Maximizing Polarographic Precision: A Modern Guide to Supporting Electrolyte Selection and Optimization

This comprehensive guide examines the critical role of supporting electrolytes in achieving reliable and sensitive polarographic analysis, a cornerstone technique in electrochemical detection for pharmaceuticals and biomolecules.

Maximizing Polarographic Precision: A Modern Guide to Supporting Electrolyte Selection and Optimization

Abstract

This comprehensive guide examines the critical role of supporting electrolytes in achieving reliable and sensitive polarographic analysis, a cornerstone technique in electrochemical detection for pharmaceuticals and biomolecules. We explore the foundational principles of how electrolyte composition affects key parameters like diffusion current, half-wave potential, and resolution. Methodological strategies for selecting and applying electrolytes across various analyte classes are detailed, followed by systematic troubleshooting approaches for common issues such as polarographic maxima, poor resolution, and background interference. Finally, we present validation frameworks and comparative analyses of traditional versus modern ionic liquid and deep eutectic solvent systems. Tailored for researchers and drug development professionals, this article provides a practical roadmap for optimizing polarographic methods to enhance data quality in biomedical research.

The Essential Role of Supporting Electrolytes in Polarography: Core Principles and Current Relevance

Technical Support Center

Troubleshooting Guides & FAQs

Q1: My polarographic wave is poorly defined or shows excessive distortion, even with a high concentration of supporting electrolyte. What could be the cause? A: This often indicates ionic strength mismatch or specific ion interactions. The supporting electrolyte's primary function is not just to conduct current but to maintain a constant ionic strength and migrate potential. Ensure the ionic strength of your supporting electrolyte is at least 100x greater than your analyte. Common culprits include:

- Insufficient Buffer Capacity: pH shifts during analysis can distort waves. Use a buffer with adequate capacity (e.g., 0.1 M) for your pH range.

- Specific Adsorption: Some electrolyte ions (e.g., I⁻, Br⁻, SCN⁻) adsorb onto the mercury electrode, altering the double-layer structure and shifting half-wave potentials. Switch to a non-adsorbing ion like perchlorate (ClO₄⁻).

- Complexation: The electrolyte may be complexing with your analyte (e.g., using citrate with a metal ion). Review stability constants.

Q2: I observe an unexpected second wave or a shift in half-wave potential (E₁/₂) when changing my supporting electrolyte. Is this normal? A: Yes, and it underscores the electrolyte's role beyond conductivity. Shifts in E₁/₂ directly reflect changes in the analyte's activity coefficient and the formation of different ion pairs or complexes. This is a critical tool for studying speciation. To troubleshoot:

- Verify the purity of your electrolyte salts (use ACS grade or higher).

- Ensure complete deoxygenation with high-purity nitrogen for 10-15 minutes; oxygen can create interfering reduction waves.

- Check for overlapping solvent/electrolyte reduction limits. The usable potential window is defined by the electrolyte's reduction (cathodic) and oxidation (anodic) potentials.

Q3: How do I choose between KCl, LiCl, and tetraalkylammonium salts for my organic molecule reduction study? A: The choice is mechanistic. See the table below for a quantitative guide based on the cation's effect on the double-layer structure.

Table 1: Effect of Supporting Electrolyte Cation on Polarographic Parameters for a Model Organic Carbonyl (in aqueous solution, pH 7 buffer)

| Electrolyte (0.1 M) | Approx. E₁/₂ Shift (vs. SCE) | Observed Effect on Waveform | Primary Mechanism |

|---|---|---|---|

| Lithium Chloride (LiCl) | ~ +0.02 V | Broader wave, slightly more positive potential | Small, hydrated Li⁺ has weak ion-pairing, diffuse double layer. |

| Potassium Chloride (KCl) | 0.00 V (Reference) | Well-defined wave | Standard, inert cation for many applications. |

| Tetraethylammonium Bromide (TEAB) | ~ -0.10 V to -0.15 V | Sharper wave, shifted negatively | Large cation eliminates specific adsorption, provides a wider negative potential window. |

| Tetrabutylammonium Perchlorate (TBAP) | ~ -0.20 V | Very sharp wave, significant negative shift | Maximized double-layer effect, ideal for organic solvent/water mixtures. |

Experimental Protocols

Protocol 1: Systematic Screening of Supporting Electrolytes for Optimal Waveform Definition Objective: To identify the optimal supporting electrolyte for a novel pharmaceutical compound's polarographic analysis. Materials: See "Scientist's Toolkit" below. Method:

- Prepare a 1.0 mM stock solution of the analyte in the primary solvent (e.g., water, methanol).

- Prepare four 25 mL supporting electrolyte solutions at 0.1 M concentration in the same solvent:

- Solution A: Potassium Phosphate Buffer (pH 7.0)

- Solution B: Lithium Perchlorate in phosphate buffer (pH 7.0)

- Solution C: Tetraethylammonium Perchlorate (TEAP) in phosphate buffer (pH 7.0)

- Solution D: Tetrabutylammonium Perchlorate (TBAP) in 1:1 Water:Acetonitrile

- For each electrolyte solution, combine 9.8 mL of electrolyte with 0.2 mL of the 1.0 mM analyte stock (final analyte conc.: 20 µM).

- Transfer to the polarographic cell. Decorate with N₂ for 12 minutes.

- Record DC polarograms from 0.0 V to -1.8 V (vs. Ag/AgCl) using a dropping mercury electrode with a 2-second drop time.

- Record and compare the half-wave potential (E₁/₂), limiting current (iₗ), and waveform shape (slope) for each electrolyte.

Protocol 2: Assessing the Effect of Ionic Strength on Half-Wave Potential Objective: To quantify the shift in E₁/₂ with varying ionic strength, confirming the electrolyte's role in controlling activity coefficients. Method:

- Prepare a primary solution containing your analyte at 50 µM in a weak buffer (e.g., 5 mM phosphate, pH 7).

- Prepare a concentrated (2.0 M) stock of an inert electrolyte (e.g., KCl, NaClO₄).

- In the polarographic cell, start with 10 mL of the primary solution (low ionic strength, I ≈ 0.015 M). Decorate and record the polarogram.

- Sequentially add small, measured volumes (e.g., 50 µL) of the concentrated electrolyte stock. After each addition, decorate briefly (2 min), record a new polarogram, and calculate the new total ionic strength.

- Plot E₁/₂ vs. the square root of ionic strength (√I). A linear shift confirms the ionic strength/activity coefficient effect predicted by the Debye-Hückel theory.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Supporting Electrolyte Optimization Studies

| Item | Function & Rationale |

|---|---|

| High-Purity Inert Salts (KCl, NaClO₄, TBAP) | Provides the inert ionic background. Must be electrochemically inert in the studied potential window to avoid interfering currents. |

| Buffer Salts (Phosphate, Acetate, Britton-Robinson) | Maintains constant pH, which is critical for analytes involving H⁺ in the electrode reaction. Prevents shifts in E₁/₂ due to pH drift. |

| Tetraalkylammonium Salts (TBAF, TBAP, TEAP) | Bulky organic cations that minimize specific adsorption and expand the cathodic potential window in aqueous and mixed solvents. |

| Mercury (Triple-Distilled) | For the working electrode (DME or HMDE). Purity is essential to prevent surface contamination and erratic drops. |

| Deoxygenation System (N₂/Ar Gas with Scrubber) | Removes dissolved O₂, which reduces in two steps (-0.05 V and -0.9 V vs. SCE) and can mask or distort analyte waves. |

| Reference Electrode (Ag/AgCl, SCE) | Provides a stable, known potential against which the working electrode is measured. Must be isolated via a salt bridge if electrolyte incompatibility exists. |

| Faraday Cage | Encloses the cell to shield from ambient electromagnetic noise, crucial for measuring low capacitive currents accurately. |

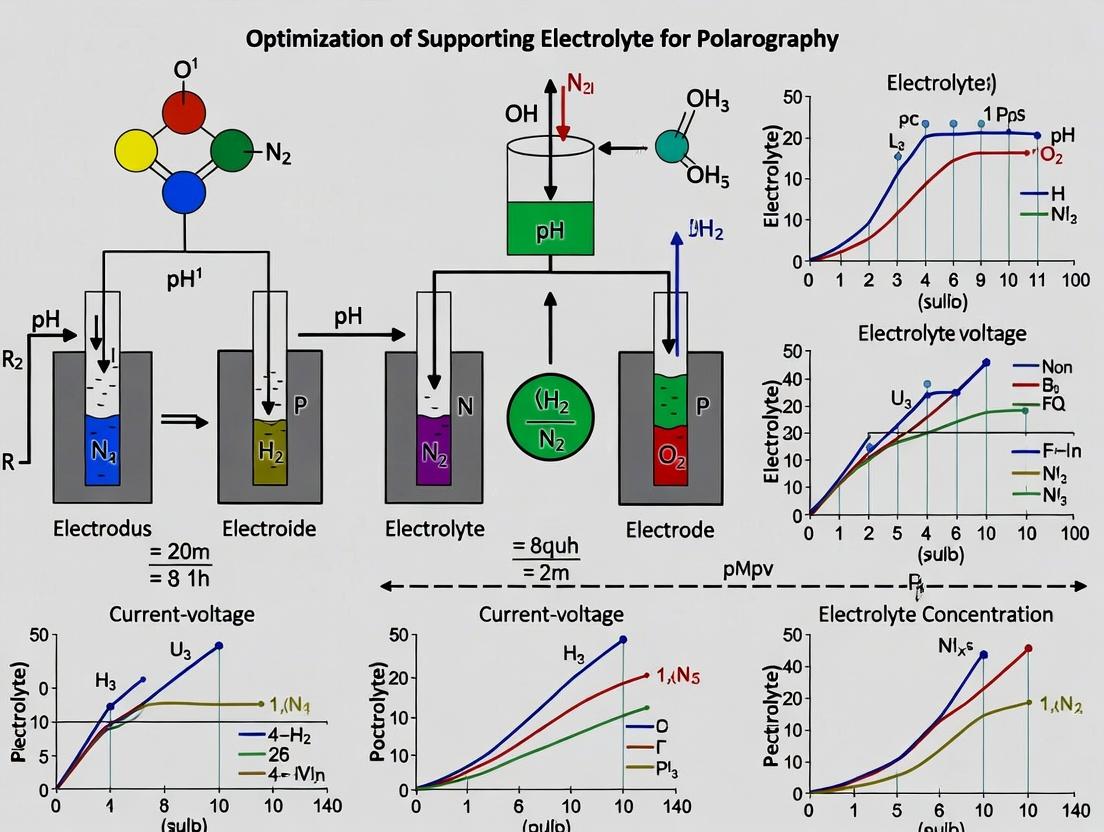

Visualization: Supporting Electrolyte Optimization Workflow

Diagram Title: Electrolyte Selection & Optimization Decision Tree

Troubleshooting Guides & FAQs

Conductivity Issues

Q1: My polarographic limiting current is lower than expected. What could be wrong with my electrolyte's conductivity? A: A low limiting current (i_d) often indicates insufficient electrolyte conductivity, leading to high solution resistance (iR drop). This distorts the polarogram. First, measure the solution's conductivity with a calibrated meter. For classical polarography, the supporting electrolyte concentration should typically be at least 100-fold greater than the analyte's. Ensure your chosen salt (e.g., KCl, LiClO4) is fully dissolved and the solution is free of precipitates. Common culprits are using deionized water instead of the specified solvent or incorrect salt weighing.

Q2: How do I choose a supporting electrolyte to maximize conductivity for a non-aqueous solvent? A: Conductivity in non-aqueous media (e.g., DMF, acetonitrile) depends on the ion size and ion-pairing tendency. Use small, weakly coordinating ions with high dissociation constants. Tetraalkylammonium salts (e.g., TBAPF6) are common, but for higher conductivity, consider tetrabutylammonium perchlorate (TBAClO4) or lithium perchlorate (LiClO4) if compatible with your system. Refer to Table 1 for comparative data.

pH & Buffering Problems

Q3: My polarographic wave is broad or ill-defined. Could pH be a factor? A: Yes. pH directly impacts the half-wave potential (E_{1/2}) for species involving H+ ions (e.g., organic molecules, metal complexes). An unbuffered or incorrectly buffered solution can cause drawn-out waves. Always use a buffer system with adequate capacity (≥ 0.05 M) that is electrochemically inert in your potential window. For example, use phosphate buffer for neutral pH or acetate for acidic pH. Verify the pH after adding all components.

Q4: The baseline current is unstable and drifting. Is this a pH issue? A: Potentially. Drifting baseline can indicate a changing pH at the electrode surface, especially if the electrode reaction consumes or produces H+ ions without sufficient buffering. It can also signal electrolyte decomposition. Implement a well-buffered system and ensure your chosen buffer does not undergo redox reactions within your scanned potential range.

Complexation & Viscosity Challenges

Q5: The half-wave potential (E{1/2}) of my metal ion has shifted unexpectedly. Why? A: Unintended complexation is the most likely cause. Trace impurities (e.g., citrate from cleaning, chloride from reference electrode leakage) can complex with metal ions, shifting E{1/2}. Use high-purity reagents and ensure your supporting electrolyte is inert. If complexation is intentional (for analysis), control the ligand concentration precisely. Increased solution viscosity from additives (e.g., for capillary flow) will decrease the diffusion coefficient, lowering id, but should not shift E{1/2}.

Q6: My dropping mercury electrode (DME) drop time is inconsistent. Could viscosity be affecting it? A: Absolutely. The drop time (t) of a DME is directly proportional to solution viscosity (η). If your prepared electrolyte solution is more viscous than pure water (e.g., due to high ionic strength or organic solvents), the drop time will increase, affecting the diffusion current. Measure the kinematic viscosity or calibrate the capillary in your final electrolyte mixture. Use the Ilkovič equation correction: i_d ∝ √(1/η).

Table 1: Key Properties of Common Supporting Electrolytes for Polarography

| Electrolyte (0.1 M) | Solvent | Relative Conductivity* | Useful pH Range | Common Complexation Interference | Relative Viscosity (vs. H2O) |

|---|---|---|---|---|---|

| Potassium Chloride (KCl) | H2O | 1.00 (Ref) | 3-11 (Unbuffered) | Low, but Cl- can complex some metals | ~1.02 |

| Lithium Chlorate (LiClO4) | H2O | 0.98 | 2-12 (Unbuffered) | Very Low | ~1.05 |

| Tetrabutylammonium Perchlorate (TBAClO4) | Acetonitrile | 0.85 | N/A (Aprotic) | Low | ~1.25 |

| Phosphate Buffer (0.05 M) + 0.1 M KNO3 | H2O | 0.95 | 5.8-8.0 | Low, can precipitate some metals | ~1.03 |

| Acetate Buffer (0.05 M) + 0.1 M KCl | H2O | 0.96 | 3.8-5.8 | Low, acetate can complex some metals | ~1.03 |

*Conductivity normalized to 0.1 M KCl in water at 25°C for illustration.

Table 2: Troubleshooting Symptom Matrix

| Symptom | Possible Cause (Property) | Diagnostic Test | Corrective Action |

|---|---|---|---|

| Low Limiting Current | High Viscosity, Low Conductivity | Measure η, measure R_solution | Increase electrolyte conc., change salt type, ensure full dissolution |

| Broad/Ill-defined Wave | Incorrect pH, Unintended Complexation | Measure pH before/after scan, add a chelator (e.g., EDTA) test | Implement adequate buffer, purify electrolyte |

| Shifted E_{1/2} | Unintended Complexation, Incorrect pH | Vary electrolyte batch, measure pH | Use ultra-pure salts, use inert electrolyte (e.g., perchlorate), control pH |

| Unstable Baseline | Poor Buffering (pH drift), Electrolyte Redox | Scan blank electrolyte, monitor pH over time | Use stronger buffer, widen potential window, change electrolyte |

| Irregular Drop Time (DME) | Changed Viscosity, Capillary Blockage | Time drops in water vs. solution, inspect capillary | Account for η in calculations, clean capillary, filter solution |

Experimental Protocols

Protocol 1: Determining Optimal Supporting Electrolyte Concentration via Conductivity Sweep Objective: To find the minimum concentration of supporting electrolyte that minimizes solution resistance for a given system.

- Prepare a 1.0 M stock solution of your candidate salt (e.g., KNO3) in the desired solvent (e.g., water).

- Prepare 50 mL of your analyte solution at the typical concentration used in your polarography (e.g., 1.0 mM Cd2+), but without supporting electrolyte.

- Using the stock, create a series of 10 mL analyte solutions with supporting electrolyte concentrations of 0.01, 0.05, 0.1, 0.2, and 0.5 M.

- Measure the conductivity of each solution at 25°C using a calibrated conductivity meter.

- Perform DC polarography on each solution. Record the limiting current (i_d) and the appearance of the polarogram.

- Plot i_d vs. conductivity. The plateau region indicates the sufficient concentration for maximal current and minimal iR drop.

Protocol 2: Assessing Buffer Capacity and Inertness for pH-Sensitive Analysis Objective: To verify that the buffer system adequately controls pH without introducing interfering currents.

- Prepare your analyte solution (e.g., a quinone) with the chosen buffer system at its nominal pH (e.g., 0.05 M phosphate, pH 7.0).

- Prepare an identical solution without the analyte (blank electrolyte).

- Using a pH meter, add small aliquots (e.g., 10 µL) of 0.1 M HCl and 0.1 M NaOH to each solution, recording the pH change. This tests buffer capacity.

- Record polarograms for both the analyte and blank solutions over the intended potential range.

- The blank polarogram should show a flat, featureless baseline. Any redox waves indicate the buffer/electrolyte is not inert and must be changed.

- The half-wave potential (E_{1/2}) of the analyte should be stable upon minor dilution.

Visualization

Title: Electrolyte Optimization Workflow for Polarography

Title: Link Between Electrolyte Properties and Polarographic Problems

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Supporting Electrolyte Optimization

| Item | Function/Benefit | Example(s) |

|---|---|---|

| High-Purity Inert Salts | Provides necessary ionic strength and conductivity without participating in redox reactions or complexing the analyte. | Potassium nitrate (KNO3), Lithium perchlorate (LiClO4), Tetrabutylammonium hexafluorophosphate (TBAPF6) |

| Electrochemically Inert Buffers | Maintains constant pH without introducing faradaic currents in the potential window of interest. | Phosphate buffer (for H2O, pH ~7), Bis-Tris buffer (for H2O, pH ~6.5), Tetraethylammonium p-toluenesulfonate (for non-aqueous) |

| Purified, Aprotic Solvents | Used for analytes insoluble in water, minimizes H+ interference. Must have wide potential window and dissolve electrolytes. | Acetonitrile (dry), N,N-Dimethylformamide (DMF, dry), Propylene Carbonate |

| Viscosity Standard Solutions | Used to calibrate or understand the impact of solution viscosity on diffusion currents and DME drop times. | Glycerol/Water mixtures, Certified viscosity oils |

| Metal Ion Analyte Standards | High-purity sources for calibration and method development. | 1000 ppm Cd²⁺ in 2% HNO3, Certified reference materials (CRMs) |

| Complexing Agents (Intentional) | Used diagnostically or analytically to shift E_{1/2} and separate overlapping waves. | Ethylenediaminetetraacetic acid (EDTA), Potassium cyanide (KCN), Ammonia solution |

| Conductivity & pH Meter | Essential for quantitative measurement of key electrolyte properties before polarographic analysis. | Calibrated benchtop meters with appropriate electrodes for solvent used. |

Troubleshooting Guides and FAQs

Q1: During my polarographic analysis for drug compound quantification, the diffusion current (id) is lower and noisier than expected, leading to poor calibration curves. What could be the issue? A: This is commonly caused by an unoptimized or contaminated supporting electrolyte. A suboptimal electrolyte composition can lead to high residual current, poor conductivity, and increased noise, directly affecting the diffusion current governed by the Ilkovič equation. First, ensure your electrolyte is deoxygenated with high-purity nitrogen for 15-20 minutes. Check for impurities by running a blank polarogram. For drug analysis, consider adjusting the electrolyte's pH and ionic strength to ensure the analyte is in its electroactive form and migration currents are eliminated. Re-purify reagents if necessary.

Q2: The half-wave potential (E1/2) for my target metal ion is shifting between experiments, making identification unreliable. How can I stabilize it? A: The half-wave potential is a characteristic constant only when the supporting electrolyte composition is constant and provides a well-defined non-complexing medium. Shifts in E1/2 indicate changes in the chemical environment. Ensure your supporting electrolyte is prepared with high precision (use volumetric flasks and analytical-grade chemicals) and is identical across runs. For metal ions, the presence of trace complexing agents (e.g., from buffer components) can drastically shift E1/2. Use a purified, complexing-agent-free electrolyte like KNO3 or HClO4 for preliminary tests. Temperature control of the cell (±0.5°C) is also critical.

Q3: My polarographic wave is drawn-out and not sigmoidal, complicating the measurement of E1/2 and id. What steps should I take? A: A non-ideal wave shape often points to issues with the electrode or uncompensated resistance. First, confirm your dropping mercury electrode (DME) is functioning correctly—the drop time should be regular and the capillary clean. A primary culprit is an inadequate concentration of supporting electrolyte. The supporting electrolyte's role is to suppress migration current and lower solution resistance. Increase its concentration so it is at least 50-100 times greater than the analyte concentration. If the problem persists, check for the presence of surface-active impurities that can adsorb on the mercury drop; these can be removed by pre-treatment (e.g., charcoal filtration) of the electrolyte solution.

Q4: When optimizing a supporting electrolyte for a new organic drug molecule, how do I choose between different buffer systems? A: The choice is critical as it affects both the half-wave potential (via pH) and the diffusion current. Follow this protocol:

- Perform a Preliminary pH Scan: Run polarograms in buffers of varying pH (e.g., Britton-Robinson buffer from pH 2-12) at a fixed analyte concentration.

- Identify the Optimal pH: Determine the pH at which the wave is best defined (maximum id, sharpest rise). This is often where the molecule is in a single, electroactive form.

- Test for Interference: At the chosen pH, test different buffer types (e.g., phosphate, acetate, ammonium). Compare the polarograms for wave definition, background current, and reproducibility. Some buffers may specifically adsorb or interact.

- Validate with the Ilkovič Equation: Confirm that id is proportional to the square root of the mercury column height (h1/2) and analyte concentration in your chosen electrolyte, verifying diffusion-controlled behavior.

Key Quantitative Data on Supporting Electrolyte Effects

Table 1: Impact of Supporting Electrolyte Concentration on Polarographic Parameters for 0.1 mM Cd²⁺ in 0.1 M KCl at 25°C

| Supporting Electrolyte (KCl) Concentration (M) | Diffusion Current, id (µA) | Half-Wave Potential, E1/2 vs. SCE (V) | Wave Slope (mV) |

|---|---|---|---|

| 0.01 | 1.85 (±0.15) | -0.602 (±0.010) | 45 |

| 0.10 | 2.10 (±0.05) | -0.599 (±0.002) | 32 |

| 1.00 | 2.12 (±0.03) | -0.598 (±0.001) | 31 |

Table 2: Effect of Buffer Type on E1/2 of a Model Drug (0.05 mM Phenobarbital) at pH 8.0

| Buffer System (0.05 M) | E1/2 vs. Ag/AgCl (V) | Diffusion Current, id (µA) | Notes |

|---|---|---|---|

| Ammonium Buffer | -1.415 | 0.245 | Well-defined wave, stable current |

| Phosphate Buffer | -1.430 | 0.231 | Slight adsorption pre-wave observed |

| TRIS Buffer | -1.460 | 0.210 | Broader wave, higher background |

Experimental Protocols

Protocol 1: Optimization of Supporting Electrolyte Ionic Strength Objective: To determine the minimum concentration of inert electrolyte required to achieve a stable, migration-free diffusion current.

- Prepare a 1.0 mM stock solution of your analyte (e.g., Pb(NO3)2) in deionized water.

- Prepare a 2.0 M stock solution of the inert salt (e.g., KNO3).

- In five polarographic cells, add aliquots of the analyte stock to achieve a final concentration of 0.1 mM.

- Add varying volumes of the KNO3 stock to achieve final concentrations of 0.01 M, 0.05 M, 0.10 M, 0.50 M, and 1.0 M. Adjust all solutions to the same final volume with deionized water.

- Deoxygenate each solution with N2 for 15 minutes.

- Record polarograms from -0.2 V to -0.8 V vs. SCE using identical DME settings (h = 60 cm).

- Plot id vs. [KNO3]^0.5. The concentration where id becomes constant is the optimal minimum ionic strength.

Protocol 2: Systematic Screening of Buffer/Electrolyte Systems for Organic Analytes Objective: To identify the supporting electrolyte yielding the best-defined polarographic wave for quantitative analysis.

- Select candidate buffers/electrolytes (e.g., 0.1 M HCl, acetate buffer pH 4.7, phosphate buffer pH 7.0, borate buffer pH 9.2, 0.1 M NaOH).

- Prepare 25 mL of each electrolyte solution. Adjust ionic strength to 0.5 M with KNO3 if necessary.

- Spike each electrolyte with an identical volume of a concentrated drug stock to reach the desired concentration (e.g., 50 µM).

- Deoxygenate and record polarograms over a suitable potential range.

- For each polarogram, measure: (a) limiting current (il), (b) half-wave potential (E1/2), (c) background current at the foot of the wave, and (d) qualitatively assess wave shape.

- The optimal system provides the highest signal-to-background ratio (il/ibackground), a reproducible E1/2, and a steep, sigmoidal wave.

Diagrams

Troubleshooting Guide for Supporting Electrolyte Issues

How Supporting Electrolyte Optimization Affects Key Parameters

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Supporting Electrolyte Optimization in Polarography

| Item | Function/Benefit in Optimization | Example(s) |

|---|---|---|

| High-Purity Inert Salts | Provides the primary ionic strength. Must be free of electroactive impurities (e.g., heavy metals) and organic surfactants. | KCl, KNO3, HClO4, tetraalkylammonium salts. |

| Buffer Compounds (Analytical Grade) | Controls pH to define analyte speciation and E1/2. Must be purified from trace metals and organics. | Phosphates, acetates, ammonia/ammonium chloride, Britton-Robinson buffers. |

| Maximum Suppressor | Suppresses polarographic maxima (irregular current peaks) that distort the wave. Used sparingly. | Triton X-100, gelatin, methyl red. |

| Oxygen Scavenging System | Removes dissolved O2, which produces interfering reduction waves. | High-purity Nitrogen or Argon gas, sometimes sodium sulfite. |

| Standard Redox Reference Solution | Validates E1/2 stability and instrument calibration. | 0.1 mM Cd²⁺ in 0.1 M KCl (E1/2 = -0.599 V vs. SCE at 25°C). |

| Mercury (Triple Distilled) | For the working electrode (DME). Purity is critical for reproducible drop time (m, t) and surface properties. | N/A |

Technical Support Center

Troubleshooting Guides & FAQs

Q1: During polarographic analysis, my baseline current is unstable and shows significant noise. What could be the cause and how do I fix it? A: This is commonly due to improper supporting electrolyte preparation or contamination.

- Cause 1: Impurities in the electrolyte salts. Use high-purity (>99.9%) reagents. Recrystallize salts if necessary.

- Cause 2: Dissolved oxygen. Oxygen causes reduction waves that interfere. Deaerate the solution by purging with high-purity nitrogen or argon for 10-15 minutes before analysis.

- Cause 3: Unoptimized buffer capacity. The chosen buffer may be insufficient to maintain pH at the electrode surface during electrolysis, causing local pH shifts. Use a buffer with a pKa within ±1 unit of your desired pH and at a concentration of at least 0.05 M.

- Protocol for Deaeration: Connect a nitrogen line to a fine capillary inserted into your polarographic cell. Bubble N₂ gently through the solution for 10 minutes. Maintain a slight N₂ overpressure above the solution during the measurement.

Q2: I observe multiple, unexpected reduction/oxidation waves. How can I determine if they are from my analyte or the supporting electrolyte? A: Perform a blank run.

- Protocol for Blank Analysis: Prepare an identical cell containing only the supporting electrolyte and solvent, with the same purification and deaeration steps. Run the polarogram under identical experimental conditions (scan rate, drop time, temperature). Any waves appearing in this blank scan are artifacts of the electrolyte system and must be accounted for. Compare this to the scan with your analyte present.

Q3: My polarographic maxima are poorly defined or absent. What parameters should I check? A: This often relates to improper choice of electrolyte or incorrect instrument settings.

- Check 1: Ionic Strength. The supporting electrolyte concentration is typically 50-100x greater than the analyte concentration to ensure migration current is eliminated. Verify this ratio.

- Check 2: Complexation. The electrolyte may be complexing with your analyte, shifting the half-wave potential (E₁/₂). Consult literature on complexation constants. Switch to a non-complexing electrolyte like tetraalkylammonium salts for preliminary tests.

- Check 3: Capillary Characteristics. Ensure the mercury drop time is consistent and not too fast. A drop time of 2-5 seconds is typical. Clean the capillary if blocked.

Q4: How do I select the correct buffer for a polarographic study of a pH-sensitive drug compound? A: The choice is critical for reproducibility.

- Define Operational pH Range: Determine the pH range relevant to your drug's stability and activity.

- Select Buffer with Matching pKa: Choose a buffer whose pKa is within your operational range (see Table 1). Avoid buffers that undergo redox reactions in your potential window.

- Verify Electrochemical Inertness: Run a blank polarogram of the buffer alone to ensure no redox activity in your scan range.

- Consider Complexation: Prefer buffers that do not complex with your drug's metal ions or functional groups (e.g., avoid citrates or phosphates if they cause precipitation).

Data Presentation

Table 1: Evolution of Common Supporting Electrolytes in Polarography

| Era / Type | Example Compounds | Typical Concentration | Primary Function & Advantage | Common Issues |

|---|---|---|---|---|

| Simple Salts (Early Era) | KCl, KNO₃, HCl | 0.1 - 1.0 M | Provide conductivity, suppress migration current. Simple, inexpensive. | Limited pH control, may participate in reactions. |

| Acid/Base Systems | Acetate buffer, Ammonia buffer | 0.05 - 0.5 M | Provides stable pH environment for pH-dependent processes. | Buffer capacity may be insufficient at electrode surface. |

| Complex Buffers (Modern) | TRIS, HEPES, Britton-Robinson | 0.05 - 0.2 M | Broad pH range, good biological relevance, consistent ionic strength. | Some (e.g., TRIS) can be electroactive; may complex metals. |

| Specialized Salts | Tetraethylammonium perchlorate (TEAP) | 0.1 M | Wide negative potential window, minimal complexation. | Hygroscopic, requires careful handling; expensive. |

Table 2: Troubleshooting Matrix for Supporting Electrolyte Issues

| Symptom | Likely Cause | Immediate Action | Preventive Solution |

|---|---|---|---|

| High Baseline Noise | Contaminated salts, dissolved O₂ | Deaerate solution, filter electrolyte. | Use ultrapure water (18.2 MΩ·cm), recrystallize salts. |

| Irreproducible E₁/₂ | Unstable pH, low buffer capacity | Check and adjust pH of bulk solution. | Increase buffer concentration (>0.05 M); use stronger buffer. |

| Multiple Unidentified Waves | Electrolyte redox activity, impurities | Run a blank polarogram. | Switch to electrochemically inert electrolyte (e.g., TEAP). |

| Distorted Waveform | Adsorption of buffer components on electrode | Clean electrode, change drop time. | Use a different buffer ion that does not adsorb (e.g., change anion). |

Experimental Protocols

Protocol: Optimization of Supporting Electrolyte for a Novel Drug Compound Objective: To identify the supporting electrolyte and buffer system that yields the most well-defined, reproducible, and sensitive polarographic wave for a pH-sensitive organic drug.

Materials: See "The Scientist's Toolkit" below.

Method:

- Prepare Stock Solutions: Prepare a 1.0 mM stock solution of the drug in purified solvent (e.g., water/ethanol mix). Prepare 1.0 M stock solutions of at least 3 candidate buffers (e.g., Acetate pH 4.5, Phosphate pH 7.0, Ammonia pH 9.5).

- Prepare Test Cells: For each buffer, prepare a polarographic cell containing:

- 9.5 mL of the 1.0 M buffer stock (diluted to yield final buffer concentration of 0.1 M).

- 0.5 mL of the 1.0 mM drug stock (final drug concentration: 50 µM).

- Add inert salt (e.g., KCl) to maintain constant ionic strength of 0.5 M if needed.

- Solution Preparation: Mix thoroughly. Adjust final pH with dilute NaOH/HCl if necessary. Deaerate with N₂ for 12 minutes.

- Polarographic Analysis: Record DC polarograms for each cell using identical instrument settings (initial potential, scan rate, drop time, temperature).

- Evaluation Criteria: Compare the limiting current (sensitivity), sharpness of the wave (slope), reproducibility of E₁/₂, and baseline stability across the different buffers.

- Blank Subtraction: Run polarograms for each buffer system without the drug and subtract any background current.

Mandatory Visualization

The Scientist's Toolkit: Research Reagent Solutions

| Reagent / Material | Specification / Function | Key Consideration for Polarography |

|---|---|---|

| Potassium Chloride (KCl) | High Purity (>99.9%). Provides inert ionic strength, suppresses migration current. | A common, simple base electrolyte. Must be free of heavy metal impurities. |

| Britton-Robinson Buffer | Universal buffer mixture (Boric acid, Phosphoric acid, Acetic acid). Covers wide pH range (2-12). | Useful for initial pH profiling of an unknown compound's redox behavior. |

| Tetraethylammonium Perchlorate (TEAP) | Specialized salt. Provides a very wide negative potential window in aprotic solvents. | Essential for studying reductions at very negative potentials; hygroscopic and potentially explosive when dry. |

| Nitrogen / Argon Gas | High-purity, oxygen-free. For deaeration of solutions to remove interfering O₂ reduction waves. | Requires a gas cleaning system (e.g., oxygen scrubber) for highest sensitivity work. |

| Triple Distilled Mercury | For the working electrode (Dropping Mercury Electrode - DME). | Purity is critical to prevent anomalous currents and contamination. Must be handled with proper toxicology controls. |

| HEPES Buffer | (4-(2-hydroxyethyl)-1-piperazineethanesulfonic acid). Biological buffer, pKa ~7.5. | Good for drug studies near physiological pH; check for electrochemical inertness in your potential range. |

Technical Support Center: Troubleshooting Guides & FAQs

Frequently Asked Questions (FAQ)

Q1: Why do I observe high background current and noisy baselines in my polarographic analysis of biological samples?

- A: This is often due to suboptimal supporting electrolyte composition. Impurities in the electrolyte (e.g., trace metals), inadequate buffering capacity leading to pH shifts, or inappropriate ionic strength can cause non-Faradaic background currents and mask the analytical signal. Optimizing purity, concentration, and pH is critical.

Q2: My target analyte peak is poorly resolved or overlaps with interference from the matrix. How can electrolyte optimization help?

- A: The supporting electrolyte dictates the electrical double layer and can facilitate complexation. By changing the electrolyte's chemical nature (e.g., switching from KCl to NH₄Cl/ NH₃ buffer), you can shift the half-wave potential (E½) of your analyte via complex formation, improving separation from interfering species.

Q3: I am getting inconsistent results between replicates. Could the electrolyte be a factor?

- A: Yes. Inconsistent deoxygenation times, electrolyte evaporation altering concentration, or photodegradation of light-sensitive components (like some complexing agents) can cause replicate variability. Standardized preparation and handling protocols for the electrolyte are essential.

Q4: For adsorptive stripping voltammetry of biomolecules, why is the choice of buffer type so crucial?

- A: The buffer ion influences the adsorption efficiency of the target molecule (e.g., protein, DNA) onto the working electrode. The pH and ionic strength must be tuned to maximize adsorption for sensitivity while maintaining the molecule's native state to avoid denaturation and loss of activity.

Troubleshooting Guide

| Symptom | Possible Cause (Electrolyte-Related) | Diagnostic Steps | Solution |

|---|---|---|---|

| High & Noisy Baseline | 1. Impure salts or contaminated water.2. Inadequate deoxygenation.3. Incorrect pH (near pKa of buffer). | 1. Run a blank with ultra-pure water and ACS-grade salts.2. Measure pH before and after experiment.3. Extend nitrogen purging time. | 1. Use highest purity reagents (HPLC/ACS grade) and ultrapure water (18.2 MΩ·cm).2. Ensure buffer capacity is 10x the analyte concentration.3. Purge with inert gas for ≥10 mins. |

| Poor Peak Shape & Resolution | 1. Electrolyte ionic strength too low/high.2. Unfavorable complexation kinetics.3. Competing adsorption of buffer components. | 1. Vary electrolyte concentration (0.1 M to 1.0 M) in a test series.2. Consult literature on complexing agents for your analyte metal ion. | 1. Optimize ionic strength to sharpen peaks. Typically 0.1 M is a start.2. Introduce/complexing agents (e.g., acetate, ammonia) to shift E½.3. Test different buffer chemistries (e.g., borate vs. phosphate). |

| Signal Drift Over Time | 1. Evaporation changing concentration.2. Photodegradation of electrolyte.3. CO₂ absorption altering pH of carbonate buffers. | 1. Measure cell volume before/after run.2. Shield cell from light.3. Monitor pH of unstirred solution. | 1. Use a sealed cell or maintain humidified gas flow.2. Use amber vials or cover cell.3. Use a closed system or non-volatile buffer. |

| Irreproducible Peak Current | 1. Inconsistent oxygen removal.2. Unstable temperature affecting viscosity/diffusion.3. Protein adsorption fouling the electrode. | 1. Standardize purging protocol.2. Monitor temperature with a probe.3. Inspect electrode surface. | 1. Use automated, timed purging.2. Use a thermostated cell jacket (±0.5°C).3. Add a non-ionic surfactant (e.g., Triton X-100) at low concentration (<0.01%). |

Experimental Protocol: Systematic Optimization of Supporting Electrolyte for Polarography

Objective: To determine the optimal supporting electrolyte composition for the sensitive detection of a target metal ion (e.g., Zn²⁺) in a protein-containing buffer.

Materials: See "The Scientist's Toolkit" below.

Methodology:

- Baseline Establishment: Prepare a 0.1 M potassium chloride (KCl) solution in ultrapure water. Deoxygenate with N₂ for 10 minutes. Record a differential pulse polarogram (DPP) from -0.2V to -1.2V vs. Ag/AgCl to establish the background.

- Ionic Strength Series: Prepare KCl electrolytes at 0.01 M, 0.1 M, and 0.5 M. Spike each with a standard 100 µM Zn²⁺ solution. Record DPP scans. Plot peak current (Ip) and peak width at half height (W½) vs. ionic strength.

- Complexation Screen: Prepare a series of 0.1 M electrolytes: KCl (control), sodium acetate buffer (pH 4.5), ammonium chloride/ammonia buffer (pH 9.0). Spike with 100 µM Zn²⁺. Record DPP. Note the shift in E½ for Zn²⁺ in each medium.

- pH Optimization: Prepare a 0.1 M ammonium chloride buffer system. Adjust aliquots to pH 7.0, 8.0, 9.0, and 10.0 with ammonia. Spike with Zn²⁺ and a model protein (e.g., 1 mg/mL BSA). Record DPP. Plot Ip vs. pH.

- Matrix Tolerance Test: Using the optimal electrolyte from step 4, perform a standard addition calibration of Zn²⁺ in the presence of increasing concentrations of BSA (0 to 10 mg/mL). Compare slope to that in pure electrolyte.

Key Data from Optimization Experiments

Table 1: Effect of Ionic Strength (KCl) on Zn²⁺ Peak Characteristics (100 µM Zn²⁺)

| Ionic Strength (M) | Peak Current (Ip, nA) | Peak Width (W½, mV) | Background Current (nA) |

|---|---|---|---|

| 0.01 | 125 ± 15 | 95 ± 8 | 12 ± 3 |

| 0.1 | 250 ± 10 | 65 ± 5 | 25 ± 5 |

| 0.5 | 245 ± 12 | 70 ± 6 | 110 ± 20 |

Table 2: Effect of Buffer/Complexing Agent on Zn²⁺ Half-Wave Potential (E½)

| Supporting Electrolyte (0.1 M) | pH | E½ for Zn²⁺ (V vs. Ag/AgCl) | Notes |

|---|---|---|---|

| Potassium Chloride | 5.5 (unbuffered) | -1.00 ± 0.02 | Reference peak |

| Sodium Acetate | 4.5 | -1.03 ± 0.02 | Minimal complexation |

| Ammonium Chloride/Ammonia | 9.0 | -1.35 ± 0.03 | Strong complexation, peak shift |

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function & Importance |

|---|---|

| ACS/HPLC Grade Salts (KCl, NaClO₄, NH₄Cl) | High-purity source of inert ions to provide ionic strength with minimal electroactive impurities. |

| Ultrapure Water (18.2 MΩ·cm) | Prevents contamination from ions, organics, or particles that increase background noise. |

| Buffer Components (e.g., CH₃COONa, H₃BO₃, (NH₄)₂CO₃) | Maintains constant pH, critical for analyte stability and complexation equilibrium. Some (e.g., NH₃, acetate) act as complexing ligands. |

| Complexing Agents (e.g., Ammonia, Acetate, EDTA) | Selectively shift the half-wave potential of target ions via complex formation, resolving overlaps. |

| Oxygen Scavenger (Nitrogen or Argon Gas) | Removes dissolved O₂, which produces large, interfering reduction currents in the -0.1V to -0.9V range. |

| Non-Ionic Surfactant (e.g., Triton X-100) | Suppresses maxima, improves polarographic wave shape, and can minimize protein adsorption. |

| Standard Reference Solutions (e.g., 1000 ppm metal ion standards) | For accurate calibration and standard addition methods in complex matrices. |

Visualization: Electrolyte Optimization Workflow

Diagram Title: Electrolyte Optimization Decision Workflow

Visualization: Role of Electrolyte in Polarographic Cell

Diagram Title: Electrolyte Functions in a Polarographic Cell

Strategic Electrolyte Selection and Protocol Development for Target Analytes

A Step-by-Step Framework for Initial Electrolyte Selection

Within the context of optimizing supporting electrolytes for polarographic research, this technical support center provides targeted guidance. The selection of an appropriate supporting electrolyte is critical, as it carries current, minimizes migration current, and controls pH and ionic strength, thereby defining the analytical window and quality of polarographic data for applications like drug analysis.

Troubleshooting Guides & FAQs

Q1: Why do I observe an indistinct or poorly formed polarographic wave? A: This is often due to incorrect electrolyte choice or concentration. The supporting electrolyte concentration should be at least 100-fold greater than the analyte concentration to suppress migration current effectively. Verify that the electrolyte does not complex strongly with your analyte, shifting the half-wave potential or distorting the wave. Check for overlapping reduction potentials of electrolyte components.

Q2: How do I resolve excessive residual current or a noisy baseline? A: This typically indicates impurities in the electrolyte or solvent. Ensure all reagents are of high analytical grade (e.g., "for polarography"). Pre-purify the supporting electrolyte solution by pre-electrolysis. Use freshly distilled solvent (e.g., water, DMF) and degas the solution thoroughly with an inert gas (N₂ or Ar) for 10-15 minutes before measurement.

Q3: My analyte's half-wave potential (E½) shifts unexpectedly when I change pH. What should I do? A: This is expected for pH-dependent processes. Systematically map E½ versus pH using a buffer system as your supporting electrolyte. Use the derived E½-pH diagram to select an optimal pH where the wave is well-defined and separated from interfering processes. Ensure the buffer has sufficient capacity and does not undergo electroreduction itself.

Q4: What causes multiple or unexpected waves in my polarogram? A: This could be due to: 1) The analyte undergoing multiple reduction steps, 2) Reduction of an impurity or oxygen (always ensure thorough deaeration), or 3) The electrolyte itself being electroactive. Consult tables of half-wave potentials for common electrolytes. Switch to a more inert electrolyte like tetraalkylammonium salts in non-aqueous media if needed.

Key Data & Comparison Tables

Table 1: Common Supporting Electrolytes for Aqueous Polarography

| Electrolyte | Typical Concentration | Useful pH Range | Key Advantages | Major Limitations |

|---|---|---|---|---|

| KCl / HCl | 0.1 M KCl, 0.01 M HCl | < 3.0 | Simple, well-defined | Acidic range only, Cl⁻ can complex some metals |

| Britton-Robinson Buffer | 0.04 M in each acid | 2.0 - 12.0 | Wide pH range, good buffer capacity | Organic components may adsorb on Hg |

| Acetate Buffer | 0.1 M CH₃COONa, CH₃COOH | 3.6 - 5.6 | Good buffer capacity, low complexity | Limited pH range |

| Phosphate Buffer | 0.1 M KH₂PO₄/Na₂HPO₄ | 5.8 - 8.0 | Physiological pH relevance | Can complex heavy metals |

| Tetraalkylammonium Salts (e.g., TBAF) | 0.1 M | N/A (non-aqueous) | Wide negative potential window, inert | Hygroscopic, requires anhydrous conditions |

Table 2: Systematic Electrolyte Selection Criteria

| Criterion | Question to Ask | Recommended Action |

|---|---|---|

| Potential Window | Does the electrolyte reduce/oxidize before my analyte? | Consult reference tables. Test blank electrolyte solution first. |

| Analyte Interaction | Does it complex with or precipitate my analyte? | Perform solubility tests and compare E½ in different media. |

| pH Control | Is my analyte's redox process pH-sensitive? | Use a buffer with pKa ±1 of desired pH. |

| Ionic Strength | Is the conductivity sufficient (I > 0.1 M)? | Adjust with an inert salt (e.g., LiClO₄ for non-aqueous). |

| Purity & Cost | Is it available in high purity at scale? | Source "polarographic grade" or plan for purification. |

Experimental Protocols

Protocol 1: Initial Screening of Electrolyte Suitability

- Prepare Solutions: Create 10 mL of 1.0 mM analyte stock solution in a suitable solvent. Separately, prepare 50 mL of each candidate supporting electrolyte solution at 0.1 M concentration.

- Blank Measurement: Place 10 mL of a candidate electrolyte into the polarographic cell. Deoxygenate with N₂ for 10 min. Record a polarogram from 0 to -2.0 V (or relevant range) to establish the background residual current and usable potential window.

- Analyte Measurement: Add an aliquot of the analyte stock to the cell to achieve a final concentration of 0.1 mM. Deoxygenate again for 5 min. Record the polarogram under identical conditions.

- Analysis: Compare waves. A suitable electrolyte will yield a well-defined, reproducible wave with a stable limiting current and low background interference.

Protocol 2: Determining Half-Wave Potential (E½) Dependence on pH

- Prepare Buffer Series: Prepare a series of supporting electrolytes covering a pH range from 2 to 12 (e.g., using HCl/KCl, acetate, phosphate, Britton-Robinson, NaOH/KCl).

- Standardize Conditions: For each buffer, prepare a solution containing 0.1 mM analyte and 0.1 M supporting electrolyte/background salt.

- Record Polarograms: Deoxygenate and record a polarogram for each solution.

- Plot & Analyze: Measure E½ for each wave. Plot E½ vs. pH. The resulting diagram identifies optimal, stable pH regions for analysis.

Visualizations

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions for Polarography

| Item | Function & Specification | Example Products/Chemicals |

|---|---|---|

| High-Purity Mercury | Forms the dropping mercury electrode (DME). Must be triply distilled for polarography to minimize impurity currents. | Triple-distilled Hg (e.g., from Sigma-Aldrich) |

| Inert Gas Supply | Removes dissolved oxygen, which produces interfering reduction waves. | Ultra-high purity (UHP) Nitrogen or Argon gas with O₂ trap |

| Background Electrolyte Salts | Provides ionic strength and defines the electrical field. Choice defines potential window. | KCl (aqueous), Tetrabutylammonium perchlorate (non-aqueous) |

| Buffer Systems | Maintains constant pH for studies of pH-dependent processes. | Britton-Robinson buffer, Phosphate buffer salts |

| Redox Potential Standard | Used for calibration of the reference electrode potential. | Saturated calomel electrode (SCE) or Ag/AgCl reference system |

| Aprotic Solvents | Expands negative potential window for reducible analytes. Must be dry and polarographic grade. | Dimethylformamide (DMF), Acetonitrile (MeCN) with molecular sieves |

| Supporting Electrolyte Purification Cell | For pre-electrolysis to remove trace metal impurities from electrolytes. | Simple cell with large Hg pool cathode and Pt anode |

Technical Support Center: Troubleshooting & FAQs

FAQ 1: How do I choose the optimal supporting electrolyte for my analyte? Answer: The choice depends on the analyte class and desired electrochemical window. For metal ions, inert electrolytes like KCl or KNO3 are standard. For organics, consider pH and complexation; use buffers like acetate (pH 3.6-5.6) or phosphate (pH 5.8-8.0). For pharmaceuticals and biomolecules, biocompatible buffers (e.g., PBS, Tris) that maintain stability are crucial. Always run a background polarogram of the electrolyte alone first.

FAQ 2: I am getting poor resolution or overlapping peaks in my polarograms for a mixture of heavy metals (e.g., Cd2+, Pb2+). What should I do? Answer: This is often due to an inappropriate electrolyte pH or lack of a complexing agent. For simultaneous determination of Cd2+ and Pb2+, use an acetate buffer at pH 4.5. If peaks still overlap, consider switching to a different complexing medium like 0.1 M KCl in 0.01 M HCl, which can improve separation. Ensure deaeration is thorough, as oxygen waves can interfere.

FAQ 3: My organic compound shows no discernible polarographic wave. What are the potential causes? Answer: First, verify the compound is electroactive within the available potential window of your electrolyte. Second, increase concentration (within solubility limits). Third, change the electrolyte system to one that facilitates proton transfer if your reaction is pH-dependent (e.g., for a quinone, use a buffer spanning its pKa). Fourth, try adding a surfactant like Triton X-100 (0.001-0.01%) to suppress maxima, which might be obscuring the wave.

FAQ 4: How can I prevent adsorption and fouling of the dropping mercury electrode (DME) by proteins or macromolecules? Answer: Adsorption is a common issue with biomolecules. Use a pulsed polarographic technique (e.g., DPP) instead of DC polarography. Modify your supporting electrolyte: incorporate a mild surfactant (e.g., 0.005% SDS) or increase ionic strength with an inert salt like NaCl. Keep analyte concentration low (< 1 µM) and include a rinsing step with electrolyte between runs.

FAQ 5: I observe high residual current and unstable baselines in non-aqueous media for hydrophobic pharmaceuticals. How can I improve this? Answer: Ensure all components are thoroughly dried. Use a high-purity, aprotic solvent like DMF or acetonitrile with 0.1 M tetraalkylammonium salts (e.g., tetrabutylammonium perchlorate, TBAP) as the supporting electrolyte. These salts are highly soluble in organic solvents and provide a wide potential window. Always use a sealed cell with a desiccant to prevent moisture ingress.

Experimental Protocols

Protocol 1: Optimization of Supporting Electrolyte for Trace Metal Analysis

- Preparation: Prepare 1.0 M stock solutions of KCl, KNO3, NH4Cl, and acetate buffer (pH 4.5).

- Background Scan: Dilute each electrolyte to 0.1 M in distilled, deionized water. Decorate with N2 for 10 min. Record a DC polarogram from -0.2 to -1.2 V vs. SCE.

- Analyte Addition: Spike each electrolyte with standard solutions of Cd2+, Pb2+, and Zn2+ to a final concentration of 5 µM each.

- Data Acquisition: After deaeration (3 min N2), record polarograms. Measure peak height (diffusion current, Id) and potential (E1/2).

- Evaluation: Select the electrolyte yielding the highest, sharpest, and best-separated peaks with the lowest background current.

Protocol 2: Assessing pH Influence on Organic Molecule Reduction

- Buffer Series: Prepare Britton-Robinson buffers from pH 2.0 to 10.0 in 1.0 pH unit increments.

- Sample Preparation: Add the organic analyte (e.g., nitrobenzene) to each buffer to a final concentration of 0.1 mM.

- Polarography: Using DPP, scan the appropriate potential window for each solution. Note the deaeration step is critical for each pH.

- Analysis: Plot E1/2 vs. pH. The breakpoints in the linear segments indicate the pKa values involved in the electrode process.

Data Presentation

Table 1: Recommended Supporting Electrolytes for Different Analyte Classes

| Analyte Class | Example Analytes | Recommended Electrolyte | Typical Concentration | Key Function | Notes |

|---|---|---|---|---|---|

| Metals | Cd²⁺, Pb²⁺, Zn²⁺ | KCl in HCl | 0.1 M KCl, 0.01 M HCl | Provides conductivity, minimizes hydrolysis | For anodic stripping, use pure KCl. |

| Organics | Nitroaromatics, Quinones | Britton-Robinson Buffer | Varies by pH | Controls proton availability | E1/2 shifts -0.059 V/pH for H⁺-coupled reactions. |

| Pharmaceuticals (Aqueous) | Paracetamol, Antibiotics | Phosphate Buffer Saline (PBS) | 0.05 M, pH 7.4 | Mimics physiological conditions | Check for specific catalytic or adsorption effects. |

| Pharmaceuticals (Non-Aq.) | Lipophilic Drugs | TBAP in Acetonitrile | 0.1 M TBAP | Conducting salt for organic solvents | Must be anhydrous conditions. |

| Biomolecules | Proteins, DNA | Tris-HCl Buffer with NaCl | 0.01 M Tris, 0.1 M NaCl, pH 7.5 | Stabilizes biomolecule, provides ionic strength | Add CaCl₂ for some enzyme studies. |

Table 2: Troubleshooting Common Polarographic Issues

| Symptom | Likely Cause | Diagnostic Test | Solution |

|---|---|---|---|

| Irregular Current Oscillations | Unstable mercury drop, vibration | Observe drop fall visually. | Level the DME, dampen vibrations, check capillary. |

| Drifting Baseline | Temperature fluctuation, electrode fouling | Record background scan over time. | Use a thermostat, clean cell, use surfactant in electrolyte. |

| Broad, Ill-Defined Waves | Slow electrode kinetics, high resistance | Compare DC and NP/DP polarography. | Switch to Differential Pulse Polarography (DPP). Use supporting electrolyte > 0.05 M. |

| Unexpected Multiple Peaks | Analyte decomposition, catalytic H⁺ reduction | Run experiment immediately after prep. | Use fresh solutions, change electrolyte pH, exclude O₂. |

Visualizations

Title: Decision Workflow for Electrolyte Selection

Title: Standard Polarographic Experiment Workflow

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function & Rationale |

|---|---|

| Potassium Chloride (KCl) | Classic inert supporting electrolyte for metal ion analysis. Provides high conductivity, minimal complexation. |

| Britton-Robinson (BR) Buffer | Universal buffer mixture (phosphoric + acetic + boric acids + NaOH) for pH 2-10 studies of organic compounds. |

| Tetrabutylammonium Perchlorate (TBAP) | Preferred supporting salt for non-aqueous polarography. Soluble in organic solvents, wide anodic window. |

| Triton X-100 | Non-ionic surfactant. Used at ~0.001% to suppress polarographic maxima and reduce electrode fouling. |

| High-Purity Mercury | For the dropping mercury electrode (DME). Must be triple-distilled to eliminate trace metal contaminants. |

| Nitrogen/Argon Gas (O₂-free) | For deaeration of solutions to remove dissolved oxygen, which produces interfering reduction waves. |

| Standard Calibration Solutions | Certified reference materials for metals (e.g., 1000 ppm Pb²⁺ in HNO₃) for quantitative analysis. |

| Capillary for DME | Glass capillary with precise internal diameter (e.g., 50-70 µm) to control mercury drop time and size. |

Technical Support Center: Troubleshooting & FAQs

Q1: During polarographic analysis, my redox peak potential (E_p) shifts unpredictably between runs, even with the same analyte. What is the primary cause and how can I fix it?

A: The most common cause is insufficient buffer capacity or inconsistent pH of the supporting electrolyte. Redox potentials are highly pH-sensitive for many species (e.g., quinones, metal complexes). A drift of 0.1 pH units can cause a significant E_p shift (see Table 1). To fix this, ensure your buffer has a capacity (β) > 0.01 mol·L⁻¹·pH⁻¹ at your working pH. Always calibrate the pH meter immediately before preparing the electrolyte and confirm the pH after adding all components (including the analyte).

Q2: I observe distorted, drawn-out, or asymmetric polarographic waves. What does this indicate, and what steps should I take?

A: Distorted waves often indicate non-ideal interactions between the analyte and the buffer components. This can be due to:

- Specific Ion Effects: Buffer ions (e.g., citrate, phosphate) may be complexing with your analyte, altering its redox kinetics.

- Insufficient Ionic Strength: The total ionic strength (I) of your supporting electrolyte is too low (< 0.1 M), leading to migration currents and poor diffusion control. Solution: Systematically vary the buffer type (see Table 2) while keeping pH and I constant (using an inert salt like KCl or NaClO₄). Use a background electrolyte with I ≥ 0.5 M for precise work.

Q3: My baseline current is noisy or shows high capacitive interference. How can I improve the signal-to-noise ratio?

A: High capacitive current often stems from impurities or redox-active contaminants in the buffer salts. To resolve:

- Use high-purity (e.g., HPLC or spectroscopy grade) buffer reagents.

- Pre-purify your supporting electrolyte solution by pre-electrolysis at a potential more negative than your scan window using a large auxiliary electrode (e.g., mercury pool).

- Ensure your inert salt (e.g., KCl) is of the highest grade, as chloride salts often contain trace metal contaminants.

- Decoxygenate solutions thoroughly with high-purity nitrogen or argon for at least 15-20 minutes before measurement.

Q4: How do I choose the optimal buffer system for a new redox-active compound in drug development?

A: Follow this experimental protocol:

- Determine pH Sensitivity: Perform preliminary polarographic scans in a universal buffer (e.g., Britton-Robinson) across a wide pH range (2-12). Plot E_p vs. pH to identify regions of stability and determine pKa values of electroactive groups.

- Screen for Inertness: At the target pH, test 2-3 different buffer systems (e.g., phosphate, acetate, TRIS) with identical ionic strength (adjusted with KCl). Overlay the polarograms. The system that yields the most reversible, well-defined wave (smallest ΔE_p, peak closest to theoretical) and no additional peaks is likely the most inert.

- Optimize Concentration: Use the Henderson-Hasselbalch equation to ensure the buffer acid/base ratio is correct. Confirm final buffer capacity by adding small aliquots of acid/base to the cell and measuring the pH change. The capacity should exceed the amount of acid/base generated during the electrode reaction.

Experimental Protocols

Protocol 1: Determining Buffer Capacity (β) for a Polarographic Supporting Electrolyte Objective: Quantify the ability of a prepared buffer system to resist pH changes. Materials: pH meter, magnetic stirrer, standardized 0.1 M NaOH, standardized 0.1 M HCl, your buffer solution. Method:

- Pipette 50.0 mL of your candidate supporting electrolyte solution into a beaker.

- Place on a stirrer, insert pH electrode, and record initial pH (pH₀).

- Add 10 successive 0.1 mL aliquots of 0.1 M HCl, recording pH after each addition.

- Repeat steps 1-2, but titrate with 0.1 M NaOH.

- Calculate buffer capacity: β = Δn / (ΔpH * V), where Δn is moles of acid/base added, ΔpH is the resulting change, and V is buffer volume (L). Plot β vs. pH.

Protocol 2: Systematic Screening of Buffer Inertness on Redox Kinetics Objective: Identify buffer-analyte interactions that distort polarographic waves. Materials: Polarograph, DME, SCE, Pt wire auxiliary, N₂ gas, analyte stock, buffer stocks (all adjusted to same pH and ionic strength with KCl). Method:

- Prepare 5 identical 10 mL solutions containing your target analyte concentration (e.g., 1 mM).

- To each, add a different buffer system (e.g., 0.05 M acetate, phosphate, TRIS, borate, carbonate) but ensure all have a final ionic strength of I = 0.5 M (using KCl) and identical pH (e.g., 7.4).

- Decoxygenate each solution for 15 min.

- Record differential pulse polarograms (DPP) for each solution using identical instrument parameters (pulse amplitude, scan rate, drop time).

- Compare peak potential (E_p), peak width at half-height (W₁/₂), and peak symmetry.

Data Presentation

Table 1: Influence of pH on Formal Potential (E°') for Model Redox Systems

| Redox Couple | Buffer System | pH | E°' (vs. SCE) / V | ΔE°'/ΔpH (V/pH unit) |

|---|---|---|---|---|

| Benzoquinone/Hydroquinone | Phosphate | 5.0 | +0.280 | -0.059 |

| Phosphate | 7.0 | +0.162 | -0.059 | |

| Phosphate | 9.0 | +0.044 | -0.059 | |

| [Fe(CN)₆]³⁻/⁴⁻ | Phosphate | 5.0 | +0.215 | ~0.000 |

| Phosphate | 7.0 | +0.215 | ~0.000 | |

| Phosphate | 9.0 | +0.212 | ~0.000 |

Table 2: Common Buffer Systems for Polarographic Supporting Electrolytes

| Buffer | pKa (25°C) | Useful pH Range | Potential Interferences & Notes |

|---|---|---|---|

| Acetate | 4.76 | 3.8 – 5.8 | Can complex some metal ions. Electrochemically inert in its range. |

| Phosphate | 2.14, 7.20, 12.67 | 5.8 – 8.0 | Strong complexing agent for many metals (Ca²⁺, Mg²⁺, lanthanides). Avoid with metal analytes. |

| TRIS | 8.07 | 7.5 – 9.0 | Contains an amine group; can be redox-active at extreme potentials or participate in reactions. |

| Ammonia | 9.25 | 8.3 – 10.3 | Strong ligand for many metal ions (e.g., Cu, Zn, Ni). Use specifically to study metal complexes. |

| Borate | 9.24 | 8.2 – 10.2 | Generally inert, but can form complexes with cis-diols (e.g., sugars). |

The Scientist's Toolkit: Key Research Reagent Solutions

| Item & Typical Specification | Function in Supporting Electrolyte Optimization |

|---|---|

| KCl or NaClO₄ (≥99.99%, trace metal basis) | Inert salt to provide high, constant ionic strength, minimizing migration effects and stabilizing liquid junction potentials. |

| Buffer Salts (e.g., KH₂PO₄/K₂HPO₄, HPLC Grade) | Maintains constant pH at the electrode-solution interface, critical for reproducible redox potentials. |

| Potassium Ferricyanide (ACS Reagent Grade) | Standard redox probe for validating electrode performance and measuring uncompensated resistance. |

| Quinhydrone (Puriss. p.a.) | 1:1 complex of benzoquinone/hydroquinone for quick calibration of pH dependence of a simple redox couple. |

| High-Purity Nitrogen or Argon (O₂ < 1 ppm) | For deoxygenation of solutions to remove interfering O₂ reduction waves. |

| Mercury (Triple-distilled, polarographic grade) | For use in Dropping Mercury Electrode (DME); provides renewable, reproducible electrode surface. |

Visualizations

Diagram 1: Buffer pH Optimization Workflow for Polarography

Diagram 2: Buffer-Analyte Interactions Affecting Redox Chemistry

Technical Support & Troubleshooting Center

Welcome to the technical support center for polarographic research, specifically focusing on the use of complexing agents to optimize supporting electrolytes. This guide addresses common experimental challenges within the framework of a thesis on "Optimization of Supporting Electrolyte for Polarography Research."

Frequently Asked Questions (FAQs) & Troubleshooting

Q1: I added a complexing agent (e.g., EDTA) to my supporting electrolyte to resolve overlapping cadmium and indium waves, but the wave heights decreased dramatically. What went wrong? A: This indicates excessive complexation, shifting the reduction potentials too far negative or making reduction electrochemically irreversible. Troubleshooting Steps:

- Check Concentration: You are likely using too high a concentration of the complexing agent. Perform a titration: systematically vary the [Complexing Agent] / [Metal Ion] ratio from 0.1 to 10.

- pH Verification: The stability constant of most complexes (like EDTA-metal complexes) is pH-dependent. Ensure your buffer pH is correct and stable. A shift of 0.5 pH units can significantly alter complex strength.

- Oxygen Purge: Confirm thorough deaeration with high-purity nitrogen for at least 10-15 minutes. Residual oxygen causes a large, interfering wave.

Q2: After adding ammonia to separate overlapping nickel and zinc waves, I get broad, ill-defined waves. How can I improve wave shape? A: Broad waves suggest slow electrode kinetics or an unstable complexation equilibrium. Troubleshooting Steps:

- Increase Ionic Strength: Ensure your supporting electrolyte (e.g., KCl, KNO₃) is at a sufficiently high concentration (≥0.1 M) to minimize migration current and stabilize the ionic atmosphere.

- Add a Maximum Suppressor: Introduce 0.005-0.01% gelatin or Triton X-100 to eliminate polarographic maxima that distort waves.

- Optimize Ammonia Concentration & Buffer: Use a consistent NH₃/NH₄⁺ buffer system (e.g., 0.1 M each) to maintain a stable pH and ligand concentration. Re-prepare the buffer if it is old, as ammonia can evaporate.

Q3: My calibration curve for lead in the presence of citrate is non-linear at lower concentrations. Is the complexing agent interfering? A: Likely yes, if the complexing agent is not in sufficient excess. Troubleshooting Steps:

- Maintain Ligand Excess: For a 1:1 complex, ensure [Citrate] > 50x [Pb²⁺] at your highest calibration standard. This swamps out minor variations and ensures a constant fraction of free metal ion.

- Check for Adsorption: Citrate can adsorb on the mercury electrode. Add a very low concentration of a non-ionic surfactant (e.g., 0.001% Triton X-100) to minimize adsorption effects.

- Standard Addition Method: If the matrix is complex, use the method of standard additions directly in your sample solution to account for matrix effects.

Q4: I'm trying to shift the cobalt wave away from the hydrogen evolution wave using tartrate, but the shift is insufficient. What are my options? A: The complex isn't strong enough for your pH/medium. Troubleshooting Steps:

- Choose a Stronger Ligand: Consider switching to a ligand with a higher stability constant for Co²⁺, such as cyanide (in a strictly controlled, vented fume hood) or ethylenediamine.

- Combine with pH Adjustment: Increase the solution pH (e.g., to pH 9-10 with an ammonia buffer) to enhance complexation with tartrate, provided your analyte allows it.

- Switch Techniques: Consider using Differential Pulse Polarography (DPP) or Square Wave Polarography (SWP) which offer better resolution of overlapping waves than classical DC polarography.

Experimental Protocol: Systematic Optimization of a Complexing Agent

Title: Protocol for Resolving Overlapping Zn²⁺ and Cd²⁺ Waves using KCN as a Complexing Agent.

Objective: To selectively shift the half-wave potential (E₁/₂) of Cd²⁺ to achieve baseline separation from Zn²⁺ in a 0.1 M KCl supporting electrolyte.

Materials: See "Research Reagent Solutions" table below.

Procedure:

- Baseline Measurement: Deaerate 25 mL of Solution A (0.1 M KCl + 0.001% gelatin + 50 µM each of Zn²⁺ and Cd²⁺) with N₂ for 12 minutes. Record a DC polarogram from -0.8 V to -1.4 V (vs. SCE).

- Complexing Agent Addition: To the same cell, add small, precise aliquots (e.g., 10-50 µL) of Solution B (1.0 M KCN in 0.1 M KCl). Stir and deaerate for 2 minutes after each addition.

- Data Collection: Record a polarogram after each addition. Continue until the Cd²⁺ wave is completely separated and precedes the Zn²⁺ wave by at least 150 mV.

- Analysis: Plot ΔE₁/₂ (shift for Cd²⁺) vs. log[CN⁻]. The linear region confirms complex formation. Determine the optimal [CN⁻] where resolution is maximized without excessive wave broadening.

Research Reagent Solutions

| Reagent | Function in Experiment | Key Consideration |

|---|---|---|

| Potassium Cyanide (KCN) | Primary complexing agent. Forms stable anionic complexes with Cd²⁺ ([Cd(CN)₄]²⁻), shifting its E₁/₂ positively. | EXTREME TOXICITY. Use in fume hood with dedicated waste collection. |

| Gelatin (Maximum Suppressor) | Eliminates polarographic maxima by adsorbing to the mercury drop, ensuring smooth, reproducible limiting currents. | Use fresh, low-concentration stock (0.1%). Excess can dampen diffusion current. |

| Potassium Chloride (KCl) | Inert supporting electrolyte. Provides high ionic strength, carries current, and minimizes migration current. | Use highest purity (≥99.99%) to avoid trace metal contamination. |

| Nitrogen Gas (N₂) | Inert gas for deaeration. Removes dissolved oxygen which reduces at ~-0.05 V and ~-0.9 V (vs. SCE), interfering with metal analysis. | Must be high purity (>99.998%) with an oxygen scrubber. |

| Ammonia/Ammonium Chloride Buffer | pH buffer and weak complexing agent. Useful for separating metals like Ni, Zn, and Co by controlled ligand concentration. | Prepare fresh; ammonia evaporates, changing pH and [ligand]. |

Quantitative Data: Effect of Complexing Agents on Half-Wave Potentials (E₁/₂)

Table: Shift in E₁/₂ (vs. SCE) for 50 µM Metal Ions in 0.1 M KCl upon Addition of Complexing Agent (25°C).

| Metal Ion | E₁/₂ in 0.1 M KCl (V) | Complexing Agent & Concentration | E₁/₂ with Agent (V) | ΔE₁/₂ (V) | Purpose of Shift |

|---|---|---|---|---|---|

| Cd²⁺ | -0.60 | 0.01 M KCN | -0.82 | -0.22 | Separate from Zn²⁺ (-1.00 V) |

| Pb²⁺ | -0.40 | 0.1 M OH⁻ (pH 13) | -0.76 | -0.36 | Separate from Ti⁺ (-0.48 V) or Cu²⁺ (0.00 V) |

| Ni²⁺ | -1.10 | 1.0 M NH₃/NH₄⁺ (pH 9) | -1.06 | +0.04 | Shift positively away from Zn²⁺ (-1.35 V in same medium) |

| Cu²⁺ | 0.00 | 0.1 M EDTA (pH 4.7) | -0.13 | -0.13 | Make reduction reversible for accurate quantification |

| In³⁺ | -0.55 | 1.0 M SCN⁻ | -0.70 | -0.15 | Separate from Cd²⁺ (-0.60 V) |

Visualization: Workflow for Optimizing Complexing Agents

Title: Workflow for Complexing Agent Optimization in Polarography

Visualization: How a Complexing Agent Separates Overlapping Waves

Title: Mechanism of Wave Separation by Selective Complexation

Technical Support Center: Troubleshooting & FAQs

FAQ: General Electrolyte Selection

- Q1: Why is my polarographic wave poorly defined or ill-shaped?

- A: This is often due to an inappropriate supporting electrolyte. The electrolyte must effectively suppress migration current and provide a suitable pH and ionic strength. Ensure your electrolyte concentration is at least 50-100 times greater than the analyte concentration. Check for overlapping reduction/oxidation potentials of electrolyte components.

Q2: How do I choose between a simple salt (e.g., KCl) and a buffer system (e.g., BR buffer)?

- A: Use a simple salt (KCl, KNO₃, LiClO₄) for molecules where pH does not influence the redox process. Always use a buffer system (acetate, phosphate, Britton-Robinson) for molecules where protons are involved in the electrode reaction (e.g., nitro group reduction, many antibiotics) to maintain a stable half-wave potential (E₁/₂).

Q3: I suspect adsorption of my drug molecule onto the electrode. What electrolyte additives can help?

- A: Adsorption, common with complex organics, causes distorted waves. Add a small concentration (0.001-0.01%) of a non-ionic surfactant (e.g., Triton X-100) to the electrolyte. This competitively desorbs the analyte, restoring a normal polarographic wave. Re-standardize as surfactants can slightly shift E₁/₂.

Troubleshooting Guide: Specific Drug Classes

- Issue: Multiple, overlapping waves for a nitroaromatic compound.

- Cause: Nitro group reduction proceeds in multi-electron steps (NO₂ → NO → NHOH → NH₂), each sensitive to pH.

Solution: Optimize buffer pH to merge steps. For example, in strongly acidic media (pH < 2), the 4-electron reduction to hydroxylamine is often a single wave. Use a citrate or acetate buffer and systematically test pH 2-7.

Issue: Poor reproducibility and shifting E₁/₂ for a heavy metal ion (e.g., Pb²⁺, Cd²⁺).

- Cause: Hydrolysis of metal ions or formation of complexes with trace impurities in the electrolyte.

Solution: Use an acidic electrolyte (e.g., 0.1 M HCl or KNO₃/HNO₃) to prevent hydrolysis. For analysis in neutral/alkaline media, add a complexing agent like 0.01 M EDTA to the electrolyte to provide a well-defined, reproducible complex reduction wave.

Issue: No discernible polarographic wave for an antibiotic (e.g., certain tetracyclines or fluoroquinolones).

- Cause: The electroactive group may not be accessible or may require a specific catalytic environment.

- Solution: Incorporate a coordinating metal ion. For example, the polarographic analysis of doxycycline is significantly enhanced in an electrolyte containing Ca²⁺ ions, which form an electroactive complex. Refer to literature for specific metal-antibiotic systems.

Experimental Protocols & Data

Protocol 1: Systematic Optimization of Supporting Electrolyte pH

- Objective: Determine the optimal pH for the polarographic analysis of Metronidazole (a nitroimidazole antibiotic).

- Materials: Britton-Robinson (BR) buffer series (pH 2-10), 1 mM standard Metronidazole solution, 0.1 M KCl (as supporting salt), nitrogen gas for deaeration.

- Method:

- Prepare 10 mL of each BR buffer pH (2, 4, 6, 8, 10) containing 0.1 M KCl.

- Transfer 9.5 mL of a buffer to the polarographic cell. Deaerate with N₂ for 10 min.

- Record the blank polarogram from -0.2 V to -1.2 V vs. SCE.

- Add 0.5 mL of 1 mM Metronidazole standard. Mix and deaerate for 2 min.

- Record the sample polarogram. Measure the diffusion current (i_d) and E₁/₂.

- Repeat for all pH values.

- Analysis: Plot id and E₁/₂ vs. pH. The pH zone offering maximum id and a stable E₁/₂ is optimal for analytical sensitivity and reproducibility.

Protocol 2: Standard Addition for Heavy Metal Analysis in a Drug Matrix

- Objective: Quantify trace lead (Pb) contamination in a calcium carbonate drug substance.

- Materials: 0.1 M HCl electrolyte, 1000 ppm Pb standard, sample solution (1 g drug dissolved in minimal dilute HNO₃, made up to volume with 0.1 M HCl).

- Method:

- Place 10.0 mL of the sample solution into the polarographic cell. Deaerate.

- Record a Differential Pulse Polarogram (DPP) from -0.2 to -0.8 V vs. Ag/AgCl. Note the peak current (i_p) for Pb (~ -0.45 V).

- Add 50 µL of 1000 ppm Pb standard. Mix, deaerate briefly, and record the DPP.

- Repeat standard addition 3-4 times.

- Analysis: Plot i_p vs. concentration of added Pb standard. Extrapolate the line to the x-intercept to find the original concentration of Pb in the sample solution.

Quantitative Data Summary: Optimal Electrolyte Formulations

Table 1: Electrolyte Formulations for Common Drug Molecules in Polarography

| Drug Molecule Class | Example Compound | Recommended Supporting Electrolyte | Optimal pH | Typical E₁/₂ (vs. SCE) | Key Consideration |

|---|---|---|---|---|---|

| Nitroaromatics | Nitrofurantoin | 0.1 M Britton-Robinson Buffer | 7.0 | -0.42 V | Well-defined 4-electron wave at neutral pH. |

| Heavy Metals | Lead (Pb²⁺) | 0.1 M HCl or 0.1 M KNO₃ | < 2.0 | -0.40 V | Acidic medium prevents hydrolysis; use Standard Addition. |

| Tetracycline Antibiotics | Doxycycline | 0.04 M Borate Buffer + 0.01 M CaCl₂ | 9.3 | -1.38 V | Ca²⁺ forms a complex, enhancing sensitivity and wave shape. |

| Fluoroquinolones | Ciprofloxacin | 0.1 M Acetate Buffer | 4.7 | -1.05 V (cathodic) | Irreversible reduction; adsorption effects minimized at this pH. |

| Antimony Drugs | Meglumine Antimoniate | 2 M HCl + 0.1 M Tartaric Acid | < 1.0 | -0.15 V (Sb³⁺/Sb) | Tartaric acid prevents precipitation and ensures stable Sb³⁺ oxidation state. |

Visualizations

Title: Electrolyte Optimization Decision Pathway

Title: pH Optimization Workflow for Drug Analysis

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Electrolyte Formulation & Troubleshooting

| Reagent/Material | Function in Polarography | Example Use Case |

|---|---|---|

| Britton-Robinson (BR) Universal Buffer | Provides a wide, continuous pH range (2-12) for systematic studies. | Optimizing pH for nitro compound or antibiotic reduction. |

| Triton X-100 (non-ionic surfactant) | Competitively displaces adsorbing analytes from the mercury electrode surface. | Eliminating maxima and restoring normal wave shape for surfactants. |

| Potassium Chloride (KCl) | A common inert supporting electrolyte with high conductivity; minimizes migration current. | General purpose analysis for ions with pH-independent redox processes. |

| Ethylenediaminetetraacetic Acid (EDTA) | Strong complexing agent for metal ions. Can mask interferences or create well-defined reduction waves. | Analyzing heavy metals in complex matrices or studying metal-drug complexes. |

| Lithium Perchlorate (LiClO₄) | Useful in non-aqueous or mixed solvents due to high solubility and wide anodic potential window. | Studying drugs insoluble in purely aqueous media. |

| Calcium Chloride (CaCl₂) | Cationic additive that can form electroactive complexes with specific drug molecules. | Enhancing the polarographic signal of tetracycline-class antibiotics. |

Diagnosing and Solving Common Polarographic Issues Through Electrolyte Engineering

Troubleshooting Poor Resolution and Overlapping Waves

Troubleshooting Guides and FAQs

Q1: During my polarographic analysis for drug compound quantification, I am getting poorly resolved, overlapping reduction waves. What is the primary cause within the context of supporting electrolyte optimization? A1: The most common cause is an inadequately optimized supporting electrolyte. A poor electrolyte choice can lead to:

- Insufficient Ionic Strength: High solution resistance causes distorted, drawn-out waves (poor resolution).

- Inappropriate pH: The proton activity can shift half-wave potentials (E₁/₂), causing waves to merge.

- Complexation Effects: The electrolyte components may form complexes with your analyte, altering E₁/₂ and causing overlaps.

- Inadequate Maximum Suppressor: Without a proper maximum suppressor (e.g., Triton X-100), pronounced maxima can obscure wave separation.

Q2: How do I systematically troubleshoot and resolve these overlapping wave issues? A2: Follow this structured protocol to isolate and correct the issue.

Experimental Protocol 1: Systematic Electrolyte Screening

- Prepare Stock Solutions: Prepare a 1.0 mM standard solution of your target analyte and a 10.0 mM stock of your internal standard (if used).

- Select Electrolyte Matrix: Prepare 0.1 M solutions of different supporting electrolytes (see Table 1). Buffer each to a specific pH relevant to your analyte's pKa.