Gold Film Electrode Preparation for Arsenic Speciation in Water: A Comprehensive Methodological Guide

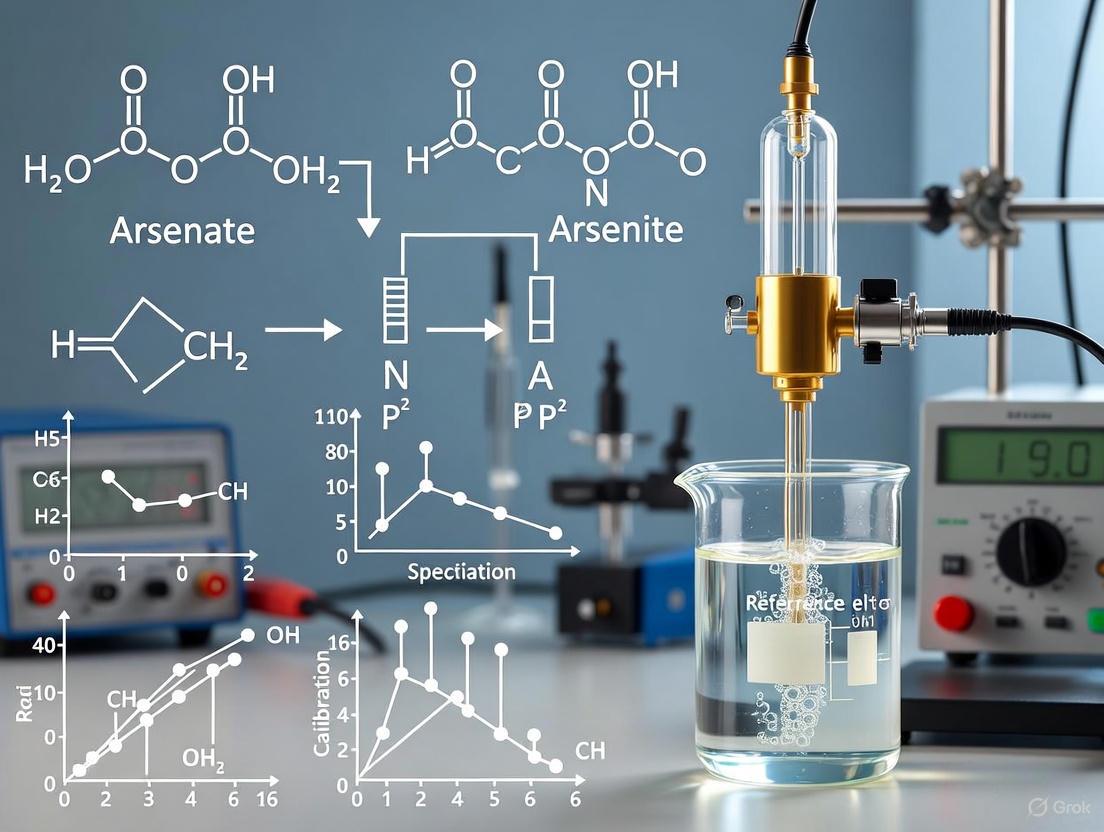

This article provides a comprehensive guide to the preparation, optimization, and application of gold film electrodes (AuFEs) for the speciation of inorganic arsenic in water.

Gold Film Electrode Preparation for Arsenic Speciation in Water: A Comprehensive Methodological Guide

Abstract

This article provides a comprehensive guide to the preparation, optimization, and application of gold film electrodes (AuFEs) for the speciation of inorganic arsenic in water. Aimed at researchers and analytical professionals, it covers foundational principles of anodic stripping voltammetry (ASV) for differentiating toxic arsenite (As(III)) from arsenate (As(V)). The content details step-by-step electrode fabrication, including substrate preparation and critical deposition parameters like potential, time, and gold electrolyte concentration. It further addresses troubleshooting common issues such as interferences and surface passivation, and validates the electrochemical methods against established spectroscopic techniques. The guide emphasizes strategies for on-site analysis, species preservation, and achieving the low detection limits required for compliance with the WHO drinking water standard of 10 μg L⁻¹.

The Critical Role of Gold Electrodes in Arsenic Speciation and Toxicity

Global Prevalence and Health Implications of Arsenic Contamination

Arsenic contamination of groundwater represents a critical public health challenge on a global scale. The World Health Organization (WHO) identifies arsenic as one of 10 chemicals of major public health concern, with an estimated 140 million people in at least 70 countries exposed to drinking water containing arsenic levels above the WHO provisional guideline value of 10 µg/L (or 10 parts per billion, ppb) [1]. This widespread contamination poses severe health risks to populations worldwide.

Health Risks from Chronic Arsenic Exposure

Long-term exposure to inorganic arsenic through drinking water is associated with a spectrum of serious health consequences. The toxicity of arsenic is highly dependent on its chemical form, with inorganic arsenic being the most toxic and significant contaminant in drinking water globally [1] [2].

- Cancerous Effects: Inorganic arsenic is a confirmed human carcinogen. Chronic exposure is linked to increased risk of cancers of the skin, bladder, lungs, kidney, and liver [1] [3].

- Non-Cancerous Effects: The first signs of prolonged exposure often manifest in the skin, including pigmentation changes, lesions, and hyperkeratosis (hard patches on palms and soles) [1]. Other serious health outcomes include:

Table 1: Health Effects of Chronic Inorganic Arsenic Exposure via Drinking Water

| Effect Category | Specific Health Outcomes |

|---|---|

| Carcinogenic Effects | Skin cancer, bladder cancer, lung cancer, kidney cancer, liver cancer [1] [3] |

| Dermatological Effects | Pigmentation changes, skin lesions, hyperkeratosis [1] |

| Cardiovascular & Metabolic Effects | Cardiovascular disease, myocardial infarction, diabetes [1] |

| Developmental & Neurological Effects | Reduced intelligence in children, impaired cognitive development, adverse pregnancy outcomes [1] [2] |

| Other Organ Systems | Pulmonary disease, liver damage, renal failure [1] |

Quantifying the Problem: Exposure Data

The scale of arsenic contamination is vast, with certain regions being more severely affected. In the United States alone, a recent report indicates that arsenic contaminates water serving an estimated 134 million people across all 50 states [4]. Regions with notably high levels of arsenic in groundwater include parts of Argentina, Bangladesh, Chile, China, India, Mexico, and the United States of America [1].

Table 2: Global and National Scale of Arsenic in Drinking Water

| Region | Estimated Population at Risk/Exposed | Key References |

|---|---|---|

| Global (70+ countries) | 140 million people above WHO guideline (10 µg/L) | WHO (2024) [1] |

| United States | 134 million people served by contaminated systems | Environmental Working Group (2025) [4] |

| Minnesota (Example State) | ~10% of private wells above 10 µg/L | Minnesota Department of Health (2024) [2] |

The Critical Need for Speciation Analysis and Advanced Detection

The accurate assessment of arsenic toxicity requires not only determining its total concentration but also identifying its specific chemical forms, a process known as speciation analysis [5]. In natural water environments, arsenic exists primarily in two inorganic oxidation states: trivalent arsenite (As(III)) and pentavalent arsenate (As(V)) [6]. The toxicity, mobility, and environmental behavior of arsenic depend critically on its oxidation state, with As(III) being more toxic and mobile than As(V) [7] [6]. This distinction is crucial for accurate risk assessment and remediation planning.

Electrochemical sensing methods, particularly those using gold-based electrodes, have emerged as powerful tools for sensitive, selective, and cost-effective arsenic detection and speciation [8] [6]. Their relevance is underscored by the need for field-deployable systems that can provide rapid, on-site analysis, overcoming the limitations of traditional laboratory-based techniques like inductively coupled plasma-mass spectrometry (ICP-MS) and atomic absorption spectrometry (AAS), which are complex and expensive [8] [6].

Experimental Protocols for Arsenic Detection Using Gold-Based Electrodes

The following protocols outline detailed methodologies for the electrochemical detection and speciation of arsenic in water samples, leveraging the affinity of arsenic for gold surfaces.

Protocol 1: Determination of As(III) and As(V) by Anodic Stripping Voltammetry (ASV) with a Rotating Gold-Film Electrode

This protocol is adapted from a established method for determining arsenic species in seawater, utilizing the high sensitivity of anodic stripping voltammetry [7].

Workflow Overview:

Materials and Reagents:

- Working Electrode: Rotating glassy carbon electrode (GCE) coated with a gold film.

- Counter Electrode: Platinum wire.

- Reference Electrode: Ag/AgCl (saturated KCl).

- Supporting Electrolyte: Hydrochloric acid (HCl, Suprapur grade), pH ~1.5-2.0.

- As(III) Standard Stock Solution (1000 ppm): Prepared by dissolving 0.132 g of primary standard As₂O₃ in a minimal amount of NaOH, adjusting pH to ~3.5 with HCl, and diluting to 100 mL with deionized water. 5 ppm hydrazinium chloride is added to prevent oxidation [7].

- Gold Plating Solution: 0.1 M HCl containing 50 mg/L of Au (as HAuCl₄).

- Gaseous SO₂ or sodium metabisulfite solution (for As(V) reduction).

- High-purity nitrogen gas for deaeration.

Procedure:

- Gold-Film Electrode Preparation:

- Polish the glassy carbon electrode surface with 0.05 µm alumina slurry, then rinse thoroughly with deionized water.

- Place the electrode in the gold plating solution (0.1 M HCl + 50 mg/L Au).

- Electroplate the gold film onto the GCE at a constant potential of -0.4 V (vs. Ag/AgCl) for 60-120 seconds while rotating the electrode at 2000 rpm. A fresh gold film should be plated before each measurement for optimal reproducibility [7].

Sample Pre-treatment and Speciation:

- Acidify the water sample (e.g., seawater, groundwater) with concentrated HCl to a final pH between 1.5 and 2.0.

- For As(III) determination: Analyze the acidified sample directly.

- For Total Inorganic Arsenic (As(T)) determination: Reduce As(V) to As(III) prior to analysis. This is achieved by adding a small volume of saturated SO₂ water (or a concentrated Na₂S₂O₅ solution, which generates SO₂) to the acidified sample. Allow the reduction to proceed for at least 30 minutes [7].

- As(V) concentration is calculated by the difference: As(V) = As(T) - As(III).

Anodic Stripping Voltammetric Measurement:

- Transfer an aliquot of the prepared sample to the electrochemical cell. Purge with nitrogen gas for 5-10 minutes to remove dissolved oxygen.

- Pre-concentration/Deposition: While rotating the gold-film electrode (2000 rpm), deposit As(0) onto the gold surface by applying a constant potential of -0.4 V (vs. Ag/AgCl) for a defined time (e.g., 2-4 minutes for nanogram-level detection). The deposition time can be adjusted based on the expected arsenic concentration [7].

- Stripping Scan: After the deposition step, stop rotation and initiate the stripping scan after a 15-second quiet time. The stripping is performed using Differential Pulse Anodic Stripping Voltammetry (DPASV) by scanning the potential from -0.4 V to +0.4 V (vs. Ag/AgCl). The peak for arsenic oxidation (As(0) to As(III)) appears at approximately +0.2 V under these conditions [7].

- Record the stripping voltammogram.

Calibration and Quantification:

- Prepare a calibration curve by standard addition, spiking known concentrations of As(III) standard into the sample matrix and repeating the measurement.

- Plot the peak current versus the concentration of As(III) added. The concentration of As(III) in the original sample is determined from this calibration curve.

Performance Metrics: This method reports a detection limit of approximately 0.19 ppb (2.5 nM) for a 4-minute deposition time, with very good precision (RSD = 2–0.6% in the 1–5 ppb range) [7].

Protocol 2: Stripping Chronopotentiometry (SCP) with a Gold Film Electrode

This protocol offers an alternative electrochemical technique with a fourfold shorter deposition time compared to some earlier SCP methods, while maintaining excellent sensitivity for arsenic speciation in complex matrices like seawater [9].

Procedure:

- Electrode Preparation: Follow the gold-film plating procedure described in Protocol 1.

- Sample Pre-treatment: Acidify the water sample and perform As(V) reduction as described in Steps 2a-c of Protocol 1.

- Stripping Chronopotentiometric Measurement:

- Pre-concentration/Deposition: Deposit As(0) onto the gold-film electrode at a constant potential (e.g., -0.4 V to -0.8 V vs. Ag/AgCl) for 60-150 seconds, with or without electrode rotation.

- Stripping Scan: After deposition, apply a constant oxidizing current in the anodic direction. Measure the potential of the working electrode as a function of time. The time required to strip (oxidize) the deposited arsenic is proportional to its concentration in the sample.

- Calibration and Quantification: Use the standard addition method with As(III) standards to quantify the arsenic concentration based on the stripping time (transition time).

Performance Metrics: This SCP method reports detection limits of 0.053 ppb (0.71 nM) for total inorganic As and 0.022 ppb (0.29 nM) for As(III) after deposition times of 60 and 150 seconds, respectively [9].

Protocol 3: Nanocomposite-Modified Electrode for As(V) Detection

This protocol utilizes a modern sensor approach, leveraging a nanocomposite-modified electrode for enhanced sensitivity. This method is designed for the detection of total inorganic arsenic after oxidative pre-treatment to convert all inorganic arsenic to As(V) [8].

Workflow Overview:

Materials and Reagents:

- Nanocomposite Components:

- Acrylic Acid Functionalized Graphene Oxide (AAGO) nanosheets.

- Polyaniline (PA), a conductive polymer.

- Poly(diallyldimethylammonium chloride) (PDDA), a cationic polymer.

- Working Electrode: Bare Glassy Carbon Electrode (GCE).

- As(V) Standard Stock Solution: Sodium dihydrogen arsenate (NaH₂AsO₄) in deionized water.

- Oxidizing agent (e.g., permanganate or peroxide) for sample pre-treatment.

Procedure:

- Synthesis of Nanocomposite Modifier:

- Synthesize AAGO nanosheets via the modified Hummer's method followed by functionalization with acrylic acid using a linker [8].

- Prepare the nanocomposite by combining PA, PDDA, and AAGO in a suitable solvent to form a homogeneous suspension or gel.

- Electrode Modification:

- Polish and clean the bare GCE.

- Deposit the prepared nanocomposite suspension onto the GCE surface (e.g., by drop-casting) and allow it to dry, forming a stable modified electrode. The positively charged PDDA enhances the adsorption of negatively charged arsenate ions (H₂AsO₄⁻/HAsO₄²⁻) [8].

- Sample Pre-treatment:

- Oxidize the water sample to convert all inorganic As(III) to As(V). This can be done by adding a mild oxidizing agent and allowing the reaction to go to completion.

- Voltammetric Measurement:

- Immerse the modified electrode in the pretreated sample.

- Perform either Cyclic Voltammetry (CV) or Differential Pulse Voltammetry (DPV) to measure the electrochemical response of As(V) adsorbed on the nanocomposite surface.

- Calibration and Quantification:

- Use the standard addition method with As(V) standards to construct a calibration curve and determine the total inorganic arsenic concentration in the sample.

Performance Metrics: The reported sensor exhibits a high sensitivity of 1.79 A/M and a low detection limit of 0.12 µM (equivalent to ~9.0 ppb) for As(V) [8].

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Reagents and Materials for Gold-Electrode Based Arsenic Detection

| Reagent/Material | Function/Application | Critical Notes |

|---|---|---|

| Glassy Carbon Electrode (GCE) | Substrate for forming the gold-film or depositing nanocomposite modifiers. | Requires meticulous polishing with alumina slurry before each plating step to ensure reproducibility [7] [8]. |

| Gold Salt (HAuCl₄) | Source of gold for electroplating the conductive film on the GCE. | The gold film's history and preparation method drastically affect response stability and sensitivity [7] [6]. |

| Hydrochloric Acid (HCl), Suprapur | Provides the optimal acidic supporting electrolyte (pH 1.5-2.0) for arsenic determination. | High-purity grade minimizes interference from other trace metals [7]. |

| Arsenic Trioxide (As₂O₃) | Primary standard for preparing As(III) stock calibration solutions. | Must be stabilized with hydrazinium chloride to prevent oxidation to As(V) [7]. |

| Sodium Dihydrogen Arsenate (NaH₂AsO₄) | Primary standard for preparing As(V) stock calibration solutions. | Used for calibration in methods targeting As(V) or total arsenic after oxidation [8]. |

| Sulfur Dioxide (SO₂) or Sodium Metabisulfite | Reducing agent for converting As(V) to electroactive As(III) prior to analysis for total inorganic arsenic. | Critical for arsenic speciation studies [7]. |

| Poly(diallyldimethylammonium chloride) (PDDA) | Cationic polymer in nanocomposites; enhances adsorption of negatively charged arsenate ions. | Improves sensor sensitivity and selectivity via electrostatic interaction [8]. |

| Functionalized Graphene Oxide (e.g., AAGO) | Nanomaterial in composite modifiers; increases electrode surface area and improves dispersion of active components. | The nano-size effect and functional groups enhance sensor performance [8]. |

Arsenic, a ubiquitous element in nature, poses a significant threat to human health and aquatic ecosystems globally. Its presence in water sources, primarily from natural geological processes and anthropogenic activities like mining and industry, represents a major environmental challenge. The toxicity of arsenic is profoundly influenced by its chemical form, or speciation. This application note details the critical toxicological differences between the two predominant inorganic species – arsenite (As(III)) and arsenate (As(V)) – and outlines the application of advanced electrochemical methods utilizing gold-film electrodes for their precise determination and speciation in water research.

Toxicity Profile: As(III) vs. As(V)

Arsenic exists in several oxidation states, but in aquatic environments, its inorganic forms, As(III) and As(V), are of primary toxicological concern. While both are harmful, their mechanisms and potency differ significantly.

Table 1: Comparative Toxicity of Inorganic Arsenic Species

| Parameter | Arsenite (As(III)) | Arsenate (As(V)) |

|---|---|---|

| Oxidation State | +3 | +5 |

| Relative Toxicity | More toxic | Less toxic |

| Primary Mechanism of Action | Binds to sulfhydryl groups in enzymes, inhibiting cellular respiration and energy production [10]. | Mimics phosphate, disrupting ATP synthesis and oxidative phosphorylation [10]. |

| Biochemical Impact | Inhibition of critical enzymes like pyruvate dehydrogenase (PDH) [10]. | Forms unstable glucose-6-arsenate, leading to depletion of ATP [10]. |

| Mobility in Environment | Generally more mobile and soluble, especially in low pH waters [11]. | More prevalent in high pH waters [11]. |

Chronic exposure to arsenic, particularly As(III), is associated with severe health consequences, including skin lesions, cardiovascular diseases, neurological disorders, and various forms of cancer [11] [10]. The World Health Organization (WHO) has established a maximum permissible limit of 10 micrograms per liter (μg/L) for total inorganic arsenic in drinking water to mitigate these risks [11].

Analytical Techniques for Arsenic Speciation

Accurate speciation is crucial for realistic risk assessment. Analytical methods fall into two broad categories: traditional chemical techniques and electrochemical methods.

Table 2: Comparison of Arsenic Speciation Techniques

| Technique | Principle | Advantages | Limitations |

|---|---|---|---|

| HG-ICP-OES (Hydride Generation Inductively Coupled Plasma Optical Emission Spectrometry) | Separation via hydride generation; detection by plasma emission. | High sensitivity; reference method [12]. | Complex sample preparation; costly instrumentation; less portable [12] [11]. |

| HPLC-ICP-MS (High-Performance Liquid Chromatography coupled with ICP-MS) | Chromatographic separation followed by mass spectrometry detection. | High selectivity and sensitivity for multiple species. | Expensive equipment; requires skilled operators; complex sample preparation [11]. |

| Anodic Stripping Voltammetry (ASV) | Electrochemical deposition and stripping on a working electrode. | High sensitivity (LOD < 0.1 μg/L [12]); portable; cost-effective; enables on-site analysis [12] [11]. | Requires optimized electrode preparation; potential interferences. |

Electrochemical methods, particularly Anodic Stripping Voltammetry (ASV), have emerged as powerful alternatives. ASV offers excellent sensitivity, requires simpler sample preparation, and can be deployed with portable potentiostats, making it ideal for both laboratory and field analysis [12] [11] [13]. A key advancement is the development of a portable DPASV (Differential Pulse ASV) method with a low detection limit of 0.10 μg L⁻¹ for total arsenic, which shows satisfactory agreement with HG-ICP-OES [12].

Gold-Film Electrodes in Arsenic Speciation

Gold electrodes are the preferred substrate for the electrochemical detection of arsenic due to their superior performance characteristics.

Advantages of Gold Electrodes

Gold electrodes provide a high hydrogen overvoltage and exhibit better reversibility for the arsenic electrode reaction, which is critical for obtaining a clear, measurable signal [7]. Furthermore, the gold surface is readily modified with thiolated molecules, although for direct arsenic detection, a clean, well-prepared gold surface is paramount [14].

Fabrication Methods for Gold-Film Electrodes

The performance of the sensor is heavily dependent on the electrode fabrication method.

- Conventional Fabrication: Methods like sputtering (a form of Physical Vapor Deposition) with photolithography produce high-quality electrodes but require cleanroom facilities and involve high capital costs, potentially exceeding $1 million [14].

- Screen-Printed Gold Electrodes (SPEs): These offer a more affordable and reproducible alternative for mass production. However, the initial investment for a screen printer is still significant ($30,000-$80,000), and the electrodes require curing at elevated temperatures [14].

- Innovative Low-Cost Methods: Recent research highlights promising, cost-effective approaches. Gold leaf electrodes offer an extremely low-cost substrate (approximately $32 per 25 sheets) suitable for low-resource settings [14]. Another novel method involves creating porous gold films using graphene oxide (GO) as a sacrificial layer. This technique involves spin-coating GO onto a thin sputtered gold film, etching the gold through the GO layer, and then removing the GO. This process creates a porous film with a high surface area, which can enhance analytical performance, and is compatible with various substrates [15].

Experimental Protocols

Protocol 1: Determination of As(III) and Total Inorganic Arsenic in Freshwater by DPASV

This protocol is adapted from recent work developing a portable method for arsenic speciation [12].

Research Reagent Solutions

| Item | Function |

|---|---|

| Solid Gold Electrode (SGE) or Gold-Film Electrode | Working electrode for deposition and stripping of arsenic. |

| Portable Potentiostat | Instrument for applying and measuring electrical potential/current. |

| HCl or HClO₄ supporting electrolyte | Provides optimal acidic medium for the electrochemical reaction [7]. |

| As(III) standard solution (e.g., from As₂O₃) | Used for calibration and quantitative determination. |

| Nitrogen gas | For de-aeration of the solution to remove dissolved oxygen. |

Workflow:

- Sample Collection and Preservation: Collect water samples in clean polyethylene bottles. Acidify samples to pH < 2 with high-purity HCl if storage is required.

- Electrode Preparation: Clean the rotating solid gold electrode according to the manufacturer's protocol. A well-prepared surface is critical for a stable response [7].

- Analysis of As(III):

- Transfer a known volume of sample or standard to the electrochemical cell.

- Add supporting electrolyte (e.g., 1 M HCl).

- Purge with nitrogen for 5 minutes to remove oxygen.

- Deposition: Hold the working electrode at a deposition potential of -0.3 V vs. Ag/AgCl while rotating to pre-concentrate As(0) onto the gold surface.

- Stripping: After a defined deposition time (e.g., 60-300 s), apply a differential pulse anodic potential scan. The peak for As(III) oxidation appears at approximately +0.1 V [12].

- Analysis of Total Inorganic Arsenic:

- To the same cell, apply an electchemical reduction at -1.2 V to reduce As(V) to As(0) using nascent hydrogen. This step avoids the use of chemical reducing agents, making the method suitable for portable analysis [12].

- Repeat the deposition and stripping sequence (Step 3). The signal obtained corresponds to total inorganic arsenic (As(III) + As(V)).

- Quantification and Speciation:

- Calculate As(III) concentration directly from the first voltammogram.

- Determine As(V) concentration by subtracting the As(III) concentration from the total inorganic arsenic concentration.

Protocol 2: Alternative Speciation via Chemical Reduction

This older protocol is effective but involves chemical reagents, making it less ideal for field-portable analysis [7] [16].

Workflow:

- Follow Steps 1-3 from Protocol 1 to determine As(III) directly.

- Chemical Reduction of As(V): To a separate aliquot of the sample, add potassium iodide (KI) and concentrated HCl to reduce As(V) to As(III) [16].

- Analyze the reduced sample using the same DPASV sequence for As(III) (Protocol 1, Step 3).

- The signal now corresponds to total inorganic arsenic. Calculate As(V) by difference.

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions for Gold-Film Electrode ASV

| Research Reagent | Function in Experiment |

|---|---|

| Solid Gold Electrode (Rotating) | High hydrogen overvoltage provides a wide potential window; superior for As deposition/stripping [7]. |

| Gold Sputtering Target | Source material for fabricating thin, uniform gold films via conventional PVD methods [14]. |

| Gold Leaf | Ultra-low-cost substrate for fabricating electrodes for use in low-resource settings (LRS) [14]. |

| Graphene Oxide (GO) Dispersion | Acts as a sacrificial layer to create porous gold films with high surface area, enhancing detection capabilities [15]. |

| Hydrochloric Acid (HCl), Suprapur | Serves as an optimal supporting electrolyte for arsenic determination, providing a fast charge-transfer reaction [7]. |

| Potassium Iodide (KI) | Chemical reducing agent used in some protocols to convert As(V) to electroactive As(III) [16]. |

| Nascent Hydrogen (electrogenerated) | A reagent-free alternative for the in-situ reduction of As(V) to As(0), ideal for portable analysis [12]. |

The critical differential toxicity between As(III) and As(V) underscores the necessity for precise speciation analysis in environmental water monitoring. Gold-film electrode-based anodic stripping voltammetry has proven to be a highly sensitive, cost-effective, and portable solution for this task. Advances in electrode fabrication, such as the use of porous gold films and low-cost materials like gold leaf, continue to enhance the accessibility and application of this technology. By providing detailed, practical protocols and a clear overview of the necessary reagents, this application note equips researchers with the tools to effectively monitor and speciate arsenic, thereby contributing to improved public health and environmental protection.

Why Gold? The Electrochemical Principles of Arsenic Detection at Gold Surfaces

The accurate detection of arsenic, particularly its inorganic forms in water, represents a critical challenge in environmental monitoring and public health protection. With the World Health Organization (WHO) setting a stringent provisional guideline value of 10 µg/L (10 ppb) for arsenic in drinking water, the development of sensitive, reliable, and field-deployable detection methods has become imperative [17] [18] [19]. Among the various analytical techniques employed, electrochemical methods, especially anodic stripping voltammetry (ASV), have emerged as powerful tools due to their high sensitivity, portability, and cost-effectiveness [20] [21]. The success of these voltammetric procedures hinges predominantly on the properties and appropriate preparation of the working electrode [17]. While materials such as platinum, silver, carbon, and various metal oxides have been investigated, gold-based electrodes have consistently demonstrated superior performance for arsenic detection, forming the cornerstone of modern electrochemical arsenic sensors [17] [22].

This application note delineates the fundamental electrochemical principles that underpin the exceptional efficacy of gold surfaces in arsenic detection. Framed within the context of a broader thesis on gold film electrode preparation for arsenic speciation in water research, this document provides a comprehensive overview of the mechanistic insights, detailed experimental protocols, and key material requirements for researchers and scientists engaged in developing advanced arsenic sensors.

Fundamental Electrochemical Principles

The preeminence of gold in arsenic electroanalysis is not serendipitous but is rooted in a series of distinct electrochemical and interfacial properties that gold uniquely possesses.

Formation of Intermetallic Compounds

The central principle governing the high sensitivity of gold electrodes toward arsenic is the ability of gold to form strong intermetallic compounds (AuxAsy) with arsenic during the preconcentration step of anodic stripping voltammetry [17]. This phenomenon significantly enhances the efficiency of arsenic extraction onto the electrode surface. The preconcentration involves the reduction of arsenite (As(III)) to elemental arsenic (As(0)), which alloys with the gold surface [17]. This intermetallic formation provides a robust and well-defined stripping signal, which is crucial for achieving low detection limits. The subsequent anodic stripping (oxidation of As(0) back to As(III)) yields a measurable current peak, the height of which is proportional to the concentration of arsenic in the solution [17].

Favorable Hydrogen Overpotential and Reaction Reversibility

Gold exhibits a relatively high hydrogen overpotential across a wide pH range [17]. This property is critically important because it suppresses the competing hydrogen evolution reaction (HER), which could otherwise occur at the negative potentials required for the electrochemical reduction of As(III) to As(0). By minimizing HER, the faradaic efficiency for arsenic deposition is significantly increased, leading to a stronger analytical signal [17]. Furthermore, gold demonstrates good reversibility of the electrode reaction at both the accumulation and stripping steps, contributing to the formation of a high, sharp, and well-defined arsenic stripping peak, which enhances measurement sensitivity and resolution [17] [22].

Underpotential Deposition (UPD)

A particularly sensitive detection mechanism exploits the phenomenon of underpotential deposition (UPD) of As ad-atoms on gold surfaces [23]. UPD occurs when a metal (or in this case, a metalloid) is deposited on a foreign substrate at a potential less negative than its thermodynamic Nernst potential. This process allows for the accumulation of a sub-monolayer of arsenic atoms, facilitating highly sensitive detection with minimal interference from common ions like Cu(II) and Cl⁻ [23]. This method enables detection at levels as low as 0.4 ppb using gold nanoparticle-modified electrodes, well below the WHO guideline [23].

Performance Data of Gold-Based Electrodes

The following tables summarize the analytical performance of various state-of-the-art gold-based electrodes for the detection of arsenic, highlighting their sensitivity, detection limits, and operational parameters.

Table 1: Performance of Gold-Based Electrodes for As(III) Detection

| Electrode Type | Electrochemical Technique | Linear Range (ppb) | Detection Limit (ppb) | Supporting Electrolyte | Key Features | Ref |

|---|---|---|---|---|---|---|

| Rotating Disk Gold-Film Electrode (on GCE) | SWASV | 10 – 250 | 1.0 | Acidic Medium | Optimized Au film deposition; RSD < 7%; Validated with real samples (shrimp, cod liver). | [17] |

| Electrochemically Etched Au Wire Microelectrode | SWASV | Not Specified | 2.6 | 0.5 M H₂SO₄ | Increased sensitivity with decreased wire diameter; Suitable for micro-analysis. | [18] |

| Nanotextured Gold Electrode (Au/GNE) | SWASV | 0.1 – 9 | 0.08 - 0.1 | Acidic Medium | Chemical-free fabrication; High sensitivity (39.54 μA ppb⁻¹ cm⁻²); Excellent selectivity. | [21] |

| Au Nanoparticle-Modified Electrode (UPD-based) | SWASV | 0.37 – 7.5 (0.005-0.1 μM) | 0.4 | Not Specified | No interference from Cu(II) or Cl⁻; Visually clear signal at low ppb levels. | [23] |

| Iron Oxide-Supported Au Nanoparticles | SWASV | Not Specified | 0.25 (As(III)) 1.5 (As(V)) | pH 7.8 | Simultaneous detection of As(III) and sulfide; Direct detection of As(V) without external reductant. | [24] |

| Co₃O₄/Au Nanoparticle Modified GCE | ASV | 10 – 900 | Not Specified | Not Specified | Wide dynamic range for As³⁺; Simultaneous detection of Hg²⁺. | [25] |

Table 2: Comparison of Gold Electrode Morphologies and Their Impact

| Electrode Morphology | Typical Substrate | Fabrication Method | Advantages | Challenges | |

|---|---|---|---|---|---|

| Solid Gold Macroelectrode | Bulk Gold | Machining/Polishing | Well-defined surface; Reusable; Good for fundamental studies. | Higher cost; Surface passivation possible. | [18] [22] |

| Gold-Film Electrode (AuFE) | Glassy Carbon, Carbon Cloth | Potentiostatic/Potentiodynamic Electrodeposition | Lower cost; Reliable; Easy production; Tunable morphology. | Requires optimization of deposition parameters. | [17] [24] |

| Gold Nanoparticles (AuNPs) | Glassy Carbon, SPCE, ITO | Electrodeposition, Chemical Synthesis | High surface area; Enhanced mass transport; Catalytic properties. | Stability and reproducibility can be variable. | [21] [26] [25] |

| Gold Micro/Mini Electrodes | Gold Wire | Electrochemical Etching, Heat Sealing | Enhanced diffusion; Reduced iR drop; Low detection limits. | Fragility; More complex fabrication. | [18] |

| Nanotextured/Gold Nanostructures | Gold Foil, Carbon | Electrochemical Oxidation-Reduction Cycles | Extremely high surface area; Superior sensitivity. | Process optimization required for consistency. | [21] |

Experimental Protocols

Protocol 1: Preparation of a Rotating Disk Gold-Film Electrode (AuFE)

This protocol details the ex-situ potentiostatic electrodeposition of a gold layer onto a glassy carbon electrode (GCE), as optimized for arsenic(III) determination using Square-Wave Anodic Stripping Voltammetry (SWASV) [17].

Workflow Overview:

Materials and Reagents:

- Working Electrode: Glassy Carbon Electrode (GCE), 3.0 mm diameter.

- Counter Electrode: Platinum wire.

- Reference Electrode: Ag/AgCl (3 M KCl).

- Gold Plating Solution: 0.25 – 4.0 mM HAuCl₄ in 0.1 M HCl or other suitable supporting electrolyte.

- Purified Water: Milli-Q water (18 MΩ·cm).

- Polishing Supplies: Alumina slurry (e.g., 0.05 µm), polishing cloth.

Step-by-Step Procedure:

Substrate Preparation (GCE Polishing):

- Polish the GCE surface thoroughly with 0.05 µm alumina slurry on a microcloth pad for 60 seconds.

- Rinse the electrode copiously with Milli-Q water to remove all alumina residues.

- Sonicate the electrode in ethanol and then in Milli-Q water for 2-5 minutes each to remove any adhered particles.

- Dry the clean GCE under a gentle stream of inert gas (e.g., N₂).

Gold Film Electrodeposition:

- Transfer the clean, dry GCE to an electrochemical cell containing the gold plating solution (e.g., 1 mM HAuCl₄ in 0.1 M HCl).

- Use a three-electrode setup: Prepared GCE (working), Pt wire (counter), Ag/AgCl (reference).

- Under controlled hydrodynamic conditions (electrode rotation at 600 – 1500 rpm), apply a constant deposition potential between 0 V and -600 mV (vs. Ag/AgCl) for a duration of 120 to 1200 seconds. Optimal conditions from the literature suggest a potential of -400 mV and a time of 300-600 s [17].

- The gold film thickness and morphology are directly controlled by the concentration of HAuCl₄, deposition potential, deposition time, and rotation speed. These parameters must be systematically optimized for the specific application.

Post-Deposition Characterization:

- Remove the newly fabricated AuFE from the plating solution and rinse gently with Milli-Q water.

- Characterize the electrode using Cyclic Voltammetry (CV) in a blank supporting electrolyte (e.g., 0.1 M HCl) to assess electrochemical active surface area (ECSA) and cleanliness.

- Optionally, characterize the film morphology using Optical Microscopy (OM) or Scanning Electron Microscopy (SEM) to correlate structure with performance [17].

Protocol 2: SWASV Detection of As(III) Using the Prepared AuFE

This protocol describes the quantitative determination of As(III) using the fabricated AuFE with Square-Wave Anodic Stripping Voltammetry.

Workflow Overview:

Materials and Reagents:

- Analyte Solution: Sample containing As(III) in 0.1 M HCl or another suitable supporting electrolyte.

- Standard Solutions: As(III) stock solution (e.g., 1000 ppm) for calibration, prepared from NaAsO₂ or As₂O₃ in 0.1 M NaOH, acidified.

- Oxygen-Free Environment: High-purity nitrogen or argon gas for deaeration.

Step-by-Step Procedure:

Solution Preparation and Deaeration:

- Prepare the sample or standard solution in an appropriate supporting electrolyte (e.g., 0.1 – 1.0 M HCl or H₂SO₄). The choice of acid and its concentration can influence the stripping peak shape and interference effects [18].

- Transfer the solution to the electrochemical cell.

- Purge the solution with high-purity nitrogen or argon for at least 10 minutes to remove dissolved oxygen, which can interfere with the measurement. Maintain a blanket of inert gas over the solution during analysis.

Preconcentration / Accumulation Step:

- Immerse the AuFE, counter, and reference electrodes into the deaerated solution.

- While stirring the solution (or rotating the electrode, if an RDE is used), apply a constant deposition potential of approximately -600 mV (vs. Ag/AgCl) for a fixed time (e.g., 150 seconds). During this step, As(III) is reduced to As(0) and forms an intermetallic compound with the gold film.

Equilibration Period:

- After the accumulation time is complete, stop the stirring and allow the solution to become quiescent for a short period (e.g., 15 seconds). This stabilizes the diffusion layer before the stripping scan.

Anodic Stripping and Measurement:

- Initiate the Square-Wave Anodic Stripping Voltammetry (SWASV) scan from the deposition potential (e.g., -600 mV) to a more positive potential (e.g., +0.2 V).

- The critical SWASV parameters are: Frequency (Hz), Pulse Amplitude (mV), and Step Potential (mV). These should be optimized; typical values are 25-50 Hz frequency, 50 mV amplitude, and 4-5 mV step potential.

- During the anodic scan, the deposited As(0) is oxidized back to As(III), producing a characteristic current peak typically around 0.0 to -0.1 V (vs. Ag/AgCl) in acidic media.

Calibration and Quantification:

- Record the stripping voltammogram and measure the peak height or area.

- Perform the same procedure for a series of standard As(III) solutions to construct a calibration curve (peak current vs. concentration).

- Determine the unknown concentration of As(III) in the sample by interpolating its peak current on the calibration curve.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Reagents and Materials for Gold-Based Arsenic Detection

| Reagent/Material | Typical Specification/Purity | Function in Experiment | |

|---|---|---|---|

| Tetrachloroauric(III) Acid (HAuCl₄) | ≥99.9% trace metals basis | Precursor for electrochemical deposition of gold films and nanoparticles onto substrate electrodes. | [17] |

| Arsenic(III) Oxide (As₂O₃) / Sodium Arsenite (NaAsO₂) | Certified Reference Material (CRM) grade | Primary standard for preparing stock and calibration solutions of As(III). | [18] |

| Hydrochloric Acid (HCl) | Ultrapure, TraceSELECT or equivalent | Serves as the supporting electrolyte (e.g., 0.1-1.0 M); provides chloride ions that can influence electrode kinetics and signal. | [17] [18] |

| Sulfuric Acid (H₂SO₄) | Ultrapure, TraceSELECT or equivalent | Alternative supporting electrolyte (e.g., 0.5 M); used to avoid chloride interference or for specific mechanistic studies. | [18] |

| Glassy Carbon Electrode (GCE) | 3.0 mm diameter, polished to mirror finish | Common substrate for the electrodeposition of gold films (AuFE) and nanoparticles. | [17] |

| Screen-Printed Carbon Electrode (SPCE) | Commercial or in-house fabricated | Disposable, portable substrate for field-deployable sensors; can be modified with AuNPs or Au-based composites. | [26] |

| Nitrogen/Argon Gas | High-purity (≥99.998%) | Used for deaeration of solutions to remove dissolved oxygen, which causes interfering background currents. | [21] |

Gold's supremacy in the electrochemical detection of arsenic is firmly grounded in its fundamental physicochemical properties: its ability to form strong intermetallic compounds with arsenic, its high hydrogen overpotential, and the favorable reversibility of the arsenic redox reaction on its surface. The development of various gold-based morphologies—from solid macroelectrodes to nanotextured films and nanoparticle composites—provides a versatile toolkit for researchers to design sensors tailored for specific requirements, ranging from ultra-sensitive laboratory analysis to robust, on-field environmental monitoring. The detailed protocols and performance data outlined in this application note serve as a foundation for the continued advancement and application of gold electrodes in addressing the global challenge of arsenic contamination in water resources.

Voltammetric techniques, particularly anodic stripping voltammetry (ASV), have emerged as powerful tools for the sensitive and cost-effective determination of trace arsenic in water samples. These methods are characterized by their high sensitivity, portability, and ability to perform in-field analysis, making them viable alternatives to more expensive laboratory-based techniques like inductively coupled plasma spectroscopy or atomic absorption spectrometry [27] [12]. The core principle of ASV involves a two-step process: first, a preconcentration step where arsenic species are electrochemically reduced and deposited onto the working electrode surface, followed by a stripping step where the deposited metals are re-oxidized, producing a measurable current signal proportional to concentration [23] [28]. For arsenic speciation, which is critical due to the significant differences in toxicity between As(III) and As(V) species, these techniques offer unique advantages, especially when coupled with gold-based electrodes that provide excellent electrochemical response for arsenic detection [12] [29].

This application note focuses on three primary voltammetric techniques—ASV, Square Wave Anodic Stripping Voltammetry (SWASV), and Differential Pulse Anodic Stripping Voltammetry (DPASV)—within the context of a broader thesis investigating gold film electrode preparation for arsenic speciation in water research. We provide a comprehensive overview of each technique's fundamental principles, experimental parameters, and performance characteristics for arsenic detection, along with detailed protocols that can be readily implemented in research settings.

Voltammetric Techniques for Arsenic Determination

Fundamental Principles and Comparative Advantages

Anodic Stripping Voltammetry (ASV) serves as the foundational technique for trace arsenic detection. Its exceptional sensitivity, which can reach parts-per-trillion levels, stems from the preconcentration step that accumulates analytes on the electrode surface prior to measurement [30]. In arsenic analysis, As(III) is first reduced to As(0) and deposited onto the electrode surface at a specific deposition potential. This is followed by applying a positive-going potential sweep that oxidizes the deposited As(0) back to As(III), generating a characteristic stripping peak current that is quantitatively related to arsenic concentration [28]. The technique is particularly effective when using gold-based electrodes, which exhibit favorable interactions with arsenic and facilitate efficient deposition and stripping processes [28] [31].

Square Wave Anodic Stripping Voltammetry (SWASV) enhances the basic ASV approach through a sophisticated potential waveform that applies a staircase potential with superimposed square waves. This waveform enables current measurement at both forward and reverse pulses, effectively minimizing capacitive background currents and significantly improving signal-to-noise ratios [27] [32]. The key advantages of SWASV include faster scan rates, reduced analysis time, and enhanced sensitivity compared to traditional linear sweep methods [32]. These characteristics make SWASV particularly suitable for the simultaneous detection of multiple metal ions, including arsenic, cadmium, and lead, in environmental samples [33]. The optimization of SWASV parameters—including deposition potential, deposition time, frequency, amplitude, and step potential—is crucial for achieving maximum sensitivity and peak resolution [27] [30].

Differential Pulse Anodic Stripping Voltammetry (DPASV) employs a series of small amplitude potential pulses superimposed on a linear potential ramp. The current is measured twice for each pulse—just before the pulse application and at the end of the pulse duration—with the difference between these measurements being recorded as the net response [12] [29]. This differential current measurement effectively cancels out non-Faradaic background currents, resulting in improved resolution for closely spaced peaks and lower detection limits. DPASV is particularly valuable for arsenic speciation studies in complex matrices, as it helps mitigate interference effects from other species commonly found in environmental water samples [12] [29]. The technique has been successfully applied for both individual arsenic species determination and simultaneous detection of multiple heavy metals.

Table 1: Comparison of Voltammetric Techniques for Arsenic Detection

| Technique | Principle | Key Advantages | Detection Limit | Linear Range |

|---|---|---|---|---|

| ASV | Preconcentration followed by linear potential sweep | High sensitivity, simple operation | 0.25 ppb [28] | 0.01-8 μM [28] |

| SWASV | Staircase potential with superimposed square waves | Fast scanning, reduced background, multi-element detection | 0.08 ppb [30] | 1-50 ppb [30] |

| DPASV | Linear ramp with superimposed pulses | Excellent peak resolution, minimized background | 0.10 μg L⁻¹ [12] | Not specified |

Arsenic Speciation Capabilities

The ability to distinguish between arsenic species, particularly the more toxic As(III) and less toxic As(V), represents a significant advantage of voltammetric techniques in environmental monitoring [29]. The speciation capability stems from the different electrochemical behaviors of these species. As(III) can be directly determined at gold electrodes at moderate deposition potentials (typically -0.3 to -0.5 V), whereas As(V) requires stronger reduction conditions or preliminary conversion to As(III) before analysis [12] [16].

For comprehensive speciation analysis, two complementary approaches have been developed. The first involves direct measurement of As(III) followed by chemical or electrochemical reduction of As(V) to As(III) for total arsenic determination, with As(V) concentration obtained by difference [12]. The second approach utilizes different deposition potentials to selectively determine As(III) and total inorganic arsenic [29]. This speciation capability is particularly important for accurate risk assessment, as As(III) is significantly more toxic and mobile in aquatic environments compared to As(V) [29]. The development of reliable speciation methods has been greatly facilitated by the use of gold film electrodes, which provide a stable and reproducible platform for arsenic redox reactions.

Experimental Protocols

Gold Film Electrode Preparation and Modification

Protocol 1: Preparation of Gold-Stained Au Nanoparticle/Pyridine/MWCNT Modified Electrode [28]

This protocol describes the preparation of a highly sensitive nanocomposite electrode for arsenic detection, which demonstrates enhanced surface area and improved electrochemical performance.

Materials Required:

- Glassy carbon electrode (GCE, 3.0 mm diameter)

- Carboxylated multiwalled carbon nanotubes (C-MWCNTs)

- 4-cyanopyridine (cPy)

- Gold nanoparticle (AuNPs) dispersion

- Gold staining solution (3 mM HAuCl₄ + 18 mM NH₂OH·HCl)

- H₂SO₄ (0.1 M)

- Polishing alumina slurry (0.05 μm)

Procedure:

- GCE Pretreatment: Polish the bare GCE sequentially with 0.3 and 0.05 μm alumina slurry on a microcloth. Rinse thoroughly with Milli-Q water between polishing steps. Clean electrochemically by cyclic voltammetry in 0.1 M K₂SO₄ solution containing 2.0 mM K₄[Fe(CN)₆] until a stable voltammogram is obtained.

- C-MWCNTs Modification: Disperse 0.2 mg/mL C-MWCNTs in ethanol using ultrasonication. Cast-coat 6 μL of the dispersion onto the cleaned GCE surface and allow to air-dry completely to obtain C-MWCNTs/GCE.

- Pyridine Modification: Immerse the C-MWCNTs/GCE in 0.1 M aqueous H₂SO₄ containing 10 mM 4-cyanopyridine. Perform cyclic voltammetry for 3 cycles between -1.2 V and -0.5 V at a scan rate of 0.1 V s⁻¹ to electroreduce cPy to pyridine radicals that covalently bind to the CNT surface, forming Py/C-MWCNTs/GCE.

- AuNPs Adsorption: Rinse the Py/C-MWCNTs/GCE with water and air-dry. Cast-coat 10 μL of AuNPs dispersion onto the electrode surface and allow to stand for 20 minutes. Wash with ultrapure water and dry under N₂ stream to obtain AuNPs/Py/C-MWCNTs/GCE.

- Gold Staining: Apply 10 μL of gold staining solution (3 mM HAuCl₄ + 18 mM NH₂OH·HCl) to the AuNPs/Py/C-MWCNTs/GCE. After 5 minutes, wash with ultrapure water to obtain the final Aus/Py/C-MWCNTs/GCE. The electrode is now ready for arsenic detection.

Protocol 2: Silver Co-deposition on Carbon Electrodes for Arsenic Detection [27]

This protocol utilizes silver co-deposition to enable arsenic detection on carbon electrodes, providing an alternative to gold-based electrodes.

Materials Required:

- Screen-printed carbon electrode or glassy carbon electrode

- Nitric acid (0.1 M)

- As(III) standard solution

- Ag(I) stock solution (prepared from AgNO₃ in 0.1 M nitric acid)

- As(III) stock solution (prepared from NaAsO₂ in 0.1 M nitric acid)

Procedure:

- Electrode Preparation: If using a glassy carbon electrode, polish and clean following standard procedures. For screen-printed electrodes, use as received.

- Solution Preparation: Prepare the supporting electrolyte (0.1 M nitric acid) containing appropriate concentrations of As(III) and Ag(I). The optimal concentration ratio should be determined experimentally.

- Co-deposition Step: Apply a deposition potential of -0.3 V to -0.5 V (vs. Ag/AgCl) to the working electrode while stirring the solution. Typical deposition times range from 60 to 300 seconds, depending on the desired sensitivity.

- Stripping Analysis: After the deposition step, stop stirring and allow the solution to become quiescent for 15 seconds. Initiate the square wave anodic stripping voltammetry scan from a negative potential to positive potentials (specific range to be optimized). The oxidation peak for arsenic typically appears around +0.15 V.

Diagram 1: Electrode modification workflow for gold-stained Au nanoparticle electrode

Arsenic Detection and Speciation Protocols

Protocol 3: DPASV for Arsenic Speciation in Water Samples [12] [29]

This protocol describes the determination and speciation of inorganic arsenic using differential pulse anodic stripping voltammetry with a solid gold electrode.

Materials Required:

- Solid gold electrode (rotating disk preferred)

- Portable potentiostat with DPASV capability

- As(III) and As(V) standard solutions

- Supporting electrolyte (various options, acid-based)

- Reference and counter electrodes

Procedure:

- Electrode Conditioning: Clean the gold electrode according to manufacturer's specifications. Typically, this involves electrochemical cycling in acidic medium until a stable voltammogram is obtained.

- As(III) Determination: Place the electrode in the sample solution with supporting electrolyte. Apply a deposition potential of -0.3 V for 60-180 seconds with solution stirring. After a quiet time of 10-15 seconds, record the DPASV scan from -0.3 V to +0.3 V. The peak at approximately +0.1 V corresponds to As(III) oxidation.

- Total Inorganic Arsenic Determination: For total arsenic determination, apply a more negative deposition potential of -1.2 V to electrochemically reduce As(V) to As(0) using nascent hydrogen. Follow the same stripping procedure as above. The total arsenic peak appears at the same potential as As(III).

- Speciation Calculation: Calculate As(V) concentration by subtracting the As(III) concentration from the total inorganic arsenic concentration.

- Calibration: Perform standard addition calibration for quantitative analysis in complex matrices.

Protocol 4: SWASV for Trace Arsenic Detection with Chemometric Optimization [30]

This protocol incorporates chemometric modeling to optimize SWASV parameters for enhanced arsenic detection performance.

Materials Required:

- Gold electrode or gold nanoparticle-modified electrode

- Nitric acid (0.1 M, pH ≈ 1) as supporting electrolyte

- As(III) standard solutions

- AUTOLAB potentiostat with NOVA software or equivalent

Procedure:

- Experimental Optimization: Optimize key parameters including deposition potential (-0.2 V to -0.5 V), deposition time (60-420 s), frequency (10-100 Hz), amplitude (10-50 mV), and step potential (2-10 mV) using a Box-Behnken experimental design.

- Chemometric Modeling: Apply principal component analysis (PCA) to discriminate As(III) signals from background noise and interfering species. Use partial least squares regression (PLSR) to establish a prediction model between optimized parameters and current response.

- Sample Analysis: Employ the optimized parameters for arsenic detection in real samples. Use a deposition potential of -0.3 V to -0.5 V for 120-300 seconds in 0.1 M nitric acid supporting electrolyte.

- Validation: Validate the method using standard reference materials or comparison with established techniques like hydride generation atomic absorption spectroscopy.

Table 2: Optimal Parameters for Voltammetric Arsenic Detection

| Parameter | ASV | SWASV | DPASV |

|---|---|---|---|

| Deposition Potential | -0.4 V [28] | -0.3 V to -0.5 V [30] | -0.3 V [12] |

| Deposition Time | 420 s [28] | 120-300 s [30] | 60-180 s [12] |

| Supporting Electrolyte | 0.1 M H₂SO₄ [28] | 0.1 M HNO₃ [30] | Acidic media [12] |

| Scan Rate | 5 V s⁻¹ [28] | Frequency: 10-100 Hz [30] | Pulse amplitude: 25-50 mV [32] |

| Linear Range | 0.01-8 μM [28] | 1-50 ppb [30] | Not specified |

| LOD | 0.25 ppb [28] | 0.08 ppb [30] | 0.10 μg L⁻¹ [12] |

The Scientist's Toolkit: Essential Materials and Reagents

Table 3: Research Reagent Solutions for Voltammetric Arsenic Determination

| Reagent/ Material | Function | Application Notes |

|---|---|---|

| Gold Electrodes (solid, film, or nanoparticle) | Working electrode substrate | Provides excellent electrocatalytic activity for arsenic redox reactions; preferred substrate for arsenic detection [12] [28] |

| Carboxylated MWCNTs | Electrode nanomodifier | Increases electroactive surface area; enhances electron transfer kinetics; provides support for metal nanoparticles [28] |

| 4-cyanopyridine | Molecular linker | Forms covalent bonds with carbon surfaces through electroreduction; stabilizes Au nanoparticles on electrode surface [28] |

| Nitric Acid (0.1 M) | Supporting electrolyte | Provides optimal acidic conditions for arsenic detection; minimizes interference [27] [30] |

| Sulfuric Acid (0.1 M) | Supporting electrolyte | Alternative acidic medium for arsenic detection; used in linear sweep ASV [28] |

| Silver Nitrate | Co-deposition agent | Enables arsenic detection on carbon electrodes through co-deposition mechanism [27] |

| Citric Acid/ Sodium Citrate | Sample preservative | Stabilizes arsenic speciation in water samples by complexing metal ions that catalyze arsenic oxidation [29] |

| Potassium Sodium Tartrate | Sample preservative | Effective complexing agent for preserving As(III)/As(V) ratio in natural water samples [29] |

Analytical Performance and Method Validation

Sensitivity and Detection Limits

Voltammetric techniques, when properly optimized, achieve exceptional sensitivity for arsenic detection, with reported detection limits well below the WHO guideline value of 10 μg L⁻¹ (0.13 μM) for drinking water [23] [12]. The specific detection limits vary depending on the technique and electrode configuration, with SWASV typically offering the lowest detection limits due to its effective background suppression. For instance, SWASV with gold nanostar-modified screen-printed carbon electrodes has demonstrated detection limits of 0.8 μg L⁻¹ for As(III) [33], while advanced LSASV with gold-stained Au nanoparticle/pyridine/MWCNT modified electrodes achieved remarkable detection limits of 0.25 ppb (3.3 nM) [28]. DPASV methods using solid gold electrodes have reported detection limits of 0.10 μg L⁻¹ for total arsenic [12], sufficient for monitoring compliance with regulatory limits.

The sensitivity of these methods is influenced by multiple factors, including electrode material, deposition time, supporting electrolyte, and the presence of interfering species. Gold-based electrodes consistently outperform other materials due to their favorable interaction with arsenic species [28] [31]. Extended deposition times generally enhance sensitivity through increased analyte accumulation but at the cost of longer analysis times. The composition and pH of the supporting electrolyte significantly impact both the deposition efficiency and the stripping peak characteristics, with acidic conditions generally preferred for arsenic detection [27] [28].

Selectivity and Interference Management

The selectivity of voltammetric methods for arsenic determination is challenged by the potential presence of interfering species in environmental samples, particularly copper ions (Cu²⁺), chloride ions (Cl⁻), and other heavy metals [27] [33]. Various strategies have been developed to mitigate these interference effects. The underpotential deposition (UPD) approach for As(III) detection on gold electrodes has demonstrated excellent immunity to interference from both Cu(II) and Cl⁻ [23]. Silver co-deposition on carbon electrodes also shows reduced susceptibility to common interferents [27]. For more complex matrices, chemometric approaches using principal component analysis (PCA) and partial least squares regression (PLSR) have been successfully employed to discriminate As(III) signals from background noise and interfering species [30].

In simultaneous multi-element detection, well-separated peaks are essential for accurate quantification. Gold nanostar-modified screen-printed carbon electrodes in modified Britton-Robinson buffer have demonstrated distinct, well-resolved peaks for Cd²⁺ (-0.48 V), As³⁺ (-0.09 V), and Se⁴⁺ (0.65 V), enabling simultaneous detection without significant overlap [33]. However, interactions between target analytes during the deposition step must be considered, as evidenced by the formation of electrochemically inactive arsenic triselenide (As₂Se₃) during simultaneous detection of As³⁺ and Se⁴⁺, which reduces peak heights for both species [33].

Diagram 2: Arsenic analysis and speciation workflow

Real Sample Analysis and Method Validation

The accuracy and reliability of voltammetric techniques for arsenic determination have been extensively validated through analysis of real water samples and comparison with established reference methods. Recovery studies in surface water analysis using SWASV with gold nanostar-modified screen-printed electrodes yielded average percent recoveries of 109% for Cd²⁺, 93% for As³⁺, and 92% for Se⁴⁺, demonstrating the method's accuracy in complex environmental matrices [33]. Comparative studies between DPASV and hydride generation coupled with inductively coupled plasma optical emission spectroscopy (HG-ICP-OES) showed satisfactory agreement for arsenic speciation in natural waters, confirming the validity of the voltammetric approach [12].

Sample preservation represents a critical aspect of accurate arsenic speciation analysis, as the distribution between As(III) and As(V) can change between sampling and analysis due to oxidation, reduction, or biological activity [29]. Studies evaluating different preservatives have identified citric acid, sodium citrate, sodium oxalate, and potassium sodium tartrate—alone or in combination with acetic acid—as effective stabilizers for inorganic arsenic species in both model solutions and natural groundwater samples [29]. These complexing agents help maintain the original As(III)/As(V) ratio by sequestering metal ions that catalyze oxidation reactions, with preservation effectiveness extending up to 6-12 days in properly treated samples [29].

Voltammetric techniques, particularly ASV, SWASV, and DPASV, offer powerful and versatile approaches for the sensitive determination and speciation of arsenic in water samples. The integration of these electrochemical methods with advanced electrode materials, particularly gold-based substrates and nanomodified composites, enables detection limits that comfortably meet regulatory requirements for drinking water monitoring. The protocols and guidelines presented in this application note provide researchers with practical methodologies for implementing these techniques in both laboratory and field settings, with special consideration given to the critical aspects of electrode preparation, interference management, and sample preservation.

When selecting an appropriate voltammetric method for arsenic determination, researchers should consider the specific requirements of their application, including the needed detection limits, analysis time, speciation capabilities, and sample matrix complexity. SWASV generally offers the best combination of sensitivity and speed for routine monitoring, while DPASV provides superior resolution in complex matrices. The continuing development of novel electrode materials and optimization strategies, including chemometric modeling, promises further enhancements in the sensitivity, selectivity, and reliability of voltammetric arsenic analysis, supporting their expanded application in environmental monitoring and public health protection.

The accurate determination of arsenic, particularly the highly toxic arsenite (As(III)), in water samples represents a critical challenge in environmental monitoring and public health protection. The World Health Organization (WHO) has established a stringent maximum contaminant level of 10 μg/L for inorganic arsenic in drinking water, necessitating the development of highly sensitive and reliable detection methods [17]. Electrochemical detection, especially anodic stripping voltammetry (ASV), has emerged as a powerful technique that combines high sensitivity with the potential for portable, on-site analysis. The success of voltammetric analysis for arsenic hinges predominantly on the properties and appropriate preparation of the working electrode [17].

Among the various electrode configurations employed, gold-based electrodes have demonstrated exceptional performance for arsenic detection due to gold's unique ability to form intermetallic compounds (AuxAsy) with arsenic during the preconcentration step, significantly enhancing arsenic extraction efficiency on the electrode surface [17]. This application note provides a detailed comparative analysis of three primary gold electrode configurations—gold-film electrodes (AuFEs), solid gold electrodes (SGEs), and nanoparticle-modified electrodes—within the context of arsenic speciation in water research. We present optimized experimental protocols, performance metrics, and practical guidance to assist researchers in selecting and implementing the most appropriate electrode system for their specific analytical requirements.

Electrode Comparison and Performance Metrics

Comparative Analysis of Electrode Architectures

The selection of electrode architecture profoundly influences the sensitivity, reproducibility, cost-effectiveness, and practical applicability of arsenic detection methods. The table below summarizes the key characteristics, advantages, and limitations of the three primary gold-based electrode types for arsenic detection.

Table 1: Comprehensive Comparison of Gold-Based Electrodes for Arsenic Detection

| Electrode Type | Detection Limit for As(III) | Linear Range | Key Advantages | Inherent Limitations |

|---|---|---|---|---|

| Gold-Film Electrode (AuFE) | 1 μg/L (1 ppb) [17] | 10–250 μg/L [17] | Superior sensitivity, cost-effective for routine use, reliable, easy production [17] | Requires optimization of deposition parameters, film stability can be variable [17] |

| Solid Gold Electrode (SGE) | 0.10 μg/L for As(tot) [12] | Not specified | Excellent conductivity, mechanically robust, suitable for portable on-site analysis [12] | Higher cost, surface passivation in halide ions, memory effects [17] |

| Gold Nanoparticle-Modified Electrode (AuNP) | 0.0096 ppb (LSV) [34] to 0.28 ppb (SWASV) [35] | 1–15 ppb [22] | Very high surface area, ultra-low detection limits, enhanced mass transport [22] | Complex and intensive preparation, stability issues over time, less reliable for routine analysis [17] |

Critical Performance Parameters for Arsenic Detection

Beyond detection limits, several analytical parameters are crucial for evaluating electrode performance in real-world applications. The following table synthesizes optimized experimental conditions and key metrics from recent studies.

Table 2: Optimized Experimental Parameters and Analytical Figures of Merit

| Parameter | Gold-Film Electrode (AuFE) | Solid Gold Electrode (SGE) | Gold Nanoparticle-Modified Electrode |

|---|---|---|---|

| Optimal Technique | Square-Wave Anodic Stripping Voltammetry (SWASV) [17] | Differential Pulse Anodic Stripping Voltammetry (DPASV) [12] | Square-Wave Anodic Stripping Voltammetry (SWASV) [35] |

| Deposition Potential | Optimized per film preparation; typically -0.3 V to -0.6 V for detection [17] | -0.3 V for As(III); -1.2 V for total As [12] | -600 mV [35] |

| Supporting Electrolyte | 1 M HCl (common) | Variable, including neutral pH for some applications [36] | 1 M HCl [34] |

| Sensitivity | 0.468 μA/μg·L⁻¹ [17] | Not specified | Not specified |

| Reproducibility (RSD) | < 7% [17] | Good agreement with HG-ICP-OES [12] | Good correlation with ICP-OES [35] |

| Key Interferents | Fe(III), Mn(II), Pb(II), Cu(II), Sn(IV), Tl(I) [17] | Minimized via electrochemical reduction of As(V) [12] | Cd, Cu, Hg [35] |

The Superiority of Gold-Film Electrodes for Routine Analysis

Gold-film electrodes (AuFEs) represent an optimal balance of performance, practicality, and cost-effectiveness for routine arsenic monitoring. Their superiority stems from several key factors:

Enhanced Analytical Performance and Practical Utility

AuFEs demonstrate a compelling combination of high sensitivity and robust reliability. The optimized AuFE protocol achieves a detection limit of 1 ppb, which is well below the WHO guideline of 10 ppb, with excellent reproducibility (RSD < 7%) [17]. This performance is sufficient for monitoring compliance with regulatory standards. The linear range from 10 to 250 μg/L covers the critical concentration region for environmental monitoring and health risk assessment [17].

From a practical standpoint, AuFEs are considered cheaper, more reliable, and easier to produce compared to bulk gold electrodes or complex nanoparticle-modified electrodes [17]. The ex-situ electrodeposition of a gold layer onto a glassy carbon substrate makes AuFEs significantly more cost-effective than solid gold electrodes while avoiding the preparation intensity and instability often associated with nanoparticle-modified surfaces [17]. This balance makes AuFEs particularly suitable for high-volume routine analysis where both cost consistency and reliability are paramount.

Tunable Morphology and Optimized Electroactive Properties

A significant advantage of AuFEs lies in the ability to precisely control their physical and electrochemical properties through systematic optimization of deposition parameters. The morphology, thickness, and electrochemical activity of the gold film can be tuned by varying key fabrication parameters, allowing researchers to tailor electrode performance to specific analytical needs [17].

The electrodeposition process enables control over the nucleation and growth of the gold layer, directly influencing the electrode's active surface area and the efficiency of arsenic preconcentration. Gold's ability to form AuxAsy intermetallic compounds during the accumulation step significantly enhances arsenic extraction efficiency compared to many other electrode materials [17]. Furthermore, gold exhibits relatively high hydrogen overpotential across a wide pH range and good reversibility of the electrode reaction at both accumulation and stripping stages, contributing to the formation of well-defined, sharp arsenic stripping peaks essential for quantitative analysis [17].

Detailed Experimental Protocols

Protocol 1: Fabrication and Optimization of Rotating Disk Gold-Film Electrodes (AuFEs)

This protocol outlines the ex-situ potentiostatic electrodeposition of gold films onto a glassy carbon rotating disk electrode for the determination of As(III) using Square-Wave Anodic Stripping Voltammetry (SWASV) [17].

Materials and Reagents

Table 3: Research Reagent Solutions for AuFE Fabrication and Analysis

| Reagent/Solution | Specification/Purity | Primary Function |

|---|---|---|

| Tetrachloroauric Acid (HAuCl₄) | Analytical Standard | Gold source for film electrodeposition |

| Hydrochloric Acid (HCl) | TraceMetal Grade, 1 M | Supporting electrolyte for deposition and analysis |

| Arsenic(III) Oxide (As₂O₃) | Certified Reference Material | Primary standard for As(III) calibration |

| Glassy Carbon Electrode (GCE) | 3 mm diameter, polished | Conductive substrate for gold film |

| Alumina Slurry | 0.05 μm particle size | Electrode surface polishing |

| High-Purity Water | >18 MΩ·cm resistivity | Solvent for all solutions |

Step-by-Step Procedure

Substrate Preparation: Polish the glassy carbon electrode (GCE) surface sequentially with 1.0, 0.3, and 0.05 μm alumina slurry on a microcloth. Rinse thoroughly with high-purity water between each polishing step and after the final polish. Sonicate the electrode in high-purity water for 5 minutes to remove adsorbed alumina particles. Dry the electrode surface under a stream of inert gas (N₂ or Ar) [17].

Gold Film Electrodeposition: Prepare a deposition solution containing 0.25 - 4 mM HAuCl₄ in 0.1 M HCl. Transfer the solution to the electrochemical cell and deoxygenate by purging with inert gas for at least 10 minutes. Immerse the cleaned and dried GCE into the solution. Set the electrode rotation speed to 600 - 1500 rpm. Apply a constant deposition potential between 0 and -600 mV (vs. Ag/AgCl) for a duration of 120 to 1200 seconds to deposit the gold film. The optimal combination found was -400 mV for 600 s with 1000 rpm rotation in 1 mM HAuCl₄ solution [17].

Electrode Characterization: Characterize the deposited gold films using Cyclic Voltammetry (CV) in 0.1 M H₂SO₄ to assess electrochemical active surface area and cleanliness. Optionally, characterize film morphology using Optical Microscopy and Scanning Electron Microscopy (SEM) to correlate structure with performance [17].

Arsenic Detection via SWASV: Transfer the AuFE to a measurement cell containing the sample and 1 M HCl supporting electrolyte. Deoxygenate the solution for 10 minutes with inert gas and maintain the gas blanket during analysis. Apply a deposition potential of -600 mV for 150 seconds while rotating the electrode at 1000 rpm to preconcentrate arsenic on the surface. After a 10-second equilibration period, record the stripping signal using square-wave voltammetry from -600 mV to +200 mV. The As(III) stripping peak typically appears around -100 mV [17].

Optimization Notes

- Parameter Interdependence: Systematically study the interaction of deposition parameters (HAuCl₄ concentration, potential, time, rotation speed) as they collectively influence film morphology and analytical sensitivity [17].

- Interference Management: The effects of interfering ions (Fe(III), Mn(II), Pb(II), Cu(II), Sn(IV), Tl(I)) should be evaluated for specific sample matrices. Standard addition methods are recommended for complex samples [17].

- Validation: Validate the method for quantitative arsenic determination in real samples (tap water, seafood) by correlating with reference methods like ICP-MS [17].

The following workflow diagram illustrates the complete AuFE fabrication and analysis process:

Protocol 2: Arsenic Speciation Using Solid Gold Electrodes

This protocol describes the use of a solid gold electrode (SGE) for differential pulse anodic stripping voltammetry (DPASV) to achieve speciation between As(III) and As(V) in water samples [12].

Materials and Reagents

- Solid Gold Electrode (SGE): Rotating disk configuration

- Supporting Electrolyte: Variable, depending on sample matrix

- Standard Solutions: As(III) and As(V) certified reference solutions

- High-Purity Water: >18 MΩ·cm resistivity

Step-by-Step Procedure

Electrode Pretreatment: Clean the solid gold electrode according to manufacturer specifications. Typically, this involves mechanical polishing and electrochemical cycling in 0.5 M H₂SO₄ until a stable cyclic voltammogram is obtained [12].

Direct As(III) Determination: Transfer the deoxygenated sample to the electrochemical cell. Apply a deposition potential of -0.3 V for a predetermined time while rotating the electrode. Record the DPASV signal and measure the stripping peak at approximately +0.1 V, which corresponds to As(III) [12].

Total Inorganic Arsenic Determination: For total As determination, apply a more negative deposition potential of -1.2 V to electrochemically reduce As(V) to As(0) using nascent hydrogen generated at the electrode surface. Record the DPASV signal as in step 2. The total arsenic concentration is determined from this measurement [12].

As(V) Quantification: Calculate the As(V) concentration by subtracting the As(III) concentration (from step 2) from the total inorganic arsenic concentration (from step 3) [12].

Application Notes

- This method achieves a detection limit of 0.10 μg/L for total arsenic and is suitable for on-site analysis with portable potentiostats [12].

- The method showed satisfactory agreement with hydride generation ICP-OES for real water samples, validating its accuracy [12].

- The use of electrochemical reduction for As(V) minimizes chemical reagent consumption and analysis time, making it ideal for field applications [12].

Advanced Applications: Towards Integrated Analytical Systems

The development of gold-film electrodes is increasingly focused on addressing complex analytical challenges in environmental monitoring. Two key areas of advancement include:

Arsenic Speciation in Complex Matrices

A significant advantage of modern AuFE systems is their capability for arsenic speciation—differentiating between the more toxic As(III) and less toxic As(V) species—without requiring extensive sample pretreatment. Advanced protocols achieve this through controlled deposition potentials: As(III) can be selectively determined at approximately -0.9 V, while total inorganic arsenic is measured at a more negative potential of -1.3 V, with As(V) concentration calculated by difference [37]. This approach has been successfully validated for direct quantitative determination and speciation of inorganic arsenic in real water samples, showing satisfactory agreement with reference spectroscopic methods [12].

Analysis of Biological and Environmental Samples

Gold-film electrodes demonstrate sufficient robustness for analyzing complex biological and environmental matrices beyond simple water samples. The optimized AuFE protocol has been successfully applied to determine arsenic in Atlantic shrimp and cod liver, demonstrating its utility in food safety monitoring [17]. The method's effectiveness in these complex matrices highlights the selective preconcentration capability of gold films even in the presence of organic interferents, provided appropriate sample preparation and standard addition quantification methods are employed.

Gold-film electrodes (AuFEs) represent a strategically optimal choice for routine arsenic speciation in water research, offering an exceptional balance of analytical performance, practical utility, and cost-effectiveness. While solid gold electrodes provide excellent mechanical stability for portable applications and nanoparticle-modified systems can achieve ultra-low detection limits, AuFEs consistently deliver the reliability, sensitivity, and ease of fabrication necessary for high-volume environmental monitoring. The protocols and comparative data presented in this application note provide researchers with a comprehensive framework for implementing AuFE technology in arsenic detection workflows, ultimately contributing to more effective water quality assessment and public health protection. The tunable nature of gold films through controlled electrodeposition ensures this platform will continue to adapt to emerging analytical challenges in environmental chemistry.

Step-by-Step Gold Film Electrode Fabrication and Analytical Protocols

Within the context of developing gold film electrodes for arsenic speciation in water research, the selection and pre-treatment of the underlying substrate electrode are critical foundational steps. The substrate electrode forms the platform upon which sensing films are deposited, and its properties profoundly influence the analytical performance of the final sensor, including its sensitivity, selectivity, and stability. While glassy carbon electrodes (GCEs) are widely used, researchers are actively exploring alternative substrates and modification strategies to enhance performance for arsenic detection. This document provides detailed application notes and protocols for the selection, pre-treatment, and modification of substrate electrodes, with a specific focus on achieving reliable speciation of arsenite (As(III)) and arsenate (As(V)) in water matrices.

Electrode Selection: Materials and Properties

The choice of substrate electrode material is dictated by its electrochemical inertness, conductivity, surface morphology, and compatibility with the modifying films essential for arsenic sensing. The following table summarizes the key substrate electrodes used in arsenic detection research.