CNT-Modified Electrodes for Gallium Detection: Advanced Strategies for Biomedical and Environmental Sensing

This article provides a comprehensive review of the latest advancements in electrode surface modification using carbon nanotubes (CNTs) for the sensitive and selective detection of gallium.

CNT-Modified Electrodes for Gallium Detection: Advanced Strategies for Biomedical and Environmental Sensing

Abstract

This article provides a comprehensive review of the latest advancements in electrode surface modification using carbon nanotubes (CNTs) for the sensitive and selective detection of gallium. It explores the foundational principles of CNT-gallium interactions, details cutting-edge fabrication methodologies for sensors, addresses critical troubleshooting and optimization challenges for real-world application, and presents rigorous validation and performance comparison against established techniques. Tailored for researchers and drug development professionals, this review synthesizes knowledge from recent high-impact studies to guide the development of robust electrochemical sensors for pharmaceutical quality control, environmental monitoring, and clinical analysis.

Gallium Detection and the CNT Advantage: Principles, Properties, and Synergies

The Critical Need for Gallium Detection in Biomedical and Environmental Contexts

Gallium is a critical metal whose applications span from high-tech electronics to advanced biomedicine. In its elemental form and as part of compounds like gallium arsenide (GaAs) and gallium nitride (GaN), it is indispensable in semiconductors, optoelectronic devices, solar cells, and LED lighting [1] [2]. Concurrently, gallium's biocompatibility and unique physicochemical properties have established its role in biomedicine, particularly in diagnostic radio-imaging and anticancer therapies [3]. However, the increased consumption of gallium carries significant environmental and health risks. Gallium compounds can cause kidney damage, hematopoietic system disorders, and other health issues upon excessive exposure [4] [2]. Consequently, developing sensitive, selective, and reliable methods for detecting gallium, especially in environmental and biological matrices, has become a pressing scientific challenge. Electrode surface modification with carbon nanotubes (CNTs) presents a promising avenue for addressing this challenge, offering enhanced sensitivity and selectivity for gallium detection [5] [6].

Gallium Detection Platforms: A Comparative Analysis

The detection of gallium(III) can be accomplished by a variety of instrumental techniques, each with distinct advantages and limitations. The table below summarizes the key characteristics of major gallium detection platforms:

Table 1: Comparison of Major Analytical Techniques for Gallium(III) Detection

| Technique | Principle | Linear Range | Limit of Detection (LOD) | Key Advantages | Key Limitations |

|---|---|---|---|---|---|

| Inductively Coupled Plasma Mass Spectrometry (ICP-MS) [6] | Ionization and mass-based detection | Not Specified | Extremely Low (implied) | High sensitivity, accuracy | High instrument cost, complex operation, laboratory-bound |

| Anodic Stripping Voltammetry (ASV) with MWCNT/SGC Lead Film Electrode [6] | Electrolytic preconcentration followed by oxidation | 3 × 10⁻⁹ to 4 × 10⁻⁷ mol L⁻¹ | 9.5 × 10⁻¹⁰ mol L⁻¹ | Ultra-low detection limit, cost-effective, portable | Requires skilled optimization, moderate throughput |

| Potentiometric Sensor with MWCNT-PVC Composite [5] | Potential change across ion-selective membrane | 7.9 × 10⁻⁷ to 3.2 × 10⁻² M | 5.2 × 10⁻⁷ M | Wide linear range, fast response (~10 s), simple operation | Moderate sensitivity compared to voltammetry |

| Colorimetric Sensor (PAH-modified AuNPs) [4] | Nanoparticle aggregation-induced color shift | 34.9–418.3 μg/L | 7.6 μg/L | Simple visual readout, instrument-free potential | Limited sensitivity, potential interference |

Electrochemical methods, particularly those leveraging carbon nanotubes, stand out for achieving detection limits comparable to ICP-MS but at a fraction of the cost and with potential for field deployment [5] [6]. The high conductivity, large surface area, and excellent electron transfer capabilities of CNTs significantly enhance the performance of electrochemical sensors [6].

Detailed Experimental Protocol: Adsorptive Stripping Voltammetry with a MWCNT/SGC Lead Film Electrode

This protocol details the determination of Ga(III) using an eco-friendly multiwall carbon nanotube/spherical glassy carbon (MWCNT/SGC) electrode modified with a lead film, as described by Grabarczyk et al. [6]. The method is highly sensitive and suitable for analyzing environmental water samples.

Principle

The method is based on Adsorptive Stripping Voltammetry (AdSV). Ga(III) ions in solution form a complex with the chelating agent cupferron. This complex is electrochemically adsorbed onto the electrode surface at a controlled potential and time. Subsequently, the potential is swept in a negative direction, reducing the metal center in the adsorbed complex (Ga³⁺ to Ga⁰). The resulting cathodic current peak is measured and is proportional to the concentration of Ga(III) in the sample [6].

Materials and Equipment

Table 2: Research Reagent Solutions for Ga(III) Detection via AdSV

| Reagent/Equipment | Specification/Function |

|---|---|

| Working Electrode | Multiwall Carbon Nanotube/Spherical Glassy Carbon (MWCNT/SGC) Electrode. Serves as the conductive substrate for lead film formation [6]. |

| Reference Electrode | Ag/AgCl or Saturated Calomel Electrode (SCE). Provides a stable and known reference potential. |

| Counter Electrode | Platinum wire. Completes the electrical circuit in the three-electrode system. |

| Supporting Electrolyte | 0.1 mol L⁻¹ Acetate Buffer, pH 5.6. Maintains optimal pH for complex formation and adsorption [6]. |

| Complexing Agent | 2 × 10⁻⁴ mol L⁻¹ Cupferron. Forms an electroactive complex with Ga(III) ions [6]. |

| Lead Film Precursor | 7 × 10⁻⁵ mol L⁻¹ Pb(II) (e.g., from Pb(NO₃)₂). In-situ formation of the lead film on the electrode substrate [6]. |

| Ga(III) Standard Solution | Prepared from Ga(NO₃)₃ in 0.01 M HCl. Used for calibration and quantification [6]. |

| Voltammetric Analyzer | Instrument capable of performing AdSV (e.g., from Metrohm, BASi). Controls potentials and records currents. |

Step-by-Step Procedure

- Electrode Preparation: The MWCNT/SGC working electrode is polished with alumina slurry (0.3 μm) on a microcloth and rinsed thoroughly with distilled water before the first use. Between measurements, a simple rinse with distilled water is sufficient [6].

- Solution Preparation: Transfer 10 mL of the supporting electrolyte (0.1 M acetate buffer, pH 5.6) to the electrochemical cell. Add the appropriate aliquots of the Pb(II) stock solution and cupferron stock solution to achieve final concentrations of 7 × 10⁻⁵ mol L⁻¹ and 2 × 10⁻⁴ mol L⁻¹, respectively. Deoxygenate the solution by purging with high-purity nitrogen or argon for 8-10 minutes.

- Lead Film Formation (in-situ): Apply a potential of -1.9 V to the working electrode for 30 seconds with stirring. This step electrodeposits a fresh lead film onto the electrode surface, which enhances the stripping signal.

- Adsorption / Preconcentration Step: Switch the stirring on and apply a potential of -0.75 V for 30 seconds. During this step, the Ga(III)-cupferron complex is adsorbed onto the lead film electrode.

- Stripping / Measurement Step: After a 5-second equilibration period without stirring, initiate the voltammetric scan from -0.75 V to -1.4 V using a square wave waveform. The recommended parameters are a frequency of 50 Hz, amplitude of 25 mV, and a step potential of 5 mV. The cathodic peak for gallium typically appears around -1.18 V (vs. Ag/AgCl) [6].

- Renewal and Calibration: For each new measurement, repeat the lead film formation step (Step 3) to ensure a fresh, reproducible electrode surface. Construct a calibration curve by repeating steps 2-5 with standard additions of Ga(III).

Critical Parameters and Troubleshooting

- pH Dependence: The pH of the acetate buffer is critical. A pH of 5.6 was identified as optimal for the formation and adsorption of the Ga(III)-cupferron complex. Deviation from this pH can significantly reduce the sensitivity [6].

- Interference Studies: The procedure is highly selective. A 100-fold excess of common ions like Al(III), Zn(II), Cd(II), Ni(II), and Fe(II) does not significantly interfere with the Ga(III) signal. Fe(III) interference can be masked by the addition of ascorbic acid [6].

- Stability and Reproducibility: The MWCNT/SGC sensor is highly stable, maintaining over 95% of its original response after 70 days of use. The relative standard deviation (RSD) for multiple measurements typically ranges from 4.5% to 6.2% [6].

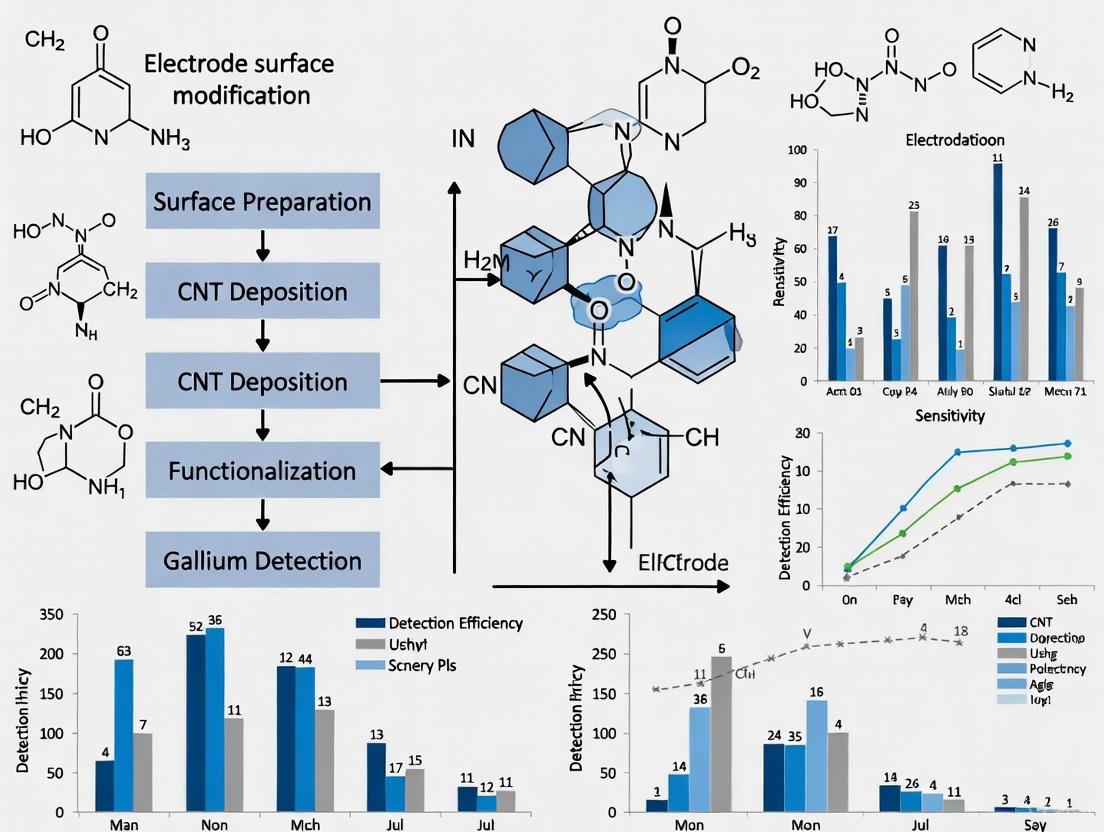

Visualization of Detection Workflow and Platform Comparison

The following diagrams illustrate the core experimental workflow and a comparative analysis of different detection platforms.

The critical need for reliable gallium detection in biomedical and environmental contexts is unequivocal. While several analytical techniques exist, electrochemical sensors incorporating carbon nanotubes represent a particularly promising path forward. The detailed protocol for the MWCNT/SGC lead film electrode demonstrates how this approach achieves exceptional sensitivity, selectivity, and practicality for monitoring gallium levels, especially in water samples [6]. As the demand for gallium continues to grow and concerns about its environmental impact and supply security intensify [2], the development and refinement of such advanced, CNT-enabled sensing platforms will be paramount for ensuring both technological progress and public health safety.

Fundamental Properties of Carbon Nanotubes for Electrochemical Sensing

Carbon Nanotubes (CNTs) have emerged as a cornerstone material in the development of advanced electrochemical sensors, particularly for trace-level detection in complex matrices. Their unique structural and electronic properties make them exceptionally suitable for enhancing sensor performance. This application note details the fundamental properties of CNTs that are critical for electrochemical sensing, with a specific focus on their application within a research program aimed at the detection of gallium species. The content is structured to provide researchers and scientists with both the theoretical foundation and practical protocols necessary to leverage CNTs in electrode surface modification for sensitive and selective gallium detection.

The exceptional suitability of CNTs for sensing stems from their intrinsic characteristics: a high specific surface area for ample analyte interaction sites, excellent electrical conductivity that facilitates efficient electron transfer, and a versatile chemistry that allows for targeted functionalization to improve selectivity [7] [8]. When integrated into an electrode, CNTs form a three-dimensional porous network that significantly increases the electroactive surface area, leading to enhanced signal strength and lower limits of detection compared to traditional electrode materials [9].

Fundamental Properties of CNTs and Their Impact on Sensing

The efficacy of CNTs in electrochemical sensors is directly derived from their physicochemical properties. The table below summarizes these key properties and their specific roles in enhancing sensor function.

Table 1: Fundamental Properties of CNTs and Their Impact on Electrochemical Sensing Performance.

| Property | Description | Impact on Sensing Performance |

|---|---|---|

| High Electrical Conductivity | CNTs exhibit ballistic charge transport and high carrier mobility, enabling efficient electron transfer [8]. | Reduces overpotential, enhances electron transfer kinetics, and amplifies the electrochemical signal. |

| Large Specific Surface Area | CNTs possess a high surface-to-volume ratio, with specific surface areas ranging from hundreds to thousands of m²/g [10]. | Provides a large number of active sites for analyte adsorption and reaction, increasing sensor sensitivity. |

| Defect Sites & Surface Chemistry | The sidewalls and ends of CNTs contain defect sites that can be functionalized with oxygenated groups or other moieties [9]. | Facilitates electrode modification, improves dispersion, and can be tailored for selective analyte binding. |

| Mechanical Strength & Chemical Stability | CNTs are structurally robust and maintain stability under a wide range of electrochemical conditions [7]. | Ensures sensor durability and a long operational lifetime, even in harsh environments. |

Sensing Mechanisms in CNT-Based Electrodes

The enhancement of electrochemical sensing by CNTs operates through several interconnected mechanisms, which are visualized in the diagram below.

Diagram 1: CNT Electrochemical Sensing Mechanisms.

The primary mechanisms include:

- Intra-CNT Charge Transfer: Analyte molecules directly adsorbing onto the CNT surface act as electron donors or acceptors, shifting the Fermi level and modulating the conductivity of the individual nanotube [8].

- Inter-CNT Junction Modulation: In a network of CNTs, the adsorption of analytes can alter the distance or potential barrier between adjacent nanotubes, significantly modulating the charge transport via quantum tunneling effects. This is often the dominant mechanism in chemiresistive sensors [8].

- Electrocatalytic Effect: The edge-plane-like defects at the ends and along the sidewalls of CNTs can catalyze redox reactions, lowering the overpotential required for electron transfer and improving the reversibility of reactions for many analytes [9].

Application in Gallium Detection Research

The detection of gallium is critical in fields ranging from environmental monitoring to medical diagnostics [10]. CNT-modified electrodes present a promising platform for developing sensitive and selective gallium sensors.

CNT-Modified Electrodes for Gallium Sensing: Performance Data

Recent research demonstrates the effectiveness of CNT-based electrodes in gallium detection assays. The following table compares key performance metrics from recent studies.

Table 2: Performance of CNT-Based Electrochemical Sensors in Gallium Detection Assays.

| Electrode Material | Detection Method | Linear Range | Limit of Detection (LOD) | Application & Key Findings | Reference |

|---|---|---|---|---|---|

| Ga/CNT modified GCE | Voltammetry | 0–200 μM | 0.05 μM | Detection of cysteine as a proxy for gallium sensor development; high sensitivity and selectivity against interferents. | [11] |

| MWCNT/Spherical Glassy Carbon with Pb Film | Adsorptive Stripping Voltammetry (AdSV) | 3 × 10⁻⁹ to 4 × 10⁻⁷ mol L⁻¹ | 9.5 × 10⁻¹⁰ mol L⁻¹ | Direct determination of Ga(III) in water samples; excellent selectivity and long-term stability (>95% response after 70 days). | [10] |

The Scientist's Toolkit: Essential Research Reagents

The following table lists key reagents and materials required for the fabrication and operation of CNT-based electrochemical sensors for gallium detection.

Table 3: Research Reagent Solutions for CNT-Based Gallium Sensing.

| Reagent/Material | Function/Description | Example Use Case |

|---|---|---|

| Multi-Walled Carbon Nanotubes (MWCNTs) | Primary conductive nanomaterial; provides high surface area and electron transfer pathways. | Base material for modifying glassy carbon or carbon paste electrodes [11] [10]. |

| Cupferron | Complexing agent; forms an electroactive complex with Ga(III) ions. | Essential for the adsorptive accumulation step in AdSV of gallium [10]. |

| Lead(II) Nitrate | Source for in-situ formation of a lead film electrode (PbFE). | Deposited on the CNT substrate to form a bismuth-like, environmentally friendly electrode for metal detection [10]. |

| Nafion 117 Solution | Cation-exchange polymer; used as a binder and protective membrane. | Helps immobilize CNTs on the electrode surface and can improve selectivity [11]. |

| Acetate Buffer (pH ~5.6) | Supporting electrolyte; provides optimal pH conditions for complex formation and electron transfer. | Used as the electrolyte medium for the Ga(III)-cupferron adsorptive stripping process [10]. |

Detailed Experimental Protocols

Protocol 1: Fabrication of a MWCNT-Modified Glassy Carbon Electrode (GCE)

This protocol describes the preparation of a stable MWCNT film on a GCE, a common substrate for subsequent functionalization specific to gallium sensing.

Materials:

- Multi-walled carbon nanotubes (MWCNTs, >98% purity)

- N,N-Dimethylformamide (DMF) or suitable solvent

- Nafion perfluorinated resin solution

- Glassy carbon working electrode (e.g., 3 mm diameter)

- Ultrasonic bath

Procedure:

- Purification of MWCNTs: (If required) Treat MWCNTs with concentrated nitric acid (e.g., 3 M) for 6-12 hours to introduce carboxyl groups and remove catalytic impurities. Wash thoroughly with deionized water until neutral pH and dry.

- Dispersion Preparation: Weigh 1-2 mg of purified MWCNTs into a glass vial. Add 1 mL of DMF. Sonicate the mixture for 30-60 minutes until a homogeneous, black, and stable dispersion is achieved with no visible aggregates.

- Electrode Pretreatment: Polish the glassy carbon electrode surface sequentially with 1.0, 0.3, and 0.05 μm alumina slurry on a microcloth. Rinse thoroughly with deionized water and then with ethanol between each polish. Dry the electrode.

- Drop-Casting Modification: Pipette a precise volume (e.g., 5-10 μL) of the well-sonicated MWCNT dispersion onto the polished surface of the GCE.

- Solvent Evaporation: Allow the solvent to evaporate at room temperature under a gentle stream of air or in a desiccator.

- Nafion Coating (Optional): To enhance film stability and impart selectivity, pipette 2-5 μL of a diluted Nafion solution (e.g., 0.1-0.5% in alcohol) over the dried MWCNT film and let it dry.

- Conditioning: The modified electrode is now ready. Condition it via cyclic voltammetry in a suitable electrolyte (e.g., 0.1 M H₂SO₄ or phosphate buffer) by scanning over a potential window until a stable voltammogram is obtained.

Protocol 2: Adsorptive Stripping Voltammetry (AdSV) for Ga(III) Detection

This protocol outlines a specific method for the ultrasensitive detection of gallium ions using a MWCNT/spherical glassy carbon electrode (MWCNT/SGCE) modified with a lead film [10].

Materials:

- Fabricated MWCNT/SGCE (or MWCNT/GCE from Protocol 1)

- Gallium(III) standard solution

- Lead(II) nitrate solution

- Cupferron solution

- Acetate buffer (0.1 M, pH 5.6)

- Nitrogen gas (for deaeration)

Workflow: The sequential steps of the AdSV protocol are illustrated below.

Diagram 2: AdSV Workflow for Gallium Detection.

Detailed Steps:

- Lead Film Formation (Plating): Immerse the MWCNT/SGCE in an electrochemical cell containing a deaerated acetate buffer (0.1 M, pH 5.6) and 7 × 10⁻⁵ mol L⁻¹ Pb(II). Apply a deposition potential of -1.9 V vs. Ag/AgCl for 30 seconds with stirring to electrodeposit a metallic lead film onto the CNT surface.

- Adsorptive Accumulation: Without removing the electrode, add the sample (or standard) containing Ga(III) and cupferron to the cell (final cupferron concentration of 2 × 10⁻⁴ mol L⁻¹). Switch the solution to quiet conditions (no stirring). Apply an adsorption potential of -0.75 V vs. Ag/AgCl for 30 seconds. During this step, the Ga(III)-cupferron complex is formed and accumulates on the surface of the lead film.

- Stripping Scan: After the accumulation period, immediately initiate a Differential Pulse Voltammetry (DPV) scan from -0.75 V to a more negative potential (e.g., -1.4 V). The reduction current of the accumulated gallium complex is measured, resulting in a peak at approximately -1.18 V.

- Quantification: The height of the stripping peak at ~-1.18 V is directly proportional to the concentration of Ga(III) in the solution. Construct a calibration curve using standard solutions for quantitative analysis.

- Electrode Renewal: For each measurement, a fresh lead film should be plated to ensure reproducibility.

Carbon nanotubes, with their exceptional electrical, structural, and chemical properties, provide a powerful platform for advancing electrochemical sensing technologies. The protocols and data presented herein establish a robust foundation for the application of CNT-modified electrodes in the specific context of gallium detection research. By leveraging the high sensitivity of adsorptive stripping voltammetry on a CNT-enhanced substrate, researchers can achieve ultra-trace detection of gallium ions, meeting the rigorous demands of environmental monitoring and biomedical analysis. The continued development of functionalization strategies will further enhance the selectivity and practical applicability of these sensors in real-world samples.

The unique interaction between carbon nanotubes (CNTs) and gallium ions/species forms the cornerstone for developing advanced electrochemical sensors and adsorption materials. CNTs serve as an exceptional scaffold due to their high specific surface area, excellent electrical conductivity, and rich surface chemistry, which promote both the adsorption of gallium and facilitate subsequent electron transfer processes [12] [6]. This synergy is critical for applications ranging from the sensitive detection of gallium in environmental samples to the efficient recovery of this technologically critical element from industrial solutions. Framed within a broader thesis on electrode surface modification, this document details the practical application of CNT-based interfaces for gallium, providing structured experimental data, detailed protocols, and essential reagent information to equip researchers in the field.

The following tables summarize key performance data and experimental conditions for various CNT-based platforms used in gallium sensing and recovery, providing a quantitative overview of the field.

Table 1: Performance of CNT-Based Electrochemical Sensors for Gallium Detection

| Sensor Type | Detection Method | Linear Range (mol L⁻¹) | Limit of Detection (mol L⁻¹) | Supporting Electrolyte | Complexing Agent | Ref. |

|---|---|---|---|---|---|---|

| PbFE/MWCNT/SGC Electrode | AdSV | 3.0 × 10⁻⁹ to 4.0 × 10⁻⁷ | 9.5 × 10⁻¹⁰ | 0.1 mol L⁻¹ Acetate Buffer, pH 5.6 | Cupferron | [6] |

| Ga/CNT Modified GCE | Voltammetry | 0 to 2.0 × 10⁻⁴ | 5.0 × 10⁻⁸ (Estimated) | Not Specified | Not Applicable | [11] |

| MWCNT-PVC Coated Pt Electrode | Potentiometry | 7.9 × 10⁻⁷ to 3.2 × 10⁻² | 5.2 × 10⁻⁷ | Not Applicable | Ionophore* | [5] |

*The potentiometric sensor used a specific 7-(2-hydroxy-5-methoxybenzyl)-5,6,7,8,9,10-hexahydro-2H benzo [b][1,4,7,10,13] dioxa triaza cyclopentadecine-3,11(4H,12H)-dione ionophore.

Table 2: Performance of CNT-Based Adsorbents for Gallium Recovery

| Adsorbent Material | Adsorption Capacity (mg/g) | Optimal pH | Equilibrium Time (min) | Key Interaction Mechanisms | Ref. |

|---|---|---|---|---|---|

| 2-CNT/UiO-66-NH₂ | 925.44 | 8 | ~60 | Ion Exchange, Chelation | [12] |

Experimental Protocols

Protocol: Fabrication of a Ga/CNT Modified Glassy Carbon Electrode (GCE) for Voltammetric Sensing

This protocol outlines the synthesis of a CNT-supported gallium catalyst and its application in modifying a GCE for the sensitive detection of biomolecules like cysteine, demonstrating the electro-catalytic utility of the Ga-CNT interface [11].

I. Materials and Reagents

- Multi-walled carbon nanotubes (MWCNT)

- Gallium(III) chloride (GaCl₃)

- Sodium borohydride (NaBH₄)

- Nafion 117 solution

- N,N-Dimethylformamide (DMF)

- Deionized water

- Glassy Carbon Electrode (GCE)

- Alumina polishing slurry

II. Step-by-Step Procedure

- Synthesis of Ga/CNT Catalyst: a. Functionalize MWCNTs via acid treatment to introduce surface groups. b. Dissolve GaCl₃ in an appropriate solvent and mix with the functionalized CNTs. c. Gradually add an aqueous solution of NaBH₄ (reducing agent) under continuous stirring to reduce Ga³⁺ to metallic Ga nanoparticles on the CNT surface. d. Filter, wash, and dry the resulting Ga/CNT composite.

Electrode Modification (Drop-Casting): a. Polish the GCE with alumina slurry sequentially to a mirror finish, then rinse thoroughly with deionized water and dry. b. Prepare an ink by dispersing 5 mg of the Ga/CNT catalyst in 1 mL of a DMF and Nafion solution. c. Sonicate the mixture for at least 30 minutes to achieve a homogeneous suspension. d. Pipette a precise volume (e.g., 5-10 µL) of the ink onto the clean, polished surface of the GCE. e. Allow the solvent to evaporate at room temperature to form a stable Ga/CNT film.

Electrochemical Measurement: a. Use the (Ga/CNT)@GCE as the working electrode in a standard three-electrode cell with Ag/AgCl as the reference and a Pt wire as the counter electrode. b. Perform Cyclic Voltammetry (CV) or Differential Pulse Voltammetry (DPV) in a solution containing the analyte to characterize the sensor's performance.

Protocol: Adsorptive Stripping Voltammetry (AdSV) of Ga(III) using a PbFE/MWCNT/SGC Electrode

This protocol describes a highly sensitive and eco-friendly method for trace-level detection of gallium in water samples using a multi-walled carbon nanotube/spherical glassy carbon (MWCNT/SGC) electrode modified with a lead film [6].

I. Materials and Reagents

- MWCNT/Spherical Glassy Carbon (SGC) Electrode

- Gallium standard solution

- Lead(II) nitrate (Pb(NO₃)₂)

- Cupferron

- Sodium acetate-acetic acid buffer (0.1 mol L⁻¹, pH 5.6)

- High-purity nitrogen gas

II. Step-by-Step Procedure

- Electrode Pretreatment and Film Formation: a. Clean the surface of the MWCNT/SGC electrode according to manufacturer specifications. b. Place the electrode into an electrochemical cell containing a deaerated acetate buffer solution (pH 5.6) and 7 × 10⁻⁵ mol L⁻¹ Pb(II). c. Apply a deposition potential of -1.9 V vs. Ag/AgCl for 30 seconds with stirring to electrodeposit a metallic lead film onto the electrode surface, forming the PbFE.

Analyte Accumulation (Adsorption Step): a. To the same cell, add the Ga(III) standard and 2 × 10⁻⁴ mol L⁻¹ cupferron. The cupferron will complex with Ga(III) in solution. b. Apply an adsorption potential of -0.75 V vs. Ag/AgCl for 30 seconds with stirring. This causes the Ga(III)-cupferron complexes to adsorb onto the lead film surface.

Stripping and Measurement: a. After the accumulation period, stop stirring and wait for a 10-second equilibration period. b. Record a voltammogram using the Square-Wave Voltammetry (SWV) technique by scanning the potential in a positive direction. c. The resulting stripping peak current is proportional to the concentration of Ga(III) in the solution.

The following workflow diagram visualizes this AdSV protocol:

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Reagents for CNT-Gallium Interface Research

| Reagent / Material | Function / Role | Example Application / Note |

|---|---|---|

| Multi-Walled Carbon Nananotubes (MWCNTs) | High-surface-area conductive support; enhances electron transfer and provides sites for metal NP decoration or analyte adsorption. | The foundational material for composite electrodes and adsorbents [11] [6]. |

| Gallium(III) Chloride (GaCl₃) | A common, soluble source of Ga(III) ions for preparing catalyst precursors or standard solutions. | Used in the synthesis of Ga/CNT nanocatalysts [11]. |

| Sodium Borohydride (NaBH₄) | Strong reducing agent used to convert ionic gallium species into metallic gallium nanoparticles on CNT surfaces. | Key for chemical reduction synthesis methods [11]. |

| Cupferron | Complexing agent that forms electroactive complexes with Ga(III), enabling its pre-concentration via adsorption on the electrode. | Critical for the sensitivity of Adsorptive Stripping Voltammetry (AdSV) [6]. |

| Nafion Perfluorinated Resin | Ion-exchange polymer binder; used to form stable films of CNT composites on electrode surfaces. | Prevents catalyst leaching and improves mechanical stability of the modified layer [11]. |

| Acetate Buffer (pH ~5.6) | Supporting electrolyte that provides a stable pH environment optimal for the formation and adsorption of Ga(III)-cupferron complexes. | A standard medium for AdSV of gallium [6]. |

| UiO-66-NH₂ MOF | Metal-Organic Framework component; provides specific binding sites (e.g., amino groups) for enhanced gallium selectivity and capacity in adsorption. | Used in composite with CNTs for high-performance recovery of Ga from solution [12]. |

Interaction Mechanisms and Conceptual Workflows

The enhanced performance of CNT-based platforms stems from synergistic interfacial interactions. The primary mechanisms include:

- Electrocatalysis: Metallic gallium nanoparticles dispersed on CNTs facilitate electron transfer reactions, lowering the overpotential for the electrochemical oxidation or reduction of target species, which is the basis for sensors like the (Ga/CNT)@GCE [11].

- Complexation & Adsorption: In AdSV, complexing agents like cupferron form stable, electroactive complexes with Ga(III) ions in solution. These complexes are then selectively adsorbed onto the hydrophobic, high-surface-area CNT-based electrode, leading to significant pre-concentration prior to measurement [6].

- Ion Exchange & Chelation: In adsorption/recovery applications, composite materials like CNT/UiO-66-NH₂ interact with Ga(III) through ion exchange with protons on functional groups (e.g., -NH₂, -OH) and the formation of stable coordination bonds (chelation) [12].

The following diagram synthesizes these mechanisms into a unified conceptual framework for understanding CNT-gallium interactions across different applications:

The accurate detection of gallium and its compounds is critical across diverse fields, from environmental monitoring and industrial process control to medical diagnostics and drug development. Traditional analytical techniques, while effective, often involve expensive instrumentation, complex sample preparation, and lengthy analysis times. Electrochemical methods present a compelling alternative, offering portability, low cost, and rapid results. A significant challenge, however, has been achieving the requisite sensitivity and selectivity for trace-level analysis, particularly in complex sample matrices like biological fluids or environmental waters.

The integration of carbon nanotubes (CNTs) into electrode design has been a pivotal advancement in overcoming these traditional limitations. CNTs confer a unique combination of high electrical conductivity, a large specific surface area, and rich surface chemistry to electrodes. This application note delineates how these properties are harnessed to fabricate advanced electrochemical sensors for gallium detection, providing detailed protocols and a toolkit for researchers in the field.

Quantitative Performance Enhancement with CNTs

The modification of electrode surfaces with CNTs consistently results in superior analytical performance. The following table summarizes key metrics from recent studies, demonstrating the enhancements in sensitivity and detection limits achievable with CNT-based platforms.

Table 1: Performance Comparison of Gallium Sensors Utilizing CNT-Modified Electrodes

| Electrode Type | Detection Method | Linear Range (mol L⁻¹) | Limit of Detection (mol L⁻¹) | Key Characteristics | Reference |

|---|---|---|---|---|---|

| PbFE/MWCNT-SGCE | AdSV | 3.0 × 10⁻⁹ – 4.0 × 10⁻⁷ | 9.5 × 10⁻¹⁰ | Wide linear range, excellent for environmental waters | [6] [13] |

| Ga/CNT modified GCE | Voltammetry | 0 – 2.0 × 10⁻⁴ | 5.0 × 10⁻⁸ | High current sensitivity of 0.0081 μA/μM | [11] |

| MWNT-PVC Coated Pt | Potentiometry | 7.9 × 10⁻⁷ – 3.2 × 10⁻² | 5.2 × 10⁻⁷ | Good selectivity over 19 metal ions, fast response | [5] |

The data shows that CNT-based electrodes achieve remarkably low detection limits, down to the sub-nanomolar level, which is crucial for detecting trace concentrations of gallium in real-world samples. The expanded linear range allows for quantification across a wide concentration span without sample dilution.

Detailed Experimental Protocols

Protocol 1: Fabrication of a Ga/CNT Modified Glassy Carbon Electrode (GCE) for Analyte Detection

This protocol details the synthesis of a CNT-supported gallium catalyst and its application in modifying a GCE for the sensitive detection of molecules like cysteine, demonstrating the utility of Ga/CNT composites in sensing [11].

Research Reagent Solutions:

- Gallium (III) Chloride (GaCl₃): ≥99.999% purity, serves as the gallium precursor.

- Multi-Walled Carbon Nanotubes (MWCNTs): Purity ≥98%, acts as the high-surface-area support.

- Sodium Borohydride (NaBH₄): 99% purity, used as the chemical reducing agent.

- Nafion 117 Solution (5%): A perfluorosulfonated ionomer, used as a binding agent to form a stable film on the electrode.

- Glassy Carbon Electrode (GCE): A standard 3 mm diameter GCE as the substrate.

Procedure:

- Synthesis of Ga/CNT Catalyst:

- Impregnate MWCNTs with an aqueous solution of GaCl₃ to achieve a target gallium loading of 5% by weight [11].

- Slowly add a NaBH₄ solution under constant stirring to reduce the gallium ions to metallic gallium nanoparticles deposited on the CNT surface [11].

- Filter the resulting material, wash thoroughly with deionized water, and dry overnight [11].

- Electrode Modification:

- Prepare an ink by dispersing 5 mg of the synthesized Ga/CNT catalyst in 1 mL of a solution containing deionized water, ethanol, and 50 μL of Nafion solution (acts as a binder) [11].

- Polish the bare GCE with alumina slurry (0.05 μm) and rinse thoroughly with deionized water.

- Deposit a precise volume (e.g., 10 μL) of the homogeneous ink onto the mirror-like surface of the GCE.

- Allow the solvent to evaporate at room temperature to form a stable Ga/CNT@GCE.

Experimental Workflow Diagram:

Protocol 2: Determination of Ga(III) using a MWCNT-Based Lead Film Electrode

This protocol describes an eco-friendly adsorptive stripping voltammetry (AdSV) method for the ultra-trace determination of gallium in water samples, highlighting the role of CNTs in enhancing substrate performance [6] [13].

Research Reagent Solutions:

- MWCNT/Spherical Glassy Carbon (SGC) Electrode: The composite substrate electrode.

- Lead(II) Nitrate (Pb(NO₃)₂): Source of Pb²⁺ ions for in-situ lead film formation.

- Cupferron: The complexing agent that forms an adsorable complex with Ga(III).

- Acetate Buffer (0.1 M, pH 5.6): The supporting electrolyte.

Procedure:

- Electrode Pre-treatment: Polish the MWCNT/SGC electrode surface before each measurement to ensure reproducibility.

- Lead Film Formation (in-situ):

- Adsorptive Accumulation:

- Stripping and Measurement:

- After a quiet time of 5 seconds, initiate a cathodic potential scan.

- Record the stripping peak current for the reduction of the adsorbed Ga(III) complex, which is proportional to the concentration of Ga(III) in the solution [6].

- Cleaning: Apply a cleaning potential to strip off any remaining material from the electrode surface between measurements.

Analytical Pathway Diagram:

The Scientist's Toolkit: Essential Research Reagents

Table 2: Key Reagents for CNT-Enhanced Gallium Sensor Development

| Reagent / Material | Function / Role in Experiment |

|---|---|

| Multi-Walled Carbon Nanotubes (MWCNTs) | Primary conductive scaffold; provides high surface area for catalyst deposition or analyte adsorption, enhancing sensitivity [11] [6]. |

| Gallium (III) Chloride (GaCl₃) | Standard precursor for gallium ions, used in sensor fabrication (as catalyst) or as a standard in detection assays [11]. |

| Nafion Solution | Cation-exchange polymer binder; forms a stable, selective film on the electrode surface, improving stability and repelling anions [11]. |

| Cupferron | Complexing agent; forms an electroactive complex with Ga(III) for highly sensitive adsorptive stripping voltammetry [6] [13]. |

| Lead(II) Nitrate | Source for lead film formation; the lead film electrode is an eco-friendly alternative to mercury electrodes for trace metal analysis [6]. |

| Acetate Buffer | Supporting electrolyte; maintains optimal pH for complex stability and electrochemical reaction [6]. |

The strategic modification of electrodes with carbon nanotubes represents a significant leap forward in electrochemical gallium detection. By directly addressing the traditional limitations of sensitivity and selectivity, CNT-based sensors unlock new possibilities for reliable, cost-effective, and rapid analysis. The detailed protocols and reagent information provided here equip researchers and drug development professionals with the foundational knowledge to implement and further innovate upon these advanced sensing platforms.

Carbon nanotubes (CNTs) have emerged as a cornerstone material for electrode surface modification, significantly enhancing the performance of electrochemical sensors. Their exceptional properties, including high surface area, excellent electrical conductivity, and remarkable mechanical strength, make them particularly advantageous for detecting metal ions such as gallium. Within the specific context of gallium detection research, the choice between multi-walled carbon nanotubes (MWCNTs), single-walled carbon nanotubes (SWCNTs), and their functionalized variants is critical, as each offers distinct advantages and limitations. This application note provides a detailed comparison of these CNT types and outlines standardized protocols for their use in modifying electrodes for gallium (Ga(III)) sensing, providing researchers and scientists with a practical framework for sensor development.

CNT Types: A Comparative Analysis

Structural and Property Comparison

CNTs are classified based on their structural configuration, which directly influences their material properties and suitability for sensing applications. The table below summarizes the key characteristics of SWCNTs, MWCNTs, and functionalized MWCNTs.

Table 1: Comparative Analysis of Carbon Nanotube Types for Sensor Applications

| Property | Single-Walled CNTs (SWCNTs) | Multi-Walled CNTs (MWCNTs) | Functionalized MWCNTs (f-MWCNTs) |

|---|---|---|---|

| Structure | Single layer of graphene [14] | Multiple concentric graphene cylinders [14] | MWCNTs with surface functional groups [15] |

| Typical Diameter | 0.4–3.0 nm [14] | 1.4–100 nm [14] | Similar to MWCNTs |

| Synthesis | Requires catalyst; bulk synthesis is difficult [14] | Can be produced without catalyst; bulk synthesis is easy [14] | Produced via post-synthesis modification (e.g., acid treatment) [15] |

| Electrical Properties | Behavior depends on chirality (metallic or semiconducting) [14] | Generally metallic conductivity [14] | Conductivity can be altered by covalent functionalization [14] |

| Mechanical Strength | High stiffness and strength [14] | Superior mechanical strength [14] | High mechanical strength retained |

| Dispersibility & Processability | Tend to aggregate; poor solubility [14] | Tend to aggregate; poor solubility [14] | Greatly enhanced dispersibility in solvents and polymers [14] [16] |

| Advantages for Sensing | High aspect ratio, sensitive electronic properties | High conductivity, ease of bulk production, structural robustness [5] | Covalent attachment for biomolecules, enhanced biocompatibility, improved interfacial interactions with matrix [17] [16] |

| Limitations for Sensing | Purity issues, defect generation upon functionalization [14] | Complex structure [14] | Defect generation can affect electrical properties [14] |

Selection for Gallium Detection

In gallium detection research, MWCNTs are the most prominently and successfully employed CNT type. Their widespread use is attributed to a favorable combination of high electrical conductivity for sensitive signal transduction, robust mechanical properties, and easier, more cost-effective bulk production compared to SWCNTs [14]. For instance, a composite electrode with MWCNTs and polyvinylchloride (PVC) demonstrated a wide linear detection range for Ga(III) from 7.9 × 10⁻⁷ M to 3.2 × 10⁻² M [5]. Furthermore, MWCNTs serve as an excellent substrate for creating advanced sensing interfaces, such as lead film electrodes for adsorptive stripping voltammetry, achieving detection limits as low as 9.5 × 10⁻¹⁰ M for Ga(III) [6].

Functionalization of MWCNTs is a key step to overcome their inherent tendency to agglomerate and to tailor their surface properties for specific applications. This process involves attaching chemical functional groups to the CNT surface, which decreases van der Waals forces and enhances interactions with the solvent or polymer matrix, leading to a more homogeneous dispersion [14]. Improved dispersion directly translates to better electrode performance and reproducibility. Functionalization also enables the covalent immobilization of ionophores or biomolecules, enhancing the sensor's selectivity and stability [17].

Table 2: Common Functionalization Methods for CNTs

| Method | Type | Process | Key Outcome |

|---|---|---|---|

| Acid Oxidation | Covalent | Treatment with strong acids (e.g., H₂SO₄/HNO₃) [15] | Generates oxygenated groups (e.g., -COOH) for better aqueous dispersibility and further chemistry [15]. |

| Amino-Functionalization | Covalent | Attachment of amine (-NH₂) groups [17] | Allows covalent bonding to polymers and biological systems (e.g., DNA) [17]. |

| Polymer Wrapping | Non-covalent | Coating with polymers [14] | Enhances dispersion without altering CNT structure; preserves electronic properties. |

Experimental Protocols for Gallium Detection

The following protocols detail two established methodologies for detecting gallium using CNT-modified electrodes.

Protocol 1: Potentiometric Sensor Using MWCNT-PVC Composite Electrode

This protocol describes the construction of a coated-wire ion-selective electrode for the potentiometric detection of Ga(III), based on a published study [5].

Workflow Overview:

Step 1: Preparation of MWCNT-PVC Composite Membrane

- Weighing: Accurately weigh the following components into a glass vial:

- 7-(2-hydroxy-5-methoxybenzyl)-5,6,7,8,9,10-hexahydro-2H-benzo[b][1,4,7,10,13]dioxatriazacyclopentadecine-3,11(4H,12H)-dione ionophore (1.0 wt%)

- Multi-walled carbon nanotubes (MWCNTs, 4.0 wt%)

- Polyvinylchloride (PVC, 31.0 wt%)

- Plasticizer (e.g., o-nitrophenyl octyl ether (o-NPOE), 64.0 wt%) [5].

- Dissolution: Add 5 mL of tetrahydrofuran (THF) to the vial and stir vigorously until all components are fully dissolved, forming a homogeneous black mixture.

Step 2: Electrode Coating

- Substrate Preparation: Clean a platinum wire electrode (diameter ~1.5 mm) following standard electrochemical cleaning procedures (e.g., polishing, sonication).

- Coating: Dip the clean platinum wire into the MWCNT-PVC composite mixture to coat its tip.

- Drying: Allow the solvent to evaporate overnight at room temperature, forming a stable polymeric membrane on the wire. Repeat the dipping process if a thicker coating is required.

Step 3: Electrode Conditioning

- Condition the newly prepared electrode by soaking it in a 1.0 × 10⁻³ M solution of Ga(NO₃)₃ for 24 hours. Then, store it in the same solution when not in use.

Step 4: Potentiometric Measurement & Data Analysis

- Setup: Assemble a standard potentiometric cell with the modified electrode as the working electrode and a suitable reference electrode (e.g., Ag/AgCl).

- Calibration: Immerse the electrode in a series of standard Ga(III) solutions with concentrations ranging from 1.0 × 10⁻⁷ M to 1.0 × 10⁻¹ M. Measure the potential (mV) developed for each solution under stirring.

- Analysis: Plot the measured potential against the logarithm of the Ga(III) concentration. The sensor should yield a linear (Nernstian) response with a slope of approximately 19.68 ± 0.40 mV/decade [5].

Protocol 2: Voltammetric Sensor Using MWCNT/Spherical Glassy Carbon Electrode

This protocol outlines a highly sensitive method for Ga(III) detection using adsorptive stripping voltammetry (AdSV) at a lead film electrode formed on an MWCNT substrate [6].

Workflow Overview:

Step 1: Fabrication of MWCNT/Spherical Glassy Carbon Electrode (MWCNT/SGCE)

- Mixing: Prepare a homogeneous paste by thoroughly mixing spherical glassy carbon powder, multi-walled carbon nanotubes, and an epoxy resin binder.

- Packing: Pack the resulting composite paste into a Teflon tube electrode body.

- Curing: Allow the epoxy resin to cure completely according to the manufacturer's instructions.

- Polishing: Before use, polish the electrode surface on fine wet polishing paper and rinse thoroughly with deionized water [6].

Step 2: Preparation of Measurement Solution

- Prepare the supporting electrolyte solution containing 0.1 M acetate buffer (pH 5.6), 7 × 10⁻⁵ M Pb(II), and 2 × 10⁻⁴ M cupferron (complexing agent).

Step 3: In-situ Lead Film Deposition

- Immerse the MWCNT/SGCE in the measurement solution. Apply a potential of -1.9 V vs. Ag/AgCl for 30 seconds with stirring. This step electrochemically deposits a fresh lead film onto the electrode surface.

Step 4: Adsorption of Ga(III)-Cupferron Complex

- After film deposition, change the potential to -0.75 V vs. Ag/AgCl and hold for 30 seconds with stirring. This facilitates the accumulation and adsorption of the electroactive Ga(III)-cupferron complex onto the lead film surface.

Step 5: Stripping Scan and Data Analysis

- Scan: Immediately after the accumulation step, record a square-wave voltammogram by scanning from -0.75 V to -1.4 V vs. Ag/AgCl.

- Analysis: Measure the peak current occurring at approximately -1.18 V vs. Ag/AgCl. Construct a calibration curve by plotting this peak current against the concentration of Ga(III) in the standard solutions. This method can achieve a detection limit in the nanomolar to sub-nanomolar range [6].

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Reagents for CNT-Based Gallium Sensor Development

| Reagent/Material | Function/Application | Example from Literature |

|---|---|---|

| Multi-Walled Carbon Nanotubes (MWCNTs) | Primary conductive nanomaterial; enhances electrode surface area and electron transfer kinetics. | Used in composite with PVC for a potentiometric Ga(III) sensor [5]. |

| Functionalized MWCNTs (f-MWCNTs) | Improve dispersion in polymer matrices and enhance biocompatibility. | Acid-treated MWCNTs used in flexible thermoelectric materials [15]. |

| Ga(III) Ionophore | Selective recognition element for gallium ions in potentiometric sensors. | A specific hexacyclic triaza compound was used [5]. |

| Cupferron | Complexing agent for Ga(III) in adsorptive stripping voltammetry; forms an electroactive complex. | Used for highly sensitive voltammetric detection of Ga(III) [6]. |

| Polyvinylchloride (PVC) | Polymer matrix for creating a robust, ion-selective membrane on the electrode. | Served as the binder in the MWCNT-PVC composite [5]. |

| Plasticizer (e.g., o-NPOE) | Imparts flexibility and mobility to ionophores within the PVC membrane. | o-Nitrophenyl octyl ether (o-NPOE) was a key membrane component [5]. |

| Lead Nitrate (Pb(II)) | Source of lead ions for forming an in-situ lead film electrode for stripping voltammetry. | Used to form the sensing film for Ga(III) detection [6]. |

The strategic selection and application of carbon nanotubes are pivotal for advancing gallium detection technologies. MWCNTs, particularly in their functionalized forms, have proven to be the most practical and effective choice, offering an optimal balance of performance, processability, and cost. The detailed protocols and comparative data provided in this application note serve as a foundational guide for researchers developing next-generation electrochemical sensors for gallium and other metal ions, enabling more sensitive, selective, and reliable analytical methods.

Fabricating CNT-Based Gallium Sensors: From Synthesis to Real-World Application

The selection of an appropriate electrode substrate is a foundational step in the development of sensitive and reliable electrochemical sensors, particularly for specialized applications such as gallium detection. The substrate forms the critical interface between the electrical circuit and the analyte, influencing electron transfer kinetics, catalytic activity, stability, and overall detection performance. For research focusing on gallium detection using carbon nanotube (CNT) modifications, the substrate choice directly impacts the effectiveness of the CNT functionalization, the accessibility of gallium binding sites, and the reproducibility of analytical signals. This application note provides a structured framework for selecting and optimizing electrode substrates, with specific consideration to their integration with CNT-based modifications for gallium sensing applications.

The performance of any electrochemical sensor is governed by the synergistic relationship between the substrate material, any modifying layers, and the target analyte. Genetic Code Expansion (GCE) technologies, while primarily biological tools for protein engineering, exemplify the importance of precision modification at functional interfaces [18] [19]. Similarly, in electrode design, the strategic modification of a chosen substrate with carbon nanotubes creates a tailored interface. This composite architecture can significantly enhance surface area, facilitate electron transfer, and provide anchoring sites for specific gallium complexes or recognition elements, as suggested by studies on gallium(III)-modified electrodes [20] [21].

Electrode Substrate Options and Characteristics

A range of electrode substrates is available, each offering distinct advantages and limitations. The choice depends on the required electrochemical window, conductivity, chemical stability, and compatibility with CNT immobilization strategies. The following table summarizes key substrate materials relevant to gallium detection research.

Table 1: Key Electrode Substrate Materials for Sensor Design

| Substrate Material | Key Properties | Advantages | Limitations | Suitability for Ga Detection/CNT Modification |

|---|---|---|---|---|

| Platinum (Pt) | High conductivity, inert, biocompatible, strong electrocatalytic activity for many reactions [22]. | Excellent electrochemical stability, suitable for anodic reactions, can be electroplated with Pt black to increase surface area [22]. | High cost, prone to fouling, high background current in some potential windows. | High. Serves as a robust, high-conductivity base. CNTs can mitigate fouling and tailor surface properties. |

| Platinum-Titanium (Pt-Ti) | Titanium core with a platinum surface layer [23]. | Combines Pt's surface properties with Ti's mechanical strength and lower cost; long lifespan and high stability [23]. | Complex fabrication; potential for delamination of Pt coating under extreme stress. | Very High. A robust and stable substrate for developing durable CNT-modified sensors. |

| Gold (Au) | High conductivity, inert, easily modified with thiol-based self-assembled monolayers. | Facile surface functionalization, well-defined surface chemistry. | Soft material, relatively expensive. | High. Excellent for controlled functionalization of CNTs via thiol chemistry. |

| Glassly Carbon (GC) | Disordered carbon with glassy, smooth surface [24]. | Wide potential window, low background current, inert. | Lower conductivity than metals, surface can be difficult to functionalize uniformly. | Moderate to High. A standard substrate; requires activation (e.g., electrochemical) for optimal CNT adhesion. |

| Carbon Nanotube Composites | High surface area, excellent electrical conductivity, modifiable surface chemistry. | Maximizes the benefits of CNTs, can be designed with polymers for flexibility. | Consistency in bulk composite fabrication can be challenging. | Very High. The substrate itself is CNT-based, ideal for maximizing surface area for gallium interaction. |

| Gallium Nitride (GaN) | Wide bandgap semiconductor, high thermal conductivity, chemically stable [25]. | High thermal/chemical stability, potential for creating Ga-sensing interfaces. | Lower intrinsic conductivity than metals, requires ohmic contacts for electrochemical use. | Emerging. Direct use of GaN or its composites with g-C3N4 [25] could offer unique gallium-affinitive properties. |

Substrate Selection Workflow

Selecting the optimal substrate requires a systematic approach that aligns material properties with the specific requirements of the sensing application. The following diagram outlines the key decision-making pathway.

The Scientist's Toolkit: Essential Research Reagents

The following table details key materials and reagents required for the fabrication and modification of electrodes for advanced sensing research.

Table 2: Essential Research Reagents for Electrode Modification

| Reagent/Material | Function/Application | Key Characteristics & Notes |

|---|---|---|

| Platinum Chloride (PtCl₄) | Electroplating precursor for creating platinum black surfaces on Pt substrates [22]. | Increases effective surface area, reducing polarization impedance. Recommended current density: ~10 mA/cm² [22]. |

| Nitrilotriacetic Acid (NTA) | Chelator for immobilizing metal ions (e.g., Ga³⁺) on electrode surfaces [20] [21]. | Forms stable complexes with gallium. Use with a spacer (e.g., isothiocyanobenzyl-NTA) for improved flexibility and reactivity [21]. |

| Gallium(III) Acetylacetonate (Ga(AA)₃) | Precursor for creating gallium-modified electrode surfaces via casting [20] [21]. | Provides a higher density of surface Ga³⁺ compared to NTA methods, but may offer less flexibility [21]. |

| Functionalized CNTs | The primary modifying agent to enhance surface area and electron transfer. | Carboxylated or amine-functionalized CNTs are preferable for covalent attachment to substrates or gallium complexes. |

| Ionic Liquids (e.g., EMIM-TFSI) | Component of composite electrodes or a dispersion medium for CNTs [26]. | Enhants ionic conductivity, can form poly(ionic liquid) gel boundaries in composites, improving damage tolerance [26]. |

| Poly(vinylidene fluoride-co-hexafluoropropylene) (PVDF-HFP) | Polymer binder for composite electrodes [26]. | Provides mechanical integrity; its polar β-phase offers improved ionic conductivity [26]. |

| Cetyltrimethylammonium bromide (CTAB) | Surfactant for dispersing CNTs and modifying surface wetting properties [27]. | Aids in creating stable, homogeneous CNT suspensions for drop-casting. |

Experimental Protocol: CNT Modification of a Platinum-Titanium Electrode for Gallium Sensing

This protocol details the steps for modifying a Pt-Ti electrode with a carbon nanotube layer, functionalizing it for enhanced gallium sensitivity, and evaluating its performance.

Materials and Equipment

- Substrate: Platinum-Titanium (Pt-Ti) electrode wire or disk (e.g., 1-3 mm diameter).

- CNT Dispersion: 1 mg/mL carboxylated multi-walled carbon nanotubes in dimethylformamide (DMF), sonicated for 30+ minutes.

- Functionalization Agents: 10 mM solution of isothiocyanobenzyl-NTA in DMF, 5 mM GaCl₃ solution in slightly acidic water (pH ~6).

- Electrochemical Cell: Standard three-electrode setup with Ag/AgCl reference and Pt wire counter electrode.

- Instruments: Potentiostat/Galvanostat, ultrasonic bath, magnetic stirrer, pH meter.

Step-by-Step Procedure

Part A: Substrate Pretreatment and CNT Modification

- Mechanical Polishing: Polish the Pt-Ti electrode surface sequentially with 1.0, 0.3, and 0.05 µm alumina slurry on a microcloth pad.

- Ultrasonic Cleaning: Rinse the electrode thoroughly with deionized water and sonicate in ethanol and then in deionized water for 2 minutes each to remove residual alumina.

- Electrochemical Activation: Perform cyclic voltammetry (CV) in 0.5 M H₂SO₄ from -0.2 V to 1.2 V (vs. Ag/AgCl) at a scan rate of 100 mV/s until a stable voltammogram characteristic of clean Pt is obtained.

- CNT Deposition (Drop-Casting): Pipette 5-10 µL of the well-dispersed CNT suspension onto the pretreated Pt-Ti electrode surface.

- Drying: Allow the electrode to dry in a clean environment at room temperature for 1 hour.

- Rinsing: Gently rinse the modified electrode with pure DMF to remove loosely bound CNTs, leaving a stable CNT film.

Part B: Functionalization for Gallium Sensing

- NTA Immobilization: Immerse the CNT/Pt-Ti electrode in the 10 mM isothiocyanobenzyl-NTA solution for 12 hours at room temperature. The isothiocyanate group will react with functional groups on the CNTs.

- Washing: Rinse the electrode copiously with DMF and phosphate buffer (pH 8.0) to remove unreacted NTA.

- Gallium Loading: Soak the NTA-modified electrode in the 5 mM GaCl₃ solution for 1 hour with gentle stirring. The Ga³⁺ ions will chelate with the immobilized NTA.

- Final Rinse: Rinse with deionized water to remove uncomplexed Ga³⁺. The functionalized electrode (Ga-NTA/CNT/Pt-Ti) is now ready for use.

The entire fabrication workflow is summarized in the following diagram.

Performance Validation and Characterization

- Cyclic Voltammetry (CV): Characterize the electrode in a standard redox probe (e.g., 1 mM K₃[Fe(CN)₆] in 0.1 M KCl). Compare the peak separation (ΔEp) and current before and after modification. A well-conducted modification should show increased peak current and a decreased ΔEp, indicating enhanced electron transfer.

- Electrochemical Impedance Spectroscopy (EIS): Perform EIS in the same redox probe solution. Fit the data to a Randles circuit model. A significant decrease in charge transfer resistance (Rct) after CNT modification confirms improved electrode kinetics.

- Analytical Performance: Using a technique like Square Wave Voltammetry (SWV), generate a calibration curve by measuring the signal response to standard solutions of gallium ions across a relevant concentration range (e.g., 10⁻¹¹ to 10⁻⁸ M, based on literature [21]). Calculate the limit of detection (LOD), sensitivity, and linear dynamic range.

Troubleshooting and Data Interpretation

Common challenges during electrode modification and their solutions are listed below.

Table 3: Troubleshooting Guide for Electrode Modification

| Problem | Potential Cause | Solution |

|---|---|---|

| Unstable or non-adherent CNT film | Inadequate substrate cleaning; poor dispersion of CNTs; insufficient functional groups on CNTs. | Ensure rigorous electrochemical pretreatment. Use fresh, well-sonicated CNT dispersions with appropriate surfactants (e.g., CTAB [27]) or functionalized CNTs. |

| High background noise | Contaminated electrode surface; incomplete removal of unbound reagents. | Implement stringent cleaning protocols between steps. Ensure thorough rinsing after each modification step. |

| Low sensitivity to gallium | Low density of NTA sites; incomplete Ga³⁺ loading; passivation of the CNT layer. | Optimize NTA concentration and immobilization time. Verify solution pH during Ga loading is optimal for NTA-Ga complexation. |

| Poor reproducibility between electrodes | Inconsistent CNT film thickness; variations in drop-casting or drying. | Automate deposition using a micro-syringe pump. Control the drying environment (temperature, humidity). |

The strategic selection and meticulous modification of the electrode substrate are paramount for pushing the boundaries of sensor performance in gallium detection research. A Pt-Ti substrate provides an excellent combination of conductivity, stability, and durability, serving as a robust platform for subsequent nanoscale engineering. The integration of a carbon nanotube layer significantly augments the electroactive surface area and facilitates electron transfer, while the final functionalization with NTA-Ga complexes imparts the necessary specificity and reactivity. By adhering to the detailed protocols and selection criteria outlined in this document, researchers can systematically develop, characterize, and troubleshoot high-performance electrodes tailored for their specific analytical challenges.

The functionalization of electrode surfaces with carbon nanotubes (CNTs) is a cornerstone of modern electroanalytical chemistry, pivotal for enhancing the performance of electrochemical sensors and biosensors. The method of CNT immobilization directly influences critical sensor parameters, including sensitivity, selectivity, stability, and reproducibility [28] [29]. This application note details three principal CNT immobilization techniques—drop-casting, electrodeposition, and in-situ growth—providing standardized protocols and a comparative analysis. The content is specifically framed within research focused on electrode surface modification for the detection of gallium and other metals, serving as a fundamental methodology chapter for a broader thesis in this field.

The selection of an appropriate immobilization strategy is not trivial; it entails balancing experimental complexity, available infrastructure, and the required performance characteristics of the final sensor [29]. Physical methods like drop-casting rely on weak physisorption forces, while electrochemical methods and in-situ growth foster stronger, more integrated interfaces between the CNTs and the electrode substrate [30] [28]. The following sections dissect each technique, providing researchers with the necessary tools to make an informed choice and execute the protocols effectively.

Techniques, Protocols, and Comparative Analysis

Drop-Casting

Overview: Drop-casting is a widely used physical adsorption technique due to its straightforward operation and minimal equipment requirements [31] [29]. It involves depositing a suspension of CNTs onto an electrode surface and allowing the solvent to evaporate, leaving behind a CNT film.

- Key Mechanism: The CNTs adhere to the electrode surface through weak forces such as van der Waals interactions, π-π stacking, and electrostatic forces [29].

- Advantages: The method is inexpensive, quick, and requires no specialized equipment, making it accessible for initial proof-of-concept studies [31].

- Disadvantages: A significant drawback is the propensity for the formed film to be non-uniform, often exhibiting the "coffee-ring" effect where CNTs accumulate at the droplet's edge upon solvent evaporation [29]. This can lead to poor reproducibility, agglomeration of CNTs, and mechanical instability of the film, which may delaminate during extended use or in flow systems [30] [29].

Detailed Protocol: Drop-Casting of CNTs onto a Glassy Carbon Electrode (GCE)

- Step 1: CNT Functionalization and Dispersion. Begin by functionalizing multi-walled CNTs (MWCNTs) to introduce surface charges that aid suspension. Reflux 200 mg of CNTs in 100 mL of 3 M HNO₃ for 24 hours. Filter the resulting solid and wash thoroughly with ultrapure water to remove acid residues. Dry the functionalized CNTs (fCNTs) at 120°C for 12 hours [30]. To prepare the casting suspension, disperse 1-2 mg of the fCNTs in 1 mL of a suitable solvent (e.g., dimethylformamide, ethanol, or aqueous solution with a surfactant) via ultrasonication for 30-60 minutes to achieve a homogeneous suspension [31].

- Step 2: Electrode Pretreatment. Clean and polish the GCE (e.g., 3 mm diameter) successively with 1.0, 0.3, and 0.05 µm alumina slurry on a microcloth. Rinse thoroughly with ultrapure water between each polishing step and sonicate in an ethanol/water bath for 5 minutes to remove any adsorbed alumina particles [29].

- Step 3: Film Deposition. Pipette a precise volume (typically 5-10 µL) of the well-dispersed fCNT suspension and drop it directly onto the mirror-like polished surface of the GCE.

- Step 4: Drying. Allow the solvent to evaporate under controlled conditions. This can be done at room temperature, under a gentle stream of nitrogen gas, or by placing the electrode under an ultraviolet lamp to form a dry CNT film [29]. The electrode is now ready for use or further modification.

Electrodeposition

Overview: Electrodeposition, or electrochemically assisted deposition, is a potent technique for creating uniform and adherent CNT films on conducting surfaces. This method offers superior control over film thickness and morphology compared to drop-casting [30] [31].

- Key Mechanism: The process involves applying a controlled potential or current to an electrode immersed in a CNT suspension. The electric field induces a force on the charged, functionalized CNTs, causing them to migrate and deposit firmly onto the electrode surface [30] [29].

- Advantages: It produces homogenous, mechanically stable films with excellent control over thickness and uniformity. The process is reproducible and facilitates the creation of well-defined layers [30] [31].

- Disadvantages: It requires a potentiostat and a standard three-electrode setup. The process is more complex than drop-casting, and the CNTs must be sufficiently functionalized to possess a surface charge for successful deposition [30].

Detailed Protocol: Electrodeposition of fCNTs via Potential Pulses

- Step 1: CNT Functionalization and Dispersion. Follow the same functionalization and dispersion procedure described in the drop-casting protocol (Step 1) to create an aqueous suspension of fCNTs. For electrodeposition, the addition of a supporting electrolyte (e.g., 0.01 M Na₂SO₄) to the fCNT dispersion is often beneficial [30].

- Step 2: Electrochemical Setup. Utilize a three-electrode cell with a polished GCE as the working electrode, a platinum wire as the counter electrode, and an Ag/AgCl electrode as the reference electrode. Immerse the working electrode in the fCNT working solution.

- Step 3: Pulsed Electrodeposition. Instead of a constant potential, apply a series of chronoamperometric pulses. A typical protocol involves applying a potential of 0.6 V vs. Ag/AgCl for 1 second, followed by a rest interval at 0.0 V for 0.5 seconds. This cycle is repeated for a total of 10 to 1400 pulses, depending on the desired film thickness [30].

- Step 4: Post-Deposition Processing. After the desired number of pulses, withdraw the working electrode from the solution, rinse it gently with ultrapure water to remove loosely adsorbed CNTs, and dry it under an infrared lamp. The modified electrode is now ready for electrochemical characterization or use [30].

In-Situ Growth

Overview: In-situ growth involves the direct synthesis of CNTs on the electrode substrate, typically using chemical vapor deposition (CVD). This technique creates a highly robust, integrated interface between the CNTs and the substrate, which is ideal for demanding applications [28].

- Key Mechanism: A catalyst layer (e.g., Ni, Fe) is first deposited on the substrate. At elevated temperatures, a carbon-containing precursor gas is introduced, which decomposes on the catalyst particles, leading to the nucleation and growth of CNTs directly from the surface [28] [32].

- Advantages: It produces a very strong mechanical and electrical connection between the CNTs and the substrate, offering exceptional stability. It allows for the creation of highly uniform, vertically aligned CNT arrays and is suitable for complex substrates like microelectrode arrays (MEAs) [28].

- Disadvantages: The process requires specialized, high-cost equipment (CVD system) and involves high temperatures, which can be incompatible with temperature-sensitive substrates like standard glass or plastics. However, advanced techniques like photothermal CVD (PTCVD) can lower the required substrate temperature (< 450°C), enabling growth on glass substrates [28].

Detailed Protocol: In-Situ Growth of CNTs on a Microelectrode Array (MEA)

- Step 1: Substrate Fabrication and Catalyst Patterning. Fabricate the MEA on a glass substrate using photolithography. Clean the substrate via successive sonication in acetone, isopropanol, and methanol, followed by oxygen plasma ashing (100 W for 5 min) [28]. Use a physical deposition method like sputter coating or electron-beam evaporation to deposit a thin layer (a few nanometers) of a metal catalyst (e.g., nickel) onto the patterned microelectrodes [28] [32].

- Step 2: CNT Growth via PTCVD. Transfer the catalyst-patterned substrate to a photothermal CVD (PTCVD) system. The growth is performed at a controlled, relatively low substrate temperature (e.g., < 400°C). The chamber is heated, and carbon precursor gases (e.g., a mixture of C₂H₂, H₂, and Ar) are introduced at specific flow rates and pressure to initiate and sustain CNT growth for a predetermined time [28].

- Step 3: Cooling and Harvesting. After the growth period, the precursor gas flow is stopped, and the system is cooled to room temperature under an inert atmosphere. The resulting substrate features CNTs grown directly from the catalytically active microelectrodes, forming a CNT/Au MEA ready for subsequent modification or testing [28].

Comparative Analysis of Techniques

Table 1: Quantitative Comparison of CNT Immobilization Techniques

| Parameter | Drop-Casting | Electrodeposition | In-Situ Growth |

|---|---|---|---|

| Film Uniformity | Low to Moderate; prone to "coffee-ring" effect [29] | High; controllable and homogeneous [30] | Very High; can produce aligned arrays [28] |

| Adhesion/Stability | Weak (physisorption); prone to delamination [30] | Strong (electrostatic binding) [30] | Very Strong (covalent, integrated interface) [28] |

| Experimental Complexity | Low | Moderate | High |

| Equipment Needs | Basic lab equipment (pipette, ultrasonicator) | Potentiostat, 3-electrode cell | CVD system, photolithography tools [28] |

| Process Temperature | Room Temperature | Room Temperature | High Temperature (e.g., < 400°C for PTCVD on glass) [28] |

| Typical Film Thickness Control | Poor | Good to Excellent | Excellent |

| Best Use Case | Rapid prototyping, low-budget research | High-performance, reproducible sensors | Demanding applications requiring maximum stability and miniaturization (e.g., MEAs) [28] |

Table 2: Essential Research Reagent Solutions and Materials

| Reagent/Material | Function/Description | Example Use Case |

|---|---|---|

| Functionalized CNTs (fCNTs) | CNTs treated with acids to introduce oxygen-containing groups (e.g., -COOH, -OH), enhancing dispersibility in water and providing surface charge for electrodeposition [30]. | Fundamental for electrodeposition; improves film quality in drop-casting. |

| Nitric Acid (HNO₃) | Strong oxidizing agent used for the functionalization of pristine CNTs [30]. | Refluxing CNTs to create fCNTs. |

| Dimethylformamide (DMF) | Polar organic solvent with high boiling point, effective at dispersing non-functionalized CNTs [32]. | Preparing stable CNT suspensions for drop-casting. |

| Sodium Sulfate (Na₂SO₄) | Inert supporting electrolyte. Increases the conductivity of aqueous solutions for electrochemical processes [30]. | Added to the fCNT dispersion during electrodeposition to enhance current flow. |

| Phosphate Buffered Saline (PBS) | A buffer solution commonly used in biological research to maintain a stable pH, crucial for enzyme activity. | Used as the electrolyte for electropolymerization of polymers like poly(p-PDA) for biosensor development [28]. |

| p-Phenylenediamine (p-PDA) monomer | A monomer used in electrosynthesis to form a permselective polymer film on the electrode surface, which can minimize interference and entrap enzymes [28]. | Immobilization of glucose oxidase on a CNT-modified electrode to create a biosensor. |

Workflow and Decision Pathway

The following diagram illustrates the experimental workflow for the three CNT immobilization techniques, highlighting their key steps and parallel processes.

The choice of CNT immobilization technique is a critical determinant in the success of an electrochemical sensing platform, especially for specialized applications like gallium detection.

- For rapid prototyping and initial feasibility studies, the drop-casting method offers an unbeatable balance of speed and simplicity, despite its limitations in film uniformity and stability.

- For most research applications requiring high performance, reproducibility, and robust films, electrodeposition presents an optimal solution. It provides excellent control over the modified interface without the extreme complexity and cost of CVD-based growth.

- For advanced applications where the ultimate mechanical stability, miniaturization, and a fully integrated electrode interface are paramount (e.g., implantable sensors or sophisticated microelectrode arrays), in-situ growth is the superior, albeit most demanding, technique.

Researchers are advised to align their choice with their specific analytical goals, available resources, and the required robustness of the final sensor. The protocols provided herein serve as a foundational guide for implementing these powerful immobilization strategies within the context of advanced materials and electroanalytical research.

The integration of metal oxides such as gallium oxide (Ga2O3) and copper oxide (CuO) with polymer matrices and carbon nanotubes (CNTs) represents a cutting-edge frontier in the development of advanced electrochemical sensors and catalytic electrodes. This approach to electrode surface modification is particularly potent for the detection and analysis of gallium and other metal ions, leveraging the synergistic properties of its constituent materials [33] [34]. Carbon nanotubes provide a high-surface-area conductive scaffold, facilitating rapid electron transfer and serving as an excellent support for the dispersion of nanomaterials [34]. Metal oxides contribute high electrocatalytic activity and chemical stability, which are crucial for enhancing sensor sensitivity and longevity [35] [33]. Furthermore, polymers can be employed to improve the selectivity, stability, and biocompatibility of the composite, while also acting as effective dispersing agents for CNTs in aqueous media, which is a critical step in reproducible electrode fabrication [36] [37].

The applicability of these nanocomposites is vividly demonstrated in recent research. For instance, a mixed metal oxide (Ga2O3-CuO) decorated CNT paste electrode has been developed as a highly electrocatalytic platform for the hydrogen evolution reaction (HER), showcasing the successful synergy between gallium and copper oxides [33]. In a separate application, a Ga2O3 nanoparticle-modified carbon paste electrode was utilized for the simultaneous electrochemical detection of heavy metal ions like Pb²⁺, Cd²⁺, and Hg²⁺, achieving impressive detection limits in the nanomolar range [35]. These examples underscore the versatility and performance of metal oxide-polymer-CNT composites in critical analytical and energy conversion applications.

Key Research Reagent Solutions

The following table details essential materials and their functions in the formulation of these advanced nanocomposites, serving as a key resource for experimental preparation.

Table 1: Essential Research Reagents for Nanocomposite Fabrication

| Reagent Category | Specific Example | Function in Application |

|---|---|---|

| Carbon Nanomaterials | Multi-Walled Carbon Nanotubes (MWCNTs) [37] [33] | Conductive scaffold; enhances electron transfer and provides high surface area for material deposition. |

| Metal Oxide Precursors | Gallium Metal [35], Copper Salts (e.g., CuSO₄) [38] | Synthesis of Ga2O3 and CuO nanoparticles, which provide electrocatalytic active sites. |

| Polymers & Dispersants | Poly(L-Proline) [37], Nanostructured Biopolymers (e.g., Cellulose Nanocrystals) [36] | Disperses CNTs in water; forms a stable, biocompatible composite film on the electrode surface. |

| Electrode Matrix | Graphite Powder, Paraffin Oil [35] | Forms the conductive paste base for composite electrodes in carbon paste electrode designs. |

| Supporting Electrolytes | Acetate Buffer [35], KCl [34] | Provides ionic conductivity and controls pH during electrochemical analysis. |

Quantitative Performance Data

The performance of electrodes modified with Ga2O3, CuO, and CNT composites is quantifiable through key electrochemical metrics. The table below summarizes representative data from recent studies for easy comparison.

Table 2: Performance Metrics of Selected Metal Oxide-CNT Composite Electrodes

| Electrode Composition | Application | Key Performance Metric | Result |

|---|---|---|---|

| Ga2O3/CPE [35] | Simultaneous detection of Pb²⁺, Cd²⁺, Hg²⁺ | Detection Limit (LOD) | Pb²⁺: 84 nM, Cd²⁺: 88 nM, Hg²⁺: 130 nM |

| Ga2O3-CuO/CNT Paste [33] | Hydrogen Evolution Reaction (HER) | Onset Potential (E₀) in neutral medium | 0.12 V vs. RHE at -10 mA cm⁻² |

| Poly(L-Proline)/MWCNTs/GCE [37] | Detection of Gallic Acid | Detection Limit (LOD) | 0.03 μmol L⁻¹ |

| GO@CuO.γ-Al2O3 Nanofluid [38] | Solar Thermal Collector | Thermal Conductivity Enhancement | 22.56% (at 0.2% conc., 50°C) |

Detailed Experimental Protocols

Protocol 1: Fabrication of a Mixed Metal Oxide (Ga2O3-CuO) Decorated CNT Paste Electrode

This protocol details the synthesis of a composite paste electrode for electrocatalytic applications such as the hydrogen evolution reaction, based on a published procedure [33].