Decoding the Polarographic Signal: A Comprehensive Guide to Half-Wave Potential Determinants in Electroanalytical Chemistry

This article provides a systematic analysis of the key parameters influencing the half-wave potential (E₁/₂) in polarography, a fundamental electroanalytical technique.

Decoding the Polarographic Signal: A Comprehensive Guide to Half-Wave Potential Determinants in Electroanalytical Chemistry

Abstract

This article provides a systematic analysis of the key parameters influencing the half-wave potential (E₁/₂) in polarography, a fundamental electroanalytical technique. Targeted at researchers, scientists, and drug development professionals, it explores the foundational electrochemical principles governing E₁/₂, details methodological best practices for accurate measurement, offers solutions for common experimental challenges, and validates findings through comparative analysis with modern techniques. The guide bridges theoretical understanding with practical application, emphasizing its critical role in quantifying redox properties for pharmaceutical and biomedical research.

The Electrochemical Blueprint: Core Principles Governing Half-Wave Potential

Within polarographic analysis, the half-wave potential (E₁/₂) is a critical diagnostic parameter. It is defined as the potential at the dropping mercury electrode (DME) at which the diffusion-limited current is equal to one-half of its limiting value (the wave height). Its fundamental role stems from its characteristic nature: for a reversible redox system, E₁/₂ is independent of analyte concentration and electrode characteristics, serving as a qualitative identifier for the electroactive species. This article, framed within a thesis on parameters affecting E₁/₂, establishes a technical support center to address practical challenges in its accurate determination.

Troubleshooting Guides and FAQs

Q1: Why is my polarographic wave broad and poorly defined, making E₁/₂ determination difficult? A: This is often due to non-idealities in the system.

- Check Supporting Electrolyte: Ensure a high concentration (typically ≥0.1 M) of inert supporting electrolyte to minimize migration current and reduce solution resistance (iR drop).

- Verify Reversibility: A broad wave can indicate quasi-reversible or irreversible electrode kinetics. The Ilkovič equation assumption of reversibility may not hold. Check temperature control, as kinetics are temperature-dependent.

- Examine Instrumentation: Confirm proper functioning of the potentiostat and the DME capillary. An irregular drop time distorts the current sampling.

Q2: My measured E₁/₂ is shifting between experiments for the same compound. What are the key parameters affecting this? A: E₁/₂ is theoretically constant for reversible systems but can be influenced by several experimental factors, a core focus of our research thesis.

- Solution Composition: Changes in pH, ionic strength, or the nature of the supporting electrolyte can shift E₁/₂, especially for species involving H⁺ in the redox process.

- Complexation: Trace impurities or intentionally added ligands form complexes with the analyte, significantly altering E₁/₂. This is the basis of qualitative analysis.

- Reference Electrode Stability: An unstable or contaminated reference electrode (e.g., SCE, Ag/AgCl) will cause systematic shifts. Regularly check and replenish the reference electrode filling solution.

Q3: How do I distinguish between a shift in E₁/₂ and a change in limiting current when comparing samples? A: Carefully analyze the entire polarogram.

- A shift along the potential axis (horizontal) indicates a change in E₁/₂, related to thermodynamics (formal potential, complexation).

- A change in the height of the wave (vertical) indicates a change in the limiting diffusion current, governed by the Ilkovič equation and related to analyte concentration and diffusion coefficient.

- Protocol: Always run a standard addition of a known analyte. If the wave height increases proportionally and E₁/₂ remains constant, your original sample's wave is correctly identified.

Experimental Protocol: Determination of E₁/₂ and Study of pH Effect

This protocol outlines the methodology for obtaining a polarographic wave and investigating a key parameter (pH) influencing E₁/₂.

1. Objective: To record the DC polarogram of a model compound (e.g., 1.0 mM Cd²⁺) and determine its E₁/₂ at varying pH levels.

2. Materials & Reagents:

- Polarograph/Potentiostat with a three-electrode cell.

- Working Electrode: Dropping Mercury Electrode (DME).

- Reference Electrode: Saturated Calomel Electrode (SCE).

- Counter Electrode: Platinum wire.

- Purified Nitrogen gas (for deaeration).

- Analytical grade KNO₃ (supporting electrolyte).

- Stock solution of 10 mM Cd(NO₃)₂.

- Buffer solutions (e.g., acetate, phosphate) covering pH 3-7.

3. Procedure: a. Cell Setup: Fill the electrochemical cell with 25 mL of 0.1 M KNO₃ and the appropriate buffer. b. Deaeration: Bubble nitrogen through the solution for at least 10 minutes to remove dissolved oxygen. Maintain a nitrogen blanket above the solution during measurement. c. Background Scan: Record a polarogram from -0.2 V to -1.0 V vs. SCE to confirm a clean baseline. d. Sample Addition: Add an aliquot of Cd²⁺ stock solution to achieve a final concentration of 1.0 mM. Deaerate briefly. e. Sample Scan: Record the polarogram over the same potential range. f. E₁/₂ Determination: Identify the limiting current (iₗ). The potential corresponding to i = iₗ/2 is the E₁/₂. g. pH Variation: Repeat steps (a) to (f) using different buffer systems to change the solution pH.

4. Data Analysis:

- Plot E₁/₂ vs. pH. For systems where H⁺ participates in the redox reaction, a linear relationship will be observed, with the slope related to the number of protons involved.

Data Presentation

Table 1: Effect of pH on the Half-Wave Potential (E₁/₂) of 1.0 mM Cd²⁺ in 0.1 M KNO₃

| pH | Supporting Buffer | E₁/₂ vs. SCE (V) | Wave Height (µA) | Notes |

|---|---|---|---|---|

| 3.0 | 0.05 M Acetate | -0.598 | 2.45 | Well-defined wave |

| 5.0 | 0.05 M Acetate | -0.601 | 2.48 | No significant shift |

| 7.0 | 0.05 M Phosphate | -0.605 | 2.43 | Slight negative shift |

| Theoretical (0.1 M KCl) | N/A | -0.599 | -- | Literature value |

Table 2: Common Troubleshooting Scenarios and Solutions

| Observed Issue | Potential Cause | Diagnostic Check | Corrective Action |

|---|---|---|---|

| Noisy Current | Electrical interference, ground loops | Run with cell disconnected. | Use a Faraday cage, ensure single-point grounding. |

| Irregular Current Steps | Irregular DME drop fall | Visually time drop fall. | Clean or re-scribe capillary, check mercury head height. |

| Wave Not S-Shaped | High solution resistance (iR drop) | Measure solution conductivity. | Increase supporting electrolyte concentration. |

| Multiple Waves | Sample impurities or multiple analytes | Perform standard addition. | Purify sample or adjust potential window. |

Visualizations

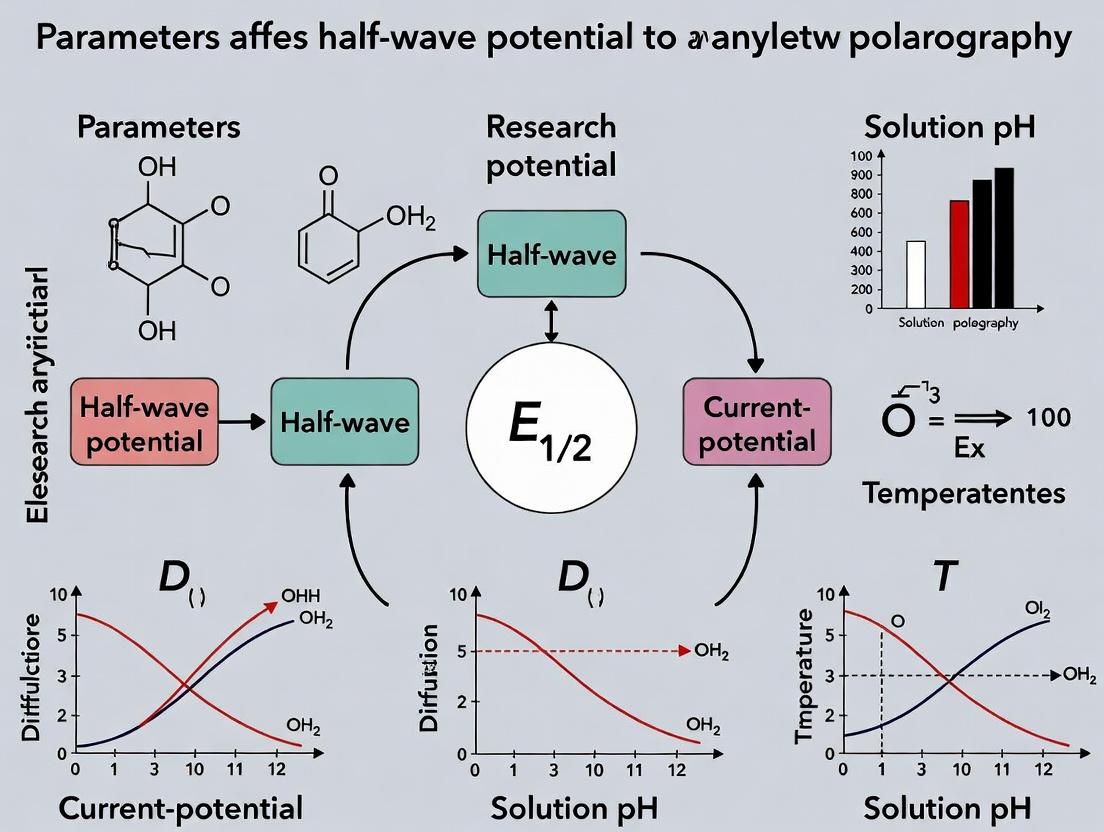

Title: Workflow for Measuring and Analyzing Half-Wave Potential

Title: Key Parameters Affecting the Half-Wave Potential

The Scientist's Toolkit: Essential Research Reagent Solutions

| Reagent/Material | Function in Polarographic Analysis |

|---|---|

| High-Purity Mercury | The working electrode material for the DME. Must be purified (e.g., acid-washed) to eliminate trace metal contaminants. |

| Inert Supporting Electrolyte (e.g., KCl, KNO₃, HClO₄) | Eliminates migration current, controls ionic strength, and defines the electrochemical window. Choice can influence E₁/₂. |

| Oxygen Scavenger (Nitrogen/Argon Gas) | Removes dissolved O₂, which produces interfering reduction waves (~ -0.05 V and -0.9 V vs. SCE). |

| Maximum Suppressor (e.g., Triton X-100) | A surface-active agent added at low concentration to suppress the polarographic maximum—anomalous current peaks that distort waves. |

| Standard Buffer Solutions | To systematically study the effect of pH on E₁/₂ for processes involving proton transfer. |

| Complexing Agent (e.g., NH₃, EDTA, Cl⁻) | Used intentionally to shift E₁/₂ via complex formation, enabling the resolution of overlapping waves or qualitative identification. |

| Internal Standard Solution (e.g., Tl⁺) | A known redox species with a stable E₁/₂ used to verify instrument calibration and electrode performance. |

Troubleshooting Guide & FAQ

Q1: During a polarographic experiment, my measured half-wave potential (E₁/₂) shows a positive shift compared to the theoretical value. What are the primary causes and solutions?

A: A positive shift in E₁/₂ often indicates kinetic or adsorption complications affecting reversibility.

- Cause 1: Slow Electron Transfer Kinetics. The system is not electrochemically reversible. The Nernst equation, which strictly applies at equilibrium, is not fully applicable. The process becomes quasi-reversible or irreversible.

- Solution: Increase temperature to improve kinetics or change supporting electrolyte to reduce activation energy. Verify reversibility via cyclic voltammetry (peak separation ~59/n mV at 298 K).

- Cause 2: Specific Adsorption of Reactants or Products. Adsorption of the reduced form onto the mercury electrode shifts E₁/₂ positively.

- Solution: Change the supporting electrolyte composition or ionic strength. Use surfactants (e.g., Triton X-100) to test for adsorption effects, but note they may suppress the polarographic maximum.

- Cause 3: Uncompensated Solution Resistance (iR Drop). This is common in non-aqueous or low-ionic-strength solutions.

- Solution: Use a supporting electrolyte at sufficient concentration (typically ≥0.1 M). Employ positive feedback iR compensation if available on your potentiostat.

Q2: The polarographic wave is drawn-out and not sigmoidal, making E₁/₂ determination difficult. How can I fix this?

A: A non-ideal wave shape suggests non-Nernstian behavior.

- Cause 1: The redox couple is not thermodynamically reversible. Coupled chemical reactions (EC, CE mechanisms) distort the wave.

- Solution: Perform a DC polarography scan at different drop times. If the wave shape is drop-time dependent, a coupled chemical reaction is likely. Conduct controlled-potential electrolysis to identify unstable products.

- Cause 2: The electrode process is complicated by preceding or following chemical reactions. Common in drug research with metal complexes or organic molecules undergoing protonation.

- Solution: Run experiments at varying pH (see Table 1). A shift in E₁/₂ with pH indicates proton involvement. Also, vary concentration of complexing agents.

- Cause 3: Polarographic Maximum. An abnormal current peak at the start of the wave.

- Solution: Add a maximum suppressor like gelatin or Triton X-100 at low concentration (0.001-0.01%).

Q3: How do I experimentally confirm that my system is reversible and thus that the Nernst equation correctly describes the E₁/₂?

A: Perform the following diagnostic tests:

- Log Plot Analysis (Ilkovič Equation): Plot log[(id - i)/i] vs. E(dme). A linear plot with a slope of (nF/2.303RT) confirms Nernstian reversibility. Deviation indicates irreversibility.

- Temperature Dependence: For a reversible process, E₁/₂ shifts slightly with temperature (based on entropy change). For an irreversible process, the shift is more pronounced and relates to activation energy.

- Drop Time Dependence: For a diffusion-controlled, reversible process, the limiting current (i_d) is proportional to the square root of the drop time. Kinetic control shows a different dependence.

Q4: In drug development, how do ligand binding and protonation states affect the half-wave potential of a metal complex?

A: These factors directly alter the standard potential (E°) in the Nernst equation. E₁/₂ ≈ E° when activity coefficients are similar.

- Ligand Binding: Stronger binding to the reduced form shifts E₁/₂ negatively. The shift is quantified by the stability constant difference.

- Protonation: If H⁺ participates in the reduction (e.g., M^(n+) + e⁻ + H⁺ → MH^(n-1)+), E₁/₂ becomes pH-dependent with a slope of -0.059 V/ph unit at 25°C.

- Protocol: To study this, run polarography in buffered solutions across a wide pH range. Keep ionic strength constant with inert electrolyte (e.g., KCl). Deoxygenate all solutions with inert gas (N₂ or Ar) for 15-20 minutes before measurement.

Data Presentation

Table 1: Effect of Experimental Parameters on Half-Wave Potential (E₁/₂)

| Parameter | Reversible System (Nernstian) | Irreversible/Quasi-Reversible System | Diagnostic Test |

|---|---|---|---|

| Variation of [Ox] | E₁/₂ independent of concentration. | E₁/₂ may shift with concentration. | DC polarography at different analyte conc. (0.1-5 mM). |

| Variation of pH | No shift unless H⁺ is involved in the electrode reaction. | Shift may occur if kinetics are pH-dependent. | Polarography in a series of buffers (pH 3-10). |

| Slope of log plot | (59/n) mV at 25°C. | > (59/n) mV. | Plot log[(i_d-i)/i] vs. E. |

| Effect of Temperature | Small, predictable shift (∂E/∂T based on ΔS). | Larger, unpredictable shift. | Measure E₁/₂ at 15°C, 25°C, 35°C. |

| Effect of Drop Time (t) | i_d ∝ t^(1/6) (diffusion current constant independent). | Abnormal dependence. | Measure i_d at varied controlled drop times. |

Table 2: Research Reagent Solutions Toolkit

| Reagent/Solution | Function in Polarography |

|---|---|

| Supporting Electrolyte (e.g., 0.1 M KCl, TBAPF₆) | Eliminates migration current, maintains constant ionic strength, defines electrical field. |

| Maximum Suppressor (e.g., 0.005% Triton X-100) | Suppresses streaming artifacts at the Hg drop to produce smooth polarographic waves. |

| Redox Standard (e.g., 1 mM [Fe(CN)₆]³⁻/⁴⁻) | Validates electrode and potentiostat performance for reversible systems. |

| Buffer Solution (e.g., BR buffer, phosphate) | Controls pH to study proton-coupled electron transfers and stabilize analyte. |

| Oxygen Scavenger (e.g., Nitrogen/Argon gas) | Removes dissolved O₂, which produces interfering reduction waves (~ -0.05 V & -0.9 V vs. SCE). |

| Hg Pool or Ag/AgCl/KCl(sat'd) Reference | Provides a stable, known reference potential for the working electrode (DME). |

Experimental Protocols

Protocol 1: Verifying Reversibility via Log Plot Analysis

- Prepare a 1.0 mM solution of your analyte in a suitable supporting electrolyte (e.g., 0.1 M KCl). Deoxygenate for 15 min.

- Record a DC polarogram from a potential positive of the reduction wave to well past the limiting current plateau. Use a standard drop time (e.g., 2 s).

- From the polarogram, record the current (i) at regular potential intervals (e.g., every 10 mV) across the rising part of the wave. Record the limiting current (i_d).

- For each data point, calculate log[(i_d - i)/i].

- Plot this value (y-axis) against the applied potential E (x-axis).

- Fit a linear regression to the central 60% of the data. A linear fit with a slope close to (59.2/n) mV at 25°C confirms a reversible, Nernstian process.

Protocol 2: Investigating pH Dependence of E₁/₂

- Prepare a stock solution of your analyte (e.g., 10 mM in organic solvent if needed).

- Prepare a series of buffered supporting electrolytes (e.g., Britton-Robinson buffer, pH 2-9), all with the same final ionic strength (adjusted with KCl).

- Spike each buffer with the stock to a final analyte concentration of 0.5 mM. Deoxygenate each.

- Record a DC polarogram for each pH solution.

- Determine E₁/₂ for each wave (potential at i = i_d/2).

- Plot E₁/₂ vs. pH. A slope of ~ -0.059 V/ph unit indicates an equal number of protons and electrons transferred in the rate-determining step.

Visualizations

Diagnosing Nernstian Behavior in Polarography Workflow

Thermodynamic & Kinetic Foundations of E1/2

Troubleshooting & FAQs: Technical Support Center

FAQ 1: Why do I observe an irreversible polarographic wave even with a theoretically reversible quinone moiety?

- Answer: This is often due to a slow electron transfer rate constant (k⁰). While the quinone/hydroquinone couple is inherently reversible, its kinetics on the electrode surface are modulated by adjacent functional groups. Bulky substituents or steric hindrance near the redox-active center can impede the necessary conformational change for electron transfer, leading to quasi-reversible or irreversible behavior. Check for alkyl chains, aryl rings, or heteroatoms adjacent to the quinone.

FAQ 2: How does changing the pH of my supporting electrolyte cause a shift in my compound's half-wave potential (E₁/₂)?

- Answer: A pH-dependent shift in E₁/₂ indicates proton-coupled electron transfer (PCET). The number of protons (m) and electrons (n) involved dictates the shift. For many organic functionalities (e.g., carbonyls, azo groups), reduction is easier (more positive E₁/₂) at lower pH as protons are readily available. Use the Nernst equation derivation: ΔE₁/₂/ΔpH = −0.059(m/n) V at 25°C. A deviation from this slope suggests a change in the PCET mechanism.

FAQ 3: My homologous series of compounds shows an unexpected, non-linear trend in E₁/₂ with increasing chain length. What could be the cause?

- Answer: Non-linear effects often arise from through-space vs. through-bond electronic effects. Initial alkyl chain elongation exhibits a small, linear inductive effect. A sudden deviation may occur when the chain length allows for intramolecular folding or interaction (e.g., a long chain folds back to shield the redox center, altering its solvation or double-layer effects). Consider conformational analysis via molecular modeling.

FAQ 4: Why does the introduction of an electron-withdrawing group (EWG) sometimes make reduction more difficult (shift E₁/₂ more negative)?

- Answer: This counter-intuitive result typically occurs when the EWG stabilizes the reduced form more than the oxidized form. For example, if reduction adds negative charge to a moiety, an adjacent EWG (like a nitro group) can stabilize that anionic product so effectively that it becomes thermodynamically less accessible, requiring more negative potential. Analyze the resonance and inductive stabilization of both redox states.

FAQ 5: I am getting poor reproducibility in drop time and current in my manual polarography setup. What are the critical checkpoints?

- Answer: Follow this checklist:

- Capillary: Ensure it is clean, vertical, and has a consistent, unchanging tip. Measure drop time in your electrolyte without potential applied; it should be constant.

- Mercury Column Height (h): Maintain a fixed, measured height. Current is proportional to √h.

- Deaeration: Inadequate oxygen removal is the most common cause of noisy, drifting baselines. Extend purging time with high-purity inert gas (N₂/Ar).

- Solution Resistance: Use a supporting electrolyte at sufficient concentration (typically 0.1 M minimum) to minimize iR drop, especially for non-aqueous studies.

Table 1: Influence of Substituents on the Half-Wave Potential of Benzene Derivatives (Reduction at DME, vs. SCE)

| Core Structure | Substituent | E₁/₂ (V) | Solvent/Supporting Electrolyte | Effect & Mechanism |

|---|---|---|---|---|

| Nitrobenzene | -H | -0.48 V | 50% EtOH, 0.1 M KCl | Reference value |

| Nitrobenzene | -p-OH | -0.33 V | 50% EtOH, 0.1 M KCl | Positive shift. -OH donates electrons, destabilizes the anion radical product. |

| Nitrobenzene | -p-NO₂ | -0.62 V | 50% EtOH, 0.1 M KCl | Negative shift. Additional -NO₂ withdraws electrons, stabilizes the anion radical product. |

| Benzaldehyde | -H | -1.32 V | DMF, 0.1 M TBAP | Reference value |

| Benzaldehyde | -p-CH₃ | -1.38 V | DMF, 0.1 M TBAP | Slight negative shift. +I effect of -CH₃ stabilizes the reactant carbonyl. |

| Benzaldehyde | -p-CN | -1.24 V | DMF, 0.1 M TBAP | Positive shift. Strong -I/-M effect of -CN destabilizes the reactant carbonyl. |

Table 2: Redox Potential Trends for Common Organic Functional Groups (Approximate Ranges)

| Functional Group | Typical E₁/₂ Range (Reduction, V vs. SCE) | Key Structural Dependencies |

|---|---|---|

| Azo (-N=N-) | -0.2 to -0.9 V | Heavily dependent on aryl substitution and pH (PCET). |

| Quinone | 0.0 to -0.5 V | Conjugation, aromaticity, and hydrogen bonding in hydroquinone. |

| Nitro (-NO₂) | -0.3 to -1.0 V | Conjugation with aromatic system; undergoes 4e⁻/4H⁺ stepwise reduction. |

| Carbonyl (>C=O) | -1.2 to -2.5 V | Adjacent π-systems (conjugation shifts positively), solvent polarity. |

| Alkene (isolated) | < -2.2 V (in DMF) | Significantly positively shifted by conjugation with EWGs or aromatics. |

Experimental Protocols

Protocol 1: Determining the Proton-Coupled Electron Transfer (PCET) Mechanism via pH Variation Objective: To establish the number of protons (m) and electrons (n) involved in the redox process of an analyte. Method:

- Prepare a stock solution of the analyte (~1 mM) in a mixed solvent (e.g., 30% water/70% DMF for poor solubility) with a constant ionic strength buffer (e.g., 0.1 M Britton-Robinson buffer adjusted from pH 2 to 12).

- For each pH, transfer 10 mL to the polarographic cell. Deoxygenate with nitrogen for 10 minutes.

- Record DC polarograms from a starting potential positive of the expected wave to a final negative potential, using a controlled drop time (e.g., 2 s).

- Measure the E₁/₂ for each wave at each pH. Plot E₁/₂ vs. pH.

- Analysis: Linear segments of the plot will have a slope ΔE₁/₂/ΔpH. Calculate m/n = -(slope / 0.059) at 25°C. A break in the plot indicates a pKₐ change in either the reactant or product.

Protocol 2: Assessing Electronic Effects in a Homologous Series Objective: To quantify the Hammett-type relationship between substituent constant (σ) and E₁/₂. Method:

- Synthesize or obtain a series of compounds with the same redox core (e.g., para-substituted nitrobenzenes).

- Prepare identical experimental conditions: e.g., 0.1 M KCl in 50% aqueous ethanol, 25°C.

- Record polarograms for each compound. Use a standard internal reference (e.g., 0.5 mM dimethylformamide) if absolute potential alignment is critical.

- Measure ΔE₁/₂ relative to the unsubstituted parent compound.

- Analysis: Plot ΔE₁/₂ vs. the substituent's Hammett σ constant (σₚ). A linear correlation (ρ is the slope) confirms the dominance of through-bond electronic effects.

Visualizations

Title: Polarographic Reduction Pathway at the Dropping Mercury Electrode

Title: How Molecular Factors Dictate the Measured Half-Wave Potential

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Polarographic Studies of Redox Potentials

| Item | Function & Rationale |

|---|---|

| High-Purity Mercury | The working electrode material for the Dropping Mercury Electrode (DME). Purity is critical to prevent alloy formation and ensure a reproducible, renewable surface. |

| Inert Gas Supply (N₂/Ar) | Used for deaeration of solutions to remove dissolved O₂, which interferes with reduction waves of organic analytes. Must be high-purity with an O₂ trap. |

| Tetraalkylammonium Salts (e.g., TBAP, TBAPF₆) | Common supporting electrolytes for non-aqueous polarography (e.g., in DMF, ACN). Provide conductivity without introducing reactive protons. |

| Aprotic Solvents (DMF, DMSO, Acetonitrile) | Allow access to very negative potentials and study of reduction processes without interference from protons, revealing "true" electron affinity. |

| Buffering Systems (Britton-Robinson, Phosphate) | For controlled aqueous pH studies to investigate Proton-Coupled Electron Transfer (PCET) mechanisms. Must be non-complexing. |

| Internal Potential Reference (e.g., Ferrocene/Ferrocenium) | Added to non-aqueous solutions to calibrate and report potentials against a known, solvent-independent standard (Fc/Fc⁺). |

| Capillary for DME | Glass capillary with precise internal diameter and length to control mercury flow and drop time, the foundation of reproducible current measurement. |

Troubleshooting Guides & FAQs

FAQ 1: Why does my half-wave potential (E₁/₂) shift when I change the supporting electrolyte?

Answer: The half-wave potential is sensitive to the ionic strength and composition of the supporting electrolyte. Changes in ionic strength alter the activity coefficients of the electroactive species, shifting the potential via the Nernst equation. Specific ion interactions (e.g., complexation) can also stabilize the reduced/oxidized form, causing a more significant shift. Always report the exact electrolyte composition and concentration.

FAQ 2: How do I choose a supporting electrolyte to minimize migration current?

Answer: The primary rule is that the concentration of the supporting electrolyte should be at least 100 times greater than the concentration of the analyte. This ensures the migration current is negligible (<<1%) compared to the diffusion current. Use electrolytes with high conductivity (e.g., KCl, LiClO₄, TBAP) to lower solution resistance.

FAQ 3: My polarographic wave is distorted or not well-defined. What could be the issue?

Answer: This is often related to improper supporting electrolyte conditions.

- Check Ionic Strength: Too low ionic strength increases solution resistance and causes poorly shaped waves.

- Check for Adsorption: Some electrolytes or their impurities adsorb on the mercury electrode. Try purifying the salt or switching to a different type (e.g., from tetraalkylammonium to alkali metal salts).

- Check for Overlapping H⁺ Reduction: In aqueous solutions at insufficient pH buffering, hydrogen ion reduction can distort the wave. Use a suitable buffer system relevant to your pH range.

FAQ 4: How can I confirm if my analyte is complexing with the supporting electrolyte?

Answer: Perform a systematic study. Measure the half-wave potential (E₁/₂) of your analyte across a range of concentrations of a suspected complexing agent (e.g., Cl⁻, CN⁻, citrate) while keeping ionic strength constant with a non-complexing salt (e.g., KClO₄). A linear plot of E₁/₂ vs. log[ligand] with a slope near the theoretical value for the complex stoichiometry confirms complexation.

Guide 1: Troubleshooting Unstable Current Readings

| Symptom | Possible Cause (Related to Supporting Electrolyte) | Solution |

|---|---|---|

| Current drifting upwards | Impurities in electrolyte undergoing slow redox reactions. | Purify the supporting electrolyte by recrystallization. Use high-purity salts. Deoxygenate solution thoroughly. |

| Noisy/fluctuating current | Solution resistance too high due to low ionic strength. | Increase concentration of supporting electrolyte. Use a more conductive salt. |

| Irregular drop time | Surfactant impurities in electrolyte adsorbing on Hg. | Clean glassware meticulously. Use a different source or batch of electrolyte. |

Guide 2: Addressing Irreversible or Broad Waves

| Observation | Diagnostic Test | Corrective Action |

|---|---|---|

| Wave is broad, ΔE₃/₄-₄/₁ > 56/n mV | Test at different concentrations of supporting electrolyte (constant ionic strength). | If broadening decreases with higher [electrolyte], increase concentration to improve kinetics. Switch to an electrolyte with different cation (e.g., Li⁺ vs. TBA⁺) which can affect double layer structure. |

| Wave is irreversible (non-Nernstian) | Perform a scan rate study. | Use a supporting electrolyte that provides a more favorable reaction environment (e.g., non-aqueous media with TBAP for organics). Ensure electrolyte does not participate in chemical steps following electron transfer. |

Key Experimental Protocols

Protocol 1: Determining the Effect of Ionic Strength on E₁/₂

Objective: To isolate and quantify the shift in half-wave potential due solely to changes in ionic strength (I), avoiding complexation effects. Methodology:

- Prepare a series of 10 solutions containing a fixed, low concentration of your analyte (e.g., 0.5 mM Cd²⁺).

- Vary the concentration of a non-complexing, inert supporting electrolyte (e.g., KClO₄) from 0.01 M to 1.0 M.

- For each solution, record the DC polarogram.

- Measure the E₁/₂ for the reduction wave.

- Plot E₁/₂ vs. √I (or log I). The slope relates to the change in activity coefficient. Key Consideration: Use an electrolyte like KClO₄ or LiNO₃ that minimally interacts with most metal ions. Maintain all other conditions (pH, temperature) constant.

Protocol 2: Investigating Specific Complexation Effects

Objective: To determine the stoichiometry and stability constant of a complex formed between the analyte and a ligand present in the supporting electrolyte. Methodology (DeFord-Hume Method):

- Prepare a set of solutions with constant ionic strength (I) maintained by a high concentration of inert salt (e.g., 1.0 M NaNO₃).

- In each solution, keep the analyte concentration constant and vary the concentration of the complexing ligand (L) (e.g., Cl⁻, NH₃).

- Record polarograms for each solution.

- For each ligand concentration, calculate the function F₀(L) = antilog[(nF/2.303RT) * (E₁/₂(simple) - E₁/₂(complex)) + log(I₄/Is)].

- Plot F₀(L) vs. [L]. The form of the plot (linear, parabolic) indicates the highest complex number. Successive extrapolations yield overall stability constants (β).

Data Presentation

Table 1: Effect of Supporting Electrolyte Cation on Half-Wave Potential of 1.0 mM Pb²⁺ in 0.1 M XCl Media

| Supporting Electrolyte (0.1 M) | E₁/₂ vs. SCE (V) | ΔE₁/₂ from KCl (V) | Notes |

|---|---|---|---|

| LiCl | -0.405 | +0.007 | Smaller cation, stronger hydration, weaker interaction. |

| NaCl | -0.410 | +0.002 | -- |

| KCl | -0.412 | 0.000 | Reference. |

| Tetramethylammonium Cl | -0.428 | -0.016 | Large organic cation adsorbs, shifts potential negatively. |

Table 2: Shift in E₁/₂ for Zn²⁺ due to Complexation in Different Electrolyte Compositions (I=0.5 M)

| Electrolyte Composition | E₁/₂ vs. SCE (V) | Ligand | Apparent Shift (V) | Inferred Complex |

|---|---|---|---|---|

| 0.5 M KNO₃ (Inert) | -1.010 | -- | 0.000 | [Zn(H₂O)₆]²⁺ |

| 0.5 M KCl | -1.040 | Cl⁻ | -0.030 | [ZnClₙ]²⁻ⁿ |

| 0.5 M KCN | -1.420 | CN⁻ | -0.410 | [Zn(CN)₄]²⁻ |

| 0.1 M NH₃ / 0.4 M KNO₃ | -1.340 | NH₃ | -0.330 | [Zn(NH₃)₄]²⁺ |

Visualizations

Experimental Workflow for Electrolyte Studies

Factors Influencing Half-Wave Potential

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in Polarography | Key Considerations |

|---|---|---|

| Inert Salts (KNO₃, KClO₄) | Maintain constant high ionic strength to suppress migration current and control activity coefficients. | KClO₄ is oxidant; avoid with strong reductants. Pre-purify to remove electroactive impurities. |

| Tetraalkylammonium Salts (TBAP, TBABF₄) | Supporting electrolyte for non-aqueous (aprotic) polarography. Large cations minimize specific adsorption. | Hydroscopic; must be stored dry. Often requires recrystallization from ethyl acetate. |

| pH Buffers (Acetate, Phosphate, Ammonia) | Control proton activity, crucial for analytes involving H⁺ in electrode reaction. | Buffer component must not complex the analyte (e.g., phosphate complexes many metals). |

| Complexing Agents (KCN, KCl, EDTA) | Deliberately added to shift E₁/₂, resolve overlapping waves, or determine stability constants. | Safety: Handle KCN with extreme care in basic solution to prevent HCN gas. |

| Oxygen Scavenger (Nitrogen/Argon Gas) | Remove dissolved O₂, which reduces in two steps (-0.05V & -0.9V vs. SCE) and interferes with analyses. | Use high-purity grade. Sparge for 10-15 minutes before measurement. |

| Electrode Cleaning Solution (Dil. HNO₃, Ethanol) | Clean glassware and cell to prevent surfactant contamination which adsorbs on Hg and affects E₁/₂. | Use trace-metal grade acids. Rinse extensively with high-purity water (18.2 MΩ·cm). |

Technical Support Center

Frequently Asked Questions (FAQs) & Troubleshooting Guides

Q1: During polarographic analysis of a novel pharmaceutical compound, my measured half-wave potential (E₁/₂) shifts significantly between different solvent systems. Why does this happen, and which solvent property is most responsible? A: This is a direct manifestation of solvent influence on electron transfer thermodynamics. The primary property is the solvent's dielectric constant (ε). A higher ε increases the solvent's ability to stabilize charged species (reactants, products, transition states) through dielectric polarization. The solvation energy change (ΔGsolv) between the oxidized and reduced states dictates the E₁/₂ shift. Use the Born approximation as a starting model: ΔE₁/₂ ∝ (1/ε) * (1/rred - 1/r_ox), where r are the ionic radii. A shift to more negative E₁/₂ in a high-ε solvent often indicates better stabilization of the reduced (anionic) state.

Q2: How can I quantitatively correct my experimental half-wave potential for solvent effects to compare data obtained in different media? A: You can reference potentials to a solvent-independent redox couple. The detailed protocol is below.

- Protocol: Referencing to the Ferrocene/Ferrocenium (Fc/Fc⁺) Couple

- Preparation: In your test solvent (e.g., DMSO, acetonitrile, DMF), prepare a 1 mM solution of your analyte with 0.1 M supporting electrolyte (e.g., TBAPF₆).

- Measurement: Record the polarogram (or cyclic voltammogram) of your analyte. Note the E₁/₂ (midpoint potential).

- Internal Standard Addition: Add a small amount of solid ferrocene (Fc) to the same cell to achieve ~0.5 mM concentration. Mix thoroughly.

- Re-measure: Record a new polarogram. You will observe your analyte wave and the new Fc/Fc⁺ wave.

- Calculation: Measure the E₁/₂ of the Fc/Fc⁺ couple in your solvent. Report your analyte's potential as E₁/₂ vs. Fc/Fc⁺. For reporting vs. Standard Hydrogen Electrode (SHE), add the known conversion factor (e.g., Fc/Fc⁺ in acetonitrile is +0.641 V vs. SHE).

Q3: My voltammetric peaks are broad and poorly resolved in a low-dielectric constant solvent (ε < 10). What is the cause and solution? A: This is likely due to high solution resistance (R_u) and improper uncompensated iR drop. Low-ε solvents have lower ionic conductivity, leading to significant potential distortion across the cell.

- Troubleshooting Steps:

- Increase Electrolyte Concentration: Use a higher concentration (e.g., 0.3-0.5 M) of a suitable supporting electrolyte to enhance conductivity.

- Employ Positive Feedback iR Compensation: If your potentiostat has this feature, enable and carefully adjust the compensation. Avoid over-compensation.

- Reduce Scan Rate: Lower your polarographic scan rate or drop time to decrease current (i), thereby minimizing the iR error.

- Use a Microelectrode: Switch to a smaller working electrode (e.g., Pt microdisk) which reduces current and minimizes iR effects.

Q4: I suspect specific solute-solvent interactions (beyond dielectric effects) are influencing my electron transfer kinetics. How can I investigate this? A: You are likely dealing with specific solvation (e.g., hydrogen bonding, Lewis acidity/basicity). To investigate:

- Solvent Parameter Correlation: Measure E₁/₂ in a series of solvents with similar ε but different donor/acceptor numbers (DN, AN). Plot E₁/₂ vs. DN or AN. A strong correlation indicates specific interactions.

- Kinetic Measurement: Use fast-scan cyclic voltammetry to measure the standard heterogeneous electron transfer rate constant (k⁰) in different solvents. A change in k⁰ that doesn't correlate with ε may indicate specific interactions affecting the transition state solvation.

- Spectroscopic Validation: Use techniques like FT-IR or NMR to detect shifts in analyte vibrational or chemical shift frequencies indicative of specific solvent coordination.

Summary of Quantitative Solvent Effects

Table 1: Common Solvent Properties and Their Impact on Polarographic Measurements

| Solvent | Dielectric Constant (ε) | Viscosity (cP) | Donor Number | Typical ΔE₁/₂ (vs. Fc/Fc⁺) Shift for Anionic Reduction* |

|---|---|---|---|---|

| Water | 80.1 | 0.89 | 18 | Reference (by definition for SHE) |

| N,N-Dimethylformamide (DMF) | 36.7 | 0.92 | 26.6 | Shifts negative |

| Acetonitrile (MeCN) | 37.5 | 0.34 | 14.1 | Shifts negative |

| Dimethyl Sulfoxide (DMSO) | 46.7 | 2.00 | 29.8 | Shifts more negative |

| Dichloromethane (DCM) | 8.93 | 0.41 | 1.0 | Shifts positive; iR issues likely |

| Tetrahydrofuran (THF) | 7.58 | 0.46 | 20.0 | Shifts positive; iR issues likely |

*General trend for reduction to an anionic product. Magnitude depends on ionic radii.

Table 2: Troubleshooting Chart for Solvent-Related Issues

| Symptom | Probable Cause | Recommended Action |

|---|---|---|

| Irreversible or broad waves | Slow electron transfer due to poor reactant solvation | Increase temperature; use a more polar solvent; check for coupled chemical reactions. |

| Inconsistent E₁/₂ between replicates | Variable water content (hygroscopic solvents) | Rigorously dry solvent and electrolyte; use molecular sieves; employ inert atmosphere glovebox. |

| High background current | Solvent or electrolyte impurity | Purify solvent (distillation); recrystallize supporting electrolyte; use higher purity grade. |

| Multiple, unclear reduction waves | Solvent-assisted side reactions (e.g., protonation) | Switch to aprotic, non-coordinating solvent with high purity; use a weaker acid supporting electrolyte. |

Experimental Protocols

Protocol: Determining the Dielectric Constant Dependence of E₁/₂ Objective: To empirically measure the relationship between solvent polarity (ε) and the half-wave potential for a model compound. Materials: See "Research Reagent Solutions" below. Procedure:

- Prepare a 1.0 mM solution of quinone (e.g., 1,4-benzoquinone) in each of the following dry, deaerated solvents: DMF, MeCN, DMSO, and a DMF:DCM mixture series (e.g., 100:0, 75:25, 50:50, 25:75 v/v). Maintain 0.1 M TBAPF₆ as supporting electrolyte.

- Using a standard three-electrode polarographic setup (DME working electrode), record the DC polarogram for each solution.

- For each polarogram, determine the E₁/₂ precisely.

- Add internal ferrocene and re-measure to obtain E₁/₂ vs. Fc/Fc⁺.

- Plot E₁/₂ (vs. Fc/Fc⁺) against the inverse of the solvent's dielectric constant (1/ε). Analyze the linearity of the relationship.

Protocol: Assessing Solvation Energy via Computational Methods Objective: To complement experimental data with calculated solvation energies. Procedure:

- Geometry Optimization: Using computational chemistry software (e.g., Gaussian, ORCA), optimize the geometry of both the oxidized and reduced states of your analyte in the gas phase at the DFT level (e.g., B3LYP/6-31+G(d)).

- Single Point Energy in Solvent: Perform a single-point energy calculation on the optimized structures using a Polarizable Continuum Model (PCM) specifying your experimental solvent (e.g., ε = 46.7 for DMSO).

- Calculation: The solvation energy (ΔGsolv) for each species is output by the software. Calculate the difference: ΔΔGsolv = ΔGsolv(red) - ΔGsolv(ox).

- Correlation: Relate the calculated ΔΔGsolv to the experimentally observed shift in E₁/₂. A more negative ΔΔGsolv correlates with a more negative (easier) reduction potential.

Diagrams

Title: Logical Flow of Solvent Impact on E₁/₂

Title: Experimental Workflow for Solvent Effect Study

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions for Solvent Effect Studies

| Reagent / Material | Function & Importance |

|---|---|

| Tetrabutylammonium Hexafluorophosphate (TBAPF₆) | Standard supporting electrolyte for non-aqueous electrochemistry. Large ions minimize ion-pairing, and PF₆⁻ is relatively inert and non-coordinating. |

| Ferrocene (Fc) | Internal redox standard for potential referencing across different solvents. Its E₁/₂ is relatively insensitive to specific solvation. |

| Distilled & Dried Solvents (DMF, MeCN, DMSO) | High-purity, anhydrous solvents are critical. Trace water can act as a proton source, drastically altering reduction mechanisms. |

| 3Å or 4Å Molecular Sieves | Used to maintain anhydrous conditions in solvent and electrolyte stock solutions. |

| Dropping Mercury Electrode (DME) | The classic working electrode for polarography. Provides a renewable, smooth surface ideal for reproducible diffusion-controlled currents. |

| Nonaqueous Reference Electrode (e.g., Ag/Ag⁺) | Provides a stable potential in organic solvents. Often filled with matching solvent/electrolyte and referenced to Fc/Fc⁺ for reporting. |

| Polarographic Cell with Gas Inlet/Outlet | Allows for deaeration of solutions with inert gas (N₂, Ar) to remove dissolved O₂, which is electroactive. |

Technical Support Center: Troubleshooting Polarography Experiments

FAQs & Troubleshooting Guides

Q1: Why does my measured half-wave potential (E₁/₂) shift significantly when I change the experimental temperature?

A: A shift in E₁/₂ with temperature indicates that the electrode reaction has a measurable entropy change (ΔS). This is a thermodynamic contribution. An increase in E₁/₂ with temperature suggests a positive ΔS for the reduction (favorable disorder increase). To isolate this effect, ensure your cell is thermally equilibrated for at least 15 minutes, use a calibrated thermometer in the solution (not just the bath), and verify that your reference electrode potential is temperature-corrected.

Q2: My polarographic wave becomes broad and poorly defined at higher temperatures. What is the cause and solution?

A: Wave broadening is typically a kinetic issue. Increased temperature accelerates the electron transfer rate (increasing the standard rate constant, k⁰), but it can also exacerbate problems like inadequate buffering (pH shifts), increased convection, or faster follow-up chemical reactions (EC mechanisms). Ensure your supporting electrolyte concentration is high (≥0.1 M) to maintain a constant ionic strength and pH. Use a three-electrode system with minimal uncompensated resistance.

Q3: How do I determine if an observed temperature effect on E₁/₂ is due to thermodynamics or kinetics?

A: You must perform a series of experiments at different temperatures and analyze the data systematically.

- Protocol: Record polarograms (or cyclic voltammograms) at 5°C intervals from 10°C to 40°C.

- Analysis:

- Plot E₁/₂ vs. T (K). A linear relationship with a significant slope (∂E₁/₂/∂T) confirms a thermodynamic contribution (ΔS° = nF(∂E₁/₂/∂T)).

- Plot the wave width (e.g., E₃/₄ - E₁/�) vs. T. A change indicates a kinetic contribution. For a reversible system, the width should be constant (~56.4/n mV at 25°C).

- For quasi-reversible systems, use the variation of peak separation (ΔEp) in cyclic voltammetry with temperature to calculate the activation energy (Ea) via an Arrhenius plot of ln(k⁰) vs. 1/T.

Q4: I suspect a temperature-induced chemical decomposition of my drug analyte. How can I confirm this during my polarographic study?

A: This is a common issue in drug development.

- Protocol for Stability Check:

- Prepare your drug solution and place it in the thermostated cell at your experimental temperature.

- Record successive polarograms every 2-5 minutes over 30-60 minutes.

- Plot limiting current (iₗ) and E₁/₂ vs. time.

- Diagnosis: A steady decrease in iₗ (diffusion-controlled) indicates loss of electroactive species. A shift in E₁/₂ suggests a change in speciation (e.g., hydrolysis). Perform this test at each key temperature. Always use freshly prepared, degassed solutions.

Table 1: Thermodynamic Parameters from Temperature-Dependent E₁/₂ Shifts for Model Compounds

| Compound / System | ∂E₁/₂/∂T (mV/K) | ΔS° of Reduction (J/mol·K) | n (electrons) | Temperature Range (°C) |

|---|---|---|---|---|

| [Fe(CN)₆]³⁻/⁴⁻ (Reversible) | ~0.0 | ~0 | 1 | 10-40 |

| Quinone/Hydroquinone | +1.2 | +116 | 2 | 15-35 |

| Cd²⁺ in 1M KCl | -0.3 | -29 | 2 | 10-40 |

| Model Drug A (Proton-Coupled) | +0.8 | +77 | 2 | 20-40 |

Table 2: Kinetic Parameters from Temperature-Dependent Voltammetry

| System | Standard Rate Constant, k⁰ @ 25°C (cm/s) | Activation Energy, Ea (kJ/mol) | Method |

|---|---|---|---|

| [Fe(CN)₆]³⁻/⁴⁻ (1M KCl) | 0.05 | 20-30 | CV (ΔEp) |

| [Ru(NH₃)₆]³⁺/²⁺ | > 0.1 | < 20 | CV (ΔEp) |

| Model Drug B (Irreversible) | 3.2 x 10⁻⁴ | 65 | Polarography (Wave Analysis) |

Experimental Protocol: Determining Thermodynamic & Kinetic Parameters

Objective: To separately determine the entropy change (ΔS°) and the electron transfer activation energy (Ea) for a reversible, one-electron reduction.

Materials: Polarograph/Voltammeter, Hanging Mercury Drop Electrode (HMDE) or DME, Pt counter electrode, Ag/AgCl reference electrode, Thermostated cell (±0.1°C), Analyte, High-purity supporting electrolyte, N₂ gas for degassing.

Methodology:

- Prepare 10 mL of a 1.0 mM analyte solution in 0.1 M supporting electrolyte. Degas with N₂ for 10 minutes.

- Set cell temperature to 10°C. Allow thermal equilibration for 15 min with gentle stirring.

- Record 3 consecutive DC polarograms (or cyclic voltammograms at slow scan rate, e.g., 50 mV/s) from a potential positive of the wave to negative of the limiting current.

- Precisely measure the half-wave potential (E₁/₂) and the limiting current (iₗ) for each polarogram. Average the values.

- Increase the temperature to 15°C. Repeat steps 2-4. Continue in 5°C increments up to 40°C.

- For Thermodynamics: Plot average E₁/₂ (in Volts) vs. Absolute Temperature (T in Kelvin). Perform a linear regression. ∂E₁/₂/∂T = slope. Calculate ΔS° = nF*(slope).

- For Kinetics (from CV): At each temperature, measure the peak separation (ΔEp). Use digital simulation software or Nicholson's method to estimate the standard rate constant (k⁰) from ΔEp. Plot ln(k⁰) vs. 1/T. The slope of the linear fit = -Ea/R.

Visualizations

Title: How Temperature Affects Polarographic Signals

Title: Temperature-Dependence Experimental Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Temperature-Controlled Polarography

| Item | Function & Specification | Critical Note for Temperature Studies |

|---|---|---|

| Thermostated Electrochemical Cell | Maintains solution temperature within ±0.1°C. Jacketed cells connected to a circulator are ideal. | Ensure the reference electrode compartment is also temperature-controlled to avoid thermal junction potentials. |

| Supporting Electrolyte (e.g., 1.0 M KCl or Phosphate Buffer) | Provides ionic conductivity, fixes ionic strength, and can control pH. | Use a high buffer capacity. Check for temperature-dependent pH shifts (especially for phosphate/amine buffers) and adjust calculations. |

| Redox Potential Reference Standard (e.g., Ferrocene/ Ferrocenium or [Ru(bpy)₃]²⁺/³⁺) | Internal reference for potential calibration, correcting for reference electrode drift with T. | Add a small amount post-experiment. Confirm its E₁/₂ is temperature-independent or well-characterized. |

| High-Purity Mercury (Triple Distilled) | For the working electrode (DME or HMDE). | Mercury resistivity changes with T; ensure potentiostat compensation is adequate for precise iR drop correction. |

| Inert Gas Supply (N₂ or Ar, Oxygen-Free) | Removes dissolved O₂, which interferes with reduction waves. | Gas solubility decreases with T. Degas after thermal equilibration at each new temperature for a consistent time. |

| Calibrated Thermometer or Probe | Directly measures solution temperature. | Do not rely on the circulator readout. Use a certified NIST-traceable probe inserted into the cell. |

Precision in Practice: Methodological Control for Accurate E₁/₂ Measurement

Technical Support Center

Troubleshooting Guides & FAQs

Q1: My polarographic wave is poorly defined and not sigmoidal. What could be wrong with my DME setup? A: This is often due to incorrect DME characteristics. Ensure:

- Capillary Clogging: The capillary tip may be partially blocked. Clean according to protocol.

- Incorrect Mercury Column Height (h): This controls drop time (

t_d). Measure and adjusthto achieve at_dbetween 3-6 seconds for a clean, renewable surface. A too-shortt_dyields an ill-defined wave. - Dirty Mercury: Use triple-distilled mercury. Oxidized mercury forms a film that distorts the current.

Experimental Protocol: Calibrating DME Characteristics

- Fill the mercury reservoir with clean Hg.

- In a quiet, vibration-free environment, suspend a clean DME capillary in air over a catch basin.

- Measure the height (

h) from the tip to the meniscus in the reservoir using a ruler. - Using a stopwatch, record the time (

t_d) for 10 drops to fall. Calculate averaget_d. - Adjust

hand repeat untilt_dis in the optimal range. Record the exacthand correspondingt_dand mercury flow rate (m).

Q2: I observe excessive noise and unstable current in my cell. How should I troubleshoot the cell design? A: This typically stems from improper cell design or setup.

- Electrical Shielding: Ensure the entire cell is housed in a grounded Faraday cage to block external electromagnetic interference.

- Vibration: Place the apparatus on a vibration-damping table. Mechanical disturbance of the DME causes current fluctuations.

- Cell Geometry & Placement: The DME, reference electrode (RE), and counter electrode (CE) must be positioned correctly. The RE Luggin capillary should be close (~2 mm) to the DME to minimize uncompensated resistance (

R_u), but not so close as to disturb diffusion. - Deaeration: Inadequate removal of dissolved oxygen is a prime noise source. Purge with high-purity nitrogen or argon for at least 15 minutes before measurement and maintain a blanket over the solution.

Q3: My measured half-wave potential (E₁/₂) shifts between experiments. Could this be related to my reference electrode? A: Yes. E₁/₂ is referenced against the potential of the RE. Instability indicates a faulty RE.

- Contamination: The RE frit may be contaminated by sample components. Soak and rinse the RE according to manufacturer guidelines.

- Filled/Leaking Electrolyte: Ensure the RE is filled to the correct level with fresh filling solution (e.g., saturated KCl for SCE). Check for crystals clogging the junction.

- Inappropriate RE Choice: Using an RE with a liquid junction potential sensitive to your solution composition (e.g., SCE in non-aqueous media) causes shifts. Select a compatible RE (see Table 2).

Experimental Protocol: Validating Reference Electrode Stability

- Measure the open-circuit potential of your RE against a second, freshly prepared, identical RE in a 0.1 M KCl solution.

- The potential should be stable and read < ±2 mV. Drift or a larger offset indicates the RE needs maintenance or replacement.

- Record this validation check before each experimental series.

Data Presentation

Table 1: Impact of DME Parameters on Polarographic Wave and E₁/₂

| Parameter | Typical Optimal Value | Effect if Too Low | Effect if Too High | Primary Impact on E₁/₂? |

|---|---|---|---|---|

Drop Time (t_d) |

3 - 6 s | Ill-defined wave, high capacitive current | Increased diffusion layer, time-dependent analysis | Minor indirect effect via current shape |

Mercury Column Height (h) |

40 - 80 cm | Short t_d, erratic drops |

Long t_d, prolonged analysis time |

No direct effect |

Mercury Flow Rate (m) |

1 - 3 mg/s | - | - | No direct effect |

Capillary Radius (r) |

25 - 50 µm | - | - | No direct effect |

Table 2: Common Reference Electrodes for Polarography

| Electrode | Full Name | Potential vs. SHE (25°C) | Typical Use Case | Advantage | Disadvantage |

|---|---|---|---|---|---|

| SCE | Saturated Calomel Electrode | +0.241 V | Aqueous, non-complexing media. | Stable, widely used. | KCl leakage; unstable in non-aq. media. |

| Ag/AgCl (sat. KCl) | Silver/Silver Chloride | +0.197 V | General aqueous work. | Simple, robust. | Ag+ may interfere in some systems. |

| Ag/Ag+ | Silver/Silver Ion | User-defined | Non-aqueous solvents (e.g., DMF, MeCN). | Compatible with organic media. | Requires careful preparation, less stable. |

| TMS | Thallium Amalgam | -0.557 V (in sat. KCl) | Used as internal ref. in some cells. | Minimizes liquid junction. | Toxic, preparation complexity. |

Mandatory Visualizations

Troubleshooting Path for Polarographic Setup Optimization

Key Parameters Influencing Measured Half-Wave Potential

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in Polarographic Setup |

|---|---|

| Triple-Distilled Mercury | High-purity working electrode material for the DME. Essential for a clean, reproducible surface. |

| DME Capillary (Glass) | Precisely controls the formation and fall of the mercury drop. The inner diameter and cleanliness are critical. |

| Saturated Calomel Electrode (SCE) | Common reference electrode for aqueous studies, providing a stable potential to measure E₁/₂ against. |

| Tetraalkylammonium Salt (e.g., TBAPF₆) | Supporting electrolyte at high concentration (~0.1 M). Carries current and fixes ionic strength, minimizing migration current. |

| High-Purity Inert Gas (N₂/Ar) | Used to deoxygenate the analyte solution by bubbling, removing O₂ which interferes by reducing in the same potential window. |

| Faraday Cage | Metallic enclosure that shields the sensitive electrochemical cell from external electromagnetic noise. |

| Vibration-Damping Table | Isolates the DME from building vibrations, preventing premature drop dislodgement and current noise. |

| Luggin Capillary | A thin tube extending from the reference electrode compartment. Positions the RE close to the DME to minimize uncompensated resistance (iR drop). |

Technical Support Center: Troubleshooting & FAQs

Q1: During polarographic analysis, my polarogram shows erratic and unstable currents, with sharp spikes or noise. What could be the cause and how do I resolve it? A: This is a classic symptom of insufficient solution deaeration. Residual oxygen reacts at the dropping mercury electrode (DME), producing overlapping reduction waves and noisy baselines. Follow this protocol:

- Protocol: Sparge the analyte solution with high-purity nitrogen (N₂) or argon (Ar) for a minimum of 15-20 minutes prior to measurement. During the scan, maintain a gentle blanket of inert gas over the solution surface. For very sensitive measurements, consider pre-saturating the purge gas by bubbling it through an electrolyte solution identical to your analyte cell to prevent solvent evaporation.

- Thesis Context: Uncontrolled oxygen reduction interferes with the accurate measurement of the half-wave potential (E₁/₂), shifting it and introducing irreproducibility due to fluctuating background currents.

Q2: I am observing an unexpected shift in the half-wave potential (E₁/₂) for my target analyte between experimental runs. How can I ensure solution purity is not the culprit? A: Contaminants, especially heavy metal ions, can complex with analytes or adsorb onto the electrode, altering the electrode process kinetics. Implement this purity check:

- Protocol: Use the highest grade chemicals available (e.g., ACS Reagent Grade or better). Utilize high-purity deionized water (resistivity ≥18.2 MΩ·cm). For critical experiments, pre-clean electrochemical cells by soaking in 50% (v/v) nitric acid overnight, followed by copious rinsing with pure water. Run a blank polarogram of your supporting electrolyte to check for impurity waves.

- Thesis Context: Impurities that complex with the analyte will directly change the standard potential of the redox couple, thereby shifting the measured E₁/₂, a core parameter in your thesis.

Q3: My polarographic wave is poorly defined or not detectable. What concentration range should my analyte be in, and how does supporting electrolyte concentration affect this? A: The analyte concentration must be within the optimal linear range of the polarographic method, and the supporting electrolyte must be in sufficient excess.

- Protocol: For classical DC polarography with DME, the typical analyte concentration range is 10⁻⁵ M to 10⁻² M. The concentration of the supporting electrolyte (e.g., KCl, HCl, buffer salts) should be at least 100 times greater than the analyte concentration to maintain a constant ionic strength and eliminate migration current.

- Thesis Context: At very low concentrations, the diffusion current (i_d) becomes too small to measure accurately, affecting the determination of E₁/₂. An insufficient supporting electrolyte concentration alters the electrical double layer, which can lead to shifts in E₁/₂.

Data Presentation: Key Parameters for Solution Preparation

Table 1: Recommended Concentration Ranges and Purity Standards

| Component | Purpose | Recommended Concentration Range | Purity Grade | Critical Parameter |

|---|---|---|---|---|

| Analyte | Species of interest for redox study | 10⁻⁵ M to 10⁻² M | ≥99.0% (or highest available) | Must be soluble and stable in the chosen solvent/electrolyte. |

| Supporting Electrolyte | Eliminates migration current, controls pH & ionic strength | 0.1 M to 1.0 M (≥100x [Analyte]) | ACS Reagent Grade, low heavy metals | Must be electroinactive in the potential window of interest. |

| Solvent | Dissolves analyte and electrolyte | N/A (bulk medium) | HPLC/Chromatography Grade | Low water content for non-aqueous work; degassed. |

| Water | Aqueous medium preparation | N/A | Type I (18.2 MΩ·cm) | Resistivity ≥18.2 MΩ·cm, TOC <5 ppb. |

| Purge Gas | Solution deaeration | N/A | High-Purity Grade (≥99.999%) | Oxygen content <1 ppm; use with in-line gas scrubber. |

Table 2: Common Issues & Systematic Troubleshooting Guide

| Symptom | Likely Cause | Immediate Action | Preventive Protocol |

|---|---|---|---|

| Noisy, unstable baseline | Inadequate deaeration (O₂ present) | Extend purging time to 25 mins; check gas lines for leaks. | Standardize a 20-min pre-purge and continuous surface blanket. |

| Shift in E₁/₂ between runs | Contaminated cell or reagents | Clean cell with acid; prepare fresh electrolyte from new stock. | Dedicate cells to specific analytes; use aliquots, not from stock bottles. |

| Poorly formed wave, low current | Analyte concentration too low | Concentrate sample or use a more sensitive technique (e.g., DP polarography). | Verify stock solution molarity; confirm solubility limits. |

| Broad, drawn-out wave | Unbuffered solution or incorrect ionic strength | Adjust pH with buffer; increase supporting electrolyte concentration. | Always use a buffer at adequate concentration (>0.05 M). |

Experimental Protocols

Protocol 1: Standard Solution Deaeration for Aqueous Polarography

- Preparation: Fill the electrochemical cell with the prepared solution containing analyte and supporting electrolyte.

- Purging: Insert a clean glass or Teflon gas dispersion tube (frit) connected to an N₂/Ar line. Sparge the solution vigorously for 15-20 minutes.

- Blanketing: After purging, raise the gas tube above the solution level but within the cell neck. Maintain a slow, continuous inert gas flow over the solution surface for the duration of the experiment.

- Verification: Record a polarogram of the blank supporting electrolyte from 0.0 V to -1.0 V vs. SCE. A flat, featureless baseline confirms successful deaeration.

Protocol 2: Preparation of a Standard Series for Calibration

- Prepare a stock solution of the analyte at a precisely known concentration (e.g., 1.00 x 10⁻³ M).

- Prepare a master batch of supporting electrolyte/buffer solution.

- Using volumetric glassware, perform serial dilutions of the analyte stock into the supporting electrolyte to create a standard series (e.g., 5 μM, 10 μM, 25 μM, 50 μM, 100 μM).

- Deaerate each standard individually following Protocol 1 before measurement.

- Plot diffusion current (i_d) vs. concentration. The linear range defines the usable concentration window for your system.

Visualization of Workflows

Standard Solution Prep & Troubleshooting Workflow

How Solution Parameters Affect Half-Wave Potential

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Polarographic Solution Preparation

| Item | Function / Rationale | Specification Notes |

|---|---|---|

| Supporting Electrolyte Salts | Provides ionic conductivity, suppresses migration current, fixes ionic strength. | Potassium chloride (KCl), Sodium perchlorate (NaClO₄), Tetraalkylammonium salts (for non-aqueous). Must be electroinactive. |

| Buffer Components | Maintains constant pH, critical as E₁/₂ for many species is pH-dependent. | Phosphate, acetate, borate, or ammonium buffers. Use at ≥0.05 M concentration. |

| High-Purity Deionized Water | Solvent for aqueous studies; contaminants can introduce spurious redox waves. | Type I water, resistivity ≥18.2 MΩ·cm at 25°C. |

| Inert Purge Gas | Removes interfering dissolved oxygen from solution. | Ultra-high purity Nitrogen (N₂) or Argon (Ar) with oxygen trap. |

| Mercury | For the Dropping Mercury Electrode (DME). Must be clean for reproducible drops. | Triple-distilled, ACS Grade. |

| Standard Reference Solutions | For calibration of current and potential axes. | Certified standard solutions of known analytes (e.g., 1.00 mM Cd²⁺). |

| Cell Cleaning Solution | To remove adsorbed contaminants from glassware and electrodes. | 50% (v/v) Nitric Acid (HNO₃), followed by pure water rinse. |

Technical Support Center

Troubleshooting Guide: Common Polarographic Issues

Issue 1: Unstable or Drifting Half-Wave Potential (E₁/₂)

- Q: Why is my measured half-wave potential drifting between repeated scans?

- A: This is often due to a contaminated mercury electrode or an unstable reference electrode potential.

- Actionable Steps:

- Clean the Dropping Mercury Electrode (DME): Rinse the capillary with dilute nitric acid (0.1 M) followed by copious amounts of deionized water.

- Check the Reference Electrode: Ensure the reference electrode (e.g., Ag/AgCl, SCE) is filled with the correct electrolyte and that the junction is not clogged. Measure its potential against a second, fresh reference electrode.

- Degas the Solution: Dissolved oxygen is a common interferent. Purge the analyte solution with an inert gas (N₂ or Ar) for at least 10 minutes before measurement and maintain a blanket gas during the run.

- Control Temperature: Use a thermostated cell. E₁/₂ can shift -0.5 to -2 mV/°C for many metal ions.

Issue 2: Poorly Defined or Broad Waves

- Q: My polarographic wave is very broad, making E₁/₂ difficult to determine accurately. What causes this?

- A: Broad waves indicate slow electrode kinetics or an uncompensated solution resistance (iR drop).

- Actionable Steps:

- Add a Supporting Electrolyte: Increase the concentration of the inert electrolyte (e.g., KCl, KNO₃) to at least 0.1 M to minimize migration current and reduce iR drop.

- Check for Unwanted Chemical Reactions: The electroactive species may be involved in a preceding or following chemical reaction (e.g., complexation). Review solution chemistry.

- Verify Instrument Settings: Ensure the correct voltage scan rate is selected. For conventional DC polarography, a slow scan rate (e.g., 0.5-2 mV/s) is typical.

Issue 3: Non-Linear Ilkovič Plot (Limiting Current vs. √Hg Height)

- Q: My plot of limiting current (iₗ) versus the square root of the mercury column height is not linear, suggesting the current is not purely diffusion-controlled.

- A: Contributions from kinetic or catalytic currents are likely.

- Actionable Steps:

- Systematic Variation of Hg Height: Measure iₗ at a minimum of five different, precisely controlled mercury heights. Plot iₗ vs. √h. A linear plot confirms diffusion control.

- Vary Ligand Concentration: If studying a metal complex, perform experiments with systematically varied ligand concentrations while keeping metal ion concentration constant. This helps isolate kinetic parameters.

- Change pH Methodically: For pH-dependent systems, perform a detailed pH study in increments of 0.2-0.5 pH units to identify proton-coupled electron transfer steps.

Frequently Asked Questions (FAQs)

Q1: How do I systematically determine if an observed shift in E₁/₂ is due to complexation or a change in pH? A: You must isolate the parameters. First, fix the pH in a well-buffered system and vary the ligand concentration in a stepwise manner. Record E₁/₂ for each step. In a separate experiment, fix the ligand concentration at zero (or a constant value) and systematically vary the pH. Compare the magnitude and direction of the shifts. Data should be organized as in Table 1.

Q2: What is the most effective way to confirm the reversibility of an electrode reaction in my polarographic experiment? A: Use cyclic voltammetry (CV) on a static mercury drop electrode (SMDE) as a complementary technique. A peak separation (ΔEp) close to 59/n mV at slow scan rates indicates reversibility. Alternatively, within DC polarography, a logarithmic analysis of the wave (plot of log[(iₗ-i)/i] vs. E) yielding a slope of 59/n mV is indicative of a reversible process.

Q3: My drug compound is poorly soluble in aqueous buffer. Can I still perform polarography? A: Yes, but you must systematically vary the solvent composition. Start with a minimal amount of a co-solvent like methanol, acetonitrile, or DMSO (e.g., 1% v/v). Ensure the supporting electrolyte is soluble. Record your baseline and then incrementally increase the co-solvent percentage (e.g., 1%, 2%, 5%) while monitoring the consistency of control measurements (e.g., standard ferrocene redox couple) to account for solvent effects on the reference potential.

Table 1: Systematic Variation of Ligand Concentration on Cd²⁺ Half-Wave Potential Supporting Electrolyte: 0.1 M KNO₃, pH = 7.0 (HEPES buffer), T = 25°C

| [CN⁻] (mM) | E₁/₂ vs. SCE (V) | ΔE₁/₂ (V) | Wave Slope (mV/log) | Interpretation |

|---|---|---|---|---|

| 0.0 | -0.601 | 0.000 | 61 | Free Cd²⁺ |

| 0.5 | -0.723 | -0.122 | 63 | Complexation |

| 1.0 | -0.782 | -0.181 | 62 | Complexation |

| 2.0 | -0.845 | -0.244 | 64 | Complexation |

| 5.0 | -0.942 | -0.341 | 60 | Complexation |

Table 2: Systematic Variation of pH on 8-Hydroxyquinoline Half-Wave Potential [Compound] = 0.1 mM, Supporting Electrolyte: 0.1 M KCl, T = 25°C

| pH (Buffer) | E₁/₂ vs. Ag/AgCl (V) | Limiting Current (nA) | Wave Character |

|---|---|---|---|

| 3.0 (Acetate) | -0.45 | 48 | Single, broad |

| 5.0 (Acetate) | -0.62 | 52 | Single |

| 7.0 (Phosphate) | -0.89 | 105 | Well-defined |

| 9.0 (Borate) | -1.15 | 108 | Well-defined |

| 11.0 (Carbonate) | -1.32 | 52 | Broadened |

Experimental Protocols

Protocol 1: Baseline Establishment for Reversible System Title: Calibration of Polarographic System Using Standard Cd²⁺ Solution.

- Preparation: Prepare 50 mL of a 0.1 mM Cd(NO₃)₂ solution in 0.1 M KNO₃. Adjust pH to 3.0 using HNO₃ to prevent hydrolysis.

- Degassing: Transfer solution to the polarographic cell. Bubble high-purity nitrogen gas through the solution for 12 minutes. Maintain a nitrogen atmosphere above the solution during runs.

- Instrument Setup: Set DME parameters (drop time: 2 s, scan rate: 1 mV/s). Set initial potential to 0.0 V vs. SCE and final potential to -1.0 V vs. SCE.

- Measurement: Record three consecutive polarograms. The average E₁/₂ for Cd²⁺ under these conditions should be -0.58 ± 0.01 V vs. SCE.

Protocol 2: Isolating the Effect of Complexation Title: Stepwise Variation of Ligand (Cyanide) Concentration.

- Stock Solutions: Prepare 100 mL of 0.1 mM Cd(NO₃)₂ in 0.1 M KNO₃. Prepare a 10 mM KCN stock solution in 0.1 M KNO₃. Caution: Use in fume hood.

- Systematic Addition: To the polarographic cell containing 10 mL of the Cd²⁺ solution, add aliquots of the KCN stock solution using a micropipette to achieve the final concentrations listed in Table 1. Stir thoroughly after each addition.

- Measurement: After each addition and degassing (2 min N₂), record the polarogram from 0.0 V to -1.2 V vs. SCE.

- Analysis: For each wave, determine E₁/₂ and the limiting current. Plot E₁/₂ vs. log[CN⁻] to determine complex stoichiometry and stability constant.

Visualizations

Title: Systematic Parameter Isolation Workflow

Title: Oxygen Interference on Polarographic Wave

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in Polarography | Key Consideration |

|---|---|---|

| High-Purity Mercury | Forms the working electrode (DME or SMDE). Must be triple-distilled to eliminate trace metal contaminants that can create interfering redox waves. | |

| Inert Salts (KCl, KNO₃, NaClO₄) | Supporting electrolyte at high concentration (≥0.1 M). Carries current to eliminate migration effects, defines ionic strength, and minimizes iR drop. | Use highest purity to avoid reducible impurities. |

| pH Buffer Solutions | Controls and stabilizes pH, which is critical for studying proton-coupled reactions or analyte stability. Must be non-complexing and electro-inactive in the potential window (e.g., phosphate, acetate, borate). | |

| Oxygen Scavengers | Removes dissolved O₂ which produces two irreversible reduction waves (-0.05 V & -0.9 V vs. SCE) that can mask analyte waves. | Pre-purge with N₂/Ar is standard. Sodium sulfite can be used in alkaline media. |

| Standard Redox Couples | Used for system calibration and verification of reference electrode potential (e.g., Ferrocene/Ferrocenium in non-aqueous media, K₃Fe(CN)₆/K₄Fe(CN)₆ in aqueous). | |

| Complexing Agents (e.g., CN⁻, EDTA, NTA) | Systematically varied to study metal speciation, stability constants, and the effect of complexation on E₁/₂. | Concentration must be known precisely; stability in the electrochemical window is required. |

Technical Support Center

Troubleshooting Guides & FAQs

Q1: My polarographic wave is distorted and not sigmoidal. What could be the cause? A: A non-ideal waveform often stems from uncompensated resistance (iR drop) or adsorption of the electroactive species or supporting electrolyte onto the dropping mercury electrode (DME). First, ensure your supporting electrolyte concentration is sufficiently high (typically ≥0.1 M) to minimize solution resistance. Verify that your reference electrode is placed correctly in the Luggin capillary to reduce iR drop. If the problem persists, consider changing the supporting electrolyte composition, as certain ions may specifically adsorb.

Q2: The measured half-wave potential (E₁/₂) shifts between experimental runs. How can I improve reproducibility? A: E₁/₂ drift is commonly linked to reference electrode potential instability or changes in liquid junction potential. Calibrate your reference electrode (e.g., Ag/AgCl, SCE) before each set of experiments using a known redox couple. Ensure a consistent and stable temperature, as E₁/₂ is temperature-dependent. Use a fresh, deoxygenated solution for each run and maintain a constant, pure inert gas (N₂ or Ar) purge flow rate.

Q3: I observe excessive noise in the sampled DC polarogram, obscuring the wave. How do I resolve this? A: High-frequency noise usually indicates electrical interference. Use a high-quality Faraday cage to enclose the electrochemical cell and grounding wires properly. Ensure all connections are secure. Low-frequency drift can be due to temperature fluctuations or mechanical vibration; isolate the setup from drafts and equipment vibration. Employ digital filtering (e.g., low-pass Savitzky-Golay) during post-processing, but be cautious not to distort the wave shape.

Q4: The Ilkovič equation predicts a different diffusion current (i_d) than I measure. What parameters should I verify? A: The Ilkovič constant is sensitive to DME characteristics and analyte properties. Precisely measure the mercury column height (h) and the drop time (t) in your experimental solution. Confirm the analyte's diffusion coefficient (D) value for your specific solvent/electrolyte system and temperature. Common causes for discrepancy include incorrect capillary m and t values, partial electrode blockage, or non-diffusion-controlled currents (e.g., kinetic currents).

Q5: How do I accurately correct for the charging (capacitive) current to achieve a true diffusion-controlled wave? A: Use pulse polarographic techniques (e.g., Normal Pulse or Differential Pulse) which are designed to minimize charging current contributions. If using DC polarography, you can perform a background subtraction by recording a polarogram of the supporting electrolyte alone under identical conditions and subtracting it from the analyte polarogram. Advanced software tools often include this subtraction function.

Table 1: Key Solution Parameters Affecting E₁/₂

| Parameter | Effect on E₁/₂ | Typical Experimental Range | Rationale |

|---|---|---|---|

| Supporting Electrolyte | Can shift by 10-100 mV | 0.1 M to 1.0 M | Changes in ionic strength and specific anion/cation adsorption alter the double-layer structure and activity coefficients. |

| pH | Significant shift for H⁺-coupled reactions | pH 2 - 12 | Direct involvement of H⁺ in redox reaction (e.g., E₁/₂ ∝ -0.059 pH for equal H⁺/e⁻ ratio). |

| Complexing Agents | Large negative shifts (up to -1 V+) | Ligand excess ≥ 10:1 | Formation of stable complexes with the oxidized form makes reduction easier (e.g., Cd²⁺ in NH₃ vs. KCl). |

| Solvent Composition | Moderate shifts (10-50 mV) | 0-50% organic modifier | Changes solvation energy, dielectric constant, and junction potentials. |

| Temperature | Minor shift (~1-2 mV/°C) | 25 ± 5 °C | Affects diffusion coefficients, equilibrium constants, and electrode kinetics. |

Table 2: Common Instrumental & Measurement Errors

| Error Source | Effect on Apparent E₁/₂ | Diagnostic Check | Correction Protocol |

|---|---|---|---|

| Uncompensated iR Drop | Shifts to more negative (reduction) | Plot i vs. E; deviation from symmetry. | Use positive feedback iR compensation or a high [supporting electrolyte]. |

| Reference Electrode Drift | Random shift between runs | Measure potential vs. a second, stable reference. | Use fresh filling solution, maintain stable T, re-calibrate frequently. |

| Incorrect Potential Scan Rate | Can shift E₁/₂ for kinetically slow systems | Vary scan rate; E₁/₂ should be constant for reversible systems. | Use standard, slow scan rates (e.g., 1-5 mV/s for DC). |

| Oxygen Interference | Overlapping waves mask E₁/₂ | Run blank solution; look for O₂ reduction waves at ~ -0.1V & -0.9V. | Purge with N₂/Ar for ≥ 15 min before scan, maintain blanket during. |

Experimental Protocols

Protocol 1: Standard DC Polarography for Reversible System E₁/₂ Determination

- Solution Preparation: Prepare a 1.0 mM solution of analyte (e.g., Cd²⁺) in a high-purity, non-complexing supporting electrolyte (e.g., 1.0 M KNO₃). Adjust pH if necessary.

- Deaeration: Transfer solution to polarographic cell. Sparge with high-purity nitrogen gas for 15 minutes to remove dissolved oxygen. Maintain a gentle N₂ blanket over the solution during measurement.

- Electrode Setup: Assemble the three-electrode system: DME as Working Electrode, Saturated Calomel Electrode (SCE) as Reference, and Platinum wire as Auxiliary.

- Instrument Settings: Set initial potential to 0.0 V vs. SCE. Set final potential to -1.4 V vs. SCE. Set scan rate to 2 mV/s. Set drop time to 2-5 seconds (use a mechanical drop knocker if integrated).

- Data Acquisition: Start the potential scan. Record the full current (i) vs. potential (E) polarogram.

- Background Subtraction: Repeat the scan on the supporting electrolyte alone and subtract this background current from the analyte polarogram.

- E₁/₂ Determination: On the corrected polarogram, identify the limiting current (id). E₁/₂ is the potential at which i = id/2.

Protocol 2: Evaluation of Complexation via E₁/₂ Shift

- Perform Protocol 1 on the metal ion in a non-complexing medium (e.g., 1 M HClO₄). Record E₁/₂(1).

- Prepare a new solution with identical metal ion concentration but in a complexing medium (e.g., 1 M NH₃ / 1 M NH₄Cl).

- Perform Protocol 1 on this new solution. Record E₁/₂(2).

- Analysis: Use the shift ΔE₁/₂ = E₁/₂(2) - E₁/₂(1) to calculate the formation constant (β) of the complex using the Lingane equation: ΔE₁/₂ = (0.059/n) log β + (0.059/n) p log [Ligand], at 25°C.

Visualizations

Title: Workflow for Precise Polarographic E₁/₂ Determination

Title: Logical Tree of Parameters Affecting E₁/₂ Measurement

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Polarographic Experiments

| Item | Function | Example & Notes |

|---|---|---|

| High-Purity Supporting Electrolyte | Minimizes migration current, provides constant ionic strength, defines electrical field. | 1.0 M KCl, KNO₃, HClO₄. Must be inert and highly soluble. |

| Oxygen Scavenging Gas | Removes interfering O₂ reduction waves from the analytical window. | Ultra-high purity (≥99.998%) Nitrogen or Argon with in-line oxygen trap. |

| Reference Electrode | Provides a stable, known potential reference point. | Saturated Calomel Electrode (SCE) or Ag/AgCl (sat'd KCl). Requires regular maintenance. |