Normal Pulse Polarography (NPP) in USP Pharmacopeia Methods: A Comprehensive Guide for Pharmaceutical Analysis

This article provides a detailed exploration of Normal Pulse Polarography (NPP) as applied in USP pharmacopeia methods for drug development and quality control.

Normal Pulse Polarography (NPP) in USP Pharmacopeia Methods: A Comprehensive Guide for Pharmaceutical Analysis

Abstract

This article provides a detailed exploration of Normal Pulse Polarography (NPP) as applied in USP pharmacopeia methods for drug development and quality control. It covers the foundational principles of this electroanalytical technique, outlines step-by-step methodological applications for drug substance and product analysis, addresses common troubleshooting and optimization strategies to ensure data integrity, and examines validation requirements and comparative advantages over other analytical techniques. Aimed at researchers and pharmaceutical scientists, the content synthesizes current USP guidelines with practical implementation insights to support robust analytical procedures in regulatory compliance.

Understanding Normal Pulse Polarography: Core Principles and USP Relevance in Pharmaceutical Analysis

What is Normal Pulse Polarography? Defining the Electroanalytical Technique.

Normal Pulse Polarography (NPP) is a voltammetric technique used for the quantitative determination of electroactive species, particularly trace metals and organic compounds, in solution. It is a differential pulse method where a series of small amplitude potential pulses is applied to a working electrode (typically a dropping mercury electrode, DME) at precise intervals relative to the mercury drop growth. The current is sampled just before the pulse application and at the end of the pulse; the difference between these two measurements is recorded versus the applied base potential. This differential approach minimizes contributions from capacitive current, significantly enhancing the signal-to-noise ratio and lowering detection limits compared to classical DC polarography. Within pharmaceutical analysis, NPP is recognized in compendial standards like the USP for its sensitivity in detecting and quantifying impurities, including catalytic hydrogen waves from nitrosamines and heavy metal residues.

Application Notes: NPP in USP Pharmacopeial Methods Research

The USP general chapter <801> "Polarography" acknowledges pulse polarographic techniques for drug substance and product analysis. NPP's primary pharmacopeial applications focus on impurity profiling and assay validation due to its high sensitivity in the parts-per-billion (ppb) range. Key research within a thesis context involves method development for specific drug monographs, validation per ICH Q2(R1) guidelines, and comparison with alternative techniques like HPLC-ICP-MS.

- Quantitative Analysis of Trace Metals: NPP is employed for determining heavy metal impurities (e.g., Pb, Cd, Zn) in active pharmaceutical ingredients (APIs) and excipients. The method's ability to speciate different oxidation states is advantageous.

- Determination of Nitro and Azo Compounds: Many drug degradants or synthetic intermediates contain reducible nitro groups. NPP provides a highly sensitive and selective means for their quantification.

- Catalytic Hydrogen Waves: The technique is uniquely suited for studying compounds that catalyze hydrogen ion reduction, a property used to detect specific classes of impurities like certain amines.

Table 1: Typical Performance Metrics for NPP in Pharmaceutical Analysis

| Analyte Class | Typical Limit of Detection (LOD) | Linear Dynamic Range | Key USP Application |

|---|---|---|---|

| Divalent Metal Ions (e.g., Cd²⁺, Pb²⁺) | 0.05 - 0.5 µg/L (ppb) | 0.1 - 100 µg/L | Heavy metals testing, impurity profiling |

| Nitroaromatics | 1.0 - 10 µg/L (ppb) | 10 - 1000 µg/L | Nitrosamine/ degradant analysis |

| Catalytic Waves (e.g., from proteins) | Variable (nM concentration) | 2-3 orders of magnitude | Bioanalytical applications |

Table 2: Comparison of Polarographic Techniques

| Parameter | Classical DC Polarography | Normal Pulse Polarography (NPP) | Differential Pulse Polarography (DPP) |

|---|---|---|---|

| Current Measurement | Continuous during drop life | Differential (final vs. initial) | Differential (pre-pulse vs. end-pulse) |

| Capacitive Current | High | Minimized | Minimized |

| Typical LOD | ~10⁻⁵ M | ~10⁻⁷ - 10⁻⁸ M | ~10⁻⁸ M |

| Peak Shape | Sigmoidal wave | Peak-shaped | Peak-shaped |

| Resolution | Lower | Higher | Highest |

Experimental Protocols

Protocol 1: Standard NPP Method for Cadmium and Lead in an API

Objective: To determine trace levels of Cd²⁺ and Pb²⁺ in a drug substance sample.

Materials: See "The Scientist's Toolkit" below.

Method:

- Supporting Electrolyte Preparation: Prepare 0.1 M ammonium acetate buffer (pH 4.6) with 0.01 M HCl. Deoxygenate with high-purity nitrogen or argon for 10 minutes.

- Standard Solution Preparation: Prepare stock solutions of 1000 mg/L Cd²⁺ and Pb²⁺. Dilute with supporting electrolyte to create a calibration series (e.g., 1, 5, 10, 25, 50 µg/L).

- Sample Preparation: Accurately weigh ~100 mg of the API into a calibrated flask. Dissolve and dilute to volume with the supporting electrolyte. Sonicate if necessary.

- Instrumental Parameters (Typical):

- Working Electrode: Static Mercury Drop Electrode (SMDE) or DME.

- Mode: Normal Pulse.

- Pulse Amplitude: 50 mV.

- Pulse Duration: 50 ms.

- Sample Period: 10 ms (at end of pulse).

- Scan Rate: 2 mV/s.

- Scan Range: -0.2 V to -0.8 V vs. Ag/AgCl (3M KCl).

- Procedure: a. Transfer 10 mL of deoxygenated supporting electrolyte to the polarographic cell. Purge with inert gas. b. Run a blank NPP scan. c. Sequentially add aliquots of standard solutions, purging briefly after each addition, and record the NPP scan. d. Replace solution with the prepared sample solution, purge, and record the NPP scan.

- Data Analysis: Measure peak heights (difference current) at approximately -0.45 V (Cd) and -0.55 V (Pb). Construct calibration curves for each ion. Use standard addition or external calibration to calculate concentration in the API sample.

Protocol 2: NPP for a Nitrosamine Impurity via Catalytic Hydrogen Wave

Objective: Qualitative detection and quantitative estimation of a nitrosamine impurity (e.g., N-Nitrosodimethylamine, NDMA).

Method:

- Supporting Electrolyte: Use a cobalt(II)-based buffer (e.g., 0.1 M ammonium buffer pH 9.3 with 5 x 10⁻⁴ M Co²⁺). The Co²⁺ acts as a catalyst precursor.

- Sample Preparation: Extract the drug product (e.g., tablet powder) with a suitable solvent (e.g., methanol), concentrate, and reconstitute in supporting electrolyte.

- Instrumental Parameters:

- Parameters as in Protocol 1, but scan from -0.8 V to -1.6 V.

- Increase pulse amplitude to 100 mV for enhanced sensitivity.

- Procedure: a. Record a baseline scan of the Co²⁺ buffer (a small Co reduction wave will be visible). b. Add the sample extract. The presence of nitrosamines will induce a sharp, enhanced "catastrophic" hydrogen evolution wave at potentials more positive than the normal hydrogen wave. c. Use standard additions of a known nitrosamine to the sample solution for quantification.

- Analysis: The height of the catalytic wave is proportional to the concentration of the nitrosamine impurity over a defined range.

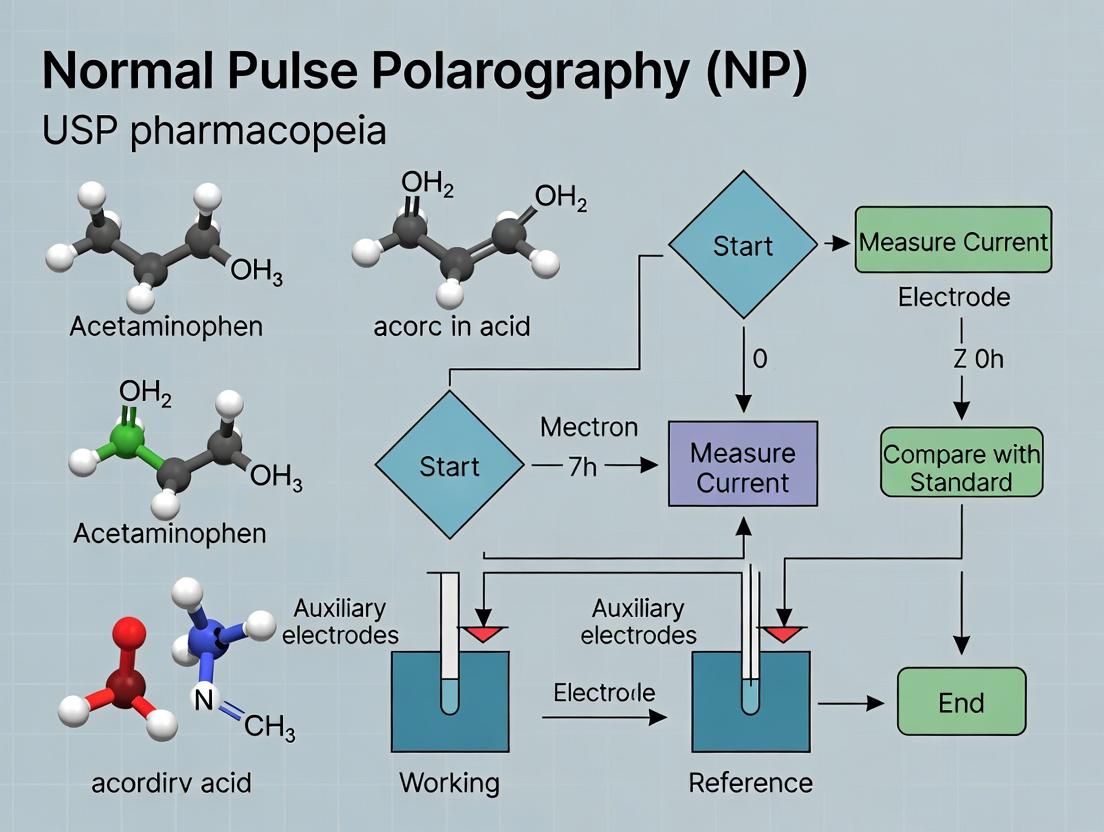

Diagrams

NPP Experimental Workflow for Quantitative Analysis

NPP Pulse Timing and Signal Measurement

The Scientist's Toolkit

Table 3: Key Research Reagent Solutions & Materials for NPP

| Item | Function & Specification | Typical Preparation/Example |

|---|---|---|

| Supporting Electrolyte | Provides ionic conductivity, fixes pH, and may complex interferents. Choice dictates redox potential. | 0.1 M acetate buffer (pH 4.6), 0.1 M ammonia buffer (pH 9.2). Must be high-purity (e.g., TraceSELECT). |

| Standard Stock Solutions | For calibration. Must be traceable to certified reference materials (CRMs). | 1000 mg/L single-element standards for metals, or USP reference standards for organic impurities. |

| Degassing Agent | Removes dissolved oxygen, which is electroactive and causes large interfering reduction waves. | High-purity nitrogen or argon gas (≥99.999%) with in-line oxygen scrubber. |

| Working Electrode | The site of the redox reaction. Provides a renewable surface. | Static Mercury Drop Electrode (SMDE) or controlled-growth DME. Triply distilled mercury. |

| Reference Electrode | Provides a stable, known potential for the cell. | Ag/AgCl (3M KCl) with Vycor or ceramic frit junction. |

| Purified Water | Solvent for all solutions to minimize background contamination. | Type I water (18.2 MΩ·cm) from a Milli-Q or equivalent system. |

| Chelating Agents (optional) | Used in some methods to shift metal reduction potentials or enhance sensitivity. | 0.001 M Dimethylglyoxime for Ni/Co analysis, or 0.01 M EDTA for masking. |

The Historical Evolution of Polarography and Its Adoption into Pharmacopeial Standards

Historical Evolution and Quantitative Milestones

Table 1: Key Historical Milestones in Polarography

| Year | Event/Development | Key Contributor(s) | Significance for Analytical Chemistry |

|---|---|---|---|

| 1922 | Invention of Polarography | Jaroslav Heyrovský | First automatic electroanalytical method using a dropping mercury electrode (DME). |

| 1925 | First Commercial Polarograph | Heyrovský & Shikata | Enabled wider experimental use. |

| 1935 | Theory of Polarographic Waves | Ilkovič & Heyrovský | Ilkovič equation established quantitative basis for diffusion-controlled currents. |

| 1950s | Advent of Pulse Polarographies | Barker & Gardner | Introduction of Normal Pulse (NPP) and Differential Pulse (DPP) greatly enhanced sensitivity and resolution. |

| 1975 | USP Monograph for Dexamethasone | USP Committee | First official pharmacopeial method employing polarography (for nitrate ester determination). |

| 1995 | USP General Chapter <801> | USP | Established guidelines for polarographic methods, including NPP. |

| 2010s-Present | Modern Electrochemical Analyzers | Multiple Vendors | Integration of computerized systems, automation, and compliance with data integrity standards (e.g., 21 CFR Part 11). |

Table 2: Adoption Timeline in Major Pharmacopeias

| Pharmacopeia | First General Chapter on Polarography | Key Monographs Utilizing NPP/DPP (Examples) | Current Status (as of 2024) |

|---|---|---|---|

| USP (United States) | <801> Polarography (1995) | Dexamethasone, Clioquinol, Riboflavin, Menadione | Active; referenced in multiple monographs for assay and impurity profiling. |

| Ph. Eur. (European) | 2.2.20. Pulse Polarography (2005) | Menadione, Clioquinol | Active, though often superseded by HPLC for new monographs. |

| JP (Japanese) | General Tests 22. Polarography (1991) | Several Vitamin Assays | Still official but limited use in new submissions. |

Application Notes: NPP in USP Methods Research

Context: Within pharmacopeial research for USP, NPP is valued for its ability to analyze electroactive species in complex matrices with minimal sample preparation. Its primary contemporary application is in the determination of trace metals, nitro/nitroso compounds, and specific functional groups (e.g., quinones) in active pharmaceutical ingredients (APIs) and finished dosage forms where specificity over HPLC is advantageous.

Key Advantages:

- Low Detection Limits: Typically 10-7 to 10-8 M for favorable analytes.

- Minimal Matrix Interference: The pulsed potential waveform reduces capacitive current.

- Direct Analysis: Often possible in dissolved samples without derivatization.

Current Research Focus: Method development for genotoxic impurity detection (e.g., nitrosamines), metal catalyst residues, and stability-indicating assays for legacy pharmaceutical compounds.

Experimental Protocols

Protocol 1: Standard USP NPP Method for the Determination of Menadione (Vitamin K3)

Scope: This protocol outlines the determination of Menadione in raw material using Normal Pulse Polarography as per USP general guidelines.

I. Materials & Preparation

- Supporting Electrolyte: 0.1 M Ammonium Acetate Buffer, pH 6.7. Dissolve 7.7 g ammonium acetate in 900 mL deionized water, adjust pH with acetic acid, dilute to 1 L.

- Menadione Standard Stock Solution (100 µg/mL): Accurately weigh 10 mg menadione reference standard into a 100 mL volumetric flask. Dissolve and dilute to volume with absolute ethanol.

- Test Solution: Accurately weigh sample equivalent to ~10 mg menadione into a 100 mL volumetric flask. Dissolve and dilute to volume with absolute ethanol.

- Deaeration Gas: High-purity nitrogen or argon.

II. Instrumentation & Parameters (Example)

- Polarograph: Computer-controlled electrochemical analyzer with a static mercury drop electrode (SMDE) or DME.

- Cell: Standard three-electrode system: Working Electrode (SMDE), Reference (Ag/AgCl, 3M KCl), Counter (Platinum wire).

- NPP Parameters:

- Initial Potential (Einitial): -0.2 V

- Final Potential (Efinal): -1.0 V

- Pulse Amplitude (ΔEpulse): 50 mV

- Pulse Duration (tpulse): 50 ms

- Sample Period: 16.7 ms (within pulse duration)

- Drop Time: 1.0 s

- Scan Rate: 5 mV/s

- Temperature: 25°C ± 1°C

III. Procedure

- Pipette 10.0 mL of supporting electrolyte into the polarographic cell.

- Degas with N2/Ar for at least 600 seconds while stirring.

- Maintain a blanket of gas over the solution and perform a blank NPP scan.

- Add an appropriate aliquot (e.g., 100 µL) of the standard stock solution to the cell. Mix. Degas for 180 seconds.

- Record the NPP polarogram. Measure the peak current (Ip) at approximately -0.6 V.

- Repeat step 4-5 for two additional standard additions.

- Repeat the procedure using the test solution.

IV. Calculations Plot Ip vs. concentration of added standard. Use standard addition or external calibration to calculate the menadione content in the test sample.

Protocol 2: NPP Method Development for Trace Metal (Pb, Cd) Residues in an API

Scope: Develop a validated NPP method for simultaneous determination of lead and cadmium at ppm levels.

I. Materials

- Supporting Electrolyte: 0.1 M HCl. Used for plating and analysis.

- Standard Metal Solutions: 1000 mg/L ICP-grade stock solutions of Pb2+ and Cd2+.

- API Sample: Known to be free of target metals (for spiking).

II. Instrumentation & Parameters

- Working Electrode: Hanging Mercury Drop Electrode (HMDE) for anodic stripping.

- Method: Normal Pulse Anodic Stripping Voltammetry (NP-ASV).

- Deposition Step: Edep = -1.2 V, tdep = 120 s (with stirring).

- Equilibration: 15 s (no stirring).

- Stripping Scan (NPP Mode): Einitial = -1.2 V, Efinal = -0.3 V. Pulse amplitude 50 mV, scan rate 20 mV/s.

III. Procedure

- Add 0.1 M HCl and known volume of sample/standard to cell.

- Degas for 300 s.

- Perform deposition at -1.2 V while stirring.

- After equilibration, record the NP-ASV polarogram.

- Identify peaks: Cd ~ -0.65 V, Pb ~ -0.45 V (vs. Ag/AgCl).

- Construct calibration curves for each metal in the range of 1-50 ppb.

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in Polarographic Analysis |

|---|---|

| High-Purity Mercury (Triple Distilled) | The working electrode material for DME or HMDE. Provides a renewable, reproducible surface with a high hydrogen overpotential. |

| Supporting Electrolyte (e.g., 0.1 M KCl, Buffers) | Carries current, minimizes migration current, and controls ionic strength and pH, which can affect half-wave potential (E1/2). |

| Oxygen Scavenger (Nitrogen/Argon Gas) | Removes dissolved oxygen, which produces interfering reduction waves, prior to and during analysis. |

| Electroactive Standard (e.g., Potassium Hexacyanoferrate(III)) | Used for routine instrumental performance verification (e.g., checking capillary characteristics, current calibration). |

| pH Buffer Solutions | Critical for analytes where protonation accompanies electron transfer. Must be electrochemically inert in the scanned range. |

| Complexing Agents (e.g., Dimethylglyoxime, Cupferron) | Used in trace metal analysis to selectively shift the reduction potential of target metals, improving resolution and sensitivity. |

| Anti-foaming Agents (e.g., Triton X-100) | Suppresses maxima on polarographic waves, which are caused by streaming effects at the DME. |

Diagrams

Application Notes

Normal Pulse Polarography (NPP) is a voltammetric technique central to modern trace analysis, particularly for active pharmaceutical ingredients (APIs) and impurities, as referenced in USP general chapters <801> and <850>. This technique's sensitivity and selectivity rely on three foundational pillars: the working electrode, the reference electrode, and the meticulously controlled pulse parameters. Within pharmacopeial research, NPP is employed for the quantitative determination of reducible or oxidizable substances, often at trace levels, in drug substances and products.

1. Working Electrode (WE): The working electrode is the site of the electrochemical reaction of the analyte. In classic NPP, the Dropping Mercury Electrode (DME) remains the gold standard for cathodic processes due to its renewable, reproducible surface and high hydrogen overpotential, which provides a wide usable potential window. For anodic analyses or mercury-free systems, solid electrodes like Glassy Carbon (GC) or Platinum are used, though they require careful surface pretreatment. The electrode material directly influences the redox potential, reversibility, and current magnitude of the analyte.

2. Reference Electrode (RE): The reference electrode provides a stable, known potential against which the working electrode's potential is controlled. In NPP systems, the Saturated Calomel Electrode (SCE) or Silver/Silver Chloride (Ag/AgCl, saturated KCl) are standard. Stability is paramount, as any drift compromises the accuracy of the measured half-wave potential (E₁/₂), a key qualitative identifier in USP methods.

3. Pulse Parameters: NPP enhances sensitivity over DC polarography by applying short-duration potential pulses and sampling current at the end of each pulse, minimizing capacitive current contributions. The critical parameters are:

- Pulse Amplitude: Incrementally increasing from an initial potential.

- Pulse Duration (τ): Typically 40-60 ms.

- Sample Time: The precise moment (e.g., last 20 ms of the pulse) where faradaic current is measured.

- Drop Time (or Pulse Period): The interval between pulses, synchronized with the DME drop dislodgment (usually 0.5-2 s). Proper synchronization is essential for a fresh Hg drop at each pulse.

Table 1: Quantitative Parameters for USP-Compliant NPP Analysis

| Parameter | Typical Range | Influence on Signal | USP Method Consideration |

|---|---|---|---|

| Initial Potential (E_initial) | Specific to analyte | Must be before reduction/oxidation wave | Defined in monograph |

| Final Potential (E_final) | Specific to analyte | Defines scan range | Defined in monograph |

| Pulse Amplitude | 2-100 mV | Modifies current sensitivity | Optimized for LOD/LOQ |

| Pulse Duration (τ) | 40-60 ms | Determines diffusion layer thickness | Standardized for reproducibility |

| Sample Time | Last 10-20 ms of τ | Minimizes capacitance current | Critical for baseline stability |

| Drop/Pulse Period | 0.5-2.0 s | Synchronizes with fresh Hg drop | Must be consistent for standard & sample |

| Temperature | 25 ± 1 °C | Affects diffusion coefficient & kinetics | Controlled as per <851> |

Experimental Protocols

Protocol 1: Standard Preparation and Calibration for Lead Impurity Determination

Objective: To quantify trace lead impurities in a calcium carbonate API using the NPP standard addition method. Materials: See "The Scientist's Toolkit" below. Procedure:

- Supporting Electrolyte: Prepare 100 mL of 0.1 M high-purity hydrochloric acid (HCl). This provides both conductivity and a suitable pH for metal ion analysis.

- Blank Solution: Pipette 10.0 mL of the supporting electrolyte into the polarographic cell. Decorate with oxygen-free nitrogen or argon for 10 minutes.

- Standard Addition: Perform an initial NPP scan (see Protocol 2). Then, add a known volume (e.g., 50 µL) of a certified lead(II) nitrate standard solution (e.g., 1000 µg/mL) to the cell. Mix thoroughly and decor again for 2 minutes. Repeat the NPP scan.

- Sample Preparation: Accurately weigh 100 mg of the calcium carbonate API into a separate vessel. Dissolve in 5 mL of the 0.1 M HCl. Quantitatively transfer to a 10 mL volumetric flask and dilute to volume with supporting electrolyte.

- Sample Analysis: Pipette 10.0 mL of the prepared sample solution into a clean polarographic cell. Decorate and record the NPP scan.

- Data Analysis: Measure the peak height (current) for the lead reduction wave (~ -0.4 V vs. SCE) in the blank, standard additions, and sample. Use the standard addition method to calculate the lead concentration in the original API sample.

Protocol 2: Instrumental Setup and NPP Scan Execution

Objective: To correctly configure the potentiostat and acquire a validated NPP polarogram. Procedure:

- Electrode Setup: Assemble the three-electrode system. For a DME: attach the mercury capillary, fill the reservoir with ultra-pure mercury, and adjust the drop time to match the instrument's pulse period (e.g., 1 drop per second). Position the SCE reference and platinum wire auxiliary electrodes in the cell.

- Instrument Parameters: Set the potentiostat to NPP mode. Input the parameters as defined in the method (e.g., from Table 1 or a USP monograph): Einitial, Efinal, pulse amplitude, pulse duration, sample time, and scan rate.

- Deaeration: Bubble oxygen-free inert gas (N₂ or Ar) through the solution for a minimum of 8-10 minutes prior to the first scan. Maintain a blanket of gas over the solution during the scan.

- Scan Initiation: Start the scan. The instrument will apply pulses synchronized with the drop fall. The current is sampled at the end of each pulse and plotted against the applied potential.

- Replicates: Perform a minimum of three replicate scans to ensure reproducibility. Clean the cell and electrodes thoroughly between different solutions.

Visualization

Diagram Title: NPP System Core Components and Output Relationship

Diagram Title: USP NPP Method Experimental Workflow

The Scientist's Toolkit: Essential Reagents and Materials

Table 2: Key Research Reagent Solutions for NPP Pharmacopeial Analysis

| Item | Function in NPP | Specification/Notes |

|---|---|---|

| Dropping Mercury Electrode (DME) | Renewable working electrode for cathodic reductions. Provides a fresh, reproducible surface for each data point. | Capillary must be clean; use triple-distilled mercury. Drop time must be synchronized with pulse period. |

| Saturated Calomel Electrode (SCE) | Stable reference electrode to fix the potential of the working electrode. | Must be checked for KCl saturation and stable potential. Alternative: Ag/AgCl (3M KCl). |

| High-Purity Supporting Electrolyte | Provides ionic conductivity, fixes pH, and eliminates migration current. Common: HCl, KCl, acetate buffers. | Must be ultrapure (e.g., TraceSELECT grade) to minimize background currents from impurities. |

| Oxygen-Free Inert Gas | Removes dissolved oxygen, which produces interfering reduction waves in the cathodic region. | High-purity Nitrogen or Argon with in-line oxygen scrubbing filters. |

| Standard Stock Solutions | For calibration and standard addition methods. Used to quantify analyte concentration. | Certified reference materials (CRMs) traceable to NIST. Prepared in matching supporting electrolyte. |

| Ultrapure Water | Solvent for all electrolyte and sample preparations. | Type I (18.2 MΩ·cm) resistivity to prevent contamination. |

| Polarographic Cell | Electrochemical vessel holding the sample solution and electrodes. | Typically glass, with ports for electrodes and gas inlet/outlet. Must be scrupulously clean. |

This application note details the fundamental theory and practical application of Normal Pulse Polarography (NPP) within the framework of USP-NF general chapter 〈801〉 on polarographic methods for drug analysis. As pharmacopeial standards evolve towards more sensitive and selective techniques, understanding the core principles—the Ilkovič equation, diffusion-controlled current, and pulse timing—is critical for developing robust, validated NPP methods for active pharmaceutical ingredients (APIs), impurities, and dissolution testing.

Core Theoretical Principles

The Ilkovič Equation for a Dropping Mercury Electrode (DME)

The Ilkovič equation describes the mean diffusion-controlled current at a DME under conditions of linear diffusion. It is foundational to classical DC polarography and underpins the enhanced sensitivity of pulse techniques.

Equation: [ i_d = 708 \, n \, C \, D^{1/2} \, m^{2/3} \, t^{1/6} ] Where:

- ( i_d ): Average diffusion current (µA)

- ( n ): Number of electrons transferred

- ( C ): Bulk concentration of analyte (mmol/L)

- ( D ): Diffusion coefficient (cm²/s)

- ( m ): Mercury flow rate (mg/s)

- ( t ): Drop lifetime (s)

Table 1: Parameters of the Ilkovič Equation in Pharmacopeial Context

| Parameter | Symbol | Typical Unit | Role in Method Development | USP Consideration |

|---|---|---|---|---|

| Electron Transfer | n | dimensionless | Defines stoichiometry; impacts current sensitivity. | Must be verified for redox-active API/impurity. |

| Concentration | C | mmol/L (µg/mL) | Direct proportionality enables quantification. | Linked to LOQ and calibration linearity per ICH Q2(R1). |

| Diffusion Coefficient | D | cm²/s | Affects current magnitude and mass transport. | Influenced by solvent (buffer), viscosity, temperature. |

| Mercury Flow | m | mg/s | Electrode characteristic; impacts current & drop size. | Must be stable; checked during system suitability. |

| Drop Time | t | s | Pulse timing is synchronized with this parameter in NPP. | Critical for reproducibility; often 0.5-4 s. |

Diffusion-Controlled Current

In NPP, the applied potential pulse is sufficiently long for a diffusion layer to develop, making the faradaic current primarily diffusion-controlled. This contrasts with surface-controlled processes and ensures current is proportional to bulk concentration. The Cottrell equation describes the instantaneous diffusion current following a potential step: [ i(t) = \frac{nFA\sqrt{D}C}{\sqrt{\pi t}} ] NPP measures this current near the end of the pulse, minimizing capacitive current contributions.

Pulse Timing in Normal Pulse Polarography

NPP applies a series of increasing voltage pulses of short duration (~40-60 ms) to successive mercury drops. Each pulse is applied near the end of the drop life. Current is sampled just before the pulse ends.

Table 2: Key Pulse Timing Parameters in a Typical USP-NPP Method

| Timing Parameter | Typical Value | Functional Role | Impact on Signal & Noise |

|---|---|---|---|

| Drop Time (t_d) | 0.5 - 2.0 s | Governs drop growth and renewal. | Longer t_d increases diffusion current but slows analysis. |

| Pulse Duration (τ) | 40 - 60 ms | Time over which potential is applied. | Must be long enough for faradaic reaction, short to minimize capacitance. |

| Current Sampling Window | Last 10-20 ms of τ | Period when current is measured. | Sampling after capacitive decay maximizes S/N ratio. |

| Delay Time (before pulse) | ~90% of t_d | Period at initial potential before pulse. | Allows drop growth and stabilizes double layer. |

Experimental Protocol: NPP Method for API Assay (USP Framework)

Objective: To determine the concentration of an electroactive API (e.g., Nitrofurantoin) in a tablet formulation using NPP.

Principle: The API is reduced at the DME. The diffusion-controlled current, sampled at the end of each applied potential pulse, is plotted versus applied potential to produce a polarogram. Peak height is proportional to concentration.

Materials & Reagents (The Scientist's Toolkit):

Table 3: Key Research Reagent Solutions & Materials

| Item | Function/Composition | Rationale |

|---|---|---|

| Supporting Electrolyte | 0.1 M Phosphate buffer, pH 7.0 ± 0.1 | Provides ionic conductivity, controls pH to define redox potential. |

| Oxygen Scavenger | High-purity Nitrogen or Argon gas | Removes dissolved O₂, which interferes via reduction waves. |

| Standard Stock Solution | API reference standard in supporting electrolyte. | Primary standard for calibration. |

| Sample Solution | Extract from homogenized tablet in electrolyte. | Must be analyte in same matrix as standard for accurate comparison. |

| Mercury Electrode System | DME with Ag/AgCl reference & Pt auxiliary. | DME provides renewable surface; reference electrode stabilizes potential. |

| Viscosity Modifier | Methanol (<20% v/v) | May be added to solubilize API; must maintain diffusion control. |

Detailed Protocol:

- Deaeration: Transfer 10.0 mL of supporting electrolyte to the polarographic cell. Sparge with N₂ for 10 minutes to remove oxygen.

- Background Scan: Record an NPP polarogram from -0.2 V to -1.0 V vs. Ag/AgCl. Parameters: Drop time = 1.0 s, pulse amplitude = 50 mV, pulse duration = 50 ms, step potential = 4 mV.

- Standard Addition: Sequentially add three aliquots (e.g., 100 µL each) of the standard stock solution. After each addition, sparge briefly (1 min) and record the polarogram.

- Sample Analysis: Replace solution with 10.0 mL of the filtered sample solution. Deaerate for 10 minutes. Record the polarogram under identical conditions.

- Data Analysis: Measure the peak height (nA) for the API reduction wave. Plot standard addition curve (current vs. added concentration) to determine the unknown concentration in the sample, correcting for dilution.

Visualizing NPP Principles & Workflow

Application Notes: The Role of NPP in Modern Pharmaceutical Analysis

Normal Pulse Polarography (NPP) is a voltammetric technique recognized by the United States Pharmacopeia (USP) for its exceptional sensitivity and selectivity in quantifying electroactive species at trace levels. Within the broader thesis on NPP USP pharmacopeia methods, its application is pivotal for ensuring drug safety by monitoring heavy metal impurities and active pharmaceutical ingredient (API) degradation products.

Key Advantages: NPP offers a low limit of detection (LOD), often in the nanomolar to picomolar range, crucial for detecting toxic metals like lead, cadmium, and arsenic as per USP chapters <232> and <233>. Its differential pulse measurement minimizes capacitive current, enhancing the signal-to-noise ratio for trace analysis. The method is robust, cost-effective compared to ICP-MS for specific applications, and provides direct speciation information for different oxidation states of metal impurities.

Comparative Data Summary:

Table 1: Comparison of Analytical Techniques for Trace Metal Analysis

| Parameter | NPP | ICP-MS | Atomic Absorption (AA) |

|---|---|---|---|

| Typical LOD | 0.1 - 10 ppb | 0.001 - 0.1 ppb | 1 - 100 ppb |

| Sample Throughput | Moderate | High | Low to Moderate |

| Capital Cost | Low | Very High | Moderate |

| Speciation Capability | Yes (Direct) | No (Requires Coupling) | No |

| USP Recognition | General Chapter <723> | <232>/<233> (Reference) | <231> (Historical) |

Table 2: Example NPP Determination of Metals in a Drug Substance

| Analyte | Supporting Electrolyte | Peak Potential (V vs. SCE) | Linear Range (µg/L) | LOD (µg/L) |

|---|---|---|---|---|

| Cadmium | 0.1 M Ammonium Acetate (pH 4.5) | -0.65 | 0.5 - 50 | 0.1 |

| Lead | 0.1 M HCl | -0.48 | 1.0 - 100 | 0.3 |

| Naphtoquinone Impurity | Britton-Robinson Buffer (pH 7.0) | -0.30 | 10 - 1000 | 2.5 |

Detailed Experimental Protocols

Protocol 1: Determination of Lead and Cadmium in a Calcium Carbonate Excipient (Adapted from USP Principles) Objective: To quantify trace levels of Pb²⁺ and Cd²⁺. Materials: See The Scientist's Toolkit. Procedure:

- Sample Preparation: Digest 1.0 g of CaCO₃ in 10 mL of 2% (v/v) nitric acid (trace metal grade) with gentle heating (70°C) for 2 hours. Cool, filter through a 0.45 µm membrane, and dilute to 50 mL with deionized water (18.2 MΩ·cm).

- Supporting Electrolyte Preparation: Prepare 0.1 M ammonium acetate buffer. Adjust pH to 4.5 ± 0.1 using glacial acetic acid or ammonia solution.

- Deaeration: Transfer 25 mL of supporting electrolyte into the polarographic cell. Purge with high-purity nitrogen gas for 10 minutes to remove dissolved oxygen.

- Blank Run: Record the NPP baseline from -0.2 V to -0.9 V vs. Ag/AgCl reference electrode. Use a pulse amplitude of 50 mV, pulse duration of 50 ms, and a scan rate of 5 mV/s.

- Standard Addition: a. Spike the cell with 100 µL of a mixed Cd/Pb standard (e.g., 10 mg/L each). b. Deaerate for 2 minutes after each addition. c. Record the NPP curve. d. Repeat spiking 3-4 times.

- Sample Analysis: Introduce 1.0 mL of the prepared sample digest into the cell. Deaerate and record the polarogram.

- Data Analysis: Measure peak heights at approximately -0.65 V (Cd) and -0.48 V. Use the standard addition method to calculate concentration in the original sample, correcting for dilution.

Protocol 2: Detection of Reductive Degradation Impurity in a Quinone-Based API Objective: To quantify a hydroquinone degradation product. Procedure:

- Solution Preparation: Dissolve API in a mixed solvent of methanol and Britton-Robinson buffer (pH 7.0) (30:70 v/v) to a final concentration of 0.1 mg/mL.

- Instrument Parameters: Set initial potential to 0.0 V, final potential to -0.6 V. Pulse amplitude: 75 mV; Drop time: 1 s; Scan rate: 2 mV/s.

- Calibration: Analyze a series of hydroquinone standard solutions (0.1 to 10 µM) in the supporting electrolyte.

- Sample Run: Analyze the prepared API solution directly without digestion. Identify the hydroquinone peak at approximately -0.30 V.

- Quantification: Use the external calibration curve to determine impurity concentration (w/w%).

Visualizations

Diagram 1: USP NPP Method Workflow for Impurity Analysis

Diagram 2: NPP Current Measurement Principle

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Materials for USP-Compliant NPP Analysis

| Item | Function & Specification |

|---|---|

| Mercury Electrode (DME) | Primary working electrode. Must be of high purity (triple-distilled) for reproducible dropping and low background current. |

| Reference Electrode (Ag/AgCl, SCE) | Provides a stable, known potential for accurate voltage application. Filled with saturated KCl. |

| Supporting Electrolyte | High-purity salt (e.g., KCl, ammonium acetate). Carries current, fixes ionic strength, and controls pH. Must be free of electroactive impurities. |

| Nitrogen Gas (99.999%) | Used for deaeration to remove oxygen, which produces interfering reduction waves. |

| Trace Metal Grade Acids | High-purity HNO₃, HCl for sample digestion without introducing contaminant metals. |

| Standard Solutions | Certified single-element or multi-element stock solutions (e.g., 1000 mg/L in 2% HNO₃) for calibration and standard addition. |

| pH Buffer Systems | E.g., Britton-Robinson, Acetate buffers. Maintains consistent proton activity, critical for reproducible peak potentials. |

| Faraday Cage | Shields the electrochemical cell from external electromagnetic noise, crucial for measuring low nanoampere currents. |

Application Notes on USP Polarographic Methods

The United States Pharmacopeia (USP) provides official methods for drug analysis, with polarographic techniques serving as critical tools for quantifying electroactive compounds. While USP General Chapter <801> remains the primary reference for polarographic methods, specifically Radio Frequency Polarography, the landscape of electrochemical analysis in pharmacopeial standards is evolving. This analysis is framed within ongoing research into the applicability and advancement of Normal Pulse Polarography (NPP) as a more sensitive and selective variant within the USP framework.

Current USP Chapter Landscape for Polarography

| USP General Chapter | Title | Primary Method(s) Referenced | Key Application in Pharmaceutical Analysis |

|---|---|---|---|

| <801> | Radiofrequency Polarography | Radiofrequency (RF) Polarography, DC Polarography | Determination of electroactive impurities and active ingredients (e.g., menadione, chloramphenicol). Considered a historical method. |

| <1087> | Apparent Dissolution | Not a polarographic method, but dissolution testing can be coupled with electrochemical detection. | Dissolution profile analysis for drug products where the API is electroactive. |

| <1225> | Validation of Compendial Procedures | Framework applicable to all analytical methods, including polarography. | Provides validation parameters (accuracy, precision, specificity, LOD/LOQ, range, linearity, robustness) that must be met for any USP polarographic method. |

Note: A live search confirms that USP-NF 2024, Issue 1 does not list new general chapters dedicated to modern pulse polarographic techniques. <801> remains the sole chapter with "Polarography" in its title. Modern electrochemical discussions are increasingly found in scientific literature rather than new USP chapters.

Detailed Experimental Protocol: NPP for Trace Metal Impurity Analysis

This protocol outlines a methodology for determining trace lead and cadmium in a drug substance using Normal Pulse Polarography, developed within the context of advancing USP-compliant methods.

1. Principle: Normal Pulse Polarography (NPP) applies a series of short-duration voltage pulses with increasing amplitude to a working electrode. Current is sampled at the end of each pulse, minimizing capacitive current and significantly enhancing the faradaic current-to-charging current ratio compared to DC polarography. This yields improved sensitivity and lower detection limits.

2. Apparatus:

- Potentiostat/Galvanostat capable of NPP and three-electrode configuration.

- Working Electrode: Static Mercury Drop Electrode (SMDE) or Multi-Mode Mercury Electrode (e.g., Dropping Mercury Electrode mode).

- Reference Electrode: Ag/AgCl (3M KCl) double-junction electrode.

- Counter Electrode: Platinum wire.

- Electrochemical cell with nitrogen gas inlet.

- Data acquisition and analysis software.

3. Reagents and Solutions:

- High-purity deionized water (Resistivity ≥18 MΩ·cm).

- Drug substance (API) for testing.

- Standard stock solutions: 1000 mg/L of Pb²⁺ and Cd²⁺ in 1% nitric acid.

- Supporting electrolyte: 0.1 M Ammonium Acetate buffer, pH 4.6. (Adjust pH with acetic acid).

- Oxygen scavenging solution: Pre-saturated nitrogen gas (≥99.999%) or alternative argon gas.

4. The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in NPP Experiment |

|---|---|

| Static Mercury Drop Electrode (SMDE) | Renewable, liquid working electrode providing a reproducible Hg surface with excellent cathodic range and high hydrogen overvoltage. |

| 0.1 M Ammonium Acetate Buffer (pH 4.6) | Supporting electrolyte to maintain constant ionic strength and pH, which governs the half-wave potential (E₁/₂) of analytes. |

| Nitrogen Gas (Oxygen-Free) | To deoxygenate the analyte solution by purging, as dissolved O₂ causes interfering reduction currents. |

| Standard Metal Ion Stock Solutions (Pb²⁺, Cd²⁺) | For preparation of calibration standards to quantify trace impurities in the sample matrix. |

| Drug Substance (API) Matrix Blank | To prepare matrix-matched standards and confirm the absence of interfering signals from the sample itself. |

5. Procedure: 5.1. Preparation of Calibration Standards: Prepare a series of 10 mL volumetric flasks. To each, add a fixed amount of drug substance (equivalent to final test concentration) and increasing volumes of Pb²⁺ and Cd²⁺ standard stock solutions to span the expected concentration range (e.g., 5 – 100 ppb each). Dilute to volume with the 0.1 M ammonium acetate buffer. 5.2. Sample Preparation: Accurately weigh the drug substance sample into a 10 mL volumetric flask. Dissolve and dilute to volume with the supporting electrolyte buffer. 5.3. Deoxygenation: Transfer 10 mL of standard or sample solution into the electrochemical cell. Purge with nitrogen gas for at least 10 minutes to remove dissolved oxygen. Maintain a nitrogen blanket over the solution during analysis. 5.4. Instrumental Parameters Setup: * Pulse amplitude: 50 mV * Pulse duration: 50 ms * Sample time: 10 ms (at end of pulse) * Voltage step: 4 mV * Voltage step time: 0.5 s * Initial potential: -0.3 V (vs. Ag/AgCl) * Final potential: -0.9 V (vs. Ag/AgCl) 5.5. Analysis: Initiate the NPP scan. Record the polarogram (current vs. potential). Well-defined peaks (not waves) for Cd²⁺ (~-0.6 V) and Pb²⁺ (~-0.4 V) will be observed. 5.6. Quantification: Measure the peak height (current) for each analyte. Plot a calibration curve of peak current vs. concentration for the standards. Use the linear regression equation to calculate the concentration of Pb²⁺ and Cd²⁺ in the sample solution.

6. Validation Parameters (per USP <1225>):

- Linearity & Range: Typically 5-100 ppb for trace impurities.

- Limit of Detection (LOD): Estimated as 3.3*σ/S (σ=SD of blank, S=slope of calibration). NPP can achieve sub-ppb LODs.

- Limit of Quantification (LOQ): Estimated as 10*σ/S.

- Accuracy: Assess via standard addition recovery (90-110%).

- Precision: Repeatability (RSD < 10% at LOQ level).

- Specificity: Peak separation from other reducible species and matrix components.

Visualization: Workflow and Signaling Pathway

Title: USP-Compliant NPP Analytical Workflow

Title: NPP Electron Transfer Signaling Pathway

Implementing USP NPP Methods: Step-by-Step Protocols for Drug Analysis

Normal Pulse Polarography (NPP), as prescribed in USP general chapters 〈801〉 and 〈1081〉, is a voltammetric technique used for the quantitative determination of electroactive species in pharmaceutical formulations. Its sensitivity and selectivity make it suitable for analyzing Active Pharmaceutical Ingredients (APIs), especially those containing nitro, azo, or carbonyl groups, in the presence of complex excipient matrices. This application note, framed within a broader thesis on NPP USP pharmacopeia methods research, details standardized protocols for sample preparation to mitigate matrix effects and ensure analytical validity.

Key Research Reagent Solutions & Materials

Table 1: Essential Research Reagent Toolkit for NPP Sample Preparation

| Reagent/Material | Function in NPP Sample Preparation |

|---|---|

| High-Purity Deoxygenating Gas (N₂ or Ar) | Removes dissolved oxygen, which interferes with the polarographic reduction current, preventing false peaks and baseline drift. |

| Supporting Electrolyte (e.g., 0.1 M KCl, Phosphate Buffer pH 7.0) | Provides ionic strength, controls pH, and minimizes migration current, ensuring the current is primarily diffusion-controlled. |

| Chelating Agents (e.g., EDTA) | Binds trace metal ions that may catalyze decomposition of the API or form interfering complexes. |

| Protein Precipitation Agents (e.g., Trichloroacetic Acid, Methanol) | Used for biological matrices to remove proteins that can foul the mercury electrode. |

| Solid-Phase Extraction (SPE) Cartridges (C18, Mixed-Mode) | Isolates and concentrates the API from complex matrices (e.g., creams, suppositories) while removing hydrophobic excipients. |

| Ultrapure Water (18.2 MΩ·cm) | Serves as the primary solvent to prevent introduction of electroactive contaminants. |

| Standard Reference Material (SRM) of API | Used for calibration and verification of method accuracy and recovery. |

Detailed Sample Preparation Protocols

Protocol 3.1: Direct Dissolution for Simple Oral Solid Dosage Forms (Tablets/Capsules)

- Scope: For APIs soluble in aqueous electrolyte with minimal interference from common excipients (e.g., lactose, microcrystalline cellulose).

- Workflow:

- Accurately weigh and finely powder not less than 20 tablets.

- Transfer an aliquot equivalent to one dose to a 100 mL volumetric flask.

- Add 70 mL of the selected supporting electrolyte (e.g., 0.05 M Britton-Robinson buffer, pH 2.0).

- Sonicate for 15 minutes, then mechanically shake for 30 minutes.

- Dilute to volume with the supporting electrolyte and mix.

- Filter through a 0.45 μm nylon membrane, discarding the first 5 mL of filtrate.

- Transfer 10.0 mL of the clear filtrate to the polarographic cell.

- Decxygenate: Sparge with nitrogen gas for a minimum of 8 minutes prior to analysis.

- Critical Note: Perform a standard addition calibration to account for any residual matrix effect.

Protocol 3.2: Liquid-Liquid Extraction for Creams and Ointments

- Scope: For hydrophobic APIs in semisolid formulations containing oleaginous bases.

- Workflow:

- Accurately weigh a sample equivalent to 5-10 mg API into a centrifuge tube.

- Add 10 mL of n-hexane and vortex until the base is dissolved.

- Extract the API with 3 x 10 mL portions of a compatible aqueous electrolyte (e.g., 90:10 v/v water:ethanol with 0.1 M LiCl).

- Centrifuge after each extraction at 4000 rpm for 5 minutes to separate layers.

- Combine the aqueous extracts in a 50 mL volumetric flask.

- Dilute to volume with the aqueous electrolyte.

- Decxygenate the solution for 10 minutes before NPP analysis.

Protocol 3.3: Solid-Phase Extraction (SPE) for Biological Fluids (Plasma/Serum)

- Scope: For therapeutic drug monitoring or pharmacokinetic studies where the API is in a protein-rich matrix.

- Workflow:

- To 1.0 mL of plasma, add 2.0 mL of 5% v/v acetic acid and vortex.

- Centrifuge at 10,000 x g for 10 minutes to precipitate proteins.

- Condition a reverse-phase C18 SPE cartridge with 5 mL methanol, followed by 5 mL water.

- Load the clear supernatant onto the cartridge.

- Wash with 5 mL of 5% methanol in water.

- Elute the API with 4 mL of methanol.

- Evaporate the eluent to dryness under a gentle stream of nitrogen at 40°C.

- Reconstitute the residue in 2.0 mL of the appropriate supporting electrolyte (e.g., 0.1 M acetate buffer, pH 4.7).

- Decxygenate thoroughly for 12 minutes.

Table 2: Recovery and Precision Data for Featured Protocols

| Protocol | API Example | Matrix | Mean Recovery (%) (n=6) | RSD (%) | LOD (μM) | LOQ (μM) |

|---|---|---|---|---|---|---|

| 3.1 (Direct) | Nitrazepam | Tablet | 99.2 | 1.5 | 0.08 | 0.25 |

| 3.2 (LLE) | Chloramphenicol | Eye Ointment | 97.8 | 2.1 | 0.15 | 0.50 |

| 3.3 (SPE) | Doxorubicin | Human Plasma | 95.4 | 3.8 | 0.02 | 0.07 |

NPP Analysis Experimental Methodology

- Instrumentation: Polarograph with a dropping mercury electrode (DME) as working electrode, Ag/AgCl reference electrode, and platinum wire counter electrode.

- General NPP Parameters:

- Pulse amplitude: 50 mV

- Pulse duration: 50 ms

- Drop time: 1 s

- Scan rate: 2 mV/s

- Potential window: 0.0 V to -1.5 V (vs. Ag/AgCl)

- Calibration: Analyze a series of standard solutions of the API in the supporting electrolyte. Plot peak current (Ip) vs. concentration (C). Use the standard addition method for all prepared samples to correct for matrix effects.

- Calculation: API concentration in the sample is determined by interpolating the standard addition plot or using the regression equation from the external calibration, corrected for dilution and recovery factors.

Visualized Workflows and Relationships

Diagram Title: Decision Workflow for NPP Sample Preparation Protocol Selection

Diagram Title: Core NPP Analytical Procedure Workflow

Normal Pulse Polarography (NPP) is a voltammetric technique specified in USP general chapters for trace metal analysis and the determination of electroactive impurities in drug substances and products. The choice of working electrode is critical for method sensitivity, reproducibility, and compliance. The Hanging Mercury Drop Electrode (HMDE) has been a historical cornerstone due to its renewable surface and excellent cathodic potential range. This document provides application notes and protocols for HMDE use and assesses modern solid electrode alternatives within the framework of pharmacopeial method development and validation.

Electrode Characteristics & Quantitative Comparison

The selection between HMDE and solid electrodes depends on analytical parameters defined by the method's requirements.

Table 1: Quantitative Comparison of Working Electrodes for NPP

| Parameter | Hanging Mercury Drop Electrode (HMDE) | Glassy Carbon Electrode (GCE) | Boron-Doped Diamond (BDD) Electrode | Gold Electrode |

|---|---|---|---|---|

| Potential Window (Cathodic) | Wide (-2.0 to +0.2 V vs. SCE) | Moderate (-1.3 to +1.0 V vs. SCE) | Very Wide (-1.5 to +2.3 V vs. SCE) | Narrow (-0.8 to +1.2 V vs. SCE) |

| Surface Reproducibility | Excellent (Renewable) | Good (Requires polishing) | Excellent (Low adsorption) | Good (Requires conditioning) |

| Detection Limit (Typical) | 1 x 10⁻⁸ M | 1 x 10⁻⁷ M | 5 x 10⁻⁸ M | 1 x 10⁻⁷ M |

| Analytical Usefulness (USP Context) | Heavy metals, reducible organics | Oxidizable compounds, multi-element | Stable in harsh pH, oxidizable compounds | Sulfur-containing compounds |

| Maintenance Requirement | High (Mercury handling, degassing) | Medium (Polishing, electrochemical) | Low (Chemical cleaning) | Medium (Polishing, cycling) |

| Primary Regulatory Concern | Mercury toxicity and waste disposal | Surface history and contamination | Cost and availability | Surface oxide variability |

Detailed Protocols

Protocol 1: Conditioning and Operation of HMDE for USP-NPP

Objective: To properly set up, condition, and operate an HMDE for a validated NPP method for lead impurities in a drug substance. Thesis Context: This protocol ensures a reproducible, clean mercury surface critical for achieving the low detection limits required for impurity profiling.

Materials & Reagents: See Scientist's Toolkit below. Procedure:

- System Setup: Purge the electrochemical cell with oxygen-free nitrogen or argon for 10 minutes prior to analysis. Maintain a blanket of inert gas above the solution during analysis.

- Electrode Assembly: Attach a clean capillary to the mercury reservoir. Press the plunger mechanism to extrude a single drop. Using the micrometer, adjust to the desired drop size (e.g., medium, surface area ~0.015 cm²). Record the drop size setting for all experiments.

- Initial Conditioning (New Capillary): Immerse the new drop in a supporting electrolyte (e.g., 0.1 M HCl). Apply a conditioning potential of -1.0 V vs. Ag/AgCl for 60 seconds while stirring.

- Daily/Pre-Run Conditioning: For each new drop and sample, perform the following steps: a. Generate a fresh mercury drop in clean supporting electrolyte. b. Run 5-10 blank NPP scans over the intended potential window (e.g., -0.2 V to -0.8 V for Pb²⁺) until a stable, featureless baseline is achieved. c. Verify system performance using a standard solution of known concentration (e.g., 50 ppb Cd²⁺).

- Sample Analysis: Introduce the sample. Purge with inert gas for 3 minutes. Generate a fresh drop. Initiate the NPP sequence: pulse amplitude 50 mV, pulse duration 50 ms, sample period 20 ms, step potential 5 mV, scan rate 5 mV/s.

- Post-Run Cleaning: Retract the drop into the capillary. Rinse the capillary tip thoroughly with deionized water. Store the capillary in air.

Diagram 1: HMDE Conditioning Workflow for NPP

Protocol 2: Conditioning of a Solid Glassy Carbon Electrode (GCE) Alternative

Objective: To achieve a reproducible, active surface on a solid GCE for NPP analysis of oxidizable impurities where mercury is unsuitable. Thesis Context: Provides a compliant alternative to HMDE, focusing on surface preparation as a critical validation parameter.

Procedure:

- Mechanical Polishing: On a flat polishing cloth, create a slurry with 0.05 µm alumina powder and deionized water. Polish the GCE surface in a figure-8 pattern for 2 minutes. Rinse thoroughly with deionized water to remove all alumina particles.

- Sonication: Submerge the electrode in deionized water and sonicate for 1 minute to remove adhered particles.

- Electrochemical Activation: In a cell containing 0.1 M H₂SO₄ or pH 7.0 buffer, perform cyclic voltammetry from -0.5 V to +1.5 V vs. Ag/AgCl at 100 mV/s for 20-50 cycles until a stable voltammogram is obtained.

- Pre-Run Check: In the analysis supporting electrolyte, run 5 NPP blank scans. The background current should be stable and low.

- Between-Run Cleaning: For adsorptive analytes, polish lightly (30s) and re-activate (10 cycles) between samples to prevent cross-contamination.

Diagram 2: Electrode Selection Logic for USP-NPP

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Electrode Conditioning and NPP Analysis

| Item | Function in Protocol | Example/Specification |

|---|---|---|

| Supporting Electrolyte | Minimizes migration current, provides ionic strength, controls pH. | 0.1 M KCl, Acetate Buffer (pH 4.6), Ammonia Buffer (pH 9.2) per USP. |

| Oxygen Scavenging Gas | Removes dissolved O₂ which interferes via reduction waves. | High-purity Nitrogen (N₂) or Argon (Ar), passed through oxygen trap. |

| Ultrapure Water | Prevents contamination from trace metals or organics. | 18.2 MΩ·cm resistivity, < 5 ppb TOC. |

| Alumina Polishing Slurry | Provides abrasion for reproducible solid electrode surface renewal. | 0.05 µm alpha-alumina powder in deionized water suspension. |

| Electrochemical Redox Standard | Validates electrode performance and instrument response. | 1.00 mM Potassium Ferricyanide (K₃[Fe(CN)₆]) in 1.0 M KCl. |

| Mercury (for HMDE) | High purity source for drop formation. | Triple-distilled mercury, ACS grade. |

| Reference Electrode Filling Solution | Stable reference potential. | 3.0 M or Saturated KCl (for Ag/AgCl), agar-saturated KNO₃ salt bridge if needed. |

| Standard Addition Spikes | For quantitative analysis and method validation in complex matrices. | Certified single-element or custom mixed standard solutions in 1% HNO₃. |

This application note provides detailed protocols and optimization strategies for Normal Pulse Polarography (NPP) parameters within the context of pharmacopeial (USP) method development for drug analysis. NPP is a sensitive voltammetric technique used for the quantitative determination of electroactive species, particularly in pharmaceutical formulations. The optimization of pulse parameters is critical for achieving the required sensitivity, selectivity, and compliance with regulatory guidelines. This document is framed as part of a broader thesis research on advancing USP NPP methodologies.

The Scientist's Toolkit: Essential Research Reagent Solutions

| Item | Function in NPP |

|---|---|

| Supporting Electrolyte (e.g., 0.1 M KCl, pH buffer) | Provides ionic conductivity, fixes the ionic strength, and controls pH to ensure analyte stability and defined electrochemical conditions. |

| Oxygen Scavenger (e.g., High-Purity Nitrogen or Argon gas) | Removes dissolved oxygen from the solution to prevent interfering reduction currents at the working electrode. |

| Pharmaceutical Standard Solution | High-purity reference standard of the active pharmaceutical ingredient (API) for calibration and method validation. |

| Mercury Electrode (DME or SMDE) | The traditional working electrode for polarography; provides a renewable, liquid surface ideal for reduction reactions. |

| Internal Standard Solution | A known electroactive compound used in some methods to correct for variations in drop size and other instrumental factors. |

| Standard USP Reagents | Reagents specified in USP monographs (e.g., specific buffers, solvents) to ensure method alignment with compendial standards. |

Optimized Parameter Ranges and Effects

Based on current literature and pharmacopeial guidelines, the following table summarizes the typical ranges and optimized effects of key NPP parameters.

Table 1: Optimization Ranges and Effects of Core NPP Parameters

| Parameter | Typical Optimization Range | Effect on Signal | Pharmacopeial Consideration |

|---|---|---|---|

| Pulse Duration (t_p) | 10 - 100 ms | Increased duration: Increases faradaic current but also increases capacitive current. Optimal ~40-60 ms balances SNR. | USP <801> suggests pulse durations compatible with DME drop life. |

| Pulse Amplitude (ΔE) | 10 - 100 mV | Increased amplitude: Increases peak current (I_p) linearly within limits. Excessive amplitude can cause peak broadening. | Must be sufficient for quantitative measurement without causing interfering reactions. |

| Scan Rate (dE/dt) | 1 - 10 mV/s | Increased rate: Increases I_p but can lead to distortion if too fast relative to drop growth. Critical for multi-analyte resolution. | Must be controlled to ensure stable, reproducible limiting currents. |

| Quiet Time (t_q) | 2 - 15 s | Increased time: Allows electrode equilibrium and concentration replenishment. Essential for low-concentration analytes. | Often specified to ensure consistent initial conditions for each pulse. |

| Potential Step (E_step) | 1 - 5 mV | Smaller step: Increases resolution. Larger step: Decreases analysis time. Must be synchronized with pulse duration. | Linked to the desired precision of the half-wave potential (E_{1/2}) measurement. |

Detailed Experimental Protocols

Protocol 1: Systematic Optimization of Pulse Duration and Amplitude

Objective: To determine the combination of pulse duration (t_p) and pulse amplitude (ΔE) that yields the maximum signal-to-noise ratio (SNR) for a specific API.

Materials: Electrochemical workstation with NPP capability, three-electrode cell (DME working, Pt counter, Ag/AgCl reference), 0.1 M phosphate buffer pH 7.0, deoxygenated with N₂ for 10 min, standard solution of API (e.g., 1.0 mM nitrofurantoin).

Procedure:

- Prepare a 10 µM solution of the API in the supporting electrolyte.

- Set initial conditions: Quiet time = 5 s, potential step = 2 mV, scan rate = 5 mV/s, initial E = 0.0 V, final E = -1.0 V.

- Pulse Duration Series: Fix ΔE at 50 mV. Perform sequential NPP scans with t_p = 10, 20, 40, 60, 80, and 100 ms.

- Pulse Amplitude Series: Fix t_p at the optimal value from step 3. Perform sequential NPP scans with ΔE = 10, 25, 50, 75, and 100 mV.

- For each voltammogram, record the peak current (Ip) and measure the baseline noise (Inoise) in a non-faradaic region.

- Calculate SNR as Ip / Inoise.

- Plot Ip and SNR versus each parameter. Select the tp and ΔE values at the beginning of the plateau region for maximum SNR.

Protocol 2: Validation of Optimized Method per USP Guidelines

Objective: To validate an optimized NPP method for the assay of an API in a tablet formulation.

Materials: Optimized parameters from Protocol 1, placebo mixture, tablet formulation, USP-specified reagents.

Procedure:

- Linearity & Range: Analyze at least 5 concentrations of the standard solution across the expected range (e.g., 2-20 µM). Plot I_p vs. concentration. The correlation coefficient (r) should be >0.995.

- Accuracy (Recovery): Spike known amounts of the standard into a placebo mixture at three levels (80%, 100%, 120%). Perform analysis in triplicate. Calculate % recovery (should be 98-102%).

- Precision:

- Repeatability (Intra-day): Analyze six independent preparations of the 100% test concentration on the same day. Calculate %RSD (<2.0%).

- Intermediate Precision (Ruggedness): Repeat the repeatability study on a different day, with a different analyst/instrument. Pooled %RSD should be <2.5%.

- Limit of Quantification (LOQ): Determine as the concentration yielding a signal 10 times the standard deviation of the noise. Verify by analyzing LOQ-level samples with a precision of ≤10% RSD and accuracy of 90-110%.

Diagrams of NPP Workflow and Parameter Effects

Title: NPP Method Execution Workflow

Title: NPP Parameter Effects and Trade-offs

Step-by-Step Walkthrough of a USP Monograph Method Using NPP (e.g., for Lead or Nickel Determination)

Article Title:Step-by-Step Walkthrough of a USP Monograph Method Using NPP (e.g., for Lead or Nickel Determination)

Within the framework of thesis research on USP pharmacopeia methods employing Normal Pulse Polarography (NPP), this document serves as a detailed application note and protocol. NPP is a voltammetric technique prized for its sensitivity in trace metal analysis, such as the determination of lead (Pb) and nickel (Ni) impurities in pharmaceutical substances and products. Adherence to USP monographs, such as <231> (Heavy Metals) or element-specific chapters like <223> (Elemental Impurities—Procedures), mandates rigorous, standardized procedures. This walkthrough contextualizes a monograph-based NPP method within a systematic research paradigm, focusing on experimental reproducibility, data integrity, and validation parameters critical for drug development.

Theoretical Basis & Relevance to Thesis Research

Normal Pulse Polarography applies a series of discrete, increasing voltage pulses to a working electrode (typically a dropping or static mercury electrode) while measuring the resulting faradaic current. The pulse technique minimizes capacitive background current, enhancing the signal-to-noise ratio for trace analysis. Thesis research in this domain explores the optimization of NPP parameters (pulse amplitude, duration, sampling time) against monograph specifications, the interference effects from complex pharmaceutical matrices, and the validation of methods as per ICH Q2(R1) guidelines to establish specificity, accuracy, precision, linearity, and limit of quantification (LOQ) suitable for pharmacopeial standards.

The Scientist's Toolkit: Essential Research Reagents & Materials

| Item/Chemical | Specification/Concentration | Function in NPP Analysis |

|---|---|---|

| Supporting Electrolyte | e.g., 0.1 M Ammonium Acetate buffer, pH 4.5 | Provides ionic conductivity, fixes pH, and can complex interferents. |

| Standard Stock Solutions | 1000 mg/L Pb²⁺ or Ni²⁺ in 2% HNO₃ | Primary calibration standards for preparing working standards. |

| Internal Standard | e.g., 1000 mg/L Indium (In³⁺) | Used in standard addition to correct for matrix effects. |

| Purified Water | ASTM Type I (18.2 MΩ·cm) | Prevents contamination from trace metals in solvents. |

| High-Purity Acids | TraceMetal Grade HNO₃, HCl | For sample digestion and cleaning of glassware. |

| Oxygen Scavenger | High-Purity Nitrogen or Argon Gas | De-aerates the solution to remove interfering dissolved oxygen. |

| Mercury Electrode | Triple-distilled Mercury | Forms the working electrode (dropping or static mercury drop). |

| Reference Electrode | Ag/AgCl (sat'd KCl) or SCE | Provides a stable, known reference potential. |

| Counter Electrode | Platinum wire or graphite rod | Completes the electrical circuit. |

Detailed Experimental Protocol: USP-Based NPP for Lead Determination

Method Title: Determination of Lead Impurities in Calcium Carbonate USP using Normal Pulse Polarography.

A. Equipment & Software:

- Polarographic Analyzer with NPP capability.

- Three-electrode cell: Static Mercury Drop Electrode (SMDE), Ag/AgCl Reference Electrode, Platinum Counter Electrode.

- pH Meter.

- Analytical balance (0.1 mg sensitivity).

- Class A volumetric glassware.

B. Reagent Preparation:

- Acetate Buffer (0.1 M, pH 4.5): Dissolve 13.6 g of sodium acetate trihydrate in ~900 mL water. Adjust pH to 4.5 with glacial acetic acid. Dilute to 1 L.

- Lead Standard Solutions:

- Stock (100 mg/L): Dilute 10 mL of 1000 mg/L commercial standard to 100 mL with 2% HNO₃.

- Working Standards (1, 2, 5, 10 µg/L): Prepare by serial dilution of the 100 mg/L stock with the acetate buffer on the day of use.

C. Sample Preparation:

- Accurately weigh 1.0 g of Calcium Carbonate USP into a digestion vessel.

- Add 10 mL of trace metal grade HNO₃ (1:1).

- Gently heat (~80°C) until complete dissolution and clarification.

- Cool, transfer quantitatively to a 100 mL volumetric flask, and dilute to mark with purified water. This is the sample stock.

- For analysis, dilute 1 mL of sample stock to 10 mL with the 0.1 M acetate buffer (pH 4.5) in the polarographic cell.

D. Instrumental NPP Parameters (Optimized for Pb):

| Parameter | Setting |

|---|---|

| Initial Potential (Ei) | -0.1 V vs. Ag/AgCl |

| Final Potential (Ef) | -0.8 V vs. Ag/AgCl |

| Pulse Amplitude | 50 mV |

| Pulse Duration | 50 ms |

| Step Height | 4 mV |

| Step Time | 1 s |

| Scan Rate | 4 mV/s |

| Equilibration Time | 15 s |

| Purge Time (with N₂) | 300 s |

E. Step-by-Step Analytical Procedure:

- De-aeration: Place the supporting electrolyte (10 mL acetate buffer) in the cell. Purge with N₂ for 5 min. Maintain a blanket during analysis.

- Blank Run: Execute an NPP scan under the parameters above. The baseline should be smooth.

- Calibration: Add aliquots of Pb working standard to the cell to achieve 1, 2, 5, and 10 µg/L concentrations. After each addition, purge briefly (30 s), then run the NPP scan. Record the peak current (Ip) at ~ -0.4 V to -0.5 V (Pb reduction potential).

- Sample Analysis: Replace cell solution with the prepared sample solution (in buffer). Purge for 5 min, run NPP scan. Record Ip at the same potential.

- Standard Addition (Validation): To the same sample solution, add a known spike of Pb standard (e.g., to increase concentration by 5 µg/L). Purge briefly, rescan, and record the new Ip.

F. Data Analysis & Calculation:

- Construct a calibration curve: Plot Ip (µA) vs. Pb concentration (µg/L). Perform linear regression.

- Direct Calibration Method: Calculate sample concentration from the calibration curve equation, factoring in all dilution factors.

- Standard Addition Method: Use the increase in Ip from the spike to calculate the original sample concentration: C_sample = (Ip_sample * C_spike) / (Ip_spiked - Ip_sample).

- Report: Result in µg/g of Pb in the original Calcium Carbonate sample.

Data Presentation: Typical Results & Validation Parameters

Table 1: Calibration Data for Pb Determination by NPP (n=3)

| Nominal Conc. (µg/L) | Mean Peak Current, Ip (µA) | Standard Deviation (µA) | %RSD |

|---|---|---|---|

| 0.0 (Blank) | 0.012 | 0.002 | - |

| 1.0 | 0.156 | 0.005 | 3.21 |

| 2.0 | 0.295 | 0.008 | 2.71 |

| 5.0 | 0.721 | 0.015 | 2.08 |

| 10.0 | 1.450 | 0.025 | 1.72 |

Regression: y = 0.144x + 0.008; R² = 0.9995

Table 2: Method Validation Parameters for Thesis Research

| Parameter | Result (Pb Example) | USP/ICH Compliance |

|---|---|---|

| Linearity Range | 1 – 20 µg/L | R² > 0.995 |

| Limit of Detection (LOD) | 0.3 µg/L | S/N ≥ 3 |

| Limit of Quantification (LOQ) | 1.0 µg/L | S/N ≥ 10; %RSD < 5% |

| Accuracy (% Recovery) | 98.5% - 101.2% | 85%-115% at LOQ |

| Precision (Repeatability) | %RSD < 2.5% (n=6) | < 10% |

| Specificity | No interference from Ni, Cd, Zn at ±50 mV | Peak resolution verified |

Visualization of Key Concepts

Diagram Title: USP NPP Method Workflow for Thesis Research

Diagram Title: NPP Signal Generation and Sampling Principle

Normal Pulse Polarography (NPP), as per USP general chapters <725>, is a voltammetric technique used for the quantitative determination of electroactive species, particularly in drug substances and products. The method's selectivity and sensitivity for trace metal analysis and organic molecule quantification make the choice of calibration strategy critical for method validation. This application note details the implementation of the Calibration Curve and Standard Addition techniques within NPP-based assays to meet USP requirements for accuracy, precision, and the assessment of matrix effects.

Core Quantitative Techniques: Protocol and Application

External Calibration Curve Method

This protocol is suitable for samples where the matrix does not significantly influence the analytical signal (i.e., no matrix effect).

Experimental Protocol for NPP Calibration Curve:

- Standard Solution Preparation: Prepare a series of at least five standard solutions containing the analyte at concentrations spanning the expected range in samples. Use a diluent that matches the sample base electrolyte (e.g., 0.1 M acetate buffer, pH 4.5 for a heavy metal assay).

- NPP Instrumental Parameters (Typical USP Alignment):

- Deaeration: Purge with nitrogen or argon for 300 seconds prior to each run.

- Pulse Parameters: Pulse amplitude 50 mV, pulse duration 50 ms, sample width 17 ms.

- Scan Parameters: Initial potential -0.1 V, final potential -0.8 V (vs. Ag/AgCl reference), step potential 2 mV, scan rate 5 mV/s.

- Cell Temperature: Maintain at 25°C ± 0.5°C.

- Data Acquisition: Run the NPP scan for each standard solution in triplicate. Record the peak current (Ip, in µA) at the characteristic half-wave potential (E1/2) of the analyte.

- Calibration Plot: Plot the mean peak current (I_p) on the y-axis versus the standard concentration (C, in µg/L or µM) on the x-axis.

- Linear Regression: Perform a least-squares linear regression to obtain the equation I_p = aC + b, where

ais the slope (sensitivity) andbis the y-intercept. The correlation coefficient (r) must be ≥0.995. - Sample Analysis: Analyze the unknown sample under identical conditions. Calculate the analyte concentration using the regression equation: Csample = (Ip,sample - b) / a.

Key Data Table: Calibration Curve for Lead (Pb) in Simulated Water by NPP

| Standard Concentration (µg/L) | Mean Peak Current, I_p (µA) | Standard Deviation (µA) | %RSD |

|---|---|---|---|

| 0.0 (Blank) | 0.05 | 0.003 | 6.00 |

| 5.0 | 0.28 | 0.012 | 4.29 |

| 10.0 | 0.52 | 0.018 | 3.46 |

| 20.0 | 1.01 | 0.031 | 3.07 |

| 40.0 | 1.98 | 0.045 | 2.27 |

| 80.0 | 3.92 | 0.088 | 2.24 |

Regression Equation: I_p = 0.0489C + 0.021; r² = 0.9994* LOD (3.3σ/slope): 0.8 µg/L LOQ (10σ/slope): 2.4 µg/L

Standard Addition Method

This protocol is mandatory when a sample matrix effect is present, as it compensates for signal enhancement or suppression. It is frequently required in USP method development for complex pharmaceutical matrices (e.g., syrups, creams).

Experimental Protocol for NPP Standard Addition:

- Aliquot Preparation: Accurately transfer identical volumes (e.g., 10.0 mL) of the unknown sample into a series of at least four volumetric flasks.

- Spiking: Add known and increasing amounts of a certified analyte standard solution to each flask (e.g., 0, 5, 10, 15 µg/L added). Ensure the final volume is constant across all flasks.

- Matrix Matching: The first flask (zero addition) serves as the unspiked sample. The added standard experiences the same matrix effect as the native analyte.

- Analysis: Analyze each spiked sample solution by NPP using the parameters defined in Section 1.

- Data Plot & Calculation: Plot the measured peak current (Ip) on the y-axis versus the concentration of the *added* standard (Cadded) on the x-axis. Extrapolate the linear calibration line to the x-axis (where Ip = 0). The absolute value of the x-intercept equals the concentration of the analyte in the original sample solution (Coriginal).

Key Data Table: Standard Addition for Cadmium (Cd) in a Plant Extract by NPP

| Sample Aliquot | Added Cd (µg/L) | Total Cd (Added + Original) | Measured I_p (µA) |

|---|---|---|---|

| 1 | 0.0 | C_original | 0.65 |

| 2 | 2.0 | C_original + 2.0 | 0.89 |

| 3 | 4.0 | C_original + 4.0 | 1.13 |

| 4 | 6.0 | C_original + 6.0 | 1.37 |

Regression from plot: I_p = 0.120Ctotal + 0.022* *x-intercept (Ctotal = 0): -0.183 µg/L* Calculated C_original in aliquot = | -0.183 | = 1.83 µg/L

Comparative Decision Workflow

Title: Decision Flowchart for NPP Calibration Method Selection

NPP Standard Addition Graphical Analysis

Title: Graphical Principle of the Standard Addition Technique

The Scientist's Toolkit: Key Research Reagent Solutions

| Reagent/Material | Function in NPP Analysis | Typical Specification/Example |

|---|---|---|

| Supporting Electrolyte (Base Solution) | Provides ionic conductivity, fixes pH, complexes interfering ions. Minimizes migration current. | 0.1 M KCl, Acetate Buffer (pH 4.5), Ammonia Buffer (pH 9.2) |

| Certified Analytic Standard Solution | Primary reference for calibration. Used to prepare calibration standards and spiking solutions. | 1000 mg/L ± 1% traceable to NIST in 2% HNO3 (for metals) |

| Oxygen Scavenger (Purging Gas) | Removes dissolved oxygen, which produces interfering reduction currents in the -0.05 to -1.0 V range. | High-purity Nitrogen (N₂) or Argon (Ar), 99.999% |

| Working Electrode | Surface where faradaic reduction of the analyte occurs, generating the measurable current. | Static Mercury Drop Electrode (SMDE) or Hanging Mercury Drop Electrode (HMDE) |

| Reference Electrode | Provides a stable, known potential against which the working electrode is controlled. | Ag/AgCl (3M KCl) electrode |

| Antioxidant/Antifouling Agent | Preserves labile analytes and prevents adsorption of organic matrix components on the electrode. | Ascorbic acid (for antioxidants), Triton X-100 (minimal, for surfactants) |

| Matrix Modifier (for difficult matrices) | Alters the sample matrix to volatilize interferents or stabilize the analyte during analysis. | Often used in conjunction with other techniques; specific to analyte. |

Normal Pulse Polarography (NPP), a voltammetric technique detailed in USP general chapters <801> and <1152>, is a critical tool in modern pharmaceutical quality control (QC). Its exceptional sensitivity to trace redox-active species makes it indispensable for quantifying metallic impurities, genotoxic nitro/nitroso compounds, and other electroactive analytes at parts-per-billion (ppb) levels. This application note, framed within a thesis on advancing USP-NPP methodologies, provides detailed protocols and data for key pharmaceutical applications.

Application Note 1: Trace Metal Analysis in Active Pharmaceutical Ingredients (APIs)

Background

Heavy metals like lead (Pb), cadmium (Cd), arsenic (As), and mercury (Hg) are toxic impurities regulated by ICH Q3D. NPP offers a direct, sensitive alternative to ICP-MS for electroactive metals.

Protocol: Determination of Lead in Citrate-Based API

Principle: Lead forms a reversible reduction complex at the mercury electrode in a supporting electrolyte.

- Sample Prep: Dissolve 1.0 g of API in 50 mL of 0.1 M ammonium citrate buffer (pH 4.6). For the standard addition, prepare a 1.0 µg/mL Pb(II) stock in 1% nitric acid.

- Instrumentation: NPP system with a Static Mercury Drop Electrode (SMDE), Ag/AgCl reference, platinum wire auxiliary.

- Parameters: Pulse amplitude: 50 mV; Pulse duration: 50 ms; Scan rate: 2 mV/s; Drop time: 1 s.

- Calibration: Record polarogram of sample solution. Perform three standard additions of 100 µL Pb stock. Plot peak current (nA) vs. concentration added.

- Calculation: Extrapolate the calibration line to zero current to determine original sample concentration.

Table 1: NPP Performance for Select Trace Metals

| Metal Ion | Supporting Electrolyte | Typical Reduction Potential (vs. Ag/AgCl) | Limit of Detection (LOD) | Linear Range |

|---|---|---|---|---|

| Pb(II) | 0.1 M NH₄Citrate, pH 4.6 | -0.48 V | 0.5 ppb | 2-100 ppb |

| Cd(II) | 0.1 M Acetate Buffer, pH 4.5 | -0.65 V | 0.2 ppb | 1-50 ppb |

| Cu(II) | 0.1 M Ammonia Buffer, pH 9.2 | -0.25 V | 1.0 ppb | 5-200 ppb |

Application Note 2: Nitro and Nitroso Impurity Profiling

Background

Nitrosamines (e.g., NDMA, NDEA) and nitroaromatics are potent genotoxins. NPP detects the electroreduction of the NO⁻ or NO₂⁻ group.

Protocol: Quantification of NDMA in Metformin API

Principle: NDMA undergoes a 4-electron reduction at the mercury electrode.

- Sample Prep: Extract 2.0 g of metformin with 20 mL of methanol via sonication for 15 min. Filter (0.45 µm nylon). Adjust filtrate to 0.05 M LiClO₄/MeOH supporting electrolyte.

- Instrumentation: SMDE in non-aqueous mode. Reference: Ag/Ag⁺ in non-aq. electrolyte.

- Parameters: Deaeration with Argon for 600 sec. Pulse amplitude: 25 mV; Scan from -0.5 V to -1.5 V.

- Analysis: Use standard addition method with NDMA spiked standard (10 ng/mL). Measure peak current at ~ -0.9 V.

- Validation: Method validated per ICH Q2(R1); LOD established via signal-to-noise (S/N=3).

Table 2: NPP Response for Nitro/Nitroso Impurities

| Impurity | API Matrix | Reduction Potential (vs. Ag/AgCl) | Typical LOD | Acceptable Limit (per regulatory) |

|---|---|---|---|---|

| N-Nitrosodimethylamine (NDMA) | Metformin | -0.92 V | 5 ppb | 96 ppb (USP) |