Optimized Protocol for Bismuth Film Electrode Preparation and Application in Sensitive Lead Detection

This article provides a comprehensive guide for researchers and scientists on the preparation, optimization, and application of bismuth film electrodes (BiFEs) for the sensitive detection of lead.

Optimized Protocol for Bismuth Film Electrode Preparation and Application in Sensitive Lead Detection

Abstract

This article provides a comprehensive guide for researchers and scientists on the preparation, optimization, and application of bismuth film electrodes (BiFEs) for the sensitive detection of lead. It covers the foundational principles of bismuth as an environmentally friendly alternative to mercury, detailed methodological protocols for electrode fabrication, advanced strategies for performance optimization and troubleshooting, and rigorous procedures for method validation and comparison with established techniques like atomic absorption spectroscopy. The content is tailored to support the development of reliable, high-performance electrochemical sensors for environmental monitoring, clinical analysis, and drug development.

Bismuth Film Electrodes: A Foundational Guide to an Eco-Friendly Mercury Alternative

Fundamental Advantages of Bismuth Film Electrodes

Bismuth Film Electrodes (BiFEs) have emerged as a premier environmentally-friendly platform for the electrochemical detection of heavy metals, effectively addressing the toxicity concerns associated with traditional mercury electrodes while maintaining excellent analytical performance [1].

Table 1: Key Advantages of Bismuth Film Electrodes over Mercury Electrodes

| Advantage | Description | Practical Implication |

|---|---|---|

| Low Toxicity | Bismuth and its salts exhibit negligible toxicity and are environmentally safe [1] [2]. | Enables fieldwork and reduces hazardous waste disposal concerns. |

| Insensitivity to Dissolved Oxygen | Detection can be performed without removing dissolved oxygen from the test medium [3] [4]. | Simplifies and speeds up the measurement process; attractive for practical applications. |

| Wide Potential Window | Offers a useful potential window in the cathodic region with a low background current [1] [5]. | Suitable for detecting elements that are reduced at negative potentials. |

| Ability to Form Alloys | Bismuth functions similarly to mercury by forming "fused" alloys with heavy metals [1] [5]. | Facilitates the preconcentration of target metals during stripping analysis, enhancing sensitivity. |

| Versatile Substrate Application | Bismuth films can be plated on various substrates like carbon, gold, and brass [3] [6] [7]. | Allows for flexibility in sensor design and cost-effective manufacturing. |

Protocols for Preparation and Modification of BiFEs

The performance of a BiFE is highly dependent on the preparation method and the nature of the substrate. The following protocols detail established methodologies for fabricating high-performance BiFEs.

Protocol: In-situ Bismuth Film Formation on Screen-Printed Electrodes

This protocol is adapted from studies on screen-printed electrodes (SPEs) and is ideal for disposable, single-use sensors [1].

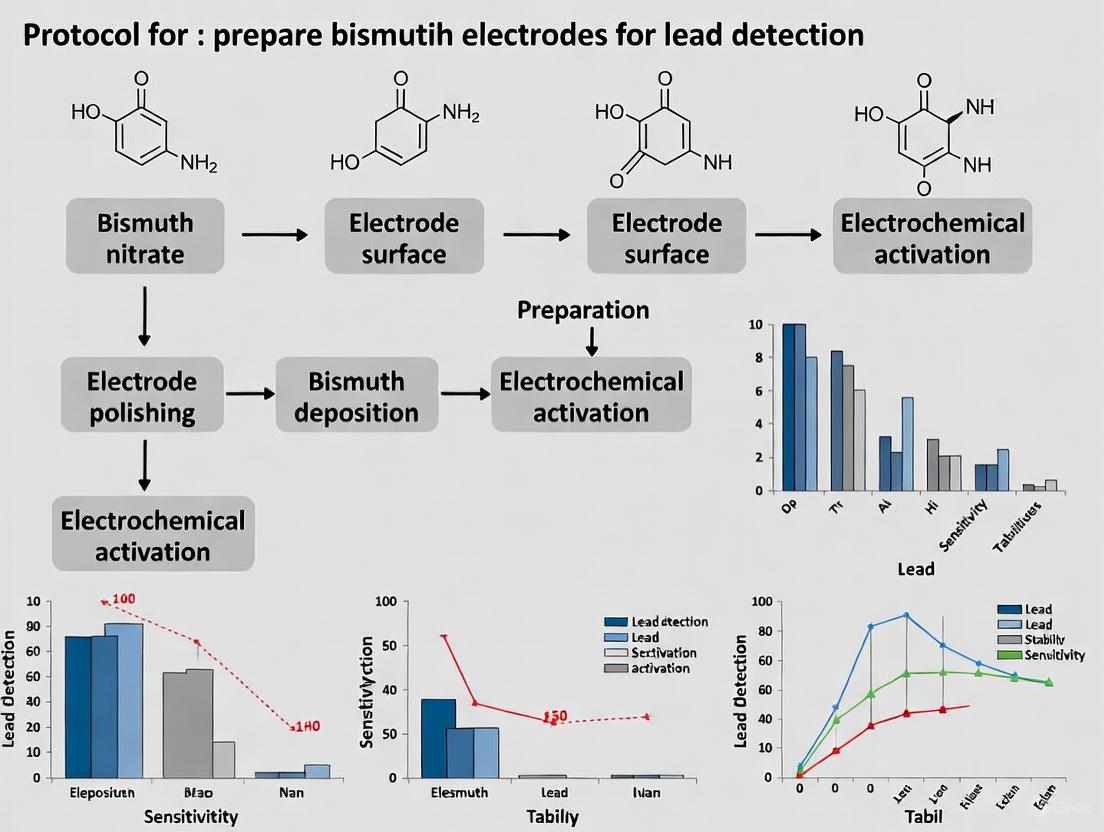

Workflow Overview:

Detailed Procedure:

- Electrode Pretreatment: Choose one of the following oxidative pre-treatments to clean and activate the carbon surface of the SPE:

- Rinsing: Rinse the pre-treated electrode thoroughly with deionized (DI) water.

- Film Deposition and Analysis: Immerse the electrode in the sample analysis solution, which contains the target analytes (e.g., Pb²⁺, Cd²⁺) and a bismuth salt (e.g., 0.1 mM Bi³⁺). Apply a deposition potential of -1.20 V for 30 seconds. During this step, both bismuth and the target heavy metals are co-deposited onto the electrode surface as an alloy. Immediately proceed with the anodic stripping voltammetry measurement [1].

Protocol: Ex-situ Bismuth Film Formation on a Brass Substrate

This protocol details the ex-situ formation of a bismuth film on a brass electrode, which can be stored and used for multiple analyses [6] [7].

Workflow Overview:

Detailed Procedure:

- Substrate Preparation: Polish the brass (Cu37Zn) electrode with 0.3 μm alumina slurry until a mirror-smooth surface is obtained. Rinse thoroughly with distilled water and air-dry [6] [7].

- Film Deposition: Prepare a deposition solution of 1 M HCl with the addition of 0.02 M Bi³⁺ (from Bismuth(III) nitrate pentahydrate). Immerse the prepared brass electrode and deposit the bismuth film using chronoamperometry at a constant potential of -0.15 V (vs. a Saturated Calomel Electrode, SCE) for 300 seconds [6] [7].

- Electrode Storage: After deposition, rinse the electrode with distilled water and air-dry. The electrode is now ready for use in square-wave anodic stripping voltammetry (SWASV) measurements.

Protocol: Under-Potential Deposition (UPD) of Bismuth on Gold Film

This advanced protocol creates a bismuth sub-monolayer on a gold electrode, enhancing sensitivity for specific applications like lead detection [3] [4].

Workflow Overview:

Detailed Procedure:

- Gold Electrode Pretreatment: Subject the thin gold film electrode to a rigorous three-step chemical cleaning to minimize charge transfer resistance.

- UPD Solution Preparation: Prepare a bismuth solution by mixing 0.25 M Bismuth(III) nitrate pentahydrate in 1 M nitric acid with 1 mM sodium chloride [3].

- Under-Potential Deposition: Place 20 µL of the bismuth solution on the sensor. Use cyclic voltammetry to perform the UPD by sweeping the potential from -0.50 V to -0.40 V (vs. a printed Ag/AgCl reference electrode) [3].

- Post-treatment: After deposition, rinse the bismuth-modified sensor with deionized water for 10 seconds and dry gently with nitrogen. The prepared sensors can be stored at 4 °C for future use [3].

Analytical Performance and Applications

BiFEs have been successfully applied to detect heavy metals at trace levels in various matrices. The tables below summarize performance data for lead (Pb) and cadmium (Cd) detection using different BiFE configurations.

Table 2: Performance Summary of Different BiFEs for Heavy Metal Detection

| Electrode Type | Analyte | Linear Range | Detection Limit | Test Medium | Citation |

|---|---|---|---|---|---|

| UPD Bi on Au | Pb²⁺ | 8 ×10⁻⁷ M to 5 ×10⁻⁴ M | Not specified (R² = 0.970) | Tap Water | [4] |

| Bi-SPE (with Bi powder) | Cd²⁺ | 5–50 μg/L | 4.80 μg/L | Acetate Buffer | [2] |

| Bi₂O₃@NPBi | Pb²⁺ | Not specified | 0.02 μg/L | Tap Water | [8] |

| Bi₂O₃@NPBi | Cd²⁺ | Not specified | 0.03 μg/L | Tap Water | [8] |

| Solid Bi Microelectrode Array | Cd²⁺ | 2×10⁻⁹ to 2×10⁻⁷ M | 2.3×10⁻⁹ M | Acetate Buffer | [9] |

| Solid Bi Microelectrode Array | Pb²⁺ | 5×10⁻⁹ to 2×10⁻⁷ M | 8.9×10⁻¹⁰ M | Acetate Buffer | [9] |

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Key Reagents and Materials for BiFE Preparation and Analysis

| Item | Typical Specification/Example | Function in Protocol |

|---|---|---|

| Bismuth Precursor | Bismuth(III) nitrate pentahydrate (Bi(NO₃)₃·5H₂O) | Source of Bi³⁺ ions for film formation, either ex-situ, in-situ, or in electrode ink [3] [1] [6]. |

| Supporting Electrolyte | Acetate buffer (0.05 M, pH ~4.6) | Provides a consistent ionic strength and pH medium for analysis and deposition [9] [6]. |

| Acid for Cleaning/Media | HNO₃, H₂SO₄, HCl (TraceSelect grade) | For electrode pretreatment and preparation of acidified stock solutions [3] [1] [6]. |

| Substrate Electrodes | Screen-printed carbon, Glassy carbon, Gold film, Brass | Base conductive surface upon which the bismuth film is formed or modified [3] [1] [6]. |

| Modifying Polymers | Nafion, Methocel, Poly(sodium-4-styrene sulfonate) | Used to coat the electrode surface to alleviate interferences and improve mechanical stability of the bismuth film [1]. |

| Standard Metal Solutions | Cd²⁺ and Pb²⁺ standard stock solutions (1000 mg/L) | Used for calibration and validation of the analytical method [1]. |

Within electroanalytical chemistry, the development of reliable and environmentally friendly sensors for detecting toxic heavy metals is a critical pursuit. For decades, mercury electrodes were the cornerstone of stripping analysis due to their excellent electroanalytical properties. However, their well-known toxicity has driven the search for safer alternatives [10]. Bismuth has emerged as a leading candidate, with its ability to form fusible alloys with heavy metals like lead, cadmium, and zinc being fundamental to its function in sensors [10] [11]. This application note, framed within a broader thesis on sensor development, details the mechanisms of bismuth-heavy metal interactions and provides detailed protocols for preparing and characterizing bismuth film electrodes (BiFEs) specifically for lead detection. The low toxicity of bismuth, coupled with its insensitivity to dissolved oxygen and its ability to form well-defined, sensitive amalgams, makes it an ideal replacement for mercury in modern electroanalysis [3] [11].

The Bismuth-Lead Alloying Mechanism in Electroanalysis

The core principle enabling bismuth film electrodes to detect lead is anodic stripping voltammetry (ASV). This process relies on the electrochemical formation of bismuth-lead alloys during the analysis.

Fundamental Interactions and Process Workflow

The analytical cycle begins with a preconcentration step, where a negative potential is applied to the bismuth-film working electrode in a solution containing Pb(II) ions. This causes the simultaneous reduction of bismuth ions (if in situ) or the substrate bismuth film and the lead ions at the electrode-solution interface:

- Bi(III) + 3e⁻ → Bi(0)

- Pb(II) + 2e⁻ → Pb(0)

The freshly reduced lead atoms do not simply deposit on the surface; instead, they interact with the reduced bismuth to form a homogeneous solid mixture or an amalgam/alloy. This alloy formation is thermodynamically favorable and is responsible for the sharp, well-defined stripping signals that make BiFEs so analytically useful [10] [11]. Following the deposition period, the potential is swept in a positive direction. During this anodic stripping step, the alloyed metals are re-oxidized. The potential at which each metal strips out of the alloy is characteristic of the metal, and the current generated is proportional to its concentration in the original solution.

The diagram below illustrates this integrated experimental workflow.

Comparative Properties of Bismuth and Lead

The table below summarizes key properties of bismuth and lead that are relevant to their alloying behavior and sensor performance.

Table 1: Comparative Properties of Bismuth and Lead Relevant to Electroanalysis

| Property | Bismuth (Bi) | Lead (Pb) | Significance in Electroanalysis |

|---|---|---|---|

| Atomic Number | 83 [12] | 82 | Confirms their status as heavy metals. |

| Toxicity | Relatively low; some salts less toxic than table salt [11] | High; a known cumulative toxin [11] | Bismuth's low toxicity is the primary driver for replacing mercury and lead in sensors. |

| Density (g/cm³) | 9.807 [12] | ~11.34 | High density contributes to the robustness of the deposited film. |

| Melting Point (°C) | 271.5 [12] | 327.5 | The low melting point of Bi is linked to its ability to form fusible alloys. |

| Behavior in Alloys | Expands 3.32% on solidification [12] | Contracts on solidification | Bismuth's expansion can help create a more uniform and stable film structure. |

| Sensitivity to O₂ | Relatively insensitive [3] [11] | Sensitive (forms oxides) | Allows for analysis without deoxygenation, simplifying the protocol. |

Detailed Experimental Protocols

This section provides two robust methodologies for preparing bismuth film electrodes, optimized for the detection of trace lead.

Protocol 1: Screen-Printed Electrode with Insoluble Bismuth Phosphate Precursor

This protocol utilizes a two-step, drop-cast method to create a stable precursor film that is electrochemically activated prior to use [13].

Key Reagents & Materials

- Screen-printed carbon electrode (SPE)

- Polystyrene sulfonate (PSS) solution: 25 mM in water

- Bismuth precursor solution: 2 mM Bi(NO₃)₃

- Phosphate solution: 4 mM Na₂HPO₄

- Activation solution: 0.01 M HCl (pH = 2)

- Analytical equipment: Micropipettes, microsyringe, drying station

Step-by-Step Procedure

- Electrode Pretreatment: Clean pristine screen-printed electrodes by immersing them in a 0.01 M HCl solution, then rinse thoroughly [10].

- Polymer Modification: Using a microsyringe, deposit 2 µL of the 25 mM PSS solution directly onto the working electrode surface. Allow it to dry completely at room temperature [13].

- Precursor Film Deposition: Mix equal volumes of the 4 mM Na₂HPO₄ and 2 mM Bi(NO₃)³ solutions. Deposit 5 µL of this mixture onto the PSS-modified working electrode. Allow it to dry completely. Electrodes prepared this way can be stored in air at room temperature [13].

- Electrochemical Activation: Prior to lead analysis, activate the electrode by performing eight cyclic voltammetry scans in a 0.01 M HCl solution (pH = 2) under the conditions intended for the subsequent differential pulse stripping analysis. This step reduces the insoluble bismuth phosphate to form the active bismuth metal film. Activated electrodes must be stored in a diluted acid solution without contact with air [13].

Protocol 2: Under-Potential Deposited Bismuth on Gold Film Electrode

This protocol employs under-potential deposition (UPD) to create a highly sensitive and homogeneous sub-monolayer bismuth film on a gold substrate [3].

Key Reagents & Materials

- Gold film electrode

- Bismuth plating solution: 0.25 M Bismuth(III) nitrate pentahydrate in 1 M nitric acid with 1 mM sodium chloride.

- Electrochemical cell with a potentiostat and Ag/AgCl reference electrode.

- Cleaning solutions: 2 M KOH, 0.05 M H₂SO₄, 0.05 M HNO₃.

Step-by-Step Procedure

- Gold Electrode Pretreatment: Perform a rigorous three-step chemical cleaning to minimize charge transfer resistance.

- Immerse the electrode in 2 M KOH for 15 minutes. Rinse with copious DI water for 30 seconds.

- Immerse in 0.05 M H₂SO₄ for 15 minutes. Rinse with DI water for 30 seconds.

- Immerse in 0.05 M HNO₃ for 15 minutes. Rinse with DI water and dry gently with a stream of nitrogen [3].

- Under-Potential Deposition of Bismuth:

- Place 20 µL of the bismuth plating solution onto the pretreated gold sensor.

- Using cyclic voltammetry, sweep the potential from -0.50 V to -0.40 V (vs. a Ag/AgCl reference electrode). This controlled potential range ensures the formation of a UPD bismuth sub-layer rather than a thick bulk film [3].

- Post-deposition Treatment: After deposition, rinse the sensor with deionized water for 10 seconds and dry gently with nitrogen. Sensors can be stored at 4°C prior to use [3].

- Gold Electrode Pretreatment: Perform a rigorous three-step chemical cleaning to minimize charge transfer resistance.

Characterization Data: X-ray Photoelectron Spectroscopy (XPS) and Time-of-Flight Secondary Ion Mass Spectrometry (TOF-SIMS) confirm the successful deposition of a homogeneous bismuth film. XPS analysis shows a higher atomic percentage of bismuth when using a 0.25 M precursor solution compared to 0.1 M, and TOF-SIMS imaging reveals uniform coverage of the gold surface [3].

Performance Data and Analytical Figures of Merit

The performance of bismuth-based sensors for lead detection is excellent, rivaling that of traditional mercury-based electrodes.

Table 2: Analytical Performance of a Bismuth Imidazolate-Based Sensor for Lead Detection [11]

| Parameter | Value / Result |

|---|---|

| Linear Range 1 | 10 – 100 μg L⁻¹ (ppb) |

| Correlation (r²), Range 1 | 0.998 |

| Linear Range 2 | 1 – 10 μg L⁻¹ (ppb) |

| Correlation (r²), Range 2 | 0.995 |

| Limit of Detection (LOD) | 0.1 μg L⁻¹ (3σ, 240 s accumulation) |

| Repeatability (RSD) | 3.8% |

| Key Innovation | BiIm coating acts as a bismuth ion reservoir, allowing multiple surface renewals. |

The Scientist's Toolkit: Essential Research Reagents

The following table details key materials and reagents required for the preparation and operation of bismuth film electrodes as described in the featured protocols.

Table 3: Essential Reagents and Materials for Bismuth Film Electrode Research

| Reagent / Material | Function / Role | Example from Protocol |

|---|---|---|

| Bismuth Nitrate (Bi(NO₃)₃) | The primary source of Bi(III) ions for electrochemical deposition or precursor formation. | Used in both Protocol 1 (precursor film) and Protocol 2 (UPD plating solution) [13] [3]. |

| Screen-Printed Electrode (SPE) | A disposable, portable, and low-cost substrate for the bismuth film. | The base platform in Protocol 1 [13]. |

| Gold Film Electrode | A high-quality, reusable substrate that facilitates under-potential deposition. | The base platform in Protocol 2 [3]. |

| Poly(styrene sulfonate) - PSS | A polymer modifier that improves the stability and adhesion of the precursor film on the electrode surface. | Deposited as a first layer in Protocol 1 [13]. |

| Acetate Buffer (pH ~4.5) | A common supporting electrolyte that provides optimal pH conditions for the deposition and stripping of heavy metals. | Used as the electrolyte in electrochemical measurements [10] [11]. |

| Nafion | A perfluorinated ion-exchange resin; used as a protective coating to alleviate interferences and improve mechanical stability. | Can be drop-cast onto the electrode after bismuth film deposition [10]. |

| Hydrochloric Acid (HCl) | Used for electrode cleaning, activation of precursor films, and as a supporting electrolyte. | Used for activation in Protocol 1 and cleaning in Protocol 2 [13] [3]. |

Troubleshooting and Critical Considerations

Successful implementation of these protocols requires attention to several critical factors. The diagram below outlines a systematic troubleshooting workflow for common issues.

- Film Stability: Activated bismuth films are prone to oxidation. For best results, store activated electrodes in a diluted acid solution and avoid contact with air [13]. The bismuth imidazolate (BiIm) sensor offers a significant advantage here, as its coating can be renewed in situ [11].

- Interference Studies: For complex sample matrices, interference studies are crucial. Competitive anions can be introduced equimolar to the analysis solution (e.g., in 0.01 M HCl) during repetitive scan experiments to assess their impact [13].

- Material Characterization: Techniques like XPS, TOF-SIMS, and SEM-EDS are invaluable for confirming the successful deposition, homogeneity, and composition of the bismuth film, as demonstrated in Protocol 2 [3].

Within electrochemical research, particularly in the development of sensors for detecting toxic heavy metals like lead, the choice of electrode material is paramount. For decades, mercury was the preferred electrode material for anodic stripping voltammetry due to its excellent electroanalytical properties. However, its severe and well-documented toxicity poses significant health and environmental risks. Bismuth-based electrodes have emerged as a high-performing and vastly safer alternative. This Application Note delineates the compelling toxicological rationale for substituting mercury with bismuth in electrochemical protocols, providing a comparative safety assessment and detailed methodologies for employing bismuth film electrodes in lead detection research.

Comparative Toxicity Profiles

The fundamental difference in toxicity between mercury and bismuth is profound, influencing laboratory safety protocols, waste disposal procedures, and environmental impact. The table below provides a quantitative and qualitative comparison of their toxicological profiles.

Table 1: Comparative Toxicity of Mercury and Bismuth

| Characteristic | Mercury | Bismuth |

|---|---|---|

| General Toxicity Classification | Potent neurotoxin; one of WHO's top ten chemicals of major public health concern [14] | Considered relatively non-toxic; some salts less toxic than sodium chloride [15] |

| Primary Health Effects | Toxic to nervous, digestive, immune systems; kidneys, lungs, skin, and eyes. Harmful to fetal development [14]. | Generally low toxicity; side effects (e.g., encephalopathy) are rare and typically linked to extreme misuse [15]. |

| Effects on Nervous System | Tremors, insomnia, memory loss, neuromuscular effects, cognitive and motor dysfunction [16] [14]. | Neurological effects are exceptionally rare and reversible upon discontinuation [15]. |

| Environmental Persistence & Bioaccumulation | High. Converts to methylmercury, which bioaccumulates in fish and biomagnifies up the food chain [17]. | Very low. Not known to bioaccumulate or pose significant environmental hazards [15]. |

| Regulatory Status | Use is strongly discouraged or banned in many applications; subject to the Minamata Convention [11] [14]. | No major restrictions; widely used in pharmaceuticals and cosmetics [15]. |

Experimental Protocols for Bismuth Film Electrode Preparation and Lead Detection

The following protocols detail the preparation of a bismuth film electrode (BiFE) using a novel bismuth imidazolate (BiIm) precursor and its application in detecting trace lead (Pb(II)) via Anodic Stripping Voltammetry (ASV).

Protocol 1: Drop-Casting Preparation of a Bismuth Imidazolate Electrode (BiImE)

This protocol describes a user-friendly, drop-casting method to create a robust sensor for trace lead detection [11].

Table 2: Reagents and Equipment for BiImE Preparation

| Item | Specification | Function/Purpose |

|---|---|---|

| Bismuth Precursor | Bismuth imidazolate (BiIm) synthesized from Bi(III) salt and 2-methylimidazole [11] | Active sensing material; acts as a reservoir of Bi ions. |

| Supporting Electrode | Glassy Carbon Electrode (GCE) | Provides a conductive, stable substrate for the sensing film. |

| Solvent | Methanol, analytical grade | Disperses BiIm powder to create a uniform suspension for drop-casting. |

| Drying Apparatus | Ambient air or gentle stream of inert gas (N₂/Ar) | Ensures rapid and even drying of the cast suspension to form a cohesive film. |

- Synthesis of BiIm Sensing Material: Synthesize the amorphous bismuth imidazolate (BiIm) powder by reacting a Bi(III) salt (e.g., Bi(NO₃)₃) with 2-methylimidazole in a suitable solvent. Isolate the resulting white powder via centrifugation or filtration [11].

- Suspension Preparation: Disperse the synthesized BiIm powder in methanol to create a homogeneous suspension.

- Electrode Substrate Preparation: Polish the glassy carbon electrode (GCE) successively with finer grades of alumina slurry (e.g., 1.0, 0.3, and 0.05 µm) on a microcloth. Rinse thoroughly with ultra-pure water between each polishing step and after the final polish.

- Film Deposition (Drop-Casting): Pipette a precise volume (e.g., 5-10 µL) of the BiIm-methanol suspension onto the clean, polished surface of the GCE.

- Drying: Allow the methanol to evaporate rapidly at room temperature, leaving a uniform BiIm coating on the GCE surface. The electrode (now BiImE) is ready for use.

Protocol 2: In Situ Bismuth Film-Coated Ultramicroelectrode Array (BF-UMEA) for Water Analysis

This protocol is optimized for high-sensitivity detection of Pb(II) and Cd(II) in water samples using an in situ plated bismuth film [18].

Table 3: Key Parameters for BF-UMEA SWASV Optimization [18]

| Parameter | Optimum Range/Value | Impact on Signal |

|---|---|---|

| Deposition Time | 120 - 240 s | Longer times increase analyte preconcentration, enhancing signal. |

| Bi(III) Concentration | 100 - 400 µg L⁻¹ | Critical for forming a uniform, active bismuth film. |

| Supporting Electrolyte | 0.1 M Acetate Buffer, pH 4.5 | Provides optimal pH and ionic strength for metal deposition/stripping. |

| Square Wave Frequency | ~15 Hz | Higher frequencies can improve peak current and resolution. |

| Square Wave Amplitude | ~50 mV | Larger amplitudes increase peak current. |

| Step Potential | ~9 mV | Finer steps improve peak definition. |

- Electrochemical Setup: Configure a standard three-electrode system.

- Working Electrode: Gold Ultramicroelectrode Array (Au-UMEA).

- Reference Electrode: Leakless Ag/AgCl.

- Counter Electrode: Platinum wire.

- Solution Preparation: Prepare the water sample or standard solution. Add Bi(III) standard solution directly to the measurement solution to a final concentration within the optimum range (e.g., 400 µg L⁻¹). Add acetate buffer (pH 4.5) to a final concentration of 0.1 M as the supporting electrolyte [18].

- In Situ Plating and Analysis via SWASV:

- Decxygenation (Optional): Bubble pure nitrogen or argon through the solution for 5-10 minutes to remove dissolved oxygen. Maintain an inert atmosphere during measurement.

- Preconcentration/Deposition: Immerse the electrode system and stir the solution. Apply a deposition potential of -1.2 V to -1.4 V (vs. Ag/AgCl) for a set time (e.g., 120-240 s). This step simultaneously reduces and co-deposits Bi(III) and target metal ions (Pb(II), Cd(II)) onto the Au-UMEA surface as an alloy.

- Equilibration: Stop stirring and allow the solution to become quiescent for a brief period (e.g., 10 s).

- Stripping: Scan the potential in the positive direction using Square Wave Voltammetry (e.g., from -1.2 V to -0.2 V). The deposited metals are oxidized (stripped) back into the solution, producing characteristic current peaks at their respective oxidation potentials.

- Data Analysis: Identify Pb(II) and Cd(II) by their peak potentials (~ -0.5 V and ~ -0.8 V vs. Ag/AgCl, respectively). Quantify the concentration by measuring the peak area or height and comparing it to a calibration curve.

Diagram 1: SWASV Workflow for Lead Detection.

The Scientist's Toolkit: Essential Reagents and Materials

Table 4: Key Research Reagent Solutions for Bismuth-Based Lead Detection

| Research Reagent | Function in Experiment |

|---|---|

| Bismuth Trioxide (Bi₂O₃) | A common bismuth precursor for bulk-modified carbon paste or screen-printed electrodes [11]. |

| Bismuth Imidazolate (BiIm) | A novel amorphous precursor for drop-cast electrodes, serving as a bismuth ion pool [11]. |

| Bismuth Nitrate (Bi(NO₃)₃·5H₂O) | The standard source of Bi(III) ions for in situ bismuth film plating [18]. |

| Acetate Buffer (pH 4.5) | The supporting electrolyte of choice; provides optimal pH for metal deposition and stripping [11] [18]. |

| Gold Ultramicroelectrode Array (Au-UMEA) | A substrate electrode offering enhanced mass transfer and signal-to-noise ratio [18]. |

The transition from mercury to bismuth-based electrodes is firmly justified by toxicological evidence and demonstrated analytical performance. Bismuth presents an exceptionally lower risk profile for researchers and the environment, aligning with modern green chemistry principles, without compromising the sensitivity required for trace metal analysis. The protocols detailed herein provide robust, reliable methodologies for implementing this safer alternative in lead detection research, contributing to more sustainable laboratory practices.

Bismuth film electrodes (BiFEs) have emerged as a leading environmentally friendly alternative to mercury-based electrodes for the sensitive detection of heavy metals, including lead, via anodic stripping voltammetry (ASV). Their low toxicity, remarkable ability to form alloys with heavy metals, insensitivity to dissolved oxygen, and wide potential window make them exceptionally suitable for environmental monitoring and analytical applications [19] [1]. The performance of these electrodes is critically dependent on three fundamental components: the substrate electrode, the source of bismuth, and the supporting electrolyte. This document provides detailed application notes and protocols for the preparation and use of BiFEs, framed within a broader thesis on standardized methodologies for lead detection research. It is structured to offer researchers, scientists, and drug development professionals a comprehensive toolkit for implementing this robust analytical technique.

Core Components of Bismuth Film Electrodes

The sensitivity, reproducibility, and overall analytical performance of a BiFE are determined by the careful selection and combination of its essential components. The interactions between the substrate, the bismuth salt, and the supporting electrolyte are crucial for forming a high-quality, electroactive bismuth film.

Substrate Electrodes

The substrate provides the conductive foundation upon which the bismuth film is deposited. Different substrate materials offer distinct advantages and are selected based on the application's requirements for cost, disposability, and performance.

Table 1: Common Substrate Electrodes for Bismuth Film Formation

| Substrate Material | Key Characteristics | Fabrication Methods | Typical Applications |

|---|---|---|---|

| Screen-Printed Carbon | Low-cost, disposable, mass-producible, suitable for field analysis [20] [1] | Inkjet printing of graphite/ionic liquid composites [20] | In-situ environmental monitoring, point-of-care testing |

| Glassy Carbon (GC) | Well-defined surface, excellent conductivity, common in laboratory research [21] | Polishing with alumina slurry, followed by chemical or electrochemical cleaning [21] | High-precision trace metal analysis in complex matrices |

| Brass (CuZn Alloy) | Readily available, economical, suitable for processing into various shapes [7] | Polishing with Al₂O₃ to a mirror finish, rinsing, and air-drying [7] | Industrial sensing, exploration of novel substrate materials |

| Silicon Wafer | Allows for precise lithographic patterning, enables mass-production of micro-sensors [19] | Sputtering of bismuth metal followed by photolithography [19] | Fabrication of miniaturized, disposable sensor devices |

Bismuth Salts and Precursors

Bismuth is introduced to the electrode surface from a solution of a bismuth salt. The choice of salt and its chemistry in solution are critical for forming a uniform and adherent film.

Table 2: Common Bismuth Salts and Deposition Methods

| Bismuth Salt / Precursor | Typical Concentration | Deposition Method | Notes and Considerations |

|---|---|---|---|

| Bismuth Nitrate (Bi(NO₃)₃) | 0.1 - 0.5 mM [1] | In-situ or ex-situ electrodeposition | Prone to hydrolysis, requiring acidic conditions (e.g., 1 M HCl) to suppress hydrolysis during ex-situ deposition [7] [1] |

| Sputtered Bismuth Metal | N/A (thin film) | Physical vapor deposition (sputtering) [19] | Avoids use of bismuth salts, simplifies procedure, allows for strict control of film thickness and geometry [19] |

| Bismuth Compounds (e.g., Bi₂WO₆) | Incorporated in composite coatings | Mixed within polymer matrices (e.g., BSA) [5] | Provides a stable crystal structure, enhances antifouling properties, and acts as a heavy metal co-deposition anchor [5] |

Supporting Electrolytes

The supporting electrolyte facilitates charge transfer, defines the pH and ionic strength of the medium, and influences the stripping peak shape and resolution. Acetate buffer is a common choice for the detection of lead and cadmium.

Table 3: Supporting Electrolytes for Lead Detection with BiFEs

| Supporting Electrolyte | pH | Analytical Application | Key Advantages |

|---|---|---|---|

| Acetate Buffer | 4.5 - 5.0 [19] [20] | Simultaneous determination of Cd(II) and Pb(II) [19] | Good buffering capacity, well-defined stripping peaks, minimal interference |

| Hydrochloric Acid (HCl) | ~1.0 [7] | Ex-situ formation of bismuth film; detection of Cd(II) [7] | Prevents hydrolysis of bismuth ions during ex-situ film formation |

| Phosphate Buffer | 5.0 [20] | Detection of Cd(II) with screen-printed electrodes [20] | Compatible with in-situ bismuth film formation |

Detailed Experimental Protocols

Protocol A: Preparation of a Screen-Printed Bismuth Film Electrode (SP-BiFE) for Lead and Cadmium Detection

This protocol is adapted from established procedures for creating disposable, yet highly sensitive, electrodes [20] [1].

Research Reagent Solutions:

- Acetate Buffer Stock (1 M, pH 4.5): Prepare from acetic acid and sodium acetate.

- Bismuth Stock Solution (1000 mg/L): Prepare from bismuth nitrate pentahydrate in 0.5 M nitric acid.

- Metal Ion Standards (1000 mg/L): Dilute as required from atomic absorption standard solutions.

Procedure:

- Electrode Pretreatment (Optional but Recommended): Preoxidize the screen-printed carbon working electrode at +1.50 V in 0.1 M acetate buffer (pH 4.4) for 120 s. This step cleans the surface and introduces functional groups that can improve film adhesion [1].

- In-situ Bismuth Film Formation and Analysis: a. Prepare the measurement solution in the voltammetric cell containing: * 0.1 M acetate buffer (pH 4.5) * Target analytes (e.g., Pb(II) and Cd(II)) * 0.1 - 0.5 mg/L (approx. 0.1 - 0.5 mM) Bi(III) from the bismuth stock solution [1]. b. Apply a deposition potential of -1.2 V vs. Ag/AgCl for 120-300 s under stirring. During this step, both Bi(III) and the target metal ions (e.g., Pb(II)) are co-reduced and form an alloy on the electrode surface. c. After the deposition step, switch off the stirrer and allow a quiet time of 15 s. d. Record the stripping voltammogram using the Square-Wave Anodic Stripping Voltammetry (SWASV) technique by scanning the potential from -1.2 V to -0.4 V. For Pb(II), a well-defined peak typically appears around -0.5 V to -0.4 V vs. Ag/AgCl [19] [21].

Protocol B: Ex-situ Formation of a Bismuth Film on a Brass Substrate

This protocol outlines a method for forming a bismuth film on a novel, economical brass substrate, as reported in recent literature [7].

Research Reagent Solutions:

- Ex-situ Plating Solution: 1 M HCl with 0.02 M Bi(NO₃)₃.

- Acetate Buffer (pH 4.35): For the stripping analysis.

Procedure:

- Substrate Preparation: Polish the brass (Cu37Zn) electrode surface with 0.3 μm Al₂O₃ slurry until a mirror-smooth finish is achieved. Rinse thoroughly with distilled water and air-dry.

- Ex-situ Bismuth Deposition: Immerse the prepared brass electrode in the ex-situ plating solution. Using chronoamperometry, deposit the bismuth film at a constant potential of -0.12 V to -0.15 V vs. SCE for 300 s [7].

- Analysis of Target Analyte: Remove the electrode from the plating solution, rinse it, and transfer it to the measurement cell containing the acetate buffer and the target Cd(II) or Pb(II) ions.

- Stripping Measurement: Apply a deposition potential of -1.2 V vs. SCE for 300 s. Subsequently, perform anodic square-wave stripping voltammetry with the following parameters: frequency 10 Hz, step potential 5 mV, and pulse amplitude 50 mV [7].

Workflow and Signaling Visualization

The following diagram summarizes the general experimental workflow for fabricating and using a bismuth film electrode for lead detection, integrating the two primary deposition methods.

General Workflow for Bismuth Film Electrode Preparation and Lead Detection

The electrochemical signaling pathway for the detection of lead, central to the ASV technique, is illustrated below.

Electrochemical Signaling Pathway for Lead Detection

The Electrochemical Window and Operational Principles of BiFEs

Bismuth film electrodes (BiFEs) represent a significant advancement in electroanalysis, emerging as a premier environmentally-friendly alternative to traditional mercury-based electrodes. Since their introduction by Wang et al. in 2000, BiFEs have gained widespread adoption for the analysis of heavy metals and organic compounds, prized for their low toxicity, favorable electrochemical properties, and ability to form multi-component alloys with target metals [1] [22]. The operational principle of BiFEs is fundamentally governed by their electrochemical window—the potential range between which the electrode material itself is neither oxidized nor reduced, thus enabling the accurate measurement of target analytes without interference from electrode decomposition [23]. This application note details the underlying principles, fabrication protocols, and analytical performance of BiFEs, contextualized within a research framework focused on lead detection.

Theoretical Foundations

The Electrochemical Window in Electroanalysis

The electrochemical window (EW) is a critical parameter for any working electrode. It defines the electrode electric potential range in a given electrolyte where the solvent, electrolyte, and electrode material are electrochemically stable. Operating outside this window leads to irreversible oxidative or reductive decomposition of these components, which generates high background currents and obscures the analytical signal of the target analyte [23]. For a substance, the EW is calculated by subtracting its reduction potential (cathodic limit) from its oxidation potential (anodic limit). A wider electrochemical window is generally desirable as it allows for the detection of a broader range of species. Bismuth electrodes offer a sufficiently wide negative potential window, making them exceptionally suitable for analyzing metals like cadmium and lead, which are detected at negative potentials [1].

Operational Principles of Bismuth Film Electrodes

The analytical efficacy of BiFEs stems from a combination of unique properties and mechanisms:

- Alloy Formation: The primary mechanism for metal detection is the formation of fused alloys between bismuth and the target metals (e.g., Pb, Cd) during the deposition step. This alloying effect facilitates the preconcentration of analytes onto the electrode surface, analogous to the process with mercury electrodes but without the associated toxicity [24] [1].

- Insensitivity to Dissolved Oxygen: A significant practical advantage of BiFEs is their relative insensitivity to dissolved oxygen. This property often eliminates the need for lengthy deoxygenation of the sample solution using inert gases like nitrogen or argon, thereby streamlining the analytical procedure and reducing analysis time [1] [7].

- Hydrogen Overpotential: Bismuth possesses a high hydrogen overpotential, similar to mercury. This characteristic suppresses the reduction of protons (H⁺) in acidic solutions, which prevents hydrogen gas evolution at the potentials required for depositing target metals. This suppression ensures a stable baseline and enhances the sensitivity of stripping measurements [6].

Fabrication Protocols for Bismuth Film Electrodes

The performance of a BiFE is highly dependent on the substrate choice and the film deposition methodology. The following protocols outline standardized procedures for creating BiFEs on various substrates.

Substrate Preparation and Pretreatment

A clean and well-prepared substrate surface is crucial for forming a uniform and adherent bismuth film.

Protocol 3.1.1: Pretreatment of Screen-Printed Carbon Electrodes (SPCEs) Screen-printed electrodes are popular for their disposability and suitability for field analysis. The following oxidative pretreatments have been shown to enhance bismuth film formation [1]:

- Type A (Acidic Pre-oxidation): Immerse the SPCE in 0.1 M acetate buffer (pH 4.4). Apply a potential of +1.50 V vs. Ag/AgCl for 120 seconds. Rinse thoroughly with deionized water.

- Type B (Basic Pre-oxidation): Immerse the SPCE in a saturated sodium carbonate solution. Apply a potential of +1.20 V vs. Ag/AgCl for 240 seconds. Rinse thoroughly with deionized water.

- Objective: These oxidative treatments introduce oxygen-containing functional groups to the carbon surface, improving its hydrophilicity and providing more nucleation sites for a more uniform bismuth electrodeposition.

Protocol 3.1.2: Pretreatment of Brass Substrates Brass offers a low-cost and readily processable alternative substrate [6] [7].

- Mechanically polish the brass electrode (e.g., Cu37Zn alloy) with an aqueous slurry of 0.3 μm alumina powder on a polishing pad until a mirror-smooth finish is achieved.

- Rinse the polished electrode copiously with distilled water and then air-dry.

- The electrode is now ready for the ex-situ deposition of the bismuth film.

Bismuth Film Deposition Methods

Bismuth films can be deposited either ex situ (prior to analysis) or in situ (directly within the analyte solution containing Bi(III) ions).

Protocol 3.2.1: Ex-Situ Deposition on a Brass Substrate [6] [7]

- Prepare a deposition solution of 1 M hydrochloric acid (HCl) containing 0.02 M bismuth(III) nitrate pentahydrate (Bi(NO₃)₃·5H₂O). The acidic medium suppresses the hydrolysis of bismuth salts.

- Immerse the pretreated brass electrode (Protocol 3.1.2) into the deposition solution.

- Using a standard three-electrode system (Brass as Working Electrode, Pt wire as Counter Electrode, Saturated Calomel Electrode (SCE) as Reference), apply a constant deposition potential of -0.15 V vs. SCE for 300 seconds (5 minutes) under stirring.

- Remove the electrode from the deposition solution. A visible bismuth deposit confirms successful film formation. Rinse gently with distilled water before use.

Protocol 3.2.2: In-Situ Deposition for Analysis This is the most common and straightforward method, where the bismuth film is plated simultaneously with the target metals during the analysis step.

- Prepare the analyte solution (e.g., a water sample acidified with 0.01 M HCl) and add a bismuth salt standard to achieve a final concentration of 0.1 - 0.5 mg/L Bi(III) [1] [25].

- Introduce the pre-treated working electrode (e.g., SPCE or GCE), counter electrode, and reference electrode into the solution.

- The bismuth film will be formed in situ during the application of the deposition potential (typically between -1.0 V and -1.4 V vs. Ag/AgCl) in the subsequent stripping analysis step.

Protocol 3.2.3: Electrodeposition of Nanoneedle-like Bismuth (nano-BiNDs) Nanostructuring the bismuth film can significantly increase the electrode's active surface area, enhancing sensitivity [22].

- Fabricate a porous graphene electrode (P-GE) via screen-printing.

- Prepare a plating solution containing a Bi³⁺-EDTA complex in acetate buffer (pH ~4.5).

- Immerse the P-GE and apply a constant potential of -1.20 V vs. (pseudo-Ag/AgCl) for 200 seconds.

- The resulting nano-BiNDs have an average length and width of 189 ± 5 nm and 20 ± 2 nm, respectively, providing a high-surface-area platform for metal deposition.

Electrode Modification with Polymers

Modifying the electrode surface with a polymer film before bismuth deposition can improve stability, enhance sensitivity, and mitigate fouling.

Protocol 3.3.1: Electropolymerization of 8-Aminonaphthalene-2-sulphonic Acid [25]

- Prepare a monomer solution of 2.0 mM 8-aminonaphthalene-2-sulphonic acid in 0.1 M HNO₃.

- Using a clean glassy carbon electrode (GCE) as the working electrode, perform cyclic voltammetry by scanning the potential between -0.8 V and +2.0 V at a scan rate of 0.1 V/s for 15 cycles.

- Transfer the polymer-modified electrode (poly(8AN2SA)/GCE) to a monomer-free 0.5 M H₂SO₄ solution and cycle the potential between -0.8 V and +0.8 V until the voltammogram stabilizes.

- The polymer-modified electrode is now ready for in-situ or ex-situ bismuth film formation. This polymer acts as a cheaper and effective alternative to Nafion.

The following workflow diagram illustrates the key decision points and pathways for fabricating a BiFE.

Analytical Protocols: Lead Detection via SWASV

Square-Wave Anodic Stripping Voltammetry (SWASV) is the gold-standard technique for trace metal detection using BiFEs. The following is a detailed protocol for lead (Pb(II)) detection.

Sample and Reagent Preparation

- Supporting Electrolyte: Use a 0.1 M acetate buffer solution (ABS), pH 4.35. This provides optimal conductivity and a pH that favors the deposition process.

- Bismuth Stock Solution (1000 mg/L): Prepare by dissolving bismuth nitrate pentahydrate in 0.5 M nitric acid.

- Lead Stock Solution (1000 mg/L): Use a certified standard solution or prepare from lead nitrate.

- Working Solutions: Dilute stock solutions daily with the supporting electrolyte. For in-situ BiFE, the measurement solution should contain 0.1 - 0.5 mg/L Bi(III) and the target Pb(II) concentration.

Instrumentation and Measurement Parameters

A standard three-electrode potentiostat is used. The following table summarizes the optimized SWASV parameters for lead detection based on recent research.

Table 1: Optimized SWASV Parameters for Lead Detection Using BiFEs

| Parameter | Recommended Value | Variation Range Studied | Substrate / Modification |

|---|---|---|---|

| Deposition Potential (Edep) | -1.2 V vs. Ag/AgCl | -1.0 V to -1.4 V | Brass, SPCE, nano-BiNDs/P-GE [6] [22] |

| Deposition Time (tdep) | 120 - 300 s | 60 - 300 s | Varies with concentration; 300 s for trace levels [6] [25] |

| Equilibrium Time | 10 - 15 s | 10 - 20 s | Allows solution quiescence before stripping [6] [7] |

| Stripping Scan | -1.0 V to -0.4 V | — | Covers stripping potentials for Cd and Pb [25] |

| Square-Wave Frequency | 10 - 25 Hz | 10 - 25 Hz | nano-BiNDs/P-GE [22] |

| Square-Wave Amplitude | 25 - 50 mV | 25 - 50 mV | nano-BiNDs/P-GE [6] [25] |

| Step Potential | 4 - 8 mV | 4 - 8 mV | nano-BiNDs/P-GE [25] [22] |

Step-by-Step SWASV Procedure

- System Setup: Place the prepared BiFE (or bare substrate for in-situ plating), counter, and reference electrodes into the measurement cell containing the sample solution with supporting electrolyte and Bi(III) (if using in-situ method).

- Preconcentration/Deposition: Under stirring, apply the deposition potential (e.g., -1.2 V) for the selected deposition time (e.g., 300 s). This step reduces and co-deposits Pb(II) and Bi(III) onto the electrode surface, forming an alloy.

- Equilibration: Stop stirring and allow the solution to become quiescent for a short equilibrium period (e.g., 10-15 s).

- Stripping: Initiate the square-wave anodic stripping scan from a negative starting potential (e.g., -1.0 V) to a more positive end potential (e.g., -0.4 V). The applied square-wave parameters (frequency, amplitude, step potential) modulate the current measurement to enhance sensitivity.

- Peak Identification: The lead content is quantified by the area or height of the stripping peak, which typically appears around -0.5 V to -0.4 V vs. Ag/AgCl under these conditions.

- Electrode Cleaning: After each measurement, hold the electrode at a relatively positive potential (e.g., +0.3 V) for 20-30 s under stirring to completely oxidize and strip any residual metals from the electrode surface, preparing it for the next analysis [24].

Performance Data and Comparison

The analytical performance of BiFEs is evaluated based on metrics such as detection limit, linear range, sensitivity, and reproducibility. The following table consolidates performance data for lead (Pb(II)) detection from recent studies.

Table 2: Analytical Performance of Various Bismuth-Based Electrodes for Lead (Pb) Detection

| Electrode Type | Linear Range (μg/L) | Detection Limit (μg/L) | Optimal Substrate / Modification | Key Feature / Advantage |

|---|---|---|---|---|

| BiFE on Brass | ~10 - 50 | ~3 (calculated) | Brass (Cu37Zn) | Low-cost, recyclable substrate [6] |

| nano-BiNDs/P-GE | 6 - 50,000 | 2.10 | Porous Graphene / Bismuth Nanoneedles | High surface area, portable [22] |

| Poly(8AN2SA)/BiFE | 1 - 40 | 0.38 | GCE / Sulphonic Acid Polymer | Cheap Nafion alternative, excellent LOD [25] |

| Bi-Poly(1,8-DAN)/CPE | 0.5 - 50 | 0.30 | Carbon Paste / Diaminonaphthalene Polymer | Good reproducibility [24] |

The Scientist's Toolkit: Essential Reagents and Materials

A successful BiFE-based analysis relies on a set of key reagents and materials, each with a specific function.

Table 3: Key Research Reagent Solutions for BiFE Fabrication and Analysis

| Reagent / Material | Function / Purpose | Example / Notes |

|---|---|---|

| Bismuth Salt | Source of Bi(III) ions for film formation. | Bismuth nitrate pentahydrate (Bi(NO₃)₃·5H₂O) dissolved in dilute HNO₃ [1]. |

| Supporting Electrolyte | Provides ionic conductivity, controls pH. | Acetate Buffer (pH 4.35): Most common for metal analysis [6] [7]. Hydrochloric Acid (0.1 M): Used for ex-situ deposition and some analyses [24]. |

| Target Metal Standards | For calibration and quantitative analysis. | Certified stock solutions of Pb(II), Cd(II), etc. (e.g., 1000 mg/L) [1]. |

| Conducting Polymer / Monomer | Electrode modifier to enhance stability and sensitivity. | 8-Aminonaphthalene-2-sulphonic acid: A cost-effective monomer for electropolymerization [25]. |

| Substrate Materials | The base for bismuth film deposition. | Screen-Printed Carbon Electrodes (SPCEs): Disposable, field-ready. Glassy Carbon Electrodes (GCEs): Reusable, standard lab electrode. Brass: Low-cost, easily fabricated [6] [1] [22]. |

| Polishing Material | For surface renewal and pretreatment of solid substrates. | Alumina slurry (0.05 - 0.3 μm) for polishing GCE and brass electrodes [6] [25]. |

Troubleshooting and Best Practices

- Film Adhesion Issues: If the bismuth film peels off or is non-uniform, ensure thorough substrate cleaning and pretreatment. Oxidative treatment of carbon surfaces (Protocol 3.1.1) significantly improves adhesion [1].

- Poorly Defined Stripping Peaks: This can result from incorrect deposition potential, insufficient deposition time, or contamination. Verify parameters against Table 1 and ensure reagents are of high purity.

- High Background Current: Operating near or beyond the cathodic limit of the electrochemical window can cause hydrogen evolution, increasing background noise. Slightly adjust the deposition potential to a less negative value [23].

- Interference Studies: For analysis in complex matrices like biological or environmental samples, interference from other cations (e.g., Zn²⁺, Cr³⁺) should be evaluated. Studies on BiFE on brass have shown no significant interference from several common cations at certain ratios, but this should be verified for each new sample type [7].

Step-by-Step Protocols for Fabricating and Applying Bismuth Film Electrodes

The selection and appropriate pretreatment of the substrate electrode are critical steps in the development of a high-performance bismuth film electrode (BiFE) for the detection of heavy metals, particularly lead. The substrate forms the foundational platform upon which the bismuth film is deposited, influencing the film's adhesion, uniformity, and overall electrochemical performance. This protocol examines three principal substrate materials: glassy carbon (GC), screen-printed carbon (SPC), and the emerging material of laser-induced graphene (LIG). Each substrate offers distinct advantages and limitations in terms of cost, reproducibility, ease of fabrication, and compatibility with bismuth film deposition. The information presented herein is designed to serve as a practical guide for researchers and scientists in selecting and preparing the optimal substrate for their specific analytical needs in lead detection, forming part of a broader thesis on standardized protocols for BiFE preparation.

Comparative Analysis of Substrate Electrodes

The following table summarizes the key characteristics, performance metrics, and optimal pretreatment methods for the three substrate electrodes, based on current literature.

Table 1: Comparative analysis of substrate electrodes for bismuth film-based lead detection.

| Feature | Glassy Carbon (GC) Electrode | Screen-Printed Carbon (SPC) Electrode | Laser-Induced Graphene (LIG) Electrode |

|---|---|---|---|

| Typical Bismuth Modification Method | In-situ or ex-situ electrochemical deposition [26] | Primarily in-situ electrochemical deposition [27] | In-situ deposition or used modification-free [28] [29] |

| Key Pretreatment Steps | Polishing with alumina slurry, rinsing, and electrochemical cleaning [26] | Electrochemical pre-anodization (e.g., in PBS, pH 9) [27] or oxidative pretreatment [10] | Optimization of laser parameters (power, speed); may include Nafion/Bi modification [29] [30] |

| Reported Detection Limit for Pb(II) | 0.0207 μM (4.29 ppb) [26] | Information not explicitly stated in search results | 2.96 ppb (modification-free) [29]; 0.41 ppb (with Bi/Nafion) [30] |

| Linear Detection Range | Information not explicitly stated in search results | 5–100 μg/L for Cd(II) [27] | 10–500 ppb (modification-free) [29] |

| Relative Cost & Disposability | High cost, reusable | Low cost, disposable [27] | Very low cost (<$0.01/electrode), disposable [29] |

| Key Advantages | Excellent sensitivity, well-established surface renewal protocols, suitable for flow systems [26] | Portability, low sample volume, mass producibility, ideal for field analysis [31] [27] | 3D porous structure, high specific surface area, facile and mask-free fabrication [28] [29] |

| Main Limitations/Challenges | Higher cost, not disposable, requires careful manual polishing | Sensitivity can be influenced by ink composition and printing parameters | Performance depends heavily on laser parameter optimization [29] |

Detailed Experimental Protocols

Protocol 1: Pretreatment of Glassy Carbon Electrodes

This protocol is adapted from studies on the simultaneous detection of Cu(II) and Pb(II) using a BiF-GC rotating disk electrode [26].

Required Materials:

- Glassy Carbon electrode (e.g., rotating disk configuration)

- Alumina polishing slurry (0.3 μm and 0.05 μm)

- Ultrasonic bath

- Deionized water

- Electrochemical cell with Ag/AgCl reference electrode and Pt counter electrode

- Potentiostat

Step-by-Step Procedure:

- Mechanical Polishing: Polish the GC electrode surface thoroughly with 0.3 μm and subsequently 0.05 μm alumina slurry on a microcloth pad.

- Rinsing: Rinse the electrode copiously with deionized water to remove all alumina residues.

- Sonication: Sonicate the electrode in deionized water for 2-5 minutes to remove any adherent particles.

- Electrochemical Cleaning: Perform electrochemical cleaning by cycling the potential in a clean supporting electrolyte (e.g., 0.1 M H₂SO₄ or acetate buffer) over a suitable potential range (e.g., -0.5 V to +1.0 V vs. Ag/AgCl) until a stable cyclic voltammogram is obtained.

- Final Rinse: Rinse the electrode with deionized water and dry it. The electrode is now ready for bismuth film deposition.

Protocol 2: Pre-anodization of Screen-Printed Carbon Electrodes

This protocol is based on the work for sensitive determination of Cd²⁺ using a pre-anodized SPCE [27].

Required Materials:

- Commercial Screen-Printed Carbon Electrodes (SPCEs)

- Phosphate Buffer Saline (PBS, 0.1 M, pH 9.0)

- Potentiostat

- Deionized water

Step-by-Step Procedure:

- Preparation: Place the SPCE in an electrochemical cell containing 0.1 M PBS (pH 9.0).

- Pre-anodization: Using a potentiostat, run Cyclic Voltammetry (CV) for 5 cycles with a potential range from +0.5 V to +1.7 V (vs. the internal Ag pseudo-reference) and a scan rate of 0.1 V/s.

- Rinsing and Drying: After the CV scans, remove the SPCE from the solution and rinse it thoroughly with deionized water. Allow it to dry at room temperature.

- Verification (Optional): The success of pre-anodization can be verified by recording a CV in a 5 mM [Fe(CN)₆]³⁻/⁴⁻ solution; a significant increase in peak current and a decrease in peak separation compared to a bare SPCE indicates successful activation [27]. The electrode is now ready for in-situ bismuth and metal deposition.

Protocol 3: Fabrication and Optimization of Laser-Induced Graphene Electrodes

This protocol synthesizes methods from recent studies on LIG electrodes for heavy metal detection [29] [30].

Required Materials:

- Polyimide (PI) tape or film

- CO₂ infrared laser engraving/cutting system

- Computer-aided design (CAD) software for electrode pattern design

- (Optional) Nafion solution, Bismuth nitrate

Step-by-Step Procedure:

- Substrate Preparation: Affix a sheet of commercial polyimide tape to a rigid, flat surface.

- Laser Parameter Optimization: Systematically optimize laser power and engraving speed to produce a high-quality LIG layer. One reported optimal condition is a laser power of 6.4 W and a speed of 30 cm/s [29]. The laser photothermal effect has a cumulative impact on the PI film, so parameters must be carefully controlled [30].

- Electrode Patterning: Use the laser system to convert the designed electrode pattern (working, counter, and reference electrode areas) on the PI film into LIG.

- Post-treatment (Optional): For enhanced performance, the LIG electrode can be modified.

Workflow Diagram for Electrode Selection and Preparation

The following diagram outlines the decision-making and preparation workflow for the three substrate electrodes, from selection to readiness for lead detection.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key reagents and materials for electrode preparation and bismuth film formation.

| Reagent/Material | Function in Protocol | Specific Example or Note |

|---|---|---|

| Alumina Polishing Slurry | Mechanical polishing and surface renewal of glassy carbon electrodes to ensure a fresh, reproducible surface. | Typically used in sequential sizes (e.g., 1.0, 0.3, and 0.05 μm) [26]. |

| Bismuth Nitrate (Bi(NO₃)₃·5H₂O) | The primary precursor for generating Bi(III) ions required for the electrochemical deposition of the bismuth film. | A common stock solution concentration is 1000 mg/L in 0.1 M HNO₃ [10] [27]. |

| Acetate Buffer | Serves as the supporting electrolyte for the deposition and stripping steps, providing optimal pH (around 4.5) for heavy metal analysis. | Prepared from sodium acetate and acetic acid [26] [27]. |

| Nafion Perfluorinated Resin | A cation-exchange polymer used to coat electrodes, improving stability, preventing film detachment, and mitigating surfactant interferences. | Typically a 0.5-5% solution in lower aliphatic alcohols/water [32] [10] [30]. |

| Ethylenediaminetetraacetic Acid (EDTA) | A complexing agent that can enhance the sensitivity and selectivity of the detection for certain metals like Pb(II) and Cu(II) [26]. | Its use requires optimization of concentration within the test solution [26]. |

| Polyimide (PI) Film | The precursor material for fabricating Laser-Induced Graphene (LIG) electrodes via laser irradiation. | Commercial Kapton tape is widely used [28] [29]. |

Bismuth film electrodes (BiFEs) have emerged as a premier environmentally friendly alternative to mercury-based electrodes for the sensitive detection of heavy metals, particularly lead, via anodic stripping voltammetry (ASV) [33] [27]. The performance of these sensors critically depends on the method used to deposit the bismuth film onto a conductive substrate. The two principal methodologies are in-situ plating, where the bismuth film is formed simultaneously with the target metal ions during the analysis, and ex-situ plating, where the bismuth film is pre-deposited in a separate step prior to the measurement [11] [34]. This application note provides detailed protocols for both methods, framed within a thesis research context on optimizing lead detection.

The choice between in-situ and ex-situ plating involves a trade-off between analytical convenience, performance, and applicability to specific sample matrices. The table below summarizes the core characteristics of each method.

Table 1: Core characteristics of in-situ and ex-situ bismuth film plating methods.

| Feature | In-Situ Plating | Ex-Situ Plating |

|---|---|---|

| Core Principle | Bi(III) ions added to sample; Bi⁰ and target metals co-deposited during pre-concentration [34] | Bi⁰ film electroplated onto substrate in a separate step before measurement [34] [7] |

| Procedure | Simplified, single-step analysis [27] | Two-step process requiring electrode transfer [34] |

| Film Stability | "Single-shot"; dissolved and re-formed each analysis cycle [34] | Long-term functional stability for multiple measurements [34] |

| Best For | Standard lab analysis, routine detection [27] [35] | Low-volume samples, flowing systems, adsorptive stripping, in-vivo measurements [34] |

| Key Advantage | Ease of use, consistent film renewal, enhanced sensitivity via alloy formation [27] [11] | No Bi(III) in sample, superior mechanical/electrochemical stability on microelectrodes [34] |

Detailed Experimental Protocols

Protocol for In-Situ Bismuth Film Plating

This protocol is adapted for lead detection using a screen-printed carbon electrode (SPCE) and square wave anodic stripping voltammetry (SWASV) [27].

3.1.1 Research Reagent Solutions

- Acetate Buffer (0.1 M, pH 4.5): Use as the supporting electrolyte.

- Bismuth Stock Solution (1000 mg/L): Prepared from Bi(NO₃)₃·5H₂O in dilute nitric acid.

- Lead Stock Solution (1000 mg/L): Prepared from Pb(NO₃)₂.

- Sodium Bromide (20 µM): Optional additive to the measurement solution.

- Pre-anodization Solution (0.1 M PBS, pH 9): For optional electrode activation [27].

3.1.2 Step-by-Step Procedure

- Electrode Pre-Treatment (Optional but Recommended): Pre-anodize the SPCE to enhance electron transfer rate and sensitivity. Immerse the SPCE in 0.1 M PBS (pH 9) and perform cyclic voltammetry for 5 cycles between 0.5 V and 1.7 V at a scan rate of 0.1 V/s. Rinse thoroughly with ultrapure water and dry at room temperature [27].

- Measurement Solution Preparation: In the electrochemical cell, combine 1 mL of 0.1 M acetate buffer (pH 4.5) with a final concentration of 150 µg/L Bi(III), the target concentration of Pb(II), and 20 µM NaBr [27].

- Co-Deposition / Accumulation Step: Immerse the pre-treated SPCE into the measurement solution. Apply a deposition potential (Ed) of -1.4 V (vs. Ag/AgCl) for 180 seconds while stirring the solution at approximately 200 rpm. During this step, both Bi(III) and Pb(II) are reduced and co-deposited as an alloy on the electrode surface [27].

- Stripping and Measurement: After the deposition time, stop stirring and allow a 10-second equilibrium period. Initiate the square-wave anodic stripping voltammetry scan from -1.4 V to -0.2 V using the following parameters: potential increment of 4 mV, amplitude of 25 mV, and frequency of 25 Hz. The oxidation (stripping) of lead from the bismuth alloy will produce a characteristic current peak around -0.5 V [27].

- Electrode Cleaning: Between measurements, clean the electrode at a potential of +0.3 V for 30 seconds with stirring to oxidize and dissolve any residual metals and bismuth film from the surface [33].

Protocol for Ex-Situ Bismuth Film Plating

This protocol details the formation of a stable bismuth film on a brass substrate, which can be used for multiple measurements of lead and other metals [34] [7].

3.2.1 Research Reagent Solutions

- Plating Solution (0.02 M Bi(III) in 1 M HCl): Dissolve Bi(NO₃)₃·5H₂O in 1 M hydrochloric acid. The acidic medium suppresses the hydrolysis of bismuth ions [7].

- Acetate Buffer (0.1 M, pH 4.5): Use as the supporting electrolyte for the measurement.

- Lead Stock Solution (1000 mg/L): Prepared from Pb(NO₃)₂.

3.2.2 Step-by-Step Procedure

- Substrate Preparation: Polish the brass electrode (e.g., Cu37Zn) with Al₂O₃ powder (0.3 µm) to a mirror-smooth finish. Rinse copiously with distilled water and air-dry [7].

- Film Electrodeposition: Immerse the polished and dried brass electrode into the separate plating solution (0.02 M Bi(III) in 1 M HCl). Using chronoamperometry, apply a constant deposition potential of -0.12 V to -0.15 V (vs. Saturated Calomel Electrode, SCE) for 300 seconds under quiescent conditions. A visible deposit should form on the brass surface [7].

- Electrode Transfer: Carefully remove the newly prepared BiFE from the plating solution, rinse gently with distilled water to remove any adhering plating solution, and air-dry.

- Measurement of Target Analyte: Transfer the ex-situ prepared BiFE to the measurement cell containing the supporting electrolyte (e.g., acetate buffer, pH 4.5) and the target Pb(II) ions.

- Deposition and Stripping: Follow a standard SWASV sequence:

- Accumulation: Apply a suitable deposition potential (e.g., -1.2 V vs. SCE) for a set time (e.g., 300 s) with stirring.

- Equilibrium: Rest for 15 seconds without stirring.

- Stripping: Record the SWASV signal from -1.1 V to -0.6 V (vs. SCE) [7].

- Film Regeneration: The same bismuth film can be used for multiple measurements. To regenerate the surface after a stripping scan, hold the electrode at a more positive potential (e.g., -0.6 V) for a short time to ensure complete oxidation of residual target metals without dissolving the underlying bismuth film [34].

Workflow and Material Selection

Procedural Workflows

The fundamental difference between the two plating methods is captured in the workflows below.

The Scientist's Toolkit: Essential Materials

Table 2: Key research reagents and materials for bismuth film electrode preparation.

| Item | Function / Role | Example Specifications / Notes |

|---|---|---|

| Bismuth Salt | Source of Bi(III) ions for film formation. | Bismuth(III) nitrate pentahydrate (Bi(NO₃)₃·5H₂O) is most common [27] [7]. |

| Supporting Electrolyte | Provides conductivity and controls pH. | 0.1 M Acetate Buffer (pH 4.5) is standard for lead detection [27] [35]. |

| Substrate Electrode | Conducting support for the bismuth film. | Screen-printed carbon (SPCE) [27], glassy carbon (GCE) [33], brass [7], pencil graphite [35]. |

| Plating Additive | Improves quality and stability of ex-situ films. | Sodium bromide (NaBr) in the plating solution [34]. |

| Acidifying Agent | Prevents hydrolysis of Bi(III) stock. | Nitric acid (HNO₃) for preparing Bi(III) stock solutions [27] [7]. |

Critical Parameters for Optimization

To achieve high sensitivity and reproducibility in lead detection, the following parameters from the cited protocols require careful optimization.

Table 3: Key parameters for optimizing bismuth film performance in lead detection.

| Parameter | In-Situ Protocol | Ex-Situ Protocol | Impact on Analysis |

|---|---|---|---|

| Deposition Potential (Ed) | -1.4 V (vs. Ag/AgCl) [27] | -0.12 V to -0.15 V (vs. SCE, for plating) [7] | Must be sufficiently negative to reduce both Bi(III) and Pb(II). Affects nucleation density and film morphology. |

| Deposition Time (td) | 180 s [27] | 300 s (for plating) [7] | Directly controls analyte pre-concentration; longer times increase signal but reduce throughput. |

| Bi(III) Concentration | 150 µg/L in measurement solution [27] | 0.02 M in plating solution [7] | Too low: incomplete coverage. Too high: excessive film thickness, broadened peaks. |

| Solution pH | 4.5 (Acetate Buffer) [27] [35] | ~0.08 (in 1 M HCl plating solution) [7] | Critically affects metal deposition efficiency and hydrogen evolution side-reactions. |

| Electrode Substrate | Pre-anodized SPCE recommended [27] | Polished brass substrate [7] | Substrate material and pre-treatment significantly influence film adhesion, homogeneity, and electron transfer. |

The performance of electrochemical sensors is fundamentally governed by the properties of the sensing interface at the electrode-electrolyte junction. Polymer coatings serve as critical modifier layers that enhance sensor functionality by improving selectivity, sensitivity, and stability. This application note details standardized protocols for fabricating and optimizing polymer-coated electrodes, with a specific focus on Nafion-modified bismuth film electrodes for the detection of heavy metals like lead. These coatings are particularly valuable for environmental monitoring, biomedical diagnostics, and pharmaceutical analysis where precise measurement of target analytes in complex matrices is required.

The integration of Nafion, a perfluorosulfonated ionomer, with bismuth films creates a synergistic sensing platform that combines effective ion-exchange capabilities with environmentally friendly electroanalysis. The protocols outlined herein are framed within a broader thesis on electrode preparation methodologies, providing researchers with reproducible procedures for constructing reliable sensing interfaces for trace-level lead detection in various sample types.

Technical Background and Principles

Properties and Advantages of Polymer Coatings

Polymer coatings enhance electrode performance through multiple mechanisms that improve the sensing interface's interaction with target analytes:

Selective Permeability: Nafion's sulfonic acid groups create a negatively charged matrix that selectively attracts cations while repelling anions, significantly reducing interference from anionic species like ascorbate and urate in biological samples [36] [37]. This property is particularly valuable for detecting cationic analytes such as heavy metals and certain neurotransmitters in complex matrices.

Preconcentration Effect: The ion-exchange structure of polymers like Nafion enables accumulation of target analytes at the electrode surface, effectively increasing local concentration and enhancing detection sensitivity through improved signal-to-noise ratios [38].

Anti-fouling Properties: Polymer films form a protective barrier that minimizes direct contact of macromolecules and surface-active compounds with the electrode surface, thereby reducing passivation and maintaining sensor performance in challenging samples like blood serum or wastewater [36].

Biocompatibility: Nafion exhibits excellent biocompatibility and stability in physiological environments, making it suitable for implantable biosensors and biomedical applications where material-tissue interactions are critical [36].

Bismuth Film Electrodes as Mercury-Free Alternatives

Bismuth film electrodes (BFEs) have emerged as environmentally friendly alternatives to traditional mercury-based electrodes for heavy metal detection. Bismuth offers favorable electrochemical properties including well-defined stripping signals, low background currents, and the ability to form multicomponent alloys with heavy metals. When combined with polymer coatings like Nafion, BFEs demonstrate enhanced performance for trace metal analysis with minimal environmental impact [39] [21].

Table 1: Comparative Sensor Performance Characteristics

| Sensor Configuration | Target Analyte | Linear Range | Detection Limit | Interference Rejection | Reference |

|---|---|---|---|---|---|

| Nafion/Pt electrode | Lead (Pb²⁺) | 0 mM to 4 mM | 0.5 nM | Minimal interference from coexisting metal ions | [40] |

| Bismuth film/GCE | Aluminum (Al³⁺) | 1.85×10⁻¹⁰ to 3.70×10⁻⁶ mol L⁻¹ | 0.025 ppb | Resistant to Pb, Cd, Zn interference | [39] |

| Bi/Nafion/BDDE | Paracetamol and Caffeine | - | 2.62×10⁻⁸ and 1.14×10⁻⁹ mol L⁻¹ | Effective separation of signals | [38] |

| Bismuth film electrode | Cd²⁺, Pb²⁺, Cu²⁺, Zn²⁺ | - | Lower than AAS for Cd | Simultaneous determination in soil | [21] |

| Nafion|CdPCNF|GC | Dopamine | 1.7 µM to 150 µM | 0.7 µM | Eliminates AA and UA interference | [37] |

Experimental Protocols

Protocol 1: Preparation of Nafion-Coated Bismuth Film Electrodes

This protocol describes the sequential modification of a glassy carbon electrode (GCE) with bismuth film and Nafion coating for sensitive detection of lead ions.

Materials and Equipment

Table 2: Essential Research Reagent Solutions

| Reagent/Material | Specification | Function/Purpose | Supplier Example |

|---|---|---|---|

| Glassy Carbon Electrode | 3 mm diameter | Working electrode platform | Various |

| Bismuth Nitrate | ≥99.0% | Bismuth film precursor | Alfa Aesar/Acros Organics |

| Nafion Solution | 5% w/v in alcohol | Cation-selective coating | DuPont |

| Acetate Buffer | 1.0 M, pH 4.5 | Deposition electrolyte | Prepared in-lab |

| Lead Standard Solution | 1000 mg/L | Primary analyte | MOL LABS |

| Supporting Electrolyte | Ammonium sulfate buffer | Measurement medium | Prepared in-lab |

| Polishing Supplies | Alumina slurry (0.3 & 0.05 µm) | Electrode surface preparation | Buehler |

Step-by-Step Procedure

Electrode Pretreatment:

- Polish the glassy carbon electrode surface successively with 0.3 µm and 0.05 µm alumina slurry on a microcloth pad.

- Rinse thoroughly with deionized water (18 MΩ·cm resistivity) between each polishing step and after the final polish.

- Sonicate the electrode in deionized water for 5 minutes to remove residual polishing material.

- Dry the electrode surface under a gentle stream of nitrogen or inert gas.

Bismuth Film Electrodeposition:

- Prepare a deaerated plating solution containing 5.00 mmol L⁻¹ Bi³⁺ in 1.00 mol L⁻¹ acetate buffer (pH 4.5) [39].

- Transfer the solution to the electrochemical cell and degas with nitrogen for 10 minutes prior to deposition.

- Using double-potential pulse chronoamperometry, apply a deposition potential of -1.00 V for 300 seconds with continuous stirring [39].

- After deposition, rinse the modified electrode gently with deionized water to remove loosely adsorbed ions.

Nafion Coating Application:

- Prepare a 0.5% Nafion solution by diluting the commercial 5% solution with absolute ethanol.

- Apply 5.0 µL of the diluted Nafion solution to the bismuth-modified electrode surface.

- Allow the solvent to evaporate at room temperature for 30 minutes, forming a thin, uniform polymer layer.

- Condition the completed Nafion/Bi/GCE by immersing in the supporting electrolyte and applying 10 cyclic voltammetry scans from -0.2 to -1.2 V.

Protocol 2: Lead Detection Using Square Wave Anodic Stripping Voltammetry

This protocol details the optimized procedure for trace lead detection using the prepared Nafion/Bi/GCE sensor.

Materials and Equipment

- Instrumentation: Potentiostat/Galvanostat with square wave voltammetry capability

- Electrochemical Cell: Standard three-electrode configuration

- Supporting Electrolyte: 0.4 mmol L⁻¹ ammonium sulfate buffer (pH 5.50) [39]

- Standard Solutions: Lead calibration standards (0.1-100 µg/L) in supporting electrolyte

- Purification System: Nitrogen gas (high purity) for deaeration

Step-by-Step Procedure

Sample Preparation:

- Mix the sample solution with supporting electrolyte in a 1:1 ratio.

- Adjust the pH to 5.50 using dilute NaOH or H₂SO₄ as needed.

- Transfer the solution to the electrochemical cell and degas with nitrogen for 15 minutes.

Analytical Measurement:

- Preconcentration Step: Apply a deposition potential of -1.20 V for 120 seconds with continuous stirring.

- Equilibration Step: Stop stirring and allow the solution to equilibrate for 15 seconds.

- Stripping Step: Record the square wave stripping voltammogram from -1.20 V to -0.20 V using the following parameters:

- Square wave amplitude: 25 mV

- Frequency: 15 Hz

- Step potential: 5 mV

Calibration and Quantification:

- Perform measurements with standard lead solutions to establish a calibration curve.

- Use the standard addition method for unknown samples to account for matrix effects.

- For continuous monitoring, perform an electrochemical cleaning step between measurements by applying 0.0 V for 30 seconds in clean supporting electrolyte.

Results and Performance Validation

Analytical Performance Metrics

The Nafion-coated bismuth film electrode demonstrates exceptional performance for lead detection with the following validated characteristics:

- Linear Range: The sensor exhibits a strong linear correlation (R² = 0.99) between current response and lead concentration in the range of 0 mM to 4 mM [40].

- Detection Limit: Remarkable sensitivity with a detection limit as low as 0.5 nM for lead ions, suitable for trace-level environmental monitoring [40].

- Response Time: Quick sensor response within 1-3 seconds, enabling rapid analysis and high-throughput screening applications [40].

- Reproducibility: Excellent electrode-to-electrode reproducibility with relative standard deviation (RSD) below 5% for multiple sensor preparations.

Interference Studies and Selectivity

The Nafion coating provides exceptional selectivity for lead detection in complex sample matrices:

- Minimal Interference: The sensor maintains accurate lead detection with minimal interference from coexisting metal ions including cadmium, zinc, and copper [40] [39].

- Anion Rejection: The negatively charged Nafion matrix effectively excludes common anionic interferents such as ascorbate, urate, and nitrite, with rejection efficiency exceeding 95% for biological samples [37].

- Stability Performance: The modified electrode retains over 90% of its initial response after 50 measurement cycles, demonstrating excellent operational stability for continuous monitoring applications.

Table 3: Optimization Parameters for Electrode Fabrication

| Parameter | Optimal Condition | Effect of Variation | Recommendation |

|---|---|---|---|

| Bismuth Concentration | 5.00 mmol L⁻¹ | Lower: Incomplete film coverageHigher: Excessive film thickness | Use fresh solution for each deposition |