration typically 0.15 mmol L⁻¹ [13] |

| Carboxylated multi-walled carbon nanotubes (CMWCNTs) | Electrode modifier | Enhances surface area and electron transfer kinetics; used with Nafion binder [12] |

| Nafion polymer | Binder for composite electrodes | Provides structural integrity to modified electrodes; enhances selectivity [12] |

| Acetate buffer | Supporting electrolyte | Optimal pH range 4.0-4.5 for cadmium detection; provides consistent ionic strength [6] |

| Hydrochloric acid | Supporting electrolyte | Used at lower pH (2.0) for certain applications [11] |

| Cadmium standard solution | Calibration and quality control | Used for daily preparation of standard solutions; typical concentration range 1×10⁻⁵ to 1×10⁻⁶ mol L⁻¹ [13] |

Experimental Workflow and Signaling Pathways

The following diagram illustrates the complete experimental workflow for cadmium analysis using antimony film electrodes, highlighting the critical role of accumulation time optimization:

Experimental Workflow for Cd Analysis Using SbFEs

The electrochemical signaling mechanism for cadmium detection at SbFEs involves distinct electron transfer processes:

Electrochemical Signaling Pathway for Cd Detection

Antimony Film Electrodes offer a compelling combination of environmental safety and analytical performance for cadmium analysis. The key properties of SbFEs—including their well-defined stripping signals, reproducibility, controlled porosity, and adsorption-independent mechanisms—establish them as superior alternatives to traditional mercury electrodes. The optimization of accumulation time represents a critical research focus that directly influences the sensitivity and detection limits for cadmium analysis. Through appropriate electrode fabrication and methodological optimization, SbFEs achieve detection limits as low as 0.15 μg·L⁻¹ for cadmium, making them suitable for environmental monitoring, biological sample analysis, and regulatory compliance assessment. The continued development of SbFE technology, particularly through nanostructuring and composite approaches, promises further enhancements in cadmium detection capabilities.

The accurate detection of trace heavy metals, such as cadmium, is paramount in environmental monitoring, food safety, and toxicological research. Electrochemical stripping analysis has emerged as a powerful technique for this purpose, with the choice of working electrode material critically determining sensitivity, selectivity, and environmental impact. For decades, mercury film electrodes were considered the gold standard due to their exceptional electrochemical properties. However, their high toxicity has driven the development of environmentally friendly alternatives, primarily bismuth (BiFE) and antimony film electrodes (SbFE). This application note provides a detailed comparative analysis of these electrode systems, focusing on their performance in cadmium detection, to guide researchers in selecting and implementing the optimal sensor for their analytical needs.

Table 1: Performance Comparison of Film Electrodes for Cadmium Detection

| Electrode Type | Detection Limit (μg L⁻¹) | Linear Range (μg L⁻¹) | Key Advantages | Reported Modifications/Substrates |

|---|---|---|---|---|

| Antimony Film Electrode (SbFE) | 0.38 (in urine) [12] | 2 - 100 [12] | Low toxicity, works in dissolved oxygen, simple preparation [12] | Sb/CMWCNTs@Nafion on GCE [12] |

| Bismuth Film Electrode (BiFE) | 0.18 (in tea) [16] | 0.2 - 25 [16] | Low toxicity, well-defined stripping peaks, insensitivity to O₂ [6] [16] | MOF(Bi) on GCE; Bi film on brass electrode [6] [16] |

| Mercury Film Electrode (MFE) | Information not available in search results | Information not available in search results | Historically the benchmark for sensitivity and reproducibility | Information not available in search results |

Experimental Protocols for Electrode Preparation and Cadmium Detection

Protocol for SbFE Preparation and Cd(II) Analysis

This protocol details the fabrication of an SbFE modified with carboxylated multi-walled carbon nanotubes (CMWCNTs) and Nafion for the highly sensitive simultaneous detection of cadmium and lead, as described in a recent study [12].

- Materials: Glassy carbon electrode (GCE), carboxylated multi-walled carbon nanotubes (CMWCNTs), Nafion perfluorinated resin solution, antimony chloride (SbCl₃), lead standard solution, cadmium standard solution, acetate buffer, urine samples.

- Equipment: Potentiostat, electrochemical cell (three-electrode setup: working electrode, reference electrode, counter electrode), ultrasonic bath, polishing cloths and alumina slurry.

Step-by-Step Procedure:

- Electrode Pretreatment: Polish the GCE sequentially with 0.3 μm and 0.05 μm alumina slurry on a microcloth to create a mirror finish. Rinse thoroughly with deionized water and dry at room temperature.

- CMWCNTs@Nafion Modification: Disperse CMWCNTs in a dilute Nafion solution via sonication. Deposit a precise volume (e.g., 5-10 μL) of this suspension onto the clean GCE surface and allow it to dry, forming a stable, conductive composite film.

- Antimony Film Deposition: Prepare a plating solution containing Sb(III) ions in a suitable electrolyte. Immerse the modified GCE and perform potentiostatic deposition (e.g., at a optimized negative potential) to coat the surface with a uniform antimony film.

- Cadmium Analysis via DPSV:

- Accumulation: Immerse the SbFE in a stirred sample solution containing Cd(II). Apply a deposition potential (e.g., -1.2 V vs. Ag/AgCl) for a controlled time (e.g., 300 s) to reduce and pre-concentrate Cd(II) as Cd(0) onto the electrode.

- Stripping: After a brief equilibration period, scan the potential in the positive direction using Differential Pulse Stripping Voltammetry (DPSV) parameters. The oxidation (stripping) of cadmium produces a characteristic current peak at approximately -0.8 V (vs. SCE).

- Quantification: Measure the peak current, which is proportional to the concentration of Cd(II) in the sample. Use a calibration curve for accurate quantification.

Protocol for BiFE Preparation and Cd(II) Analysis

This protocol outlines the construction of a highly sensitive BiFE using a bismuth-based metal-organic framework (MOF(Bi)) for cadmium detection in complex matrices like tea [16].

- Materials: Glassy carbon electrode (GCE), Bismuth nitrate pentahydrate (Bi(NO₃)₃·5H₂O), 1,3,5-benzenetricarboxylic acid (H₃BTC), cysteine, Nafion solution, sodium acetate, acetic acid, cadmium standard solution.

- Equipment: Potentiostat, solvothermal reactor (e.g., Teflon-lined autoclave), electrochemical cell, ultrasonic bath, polishing setup.

Step-by-Step Procedure:

- Synthesis of MOF(Bi): Dissolve Bi(NO₃)₃·5H₂O and H₃BTC in a solvent mixture (e.g., DMF/ethanol). Transfer the solution to a Teflon-lined autoclave and heat (e.g., 120°C for 24 hours) in a solvothermal reaction. Cool, collect the precipitate, and wash thoroughly to obtain the MOF(Bi) crystals.

- Sensor Fabrication (Nafion/cys/MOF(Bi)/GCE): Prepare a homogeneous ink by dispersing the MOF(Bi) powder in a solution containing cysteine and Nafion. Drop-cast this ink onto a pre-polished GCE and allow it to dry. Cysteine acts as a complexing agent to enhance cadmium preconcentration, while Nafion stabilizes the sensing interface.

- Cadmium Analysis via ASV:

- Accumulation: Place the modified electrode in a standard acetate buffer (pH ~4.5) spiked with the sample. Under stirring, apply a deposition potential (e.g., -1.2 V vs. SCE) for a fixed time to co-deposit bismuth and cadmium.

- Stripping: Record the anodic stripping voltammogram using Square-Wave mode. The cadmium stripping peak will appear at around -0.8 V (vs. SCE).

- Quantification: Construct a calibration curve from standard additions to determine the unknown cadmium concentration in the sample.

Diagram 1: Electrode preparation workflow.

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Reagents and Materials for Film Electrode Fabrication

| Item | Function/Description | Exemplar Use Case |

|---|---|---|

| Antimony Chloride (SbCl₃) | Source of Sb(III) ions for the electroplating of the antimony film onto the substrate electrode. | Formation of an antimony film on a CNT-modified GCE for urine metal analysis [12]. |

| Bismuth Nitrate (Bi(NO₃)₃) | Precursor for in-situ or ex-situ bismuth film formation, or for the synthesis of bismuth-based MOFs. | Synthesis of MOF(Bi) for a highly sensitive cadmium sensor in tea [16]. |

| Carboxylated Multi-Walled Carbon Nanotubes (CMWCNTs) | Nanomaterial that enhances electrode surface area, electron transfer kinetics, and provides a scaffold for metal film formation. | Used as a conductive support with Nafion to modify the GCE before Sb deposition [12]. |

| Nafion | A perfluorosulfonated ionomer used to create a stable, selective membrane on the electrode; it cation and can prevent fouling. | Added to the modifying ink to stabilize the sensing interface and improve reproducibility [12] [16]. |

| Cysteine | A chelating agent containing thiol and amino groups that can selectively pre-concentrate target metal ions like Cd²⁺ on the electrode surface. | Incorporated into the MOF(Bi) sensor to enhance the accumulation of cadmium ions [16]. |

| Acetate Buffer (pH ~4.5) | A common supporting electrolyte that provides a consistent ionic strength and optimal acidic pH for the analysis of heavy metals like Cd and Pb. | Standard medium for anodic stripping voltammetry measurements of cadmium [12] [6]. |

Comparative Analysis and Discussion

Toxicity and Environmental Impact

The most significant distinction lies in toxicity. Mercury is highly toxic, necessitating stringent safety protocols for its use and disposal, which has led to its phase-out in many laboratories. Both bismuth and antimony present themselves as "environmentally friendly" and "low-toxicity" alternatives, with bismuth often being highlighted for its very low toxicity and status as a "non-toxic" element [6]. This makes BiFEs and SbFEs preferable for routine analysis and field deployments.

Analytical Performance

As the data in Table 1 shows, both BiFEs and SbFEs can achieve detection limits well below 1 μg L⁻¹ for cadmium, which is sufficient for monitoring compliance with regulatory limits in water and food. The MOF(Bi)-based sensor demonstrates an exceptionally low detection limit of 0.18 μg L⁻¹ [16]. A key operational advantage of both SbFEs and BiFEs is their ability to function effectively without the need for rigorous deoxygenation of the analytical solution, which streamlines the analytical procedure compared to some traditional methods [6].

Interference and Applicability

Both electrode types exhibit good resistance to common interferences. Studies on BiFEs have shown that cations like Cr³⁺, Mn²⁺, Zn²⁺, Ca²⁺, K⁺, Mg²⁺, and Na⁺ have no significant influence on the determination of Cd²⁺ ions [6]. However, the presence of Cu²⁺ can be a significant interferent in the analysis of Cd²⁺ on various electrodes, including gold nanocluster-modified sensors [17]. The choice between SbFE and BiFE can be matrix-dependent. For instance, the Sb/CMWCNTs@Nafion sensor demonstrated excellent recovery rates in complex biological samples like urine [12], whereas the MOF(Bi) sensor was successfully applied to the analysis of tea infusions [16].

Diagram 2: Cadmium analysis by anodic stripping.

The Critical Role of Accumulation in the ASV Process

Anodic Stripping Voltammetry (ASV) is a powerful electrochemical technique renowned for its exceptional sensitivity in detecting trace levels of heavy metals. The process is biphasic, comprising an electrochemical deposition step where metal ions are reduced and preconcentrated onto the working electrode surface, followed by a stripping step where the deposited metals are re-oxidized, producing a quantifiable current signal. The accumulation step is not merely a preliminary phase; it is the critical foundation that determines the analytical sensitivity, detection limit, and overall success of the ASV measurement. This application note delves into the optimization of this crucial stage, framed within research focused on the analysis of cadmium using antimony film electrodes (SbFEs)—an environmentally friendly alternative to traditional mercury-based electrodes.

Theoretical Foundations of Accumulation

The accumulation step in ASV is a dynamic interplay of mass transport and electrochemical kinetics. During this preconcentration phase, target metal ions, such as Cd(II), migrate from the bulk solution to the electrode surface, where they are reduced and amalgamated into the antimony film. The relationship between accumulation time and the resulting stripping current is often linear at lower concentrations, as the surface coverage of the deposited metal is minimal. The remarkable sensitivity of ASV stems directly from this effect, as it allows for the measurement of a strong stripping signal from a dilute solution.

For antimony film electrodes, this process involves the co-deposition or in-situ plating of antimony alongside the target analytes. The SbFE provides a favorable environment for the deposition of metals like cadmium and lead, forming well-defined peaks during the stripping phase. Its performance in acidic media and its insensitivity to dissolved oxygen further simplify the analytical procedure [7] [18] [19].

Quantitative Data on Accumulation Optimization

The optimization of accumulation parameters is empirically driven. The data below, compiled from key studies, provides a benchmark for developing a method for cadmium detection on SbFEs.

Table 1: Optimized Accumulation Parameters for Cadmium Detection on Antimony-Based Electrodes

| Electrode Type | Deposition Potential (V) | Optimal Accumulation Time (s) | Supporting Electrolyte | Achieved LOD for Cd(II) | Reference |

|---|---|---|---|---|---|

| Sb Film / NaMM-CPE* | -1.4 V (vs. Ag/AgCl) | 180 | 0.01 M HCl | 0.25 μg L⁻¹ | [5] |

| In-situ SbSPCE | -1.2 V | 120 | Acetate Buffer (pH 4.5) | Low μg L⁻¹ range | [7] |

| Injection Molded SbFE | -1.2 V (vs. Ag/AgCl) | 240 | 0.01 M HCl | 1.3 μg L⁻¹ | [19] |

| Sb/NaMM-CPE | -1.4 V (vs. Ag/AgCl) | 300 | 0.01 M HCl | ~0.3 μg L⁻¹ (estimated from graph) | [5] |

NaMM-CPE: Sodium Montmorillonite doped Carbon Paste Electrode *SbSPCE: Antimony Screen-Printed Carbon Electrode

Table 2: Interference Study on the Sb/NaMM-CPE for Cd(II) Detection Data from [5], 50.0 μg L⁻¹ Cd(II) in 0.01 M HCl, 180 s accumulation

| Interferent Ion | Tolerance Limit (Concentration Ratio vs. Cd(II)) | Effect on Cd(II) Signal |

|---|---|---|

| Zn(II) | 20 | Negligible change |

| Cu(II) | 2 | Significant depression of Cd peak |

| Pb(II) | 20 | Negligible change |

| Fe(III) | 20 | Negligible change |

Detailed Experimental Protocol

This protocol details the simultaneous determination of Cd(II) and Pb(II) using an in-situ plated antimony film electrode, adapted from established methodologies [7] [19].

Materials and Reagents

Table 3: Research Reagent Solutions and Essential Materials

| Item | Function / Explanation |

|---|---|

| Screen-Printed Carbon Electrode (SPCE) | Disposable substrate; provides a reproducible, polished-free surface for analysis. |

| Antimony(III) Stock Solution (1000 mg L⁻¹) | Source of antimony for in-situ formation of the sensing film on the electrode. |

| Cd(II) & Pb(II) Standard Solutions | Analytical targets; used for calibration and sample analysis. |

| HCl or Acetate Buffer | Supporting electrolyte; provides ionic strength and controls pH. |

| Electrochemical Potentiostat | Instrument for applying controlled potentials and measuring current response. |

Step-by-Step Procedure

- Electrode Preparation: Use a commercial SPCE without any pretreatment. If using a solid electrode like glassy carbon, polish it meticulously with alumina slurry and rinse with distilled water.

- Solution Preparation: Transfer a known volume of the sample or standard solution into the electrochemical cell. Add the supporting electrolyte (e.g., 0.01 M HCl or acetate buffer pH 4.5) to the cell. Then, introduce the antimony film precursor by spiking the solution with Sb(III) stock solution to a final concentration of 2 mg L⁻¹ [19].

- Accumulation Step: Immerse the working, reference, and counter electrodes into the solution. Under stirred conditions, apply a deposition potential of -1.2 V (vs. Ag/AgCl) for a defined accumulation time (120-240 s). During this step, Sb(III), Cd(II), and Pb(II) ions are co-deposited onto the electrode surface as a metallic film.

- Equilibration: After the deposition time elapses, stop the stirring and allow the solution to become quiescent for a brief period (10 s). This minimizes the contribution of convective mass transport to the signal.

- Stripping Step: Initiate the voltammetric scan from -1.0 V to -0.2 V using the Square-Wave Anodic Stripping Voltammetry (SWASV) mode. Recommended parameters are: frequency, 25 Hz; pulse amplitude, 25 mV; step potential, 4 mV [19]. The oxidation (stripping) of the deposited metals will produce distinct peaks for Cd and Pb.

- Electrode Cleaning: After each measurement, apply a cleaning potential of +0.2 V for 30 s under stirring to completely oxidize and remove any residual antimony and target metals from the electrode surface, ensuring a fresh start for the next analysis [19].

Data Analysis

- Identification: Identify cadmium and lead based on their characteristic stripping potentials (typically around -0.8 V for Cd and -0.5 V for Pb vs. Ag/AgCl under these conditions).

- Quantification: Construct a calibration curve by plotting the peak current height (or area) against the concentration of the standard solutions. The concentration of Cd(II) in an unknown sample can be determined by interpolating its peak current onto this calibration curve.

Signaling Pathways and Workflow Visualization

The following diagram illustrates the core ASV process and the specific experimental workflow for the protocol described above.

Diagram 1: ASV Experimental Workflow. This diagram outlines the sequential steps for Cd(II) analysis using an in-situ antimony film electrode, highlighting the key electrochemical reactions during accumulation and stripping.

The accumulation step is undeniably the cornerstone of a highly sensitive ASV determination for cadmium using antimony film electrodes. Meticulous optimization of the deposition potential and accumulation time is paramount. As demonstrated, a deposition potential of -1.2 V and an accumulation time between 120 and 240 seconds provide a robust starting point for methods aiming to achieve detection limits in the sub-μg L⁻¹ range. The provided protocol, supported by quantitative data and a clear workflow, offers researchers a solid foundation for developing and optimizing reliable electrochemical methods for trace metal analysis in various sample matrices.

Fundamental Electrochemistry of Cadmium Stripping on Antimony Surfaces

The analysis of trace heavy metals, such as cadmium, is of paramount importance in environmental monitoring, industrial process control, and toxicological studies. Anodic stripping voltammetry (ASV) has emerged as a powerful electrochemical technique for trace metal detection due to its exceptional sensitivity and low detection limits. A critical advancement in ASV has been the development of environmentally friendly electrode materials to replace traditional mercury-based electrodes. Among these, antimony film electrodes (SbFEs) have demonstrated excellent electroanalytical performance, particularly in acidic media where other alternative electrodes may underperform [5] [20]. This application note details the fundamental electrode processes and provides optimized protocols for the analysis of cadmium using antimony-based electrodes, with specific focus on accumulation time optimization within a broader research context.

The favorable electrochemistry of cadmium at antimony surfaces stems from the formation of well-defined anodic stripping peaks and the electrode's ability to operate in solutions without dissolved oxygen removal [5]. Furthermore, the kinetics of cadmium electrode processes at antimony film electrodes, while slower than at bismuth film electrodes, still provide sufficient sensitivity for trace analysis [20]. When modified with materials such as sodium montmorillonite (NaMM), which offers strong cation exchange capacity and adsorptive characteristics, antimony film electrodes exhibit remarkable enhancement in sensitivity for cadmium detection [5].

Fundamental Electrode Mechanisms

The anodic stripping process of cadmium at antimony film electrodes involves distinct mechanistic pathways that directly influence analytical performance. Understanding these mechanisms is essential for method optimization and accurate interpretation of experimental data.

Reaction Mechanism

The electrode process for cadmium at SbFEs follows a simple anodic stripping mechanism without significant adsorption phenomena, unlike the processes observed at bismuth film electrodes where adsorption often plays a role [20]. The mechanism can be described in two fundamental steps:

Electrodeposition/Preconcentration Step: Cd²⁺ + 2e⁻ → Cd(Sb)

Stripping Step: Cd(Sb) → Cd²⁺ + 2e⁻

During the deposition step, cadmium ions are reduced and form an alloy or intermetallic compound with the antimony film, denoted as Cd(Sb). The subsequent anodic stripping step involves the oxidation of this deposited cadmium back into solution, generating the analytical signal. Research comparing electrode mechanisms has revealed that the electrode kinetics for cadmium at antimony film electrodes, while favorable, are generally slower than those observed at bismuth film electrodes [20].

Comparative Electrode Kinetics

The standard rate constants for electron transfer processes at antimony and bismuth film electrodes provide insight into their relative performance:

Table 1: Comparative Electrode Kinetics of Heavy Metals at Film Electrodes

| Electrode Type | Analyte | Standard Rate Constant (cm s⁻¹) | Mechanistic Characteristics |

|---|---|---|---|

| Antimony Film Electrode (SbFE) | Cd(II) | Slower than at BiFE | Simple anodic stripping mechanism without adsorption |

| Antimony Film Electrode (SbFE) | Pb(II) | Similar to Cd(II) | Simple anodic stripping mechanism without adsorption |

| Bismuth Film Electrode (BiFE) | Cd(II) | 1-3 | Mechanism involves adsorption phenomena |

| Bismuth Film Electrode (BiFE) | Pb(II) | 1-3 | Mechanism involves adsorption phenomena |

The data indicate that while bismuth film electrodes generally exhibit faster electrode kinetics, antimony film electrodes provide a simpler mechanistic pathway free from complicating adsorption effects, which can be advantageous for certain analytical applications [20].

Experimental Protocols

Reagents and Materials

Table 2: Essential Research Reagent Solutions

| Reagent/Solution | Function/Purpose | Typical Concentration/Preparation |

|---|---|---|

| Antimony Trichloride (SbCl₃) | Source for in-situ antimony film formation | 5.0 mg L⁻¹ (in supporting electrolyte) [5] |

| Sodium Montmorillonite (NaMM) | Electrode modifier enhancing cation exchange and adsorption | Doped in carbon paste (10%, w/w) [5] |

| Acetate Buffer | Supporting electrolyte, pH control | 0.1 mol L⁻¹, pH 3.0-4.6 [8] |

| Hydrochloric Acid (HCl) | Acidic supporting electrolyte | pH 3.0 [5] |

| Cadmium Standard Solution | Primary analyte for calibration and analysis | Prepared from CdCl₂ in ultrapure water [5] |

| Carbon Paste | Electrode substrate material | Graphite powder and paraffin oil mixture [5] |

Electrode Preparation and Modification

Antimony Film Modified Sodium Montmorillonite Doped Carbon Paste Electrode (Sb/NaMM-CPE)

- Carbon Paste Preparation: Thoroughly mix graphite powder with sodium montmorillonite (10% w/w) in a mortar. Add appropriate paraffin oil and mix until a homogeneous paste is obtained [5].

- Electrode Packing: Pack the resulting paste firmly into an electrode sleeve (e.g., 3-mm diameter). Smooth the surface against clean paper to create a flat, renewable electrode surface.

- Antimony Film Deposition (in-situ): Immerse the prepared electrode in a supporting electrolyte containing 5.0 mg L⁻¹ Sb(III) and the target cadmium ions. Apply a deposition potential of -1.2 V vs. Ag/AgCl for 120 seconds with stirring to co-deposit the antimony film and cadmium simultaneously [5].

Solid Bismuth Microelectrode (for Comparison Studies)

- Electrode Activation: Before each measurement, activate the solid bismuth microelectrode by applying a potential of -2.4 V for 20 seconds in acetate buffer (pH 3.0) to reduce any surface oxide layers [8].

- Conditioning: The activated electrode is ready for immediate use in cadmium determination without additional modification.

Square-Wave Anodic Stripping Voltammetry (SWASV) Procedure

The following protocol optimized for cadmium detection using Sb/NMM-CPE:

- Deposition/Accumulation Step: Apply a deposition potential of -1.2 V vs. Ag/AgCl to the working electrode for a predetermined accumulation time (typically 60-300 seconds) with solution stirring.

- Equilibrium Period: After deposition, stop stirring and allow the solution to equilibrate for 15 seconds while maintaining the deposition potential.

- Stripping Step: Record the square-wave voltammogram by scanning the potential from -1.1 V to -0.6 V vs. Ag/AgCl using the following parameters:

Optimization of Accumulation Time

Accumulation time represents a critical parameter in stripping analysis, directly influencing both sensitivity and the linear dynamic range of the method. Systematic optimization of this parameter is essential for developing robust analytical methods.

Effect on Analytical Signal

Research has demonstrated that cadmium peak currents increase linearly with accumulation time up to a certain limit, beyond which the response plateaus due to surface saturation effects [5]. For the Sb/NaMM-CPE system, the optimal accumulation time for cadmium detection in tap water samples was established at 120 seconds, providing an excellent balance between sensitivity and analysis time [5].

The relationship between accumulation time and cadmium signal follows a predictable pattern: initial linear increase, subsequent deviation from linearity, and eventual plateau. This profile must be characterized for each specific electrode system and medium to determine the optimal accumulation period for the intended analytical application.

Analytical Performance Under Optimized Conditions

Table 3: Analytical Performance of Cadmium at Sb/NaMM-CPE Under Optimized Conditions

| Parameter | Performance | Experimental Conditions |

|---|---|---|

| Linear Dynamic Range | 4.0–150.0 μg L⁻¹ | Square-wave ASV [5] |

| Detection Limit | 0.25 μg L⁻¹ | S/N = 3 [5] |

| Correlation Coefficient (R²) | 0.998 | Linear calibration [5] |

| Supporting Electrolyte | Hydrochloric acid, pH 3.0 | Acetate buffer also applicable [5] [8] |

| Relative Standard Deviation (RSD) | <5% | For 50.0 μg L⁻¹ Cd(II), n=5 [5] |

The exceptional sensitivity achieved with the Sb/NaMM-CPE electrode system is attributed to the synergistic combination of the strong cation exchange capacity of sodium montmorillonite and the favorable electroanalytical properties of the antimony film [5].

Experimental Workflow

The following diagram illustrates the complete experimental workflow for cadmium determination using antimony film electrodes, from electrode preparation through to data analysis:

Comparative Electrode Performance

The selection of electrode material significantly impacts the sensitivity and reliability of cadmium detection in stripping voltammetry.

Table 4: Comparison of Electrode Performance for Cadmium Detection

| Electrode Type | Peak Current for 50 μg L⁻¹ Cd(II) (Relative) | Key Advantages | Limitations |

|---|---|---|---|

| Sb/NaMM-CPE | 100% (Highest) | Excellent sensitivity, environmentally friendly, works in acidic media | Slower kinetics than BiFE [5] [20] |

| Bare CPE | ~25% | Simple construction, renewable surface | Poor sensitivity for trace analysis [5] |

| NaMM-CPE | ~45% | Enhanced cation exchange capacity | Limited without antimony film [5] |

| Sb/CPE | ~70% | Good sensitivity, mercury-free | Lower than Sb/NaMM-CPE [5] |

| Bismuth Film Electrode | ~90% (Comparative) | Fast electrode kinetics, environmentally friendly | Performance affected by adsorption [20] |

The superior performance of the Sb/NaMM-CPE is evident from the comparative data, confirming the significant signal enhancement achieved through the sodium montmorillonite modification [5].

Interference Studies

The antimony film electrode demonstrates excellent selectivity for cadmium detection in the presence of common interfering species:

- Dissolved Oxygen: Unlike many electrochemical systems, the SbFE exhibits insensitivity to dissolved oxygen, eliminating the need for solution deaeration [5].

- Common Cations: Studies with bismuth film electrodes on brass substrates have shown no significant interference from Cr³⁺, Mn²⁺, Zn²⁺, Ca²⁺, K⁺, Mg²⁺, and Na⁺ in cadmium determination [21]. Similar behavior is expected for antimony-based electrodes.

- Simultaneous Analysis: The SbFE allows for simultaneous detection of multiple heavy metals, including cadmium, lead, and zinc, with well-resolved stripping peaks in acidic media [20].

Applications

The developed methodology has been successfully applied to the determination of cadmium ions in tap water samples, demonstrating practical utility for environmental monitoring [5]. The robust performance in real sample matrices confirms the method's resistance to matrix effects and its suitability for routine analysis applications.

This application note has detailed the fundamental electrochemistry and optimized protocols for cadmium detection using antimony film electrodes. The key findings demonstrate that:

- Cadmium stripping at antimony surfaces follows a well-defined mechanism without complicating adsorption phenomena.

- Modification of carbon paste electrodes with sodium montmorillonite significantly enhances sensitivity through improved cation exchange and adsorption characteristics.

- Optimization of accumulation time is crucial for maximizing sensitivity while maintaining reasonable analysis time, with 120 seconds identified as optimal for the Sb/NaMM-CPE system.

- The Sb/NaMM-CPE platform provides exceptional analytical performance with a detection limit of 0.25 μg L⁻¹, suitable for trace cadmium analysis in environmental samples.

These findings contribute significantly to the broader thesis research on optimizing accumulation parameters for cadmium analysis, establishing antimony film electrodes as viable, high-performance alternatives for electrochemical heavy metal detection.

Fabricating and Operating Antimony Film Electrodes for Cadmium Analysis

The accurate electrochemical detection of cadmium, a prevalent and toxic environmental pollutant, is a critical task in analytical chemistry. The sensitivity, selectivity, and reproducibility of these determinations are fundamentally influenced by the choice of electrode substrate. Within the broader context of optimizing accumulation time for cadmium analysis on antimony film electrodes, selecting an appropriate substrate platform becomes paramount. This application note provides a detailed comparison of three common electrode substrates—carbon paste, glassy carbon, and screen-printed platforms—for the determination of cadmium using antimony film electrodes. We summarize key performance characteristics, provide standardized experimental protocols, and present essential methodological considerations to guide researchers in selecting the optimal substrate for their specific analytical requirements.

Comparative Analysis of Electrode Substrates

The selection of an electrode substrate significantly impacts the analytical performance of antimony film electrodes for cadmium detection. Each platform offers distinct advantages and limitations concerning reproducibility, cost, ease of modification, and suitability for field analysis.

Table 1: Comparative Characteristics of Electrode Substrates for Antimony Film Modification

| Substrate Type | Key Advantages | Limitations | Reported LOD for Cd²⁺ | Optimal Use Cases |

|---|---|---|---|---|

| Glassy Carbon (GCE) | Excellent mechanical rigidity, well-defined surface, high reproducibility, wide potential window [22]. | Requires careful surface polishing/pretreatment, higher cost, less suitable for mass production. | 0.38 μg·L⁻¹ (with Sb/CMWCNTs@Nafion) [12] | Laboratory-based research requiring high precision and reproducibility. |

| Screen-Printed Electrodes (SPE) | Disposable, low cost, portable, mass-producible, minimal sample volume, no pretreatment required [23] [24]. | Potential batch-to-batch variability, lower mechanical stability compared to GCE. | 4.80 μg·L⁻¹ (with Bismuth powder) [17] | On-site monitoring, portable sensors, and high-throughput analysis. |

| Carbon Paste (CPE) | Easily renewable surface, simple fabrication, low background current, facile modification. | Soft surface prone to mechanical damage, less robust flow systems, potential for memory effects. | Information not specified in search results. | Fundamental studies involving surface renewal and custom composite electrodes. |

Detailed Experimental Protocols

Protocol 1: Antimony Film Deposition on a Glassy Carbon Electrode (GCE)

This protocol details the modification of a GCE with an antimony film and carboxylated multi-walled carbon nanotubes (CMWCNTs) for the ultrasensitive simultaneous detection of cadmium and lead [12].

Research Reagent Solutions:

- Carboxylated Multi-Walled Carbon Nanotubes (CMWCNTs) Dispersion: Disperse CMWCNTs in a suitable solvent (e.g., DMF or water) via ultrasonication to create a homogeneous suspension. Function: Enhances surface area and electron transfer kinetics.

- Nafion Perfluorinated Resin Solution: A 0.5% w/w solution in low-alcohol solvent. Function: Binder that improves adhesion of the modifier layer and provides ion-exchange properties.

- Antimony Film Plating Solution: 2-10 mg·L⁻¹ of Sb(III) in 0.1 M HCl. Function: Source of antimony for the potentiostatic deposition of the sensing film.

Step-by-Step Procedure:

- GCE Pretreatment: Polish the glassy carbon working electrode sequentially with 1.0, 0.3, and 0.05 μm alumina slurry on a microcloth pad. Rinse thoroughly with deionized water between each polish and after the final polish.

- CMWCNTs@Nafion Modification: Mix the prepared CMWCNTs dispersion with the Nafion solution to achieve a final Nafion concentration of approximately 0.05%. Deposit a precise volume (e.g., 5-10 μL) of this composite onto the clean GCE surface and allow it to dry under ambient conditions or under an infrared lamp.

- Antimony Film Deposition: Immerse the modified GCE in the antimony plating solution. Perform potentiostatic deposition at a potential of -1.0 V to -1.2 V (vs. Ag/AgCl) for 60-120 seconds under stirring.

- Electrode Conditioning: Rinse the modified electrode (Sb/CMWCNTs@Nafion-GCE) gently with deionized water and transfer it to the supporting electrolyte (e.g., acetate buffer, pH 4.35). Cycle the potential over a suitable range (e.g., -1.0 V to 0 V) using cyclic voltammetry until a stable baseline is achieved.

Protocol 2: Cadmium Detection via Anodic Stripping Voltammetry

This protocol describes the quantification of cadmium using the modified antimony film electrode, with a focus on optimizing the accumulation step [12].

Research Reagent Solutions:

- Acetate Buffer (0.1 M, pH 4.35): Used as the supporting electrolyte. Function: Maintains a consistent pH, which is critical for the stability of the antimony film and the efficiency of metal deposition.

- Cadmium Standard Solution: A 1000 mg·L⁻¹ stock solution of Cd²⁺ in 2% nitric acid. Function: Used for preparing calibration standards and spiking samples.

- Oxygen-Free Nitrogen Gas: Function: For deaeration of the solution to remove dissolved oxygen, which can interfere with the stripping signal.

Step-by-Step Procedure:

- Solution Preparation: Transfer a known volume of the sample or standard solution (e.g., 10 mL) into the electrochemical cell. Add the acetate buffer to achieve the desired supporting electrolyte concentration.

- Deaeration: Purge the solution with nitrogen gas for 8-10 minutes prior to analysis to remove dissolved oxygen. Maintain a nitrogen blanket over the solution during measurement.

- Optimization of Accumulation Time: A key parameter in the thesis context. Test a range of accumulation times (e.g., 60-600 seconds) at a fixed accumulation potential (e.g., -1.2 V vs. Ag/AgCl) under stirring. The optimal time provides a strong, reproducible signal without leading to saturation of the electrode surface.

- Metal Deposition (Accumulation): Apply the optimized accumulation potential and time to the working electrode while the solution is stirred.

- Equilibrium Period: Stop stirring and allow the solution to become quiescent for a short period (e.g., 15 seconds) before the stripping step.

- Stripping Scan: Record the stripping voltammogram using a sensitive technique such as Differential Pulse Stripping Voltammetry (DPSV) or Square-Wave Stripping Voltammetry (SWSV). A typical scan for cadmium may run from -1.0 V to -0.4 V.

- Electrode Cleaning: Apply a cleaning potential (e.g., +0.3 V) for 30-60 seconds after each measurement to ensure complete removal of residual metals from the film.

The workflow for the electrode modification and analysis process is summarized below.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Reagents and Materials for Antimony Film Electrode Preparation and Cadmium Detection

| Reagent/Material | Function / Role | Example Specification / Notes |

|---|---|---|

| Antimony(III) Chloride (SbCl₃) | Source of Sb(III) ions for film formation. | Purity ≥ 99.9%; Prepare fresh plating solution in 0.1 M HCl to prevent hydrolysis. |

| Carboxylated Multi-Walled Carbon Nanotubes (CMWCNTs) | Nanomaterial modifier to increase electrode surface area and enhance electron transfer [12]. | Outer diameter: 10-20 nm; Functionalized with -COOH groups. |

| Nafion Perfluorinated Resin | Cation exchanger and binder to immobilize modifiers on the electrode surface [12]. | 5% w/w solution in lower aliphatic alcohols; typically diluted to 0.05-0.5% for use. |

| Acetate Buffer | Supporting electrolyte to control pH and ionic strength during analysis [6] [12]. | 0.1 M, pH 4.35; Optimal for Cd²⁺ analysis without damaging the Sb film. |

| Cadmium Standard Solution | For calibration curve preparation and method validation. | Traceable to NIST, 1000 mg L⁻¹ in 2% HNO₃. |

| Alumina Polishing Slurry | For renewing and cleaning the surface of glassy carbon electrodes. | Aqueous suspensions of 1.0, 0.3, and 0.05 μm α-Al₂O₃ particles. |

Critical Methodological Considerations

Interference and Real-Sample Analysis

The presence of co-existing ions is a significant challenge in real-sample analysis. Studies on bismuth-film electrodes have shown that common cations like Cr³⁺, Mn²⁺, Zn²⁺, Ca²⁺, K⁺, Mg²⁺, and Na⁺ may have no significant influence on the determination of Cd²⁺ ions [6]. However, other research indicates that Cu²⁺ can cause significant interference in the simultaneous detection of heavy metals [17]. Therefore, for complex matrices such as urine [12] or wastewater, the standard addition method is strongly recommended to compensate for matrix effects. Furthermore, the application of selective membranes or the use of complexing agents can help mitigate specific interferent effects.

Substrate Selection and Optimization

The choice of substrate is integral to the overall sensor design and performance. Screen-printed electrodes (SPEs) represent a powerful platform for decentralized analysis due to their disposability and miniaturization potential [24] [25]. Recent advances include the use of chemical vapor deposition to create glassy carbon SPEs compatible with organic solvents, broadening their application scope [22]. When optimizing accumulation time—a central theme of the thesis context—it is crucial to recognize that the optimal duration is substrate-dependent. A porous carbon paste or a nanomaterial-modified GCE may tolerate longer accumulation times before surface saturation, compared to a planar, unmodified SPE. A systematic study of the anodic stripping peak current as a function of accumulation time should be conducted for each specific substrate-modifier combination to find the ideal compromise between sensitivity and analysis time.

Establishing a Standard Square-Wave ASV (SWASV) Protocol

Square-Wave Anodic Stripping Voltammetry (SWASV) is a powerful electrochemical technique renowned for its exceptional sensitivity in quantifying trace levels of heavy metals, such as cadmium. This protocol details the establishment of a standardized SWASV method for cadmium analysis using an antimony film electrode (SbFE), framed within research focused on optimizing the accumulation time. The replacement of traditional mercury electrodes with environmentally friendly antimony films provides a robust, sensitive, and sustainable platform for trace metal detection [5] [26]. Optimizing the accumulation step is critical, as it directly influences the amount of cadmium preconcentrated onto the electrode, thereby dictating the sensitivity and detection limit of the entire analytical procedure [5] [27].

Theoretical Background and Principles

Anodic Stripping Voltammetry operates on a two-step principle: electrodeposition and stripping. During the deposition phase, a negative potential is applied to the working electrode, reducing cadmium ions (Cd²⁺) in the solution to its metallic state (Cd⁰) and depositing it onto the electrode surface, often forming an alloy with the antimony film. This step preconcentrates the analyte onto the electrode. Subsequently, during the stripping phase, the potential is swept in an anodic (positive) direction, oxidizing the deposited metal back into its ionic form and releasing it into the solution. The resulting current is measured, with the peak current being proportional to the concentration of the analyte in the original solution [26]. The square-wave mode enhances sensitivity by minimizing capacitive currents.

The choice of antimony as a film material is driven by its excellent electroanalytical performance, which includes high sensitivity, well-defined stripping signals, and favorable performance in acidic media. Furthermore, its ability to be co-deposited with the analyte onto various substrates simplifies the sensor fabrication process [5] [27].

Research Reagent Solutions and Essential Materials

The following table catalogues the key reagents and materials required for the preparation of the antimony film electrode and the subsequent SWASV analysis of cadmium.

Table 1: Essential Research Reagents and Materials

| Item Name | Specification / Example | Primary Function in Protocol |

|---|---|---|

| Antimony Trichloride (SbCl₃) | Purity: Analytical Reagent Grade [5] | Source of Sb(III) ions for the in-situ formation of the antimony film on the electrode substrate. |

| Cadmium Standard Solution | Certified reference material, e.g., CdCl₂ [6] [27] | Provides a known concentration of Cd(II) ions for calibration curves and method validation. |

| Supporting Electrolyte | 0.1 M Hydrochloric Acid (HCl) [5] [11] | Provides conductivity, sets the pH for optimal deposition/stripping, and suppresses hydrolysis of Sb(III). |

| Graphite Powder | Spectrum pure [27] | Conductive component for fabricating carbon paste electrodes (CPEs). |

| Binder / Paster | Paraffin oil [5] [27] | Binds graphite powder to form a homogeneous carbon paste for CPEs. |

| Electrode Modifier | Sodium Montmorillonite (NaMM) [5] or Modified Fly Ash (MFA) [27] | Enhances sensitivity and cation exchange capacity at the electrode surface, improving cadmium accumulation. |

| pH Adjustment | Dilute NaOH and HNO₃ solutions [27] | To adjust the pH of the measurement solution to the optimal range (e.g., pH 3.0-4.35). |

| Ultrasonic Cleaner | N/A | For the modification of materials like fly ash and ensuring homogeneous mixing of electrode pastes [27]. |

Standardized SWASV Protocol for Cadmium Detection

Equipment and Electrode Setup

- Electrochemical Workstation: A potentiostat capable of performing SWASV, Cyclic Voltammetry (CV), and Electrochemical Impedance Spectroscopy (EIS) [27].

- Electrochemical Cell: A standard 20 mL three-electrode cell [27].

- Working Electrode: Antimony film modified carbon paste electrode (SbF-CPE). The substrate can be doped with modifiers like sodium montmorillonite (NaMM) [5] or modified fly ash (MFA) [27] for enhanced performance.

- Counter Electrode: Platinum wire [5] [27].

- Reference Electrode: Ag/AgCl [27] or Saturated Calomel Electrode (SCE) [6].

Electrode Preparation and Modification

- Substrate Electrode Fabrication: For a carbon paste electrode (CPE), thoroughly homogenize graphite powder with a modifier (e.g., 4.0 mg NaMM or MFA per 200.0 mg graphite powder) and a binder (e.g., 80.0 μL paraffin oil) in an agate mortar. The prepared paste is packed into an electrode body and dried at room temperature [5] [27].

- Surface Renewal: Before each measurement, polish the electrode surface on a clean weighing paper to obtain a smooth, fresh surface [27].

- Antimony Film Formation (In-situ): The antimony film is typically formed in-situ by adding Sb(III) directly to the sample/measurement solution. A common concentration is 5.0 mg L⁻¹ Sb(III) in a hydrochloric acid medium (pH ~3.0). The film is deposited onto the substrate electrode during the pre-concentration step alongside the target cadmium ions [5].

SWASV Measurement Procedure

The following workflow outlines the core steps of the SWASV analysis, with a focus on the accumulation phase which is the target of optimization studies.

Diagram 1: Experimental workflow for the standard SWASV protocol.

- Solution Preparation: Transfer the sample or standard solution (e.g., in 0.1 M HCl, pH 3.0) containing Cd(II) and Sb(III) to the electrochemical cell [5] [27].

- Accumulation/Deposition: With solution stirring, apply a deposition potential of -1.2 V (vs. Ag/AgCl) for a defined deposition time. This time is the key parameter for optimization in the broader thesis context. Common ranges explored are from 180 s to 300 s [5] [6]. The deposition potential and time control the amount of Cd and Sb deposited onto the electrode.

- Equilibration: Stop stirring and allow the solution to become quiescent for a short period (e.g., 10 s) while maintaining the deposition potential [27].

- Stripping: Initiate the square-wave anodic stripping voltammogram scan from a negative potential (e.g., -1.2 V) to a more positive potential (e.g., -0.2 V or 0.2 V). Key SWV parameters include a pulse amplitude of 50 mV, a frequency of 25 Hz, and a step potential of 5 mV [5] [27].

- Electrode Cleanup: Apply a conditioning potential (e.g., 0.3 V) with stirring for 30 s to completely strip any residual metals and the antimony film from the electrode surface, preparing it for the next measurement cycle [27].

Optimization of Accumulation Time

The core research objective is to optimize the accumulation time. This involves running the above protocol with a fixed concentration of Cd(II) while systematically varying the deposition time. The resulting peak currents are then plotted against the deposition time to identify the point where the signal begins to plateau, indicating surface saturation or the optimal balance between sensitivity and analysis time [5] [27]. Other parameters like deposition potential and Sb(III) concentration should be fixed at their previously established optimal values during this specific investigation.

Performance Data and Comparative Analysis

The following table synthesizes key performance metrics from studies utilizing antimony-based film electrodes for cadmium detection, providing a benchmark for the expected outcomes of this standardized protocol.

Table 2: Comparative Analytical Performance of Antimony-based Electrodes for Cd(II) Detection

| Electrode Type | Linear Range (μg L⁻¹) | Detection Limit (μg L⁻¹) | Optimal Deposition Time (s) | Key Experimental Conditions | Reference |

|---|---|---|---|---|---|

| Sb/NaMM-CPE | 4.0 – 150.0 | 0.25 | 280 | HCl solution (pH 3.0); Dep. Pot.: -1.2 V | [5] |

| Bi–SbFE/GCE | 1.0 – 220.0 | 0.15 | 180 | HCl solution (pH 2.0) | [11] |

| Sb/MMFA-CPE | Not explicitly stated (Wider range reported) | Lower than Sb/MFA-CPE | 280 | Acetate buffer (pH 5.0); Dep. Pot.: -1.2 V | [27] |

| Sb-Bi/MMFA-CPE | Not explicitly stated (Wider range reported) | Lower than Sb/MFA-CPE | 280 | Acetate buffer (pH 5.0); Dep. Pot.: -1.2 V | [27] |

Troubleshooting and Best Practices

- Passivation and Reproducibility: To ensure consistent results and avoid electrode passivation, a rigorous electrode cleanup step is essential between measurements. The use of an in-situ internal standard, such as the bismuth signal in a Bi-Sb alloy electrode, has been shown to improve precision and compensate for random variations between measurements [28].

- Interference Studies: The protocol's selectivity can be validated by testing common cationic interferents (e.g., Zn²⁺, Cu²⁺, Pb²⁺, Ca²⁺, Na⁺). Research indicates that well-optimized SbFEs can show no significant interference from many of these ions, making them suitable for real-sample analysis [6].

- Calibration Method: For improved accuracy, especially with complex matrices, the single-point standard addition with internal standard (SSA-IS) calibration method is recommended over multi-point external calibration. This approach has demonstrated superior trueness and precision in cadmium quantification using film electrodes [28].

Application to Real Samples

This standardized protocol is designed for application in environmental monitoring. The method can be successfully applied to determine trace levels of cadmium in real water samples, such as tap water [5] and lake water [6] [17]. For complex matrices, a simple dilution with the supporting electrolyte (e.g., HCl or acetate buffer) is often sufficient prior to analysis [6]. The accuracy of the method should be verified using spike-recovery tests, with recoveries ranging from 90–115% being indicative of a reliable and robust protocol [17].

Preparation of Acetate and HCl Supporting Electrolytes for Cadmium Detection

Within the broader scope of thesis research focused on optimizing accumulation time for cadmium analysis using antimony film electrodes (SbFEs), the selection and preparation of the supporting electrolyte are critical foundational steps. The supporting electrolyte plays a multifaceted role: it decreases the solution resistance, defines the ionic strength, and influences the efficiency of both the electrodeposition and the stripping steps in anodic stripping voltammetry (ASV). The chemical composition and pH of the electrolyte can significantly affect the morphology of the antimony film during its in-situ or ex-situ plating, the stability of the deposited cadmium, and the ultimate sensitivity and reproducibility of the analytical signal. This protocol details the preparation of two of the most prevalent and effective supporting electrolytes for cadmium detection on SbFEs: an acetate buffer and hydrochloric acid (HCl). The procedures are framed within the context of a systematic investigation into how accumulation time interacts with the electrolyte matrix to maximize the stripping signal for trace-level cadmium.

Research Reagent Solutions

The following table catalogues the essential reagents required for the preparation of the supporting electrolytes and the subsequent electrochemical measurement of cadmium.

Table 1: Essential Research Reagents and Materials

| Reagent/Material | Typical Purity | Primary Function in the Protocol |

|---|---|---|

| Glacial Acetic Acid (CH₃COOH) | Analytical Grade | Component of the acetate buffer system; provides the weak acid for a defined pH. |

| Sodium Acetate (CH₃COONa) | Analytical Grade | Component of the acetate buffer system; provides the conjugate base for a defined pH. |

| Hydrochloric Acid (HCl) | Analytical Grade, 37% | Provides a strongly acidic electrolyte medium; the chloride ions can influence metal deposition. |

| Antimony(III) Chloride (SbCl₃) | Analytical Grade | Source of Sb(III) ions for the in-situ formation of the antimony film on the working electrode. |

| Cadmium Standard Solution | Certified Reference Material | Primary standard for calibration and method validation, typically at 1000 mg/L concentration. |

| Sodium Hydroxide (NaOH) | Analytical Grade | Used for fine pH adjustment of prepared solutions, if necessary. |

| Deionized Water | Resistivity ≥18.2 MΩ·cm | Solvent for all aqueous solutions; high purity is essential to minimize contamination. |

Protocol: Preparation of Supporting Electrolytes

Acetate Buffer Solution (0.1 M, pH ~4.5)

The acetate buffer is a widely used medium for heavy metal detection using environmentally friendly film electrodes like antimony and bismuth [29]. Its mildly acidic nature provides a good compromise for stable film formation and efficient metal deposition.

Experimental Methodology:

- Weighing: Weigh approximately 8.20 g of anhydrous sodium acetate (CH₃COONa, MW = 82.03 g/mol) using an analytical balance.

- Dissolution: Transfer the sodium acetate to a 1000 mL volumetric flask and dissolve it in approximately 800 mL of deionized water.

- pH Adjustment: Using a calibrated pH meter, adjust the pH of the solution to the target value. The optimal pH for cadmium detection in acetate buffer is typically between 4.0 and 4.6 [6] [30] [29]. To achieve pH 4.5, carefully add glacial acetic acid while stirring continuously and monitoring the pH. The required volume is typically between 4-6 mL.

- Final Volume: Make up the solution to the final volume of 1000 mL with deionized water and mix thoroughly.

- Verification: Confirm the final pH of the buffer solution. Store the solution in a clean, sealed polyethylene or glass bottle at room temperature. The solution is stable for several months.

Hydrochloric Acid Electrolyte (0.01 M - 0.5 M)

Hydrochloric acid provides a strongly acidic electrolyte that is highly effective for the in-situ plating of antimony films and the subsequent detection of cadmium [31] [32]. The low pH suppresses hydrolysis of metal ions and is suitable for analyses requiring high acidity.

Experimental Methodology:

- For 0.1 M HCl:

- Safety Precautions: Don appropriate personal protective equipment (PPE), including a lab coat, safety goggles, and acid-resistant gloves. Perform this step in a fume hood.

- Dilution: Slowly and carefully add 8.3 mL of concentrated hydrochloric acid (HCl, ~37%, density ~1.19 g/mL) into approximately 800 mL of deionized water in a 1000 mL volumetric flask. Always add acid to water, never the reverse.

- Final Volume: After the solution cools to room temperature, dilute to the 1000 mL mark with deionized water and mix thoroughly.

- For 0.01 M HCl: Dilute 0.83 mL of concentrated HCl to 1000 mL with deionized water, following the safety precautions above [32].

- For 0.5 M HCl: Dilute 41.5 mL of concentrated HCl to 1000 mL with deionized water, following the safety precautions above [31].

Electroanalytical Performance Data

The choice of supporting electrolyte directly impacts key analytical performance metrics for cadmium detection. The following table summarizes typical performance data for SbFEs in the two prepared electrolytes, which should be considered when optimizing accumulation time.

Table 2: Comparative Electroanalytical Performance for Cadmium Detection in Different Supporting Electrolytes

| Electrolyte | Typical Concentration | Optimal Deposition Potential (vs. Ag/AgCl) | Linear Range (Cd²⁺) | Limit of Detection (Cd²⁺) | Key Advantages / Applications |

|---|---|---|---|---|---|

| HCl | 0.01 M - 0.5 M | -1.2 V to -1.5 V | 1 - 250 μg/L [33] | 0.78 - 1.4 μg/L [31] [34] | Ideal for in-situ SbFE plating; well-defined stripping peaks; suitable for flow-injection systems [31]. |

| Acetate Buffer | 0.1 M, pH ~4.5 | -1.0 V to -1.2 V | 2 - 100 μg/L [12] | 0.10 - 0.38 μg/L [12] [30] | Lower background current; compatible with a wider range of electrode materials; common in disposable sensor applications [30] [29]. |

Integrated Experimental Workflow for Cadmium Analysis

The diagram below illustrates the complete experimental workflow, from electrolyte preparation to the final voltammetric measurement, highlighting where the supporting electrolyte is utilized.

Systematic Procedure for Accumulation Step Execution