Beyond the Dropping Mercury Electrode: Modern Solutions to Classical Polarography Limitations in Biomedical Research

This article examines the historical and technical limitations of classical DC polarography, focusing on sensitivity, resolution, and operational constraints.

Beyond the Dropping Mercury Electrode: Modern Solutions to Classical Polarography Limitations in Biomedical Research

Abstract

This article examines the historical and technical limitations of classical DC polarography, focusing on sensitivity, resolution, and operational constraints. It explores modern electrochemical methodologies that address these shortcomings, detailing their principles, applications in drug development and biosensing, and optimization strategies. A comparative analysis validates these advanced techniques against classical approaches, concluding with their transformative implications for analytical precision in pharmaceutical and clinical research.

Why Classical DC Polarography Hits Its Limits: Understanding Sensitivity, Resolution, and Practical Constraints

The Legacy and Core Principle of Classical DC Polarography

Classical DC polarography, developed by Jaroslav Heyrovský in the 1920s, is a voltammetric technique where a gradually increasing DC voltage is applied to a working electrode, typically a dropping mercury electrode (DME), versus a reference electrode. The resulting current is measured and plotted as a polarogram. The core principle is the redox reaction of electroactive species at the electrode surface, characterized by the Ilkovič equation, which describes the diffusion-controlled limiting current. Its legacy lies in establishing the foundation for all modern electroanalytical techniques, providing a robust method for qualitative and quantitative analysis of metal ions, organic compounds, and pharmaceuticals based on their characteristic half-wave potentials.

Technical Support Center

Troubleshooting Guides & FAQs

Q1: My polarogram shows excessive noise and an unstable baseline. What could be the cause? A: This is commonly caused by electrical interference, contaminated electrolyte, or an issue with the dropping mercury electrode.

- Solution: Ensure all equipment is properly grounded. Use a high-quality, purified supporting electrolyte (e.g., KCl, HClO4). Check the DME capillary for blockages or irregular drops—clean or re-silanize if necessary. Employ a Faraday cage if interference persists.

Q2: The measured diffusion current is not proportional to analyte concentration as predicted by the Ilkovič equation. A: This indicates the process is not purely diffusion-controlled.

- Solution: Verify that the system is deoxygenated by purging with an inert gas (N2, Ar) for at least 10-15 minutes. Check for the presence of adsorption phenomena or kinetic limitations. Ensure the concentration is within the linear range and that the capillary characteristics (m, t) are correctly measured.

Q3: I observe overlapping waves, making half-wave potential determination impossible. A: This is a fundamental limitation of classical DC polarography when analyzing complex mixtures.

- Solution: Modify the supporting electrolyte to complex with specific ions, shifting their half-wave potentials (e.g., use ammonia buffer for metal ions). If available, switch to a differential pulse or square-wave voltammetry method, which offer superior resolution.

Q4: The residual current is unusually high, obscuring the Faradaic signal. A: High residual current is often due to capacitive charging of the constantly renewing mercury drop and/or impurities.

- Solution: Ensure rigorous purification of all reagents. Use a three-electrode system to compensate for iR drop. Consider background subtraction using a blank solution polarogram. This limitation is a key driver for moving to pulsed techniques which sample current at the end of the drop life.

Q5: My experiment requires sub-micromolar detection limits, but DC polarography is insufficiently sensitive. A: Correct. The sensitivity of classical DC polarography is limited by the capacitive current.

- Solution: This intrinsic limitation must be overcome by adopting advanced techniques. Implement stripping voltammetry (e.g., anodic stripping voltammetry) for trace metal analysis or switch to pulse voltammetries (DPV, SWV) which significantly enhance the signal-to-noise ratio.

Experimental Protocol: Standard DC Polarography for Cd²⁺ and Pb²⁺ Analysis

1. Objective: To quantitatively determine the concentration of Cadmium (Cd²⁺) and Lead (Pb²⁺) ions in a sample solution using classical DC polarography.

2. Materials & Reagents:

- Polarograph with three-electrode cell.

- Working Electrode: Dropping Mercury Electrode (DME).

- Reference Electrode: Saturated Calomel Electrode (SCE).

- Counter Electrode: Platinum wire.

- High-purity Nitrogen gas.

- Supporting Electrolyte: 0.1 M HCl.

- Standard stock solutions: 1.0 mM Cd²⁺ and 1.0 mM Pb²⁺ in 0.1 M HCl.

- Sample solution.

3. Procedure:

- Cell Setup: Fill the polarographic cell with 10 mL of 0.1 M HCl (blank supporting electrolyte). Insert the three electrodes.

- Deaeration: Bubble high-purity nitrogen through the solution for 15 minutes to remove dissolved oxygen. Maintain a nitrogen blanket over the solution during measurement.

- Blank Run: Record a polarogram from -0.2 V to -1.0 V vs. SCE. This is the background curve.

- Standard Addition: Add a known volume (e.g., 100 µL) of the 1.0 mM Cd²⁺ standard solution. Deaerate for 2 minutes. Record the polarogram under identical conditions.

- Repeat Addition: Make 2-3 further standard additions of the Cd²⁺ solution, recording a polarogram after each.

- Repeat for Pb²⁺: Repeat steps 4-5 using the Pb²⁺ standard solution in a fresh aliquot of supporting electrolyte or a mixture.

- Sample Measurement: Replace the cell solution with 10 mL of the unknown sample in 0.1 M HCl. Deaerate and record the polarogram.

4. Data Analysis:

- Measure the wave height (limiting current, i_l) for each standard addition.

- Construct a standard addition calibration plot of i_l vs. concentration of added standard.

- Extrapolate the line to find the original concentration of the analyte in the sample.

- Identify analytes by their characteristic half-wave potentials (E_{1/2}): Cd²⁺ ≈ -0.6 V, Pb²⁺ ≈ -0.4 V vs. SCE in HCl.

Data Presentation: Key Parameters in DC Polarography

Table 1: Characteristic Half-Wave Potentials in Different Supporting Electrolytes (vs. SCE)

| Ion | 0.1 M KCl | 0.1 M HCl | 1 M NH₃ / 1 M NH₄Cl | Notes |

|---|---|---|---|---|

| Cd²⁺ | -0.60 V | -0.62 V | -0.81 V | Forms ammine complex |

| Pb²⁺ | -0.40 V | -0.44 V | -0.72 V | Forms ammine complex |

| Zn²⁺ | -1.00 V | -1.00 V | -1.36 V | Irreversible in KCl/HCl |

| O₂ (1st wave) | -0.05 V | -0.05 V | -0.04 V | Major interference |

Table 2: Ilkovič Equation Parameters and Their Influence

| Parameter | Symbol | Typical Value/Range | Influenced By | Impact on Limiting Current (i_l) |

|---|---|---|---|---|

| Drop Mass Flow Rate | m | 1-2 mg/s | Mercury height, capillary bore | i_l ∝ m^(2/3) |

| Drop Time | t | 3-6 s | Mercury height, potential | i_l ∝ t^(1/6) |

| Diffusion Coefficient | D | ~10⁻⁵ cm²/s | Analyte, temp., medium | i_l ∝ D^(1/2) |

| Analyte Concentration | C | 1 µM - 10 mM | Sample | i_l ∝ C |

Visualizations

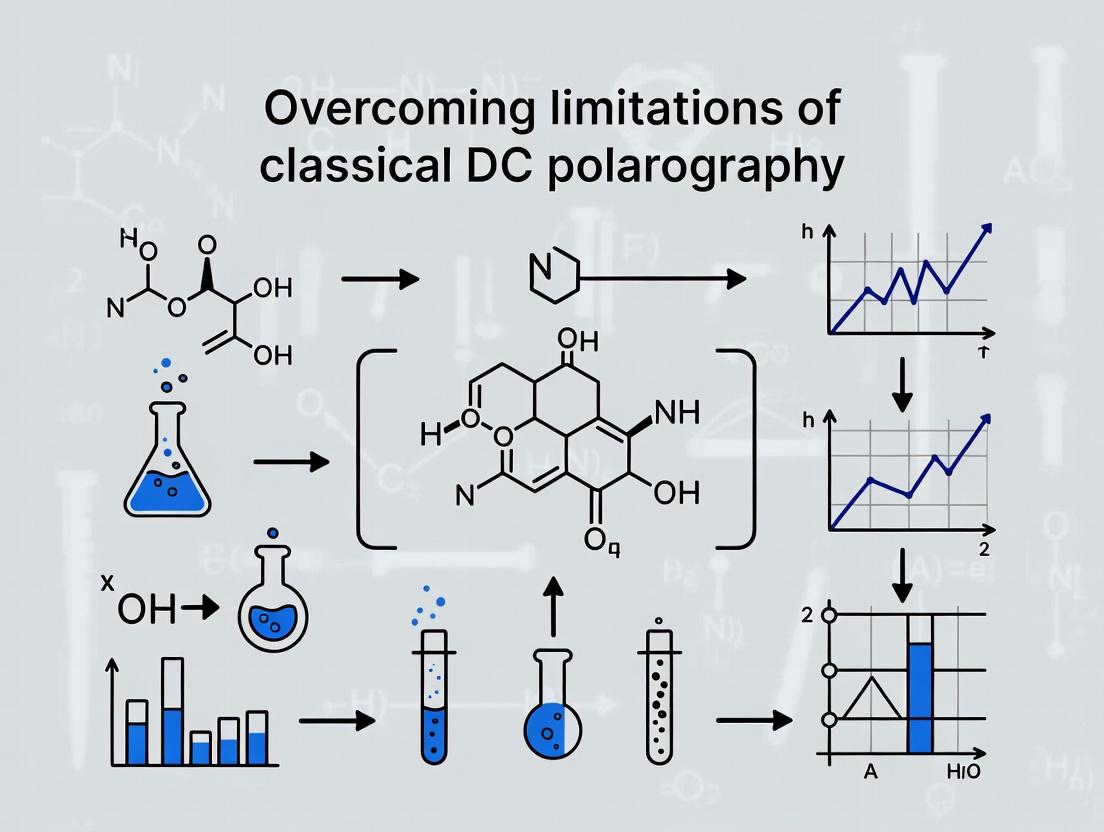

Diagram 1: DC Polarography Core Principle & Signal Components

Diagram 2: Troubleshooting Overlapping Waves Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Classical DC Polarography

| Item | Function / Rationale |

|---|---|

| Dropping Mercury Electrode (DME) | The quintessential working electrode. Its renewable surface eliminates passivation, provides a reproducible hydrogen overpotential, and allows for steady-state diffusion. |

| High-Purity Mercury (Triple Distilled) | Source for the DME. Must be free of metallic impurities to avoid contaminating the electrochemical cell and introducing spurious currents. |

| Saturated Calomel Electrode (SCE) | A stable, common reference electrode to provide a fixed potential against which the working electrode is controlled. |

| 0.1 M KCl or HCl Supporting Electrolyte | To carry the bulk of the current (minimize migration) and fix the ionic strength. Must be of the highest purity (e.g., Suprapur grade). |

| Nitrogen (Oxygen-Free, High Purity) | To remove dissolved oxygen, which produces two interfering reduction waves in the middle of the useful potential window. |

| Maximum Suppressor (e.g., Triton X-100) | A surface-active agent added in trace amounts (~0.001%) to suppress the polarographic maxima—anomalous current peaks caused by solution streaming. |

| Standard Solutions for Calibration | High-purity, certified metal ion or organic compound standards for quantitative analysis via the standard addition method. |

Technical Support Center

Troubleshooting Guides

Issue: High Background Noise Obscuring Low-Concentration Analytic Signal

- Q: What are the primary sources of noise in DC polarography for trace analysis?

- A: The main sources are: 1) Capacitive current from the double-layer charging, 2) Residual current from impurities in the supporting electrolyte, 3) Oxygen reduction current if deaeration is incomplete, and 4) Stochastic noise from the mercury electrode growth and fall.

- Q: What steps can be taken to minimize capacitive and residual currents?

- A: Implement a high-quality, multi-stage purification system for your supporting electrolyte. Use a three-electrode system with a potentiostat to precisely control the working electrode potential. Employ a differential pulse or square-wave waveform instead of classical DC to discriminate against capacitive current.

Issue: Poor Signal-to-Noise Ratio at Sub-Micromolar Concentrations

- Q: Why does my polarographic wave become indistinguishable from the baseline at low nM concentrations?

- A: In classical DC polarography, the faradaic signal (proportional to concentration) decreases linearly, while the capacitive current remains relatively constant. Below a certain concentration threshold (typically ~10⁻⁵ M for many organics), the signal is lost in the noise envelope.

- Q: What instrumental modifications can improve SNR?

- A: Switch to a Static Mercury Drop Electrode (SMDE) or Hanging Mercury Drop Electrode (HMDE) for more stable drop geometry. Use advanced polarographic techniques like Differential Pulse Polarography (DPP) or Square-Wave Polarography (SWP), which can improve sensitivity by 100-1000x over classical DC.

Frequently Asked Questions (FAQs)

Q: What is the practical lower limit of detection (LOD) for classical DC polarography, and how does it compare to modern techniques?

- A: Classical DC polarography typically has a LOD in the range of 10⁻⁵ to 10⁻⁶ M (1-10 µM). Modern pulse techniques (DPP, SWP) achieve LODs of 10⁻⁷ to 10⁻⁸ M (0.01-0.1 µM). For comparison, techniques like HPLC-MS or ICP-MS can reach LODs in the pM or lower range.

Q: Can I modify my existing DC polarograph to perform more sensitive pulse measurements?

- A: Most classical DC polarographs cannot be easily upgraded. Transitioning to DPP or SWP requires a modern potentiostat capable of generating complex voltage waveforms and synchronized current sampling. A dedicated modern electrochemical workstation is recommended.

Q: What are the best practices for sample preparation to maximize sensitivity in trace analysis?

- A: 1) Use ultrapure reagents and water (18.2 MΩ·cm). 2) Perform all preparations in a clean, particulate-controlled environment. 3) Implement rigorous deaeration with high-purity inert gas (N₂ or Ar) for at least 10-15 minutes before analysis. 4) Consider electrochemical or chemical pre-concentration of the analyte onto the electrode surface.

Table 1: Comparison of Polarographic Technique Sensitivities

| Technique | Typical Limit of Detection (LOD) | Key Advantage for Trace Analysis | Primary Noise Source Mitigated |

|---|---|---|---|

| Classical DC Polarography | 1 x 10⁻⁵ M - 1 x 10⁻⁶ M | Simplicity, wide potential window | None (baseline technique) |

| Differential Pulse Polarography (DPP) | 1 x 10⁻⁷ M - 1 x 10⁻⁸ M | Excellent discrimination against capacitive current | Capacitive Current |

| Square-Wave Polarography (SWP) | ~1 x 10⁻⁸ M | Speed and very high sensitivity | Capacitive Current |

| Stripping Voltammetry (on HMDE) | 1 x 10⁻⁹ M - 1 x 10⁻¹¹ M | Pre-concentration step amplifies signal | Requires careful background subtraction |

Table 2: Impact of Supporting Electrolyte Purity on Background Current

| Electrolyte Grade | Conductivity | Residual Current (at -0.5V vs. SCE) | Recommended for Analysis > |

|---|---|---|---|

| Technical Grade | High | > 50 nA | Qualitative work only |

| Analytical Grade | Moderate | ~20 nA | Concentrations > 10⁻⁴ M |

| Ultrapure (e.g., Zone-Refined) | Low | < 5 nA | Trace analysis (< 10⁻⁶ M) |

Experimental Protocols

Protocol 1: Standard Method for Trace Metal Analysis via Differential Pulse Polarography (DPP)

- Objective: Determine sub-µM concentrations of Cd²⁺ and Pb²⁺ in a simulated water sample.

- Materials: See "The Scientist's Toolkit" below.

- Procedure:

- Cell Assembly: Fill the electrochemical cell with 25 mL of 0.1 M ultrapure HCl supporting electrolyte.

- Deaeration: Bubble high-purity nitrogen gas through the solution for 15 minutes to remove dissolved oxygen. Maintain a nitrogen blanket over the solution during the run.

- Baseline Recording: Using the SMDE, run a DPP scan from -0.2V to -0.8V vs. Ag/AgCl. Parameters: Pulse amplitude 50 mV, pulse width 50 ms, scan rate 5 mV/s. This establishes the background.

- Standard Addition: Add a known aliquot (e.g., 50 µL) of a standard solution containing Cd²⁺ and Pb²⁺. Stir with nitrogen for 60 seconds.

- Sample Scan: Repeat the DPP scan under identical conditions.

- Analysis: Measure the peak heights at approximately -0.6V (Cd) and -0.4V (Pb). Use the standard addition method to calculate the original concentration in the sample.

Protocol 2: Minimizing Oxygen Interference in Organic Trace Analysis

- Objective: Accurately measure trace levels of an electroactive pharmaceutical (e.g., nitrofurantoin) by eliminating the overlapping oxygen reduction wave.

- Procedure:

- Prepare a 0.05 M phosphate buffer (pH 7.0) supporting electrolyte, purified over activated charcoal.

- Deaerate with argon (often more effective than N₂ for organic solutions) for a minimum of 20 minutes.

- Perform a blank SWP scan from -0.2V to -1.0V to confirm the absence of the O₂ reduction wave (~-0.8V to -0.9V at pH 7).

- Introduce the sample. If deaeration is complete, the analyte peak (e.g., -0.5V for nitrofurantoin) will be clear of interference.

Visualizations

Title: Causes & Solutions for Inadequate Sensitivity

Title: DPP Trace Analysis Workflow

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in Trace Polarography | Key Consideration for Sensitivity |

|---|---|---|

| Ultrapure Supporting Electrolyte (e.g., KCl, HClO₄) | Provides ionic strength, controls pH, and defines the conductive medium. | Must be zone-refined or similarly purified to minimize residual faradaic currents from impurities. |

| High-Purity Inert Gas (N₂ or Ar, 99.999+%) | Removes dissolved oxygen, which produces a large, interfering reduction wave. | Argon is denser and can provide a better blanket. Use with an inline oxygen scrubber. |

| Static Mercury Drop Electrode (SMDE) | Provides a reproducible, renewed mercury surface with low noise characteristics. | More stable than a DME for pulse techniques, leading to better signal averaging. |

| Ag/AgCl Reference Electrode (with KCl Bridge) | Provides a stable, known potential against which the working electrode is controlled. | Use a sealed, double-junction design to prevent contamination of the sample by Cl⁻ or K⁺. |

| Glassware Cleaning Solution (e.g., 50% HNO₃ bath) | Removes adsorbed metal ions from all glassware and cells. | Essential for part-per-billion (ppb) level metal analysis to prevent cross-contamination. |

| Potentiostat/Galvanostat with Pulse Capabilities | Applies precise voltage waveforms and measures resulting micro-currents. | Must have low current noise (< 1 pA RMS) and capable of DPP/SWP for trace work. |

Troubleshooting Guides & FAQs

Q1: In my DC polarography experiment, I observe a single, broad, asymmetric wave when I expect two distinct signals from analytes with known but close E½ values (e.g., ΔE½ < 200 mV). What is the primary cause and how can I confirm it?

A1: The primary cause is the inherent diffusional broadening of polarographic waves in classical DC polarography. The overlap is severe when ΔE½ is less than approximately 200 mV. To confirm, you can spike your sample with a known concentration of one of the suspected analytes. A non-additive increase in the wave height confirms overlap. Alternatively, switch to a technique with better potential resolution (see Protocol 1: Differential Pulse Polarography).

Q2: How can I quantitatively assess the degree of overlap between two unresolved polarographic waves?

A2: You can perform a deconvolution analysis using known broadening parameters. The key metric is the peak separation (ΔEp) relative to the sum of the half-widths (W) of the individual waves. For DC polarography, the width at half height (W₁/₂) for a reversible wave is approximately 56.4/n mV at 25°C. Overlap is severe when ΔE½ < W₁/₂.

Table 1: Resolution Criteria for DC Polarography (Reversible Processes)

| ΔE½ (mV) | Expected Resolution | Visual Diagnosis |

|---|---|---|

| > 200 | Good | Two distinct sigmoidal waves. |

| 100 - 200 | Partial | A single wave with a shoulder or clear asymmetry. |

| < 100 | Poor | A single, apparently symmetric wave. |

Q3: What are the most effective modern voltammetric techniques to overcome poor potential resolution for electroactive drug compounds?

A3: Pulse voltammetric techniques, which suppress capacitive current, offer significantly improved resolution.

- Differential Pulse Polarography (DPP): The most direct upgrade, offering peak widths of ~90-100 mV, allowing resolution of ΔE½ down to ~50 mV.

- Square Wave Voltammetry (SWV): Provides the highest effective scan rate and best background suppression, with typical peak widths of ~60-80 mV, enabling resolution of ΔE½ as low as 25-40 mV.

Experimental Protocols

Protocol 1: Differential Pulse Polarography (DPP) for Resolving Overlapping Signals

Principle: A small amplitude pulse (~25-50 mV) is superimposed on a slowly changing DC potential. The current is sampled just before the pulse application (I₁) and at the end of the pulse (I₂). The output is the difference (I₂ - I₁) vs. DC potential, producing a peak-shaped response with lower diffusional broadening.

Methodology:

- Instrument Setup: Use a three-electrode system (DME/HDME, Ag/AgCl ref., Pt wire aux.).

- Solution: Prepare your sample in a suitable supporting electrolyte (e.g., 0.1 M phosphate buffer, pH 7.4). Deoxygenate with N₂ or Ar for 10-15 min.

- Parameters: Set pulse amplitude to 50 mV, pulse duration to 50 ms, scan increment to 2-4 mV, and scan rate to 2-5 mV/s.

- Measurement: Record the DPP voltammogram over the potential window of interest.

- Analysis: Identify peak potentials (Ep). The peak current (Ip) is proportional to concentration. Use standard addition for quantitation in complex matrices.

Protocol 2: Using SWV for Ultimate Resolution in Drug Analysis

Methodology:

- Setup: Same three-electrode system as above.

- Parameters: Set frequency (f) to 15-25 Hz (higher f gives sharper peaks but may distort irreversible systems). Set square wave amplitude (Esw) to 25 mV and step potential (ΔEs) to 5-10 mV.

- Measurement: Record the forward, reverse, and net currents. The net current (forward-reverse) is used for analysis, offering excellent background subtraction.

- Deconvolution: For severely overlapping peaks (ΔEp < W), use built-in or external software (e.g., GPES, Origin) to perform peak fitting assuming a Gaussian or Lorentzian shape.

Visualizations

Title: DPP Signal Generation & Broadening Reduction Workflow

Title: Signal Resolution Comparison Across Voltammetric Techniques

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Resolving Close Potentials

| Item | Function & Rationale |

|---|---|

| Hanging Mercury Drop Electrode (HMDE) | Stationary working electrode for pulse techniques. Provides a renewable, perfectly spherical surface for highly reproducible measurements in DPP/SWV. |

| Supporting Electrolyte (e.g., 0.1 M TBAP in DMSO) | Minimizes solution resistance (iR drop) and ensures current is driven by analyte diffusion. Choice dictates potential window. |

| Internal Standard (e.g., 1.0 mM Cadmium Chloride) | A known reversible redox couple added to the sample to verify instrument performance and potential calibration. |

| Deoxygenation Gas (Argon, 99.999%) | Removes dissolved oxygen, which produces overlapping reduction waves (~ -0.1 V to -0.9 V vs. Ag/AgCl) that interfere with analyte signals. |

| Standard Solutions of Pure Analytes | Necessary for determining individual peak potentials and shapes, which are required for deconvolution of overlapping signals in mixture analysis. |

| Software with Deconvolution Modules (e.g., GPES, NOVA) | Enables mathematical fitting of overlapping peaks using non-linear regression algorithms for quantitative analysis of unresolved mixtures. |

Technical Support Center

Troubleshooting Guides & FAQs

Q1: Why does my polarographic experiment take several hours to complete a single scan, and how can I accelerate it? A: The slow scan rate (typically 0.5-5 mV/s) in classical DC polarography is inherent to the dropping mercury electrode (DME) process. Each data point is averaged over the lifetime of a single mercury drop (2-8 seconds). To accelerate:

- Implement Modern Voltammetry: Switch to techniques like Square Wave Voltammetry (SWV) or Differential Pulse Voltammetry (DPV) on a static mercury drop electrode (SMDE). These methods apply rapid potential pulses and sample current at specific times, drastically reducing scan time to 1-5 minutes.

- Optimize DME Parameters: If you must use DME, reduce the drop time to the minimum stable value (e.g., 2 s) and increase the potential step size within acceptable resolution limits (e.g., from 1 mV to 2 mV).

Q2: I am obtaining noisy and irreproducible polarograms when I try to increase the scan rate. What is the cause and solution? A: This is caused by increased capacitive (charging) current relative to the faradaic (analytical) current at faster scan rates.

- Cause: The double-layer capacitance must be charged with each potential change. Faster scans require more current for this charging, obscuring the signal.

- Solution: Use pulse voltammetric techniques (DPV, SWV). They measure current just before the potential pulse (where capacitive current has decayed) and at the end of the pulse, effectively subtracting the capacitive background. See Table 1 for quantitative comparison.

Q3: How can I automate my polarographic analysis to run multiple samples or replicates overnight? A: Automation requires moving away from the manual DME.

- Protocol for Automated Multi-Sample Analysis:

- Equipment: Use a modern potentiostat with an automated SMDE or mercury film electrode (MFE) system and an auto-sampler.

- Cell Preparation: Load sample vials into the auto-sampler carousel.

- Method Programming: Create a sequence method in the instrument software. For each sample position, program a cleaning step (e.g., 30-second purge with N₂), an equilibration time (10 s), and the electrochemical protocol (e.g., a DPV scan from -0.1V to -1.2V).

- Execution: Start the sequence. The instrument will run replicates and proceed to the next sample without intervention.

Data Presentation

Table 1: Comparison of Scan Times and Key Parameters in Polarographic Methods

| Method | Typical Scan Rate | Approx. Time per Scan | Key Advantage for Speed | Typical Detection Limit (M) |

|---|---|---|---|---|

| Classical DC Polarography (DME) | 0.5 - 5 mV/s | 10 - 60 minutes | N/A (Baseline) | ~1 × 10⁻⁵ |

| Differential Pulse Polarography (DPP) | 1 - 10 mV/s with pulse | 1 - 5 minutes | Capacitive current rejection | ~1 × 10⁻⁷ |

| Square Wave Voltammetry (SWV) | 50 - 500 mV/s (effective) | 10 - 60 seconds | Extremely fast, high sensitivity | ~1 × 10⁻⁸ |

Table 2: Research Reagent Solutions & Essential Materials

| Item | Function & Relevance to Overcoming Slow Scan Rates |

|---|---|

| Static Mercury Drop Electrode (SMDE) | Provides a renewable, static mercury surface essential for implementing fast pulse techniques (SWV, DPV) by eliminating the growth-related current fluctuations of the DME. |

| Supporting Electrolyte (e.g., 0.1 M KCl, Phosphate Buffer) | Minimizes solution resistance (iR drop) which distorts signals at faster scan rates, and defines the electrochemical window. |

| Oxygen Scavenger (High-Purity N₂ or Ar gas) | Required for deaeration to remove dissolved O₂, which creates interfering reduction currents. Critical for reproducible baselines in sensitive pulse methods. |

| Standard Solutions for Calibration (e.g., 1 mM Cd²⁺, Pb²⁺) | Used to validate instrument response time, sensitivity, and resolution when optimizing new, faster methods. |

| Potentiostat with Pulse Voltammetry Software | The core hardware/software required to apply and analyze the sophisticated potential waveforms used in fast scan techniques. |

Experimental Protocols

Protocol: Optimizing a Square Wave Voltammetry (SWV) Method for Rapid Analysis. Objective: To determine the concentration of an electroactive pharmaceutical compound in under 2 minutes. Materials: Potentiostat with SWV capability, SMDE (working), Ag/AgCl reference electrode, Pt wire counter electrode, 10 mL supporting electrolyte (0.1 M acetate buffer, pH 4.5), nitrogen purging system, standard stock solution of analyte. Method:

- Cell Setup: Add 10 mL of supporting electrolyte to the electrochemical cell. Assemble the three-electrode system.

- Deaeration: Purge the solution with nitrogen for 8 minutes to remove oxygen. Maintain a nitrogen blanket over the solution during analysis.

- Background Scan: Run an SWV scan over the expected potential range (e.g., from +0.2 V to -1.0 V) using the following initial parameters: frequency (f) = 25 Hz, step potential (Estep) = 5 mV, amplitude (Esw) = 50 mV. This records a background voltammogram.

- Standard Addition: Add a known small volume (e.g., 20 µL) of standard analyte stock solution. Mix. Purge with N₂ for 1 minute.

- Sample Scan: Run the SWV scan again with identical parameters.

- Analysis: Repeat steps 4-5 for 3-4 additions. Measure the peak current for each addition. Plot peak current vs. concentration to create a standard addition curve for quantitative analysis. Key Speed Advantage: The entire multi-addition calibration and sample analysis can be completed in under 15 minutes, compared to hours with DC polarography.

Visualizations

Troubleshooting Guides & FAQs

Q1: The mercury drop electrode in our polarograph is unstable, with irregular drop times. What could be the cause and solution?

A: This is often due to a clogged or contaminated capillary. Mercury oxide or dust can obstruct the fine bore.

- Troubleshooting Protocol: First, visually inspect the capillary tip under a magnifier. Then, perform a cleaning procedure.

- Cleaning Methodology:

- Retract the mercury reservoir to its lowest position.

- Carefully immerse the capillary tip in a 1:1 nitric acid (HNO₃) solution for 30 seconds.

- Rinse thoroughly with copious amounts of deionized water.

- Dry the tip gently with a lint-free cloth.

- Extend the mercury reservoir and allow fresh Hg to flush through the capillary for 2-3 minutes into a waste container.

- Re-hang a fresh drop and measure drop time. It should be consistent (±0.1 s) at a given height.

Q2: How do we safely contain and dispose of mercury waste from our polarographic experiments?

A: Safe handling is non-negotiable. Use a contained, spill-proof workstation.

- Containment Protocol: Perform all experiments over a deep polyethylene tray with raised edges. Conduct initial mercury drop formation and detachment into a beaker half-filled with water to amalgamate and trap droplets.

- Disposal Procedure: Collect all waste (contaminated solutions, spent electrodes, cleaning residues) in a dedicated, labeled, sealed container. Contact your institutional environmental health and safety (EHS) office for approved hazardous waste disposal as a toxic metal. Do not pour down the drain or dispose of in regular trash.

Q3: Our analyte solution appears to form a precipitate or film on the mercury electrode surface, distorting the polarogram. How can we mitigate this?

A: This is likely surface adsorption or compound formation.

- Mitigation Methodology: Implement a chemical or electrochemical cleaning step between scans.

- Chemical: Add a non-ionic surfactant (e.g., Triton X-100) at a very low concentration (0.0005-0.001% v/v) to suppress maxima and improve surface renewal.

- Electrochemical: Apply a conditioning potential at the end of each scan cycle (e.g., -1.8 V vs. SCE for 5 seconds) to electrochemically reduce/desorb surface films before the next drop grows.

- Ensure adequate supporting electrolyte concentration (≥0.1 M) to minimize adsorption of ionic species.

Q4: Are there validated alternative methods to classical DC polarography that avoid mercury entirely for drug analysis?

A: Yes, modern voltammetric techniques using solid electrodes are widely validated for pharmacopoeial analysis.

- Alternative Experimental Protocol (for dissolution testing of an active pharmaceutical ingredient):

- Electrode: Use a glassy carbon working electrode, Ag/AgCl reference, platinum wire counter.

- Preparation: Polish the electrode with 0.05 μm alumina slurry, rinse with deionized water and methanol.

- Technique: Employ Differential Pulse Voltammetry (DPV) for higher sensitivity.

- Parameters: Scan from +0.8 V to +1.2 V (solute-dependent). Pulse amplitude 50 mV, pulse width 50 ms, scan rate 10 mV/s.

- Calibration: Use standard addition method directly in the dissolution vessel buffer.

Comparative Data: Mercury vs. Alternative Electrodes

Table 1: Operational & Environmental Comparison

| Parameter | Mercury (DME/HDME) | Solid Electrodes (Glassy Carbon, Gold) |

|---|---|---|

| Renewable Surface | Excellent (each drop) | Requires polishing/cleaning |

| Hydrogen Overpotential | Very High (≈ -1.8V in acidic) | Moderate to Low |

| Cathodic Range | Very Wide | Limited by solvent/electrolyte reduction |

| Oxidative Range | Narrow (Hg oxidizes ≈ +0.4V) | Wide (up to +1.2V in aqueous) |

| Toxicity & Handling | High Risk; Special Disposal | Low Risk; Standard Protocols |

| Maintenance | Capillary cleaning, Hg purity | Mechanical/Electrochemical polishing |

Table 2: Analytical Performance in Drug Analysis

| Technique | Typical LOD (mol/L) | Reproducibility (%RSD) | Suitability for Complex Matrices |

|---|---|---|---|

| Classical DC Polarography (Hg) | ~10⁻⁶ | 1.5-3.0% (drop-to-drop) | Good, but fouling possible |

| Differential Pulse Polarography (Hg) | ~10⁻⁸ | 1.0-2.0% | Excellent with surface renewal |

| DPV on Solid Electrode | ~10⁻⁸ | 2.0-5.0% (requires care) | Can require derivatization or cleanup |

Experimental Workflow: Modern Solid Electrode Analysis

Title: Workflow for Solid Electrode Drug Analysis via DPV

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Mercury Electrode Maintenance & Alternatives

| Item | Function & Specification |

|---|---|

| Triply Distilled Mercury | High-purity Hg for DME reservoir to minimize trace metal contamination. |

| Nitric Acid (1:1 v/v) | Cleaning solution for unclogging the glass capillary of the DME. |

| Potassium Chloride (Sat. Calomel Electrode) | Provides stable reference potential (SCE) for all polarographic measurements. |

| Triton X-100 Surfactant | Maxima suppressor; used at <0.001% to prevent polarographic maxima without suppressing faradaic current. |

| Mercury Waste Container | Sealed, unbreakable container for spent Hg and contaminated materials. |

| Alumina Polishing Slurries (0.05 & 0.3 µm) | For resurfacing/renewing solid electrodes (e.g., glassy carbon) as an alternative to Hg. |

| Nafion Coating Solution | Permselective membrane to coat solid electrodes, improving selectivity in biological/drug matrices. |

| High-Purity Inert Gas (N₂/Ar) | For deaerating solutions to remove interfering dissolved oxygen prior to scanning. |

The Foundational Need for Modern Electrochemical Evolution.

Technical Support Center: Modern Electrochemical Methods for Research

Welcome to the technical support center for researchers overcoming the limitations of classical DC polarography. This guide provides troubleshooting and FAQs for modern pulse and stripping voltammetry techniques, which offer enhanced sensitivity, speciation capabilities, and reduced capacitive current interference.

Frequently Asked Questions (FAQs) & Troubleshooting

Q1: Our lab is transitioning from classical DC polarography to Differential Pulse Polarography (DPP) for trace metal analysis in pharmaceutical samples. We are not achieving the theoretical 10-50x improvement in detection limit. What are the most common culprits? A: The expected sensitivity gain from pulse techniques can be compromised by:

- Improper Pulse Parameters: The pulse amplitude (ΔE), pulse duration (tp), and step time must be optimized. A common error is using a pulse amplitude that is too large, causing peak broadening. Start with ΔE = 50 mV, tp = 50 ms.

- Uncompensated Resistance (Ru): High Ru in non-aqueous or low-ionic-strength solutions distorts the applied pulse, broadening peaks and lowering height. Always use a supporting electrolyte at ≥0.1 M concentration and ensure your instrument's IR compensation is correctly calibrated.

- Oxygen Interference: Dissolved oxygen is more problematic in sensitive pulse techniques. Rigorous deoxygenation with an inert gas (N₂ or Ar) for 7-10 minutes is mandatory, with a blanket maintained during measurement.

Q2: When using Anodic Stripping Voltammetry (ASV) for ultra-trace drug compound analysis, our reproducibility between replicates is poor (<15% RSD). What steps should we check? A: Poor reproducibility in ASV typically stems from the deposition step. Follow this protocol:

- Electrode Surface Renewal: Mechanically polish the working electrode (e.g., glassy carbon, mercury film) before each deposition sequence using an alumina slurry (0.05 µm) on a microcloth pad. Rinse thoroughly with deionized water.

- Strict Control of Deposition Conditions: Use a dedicated, magnetically stirred sample stand. Control deposition time (± 0.1 s) and potential (± 0.5 mV) precisely. The stirring rate must be identical for all standards and samples.

- Memory Effects: Implement a "cleaning" step at a positive potential after each stripping scan to remove residual analyte from the electrode. For a mercury electrode, hold at +0.4 V for 30 s in clean supporting electrolyte.

Q3: In Square Wave Voltammetry (SWV), how do we differentiate between a reversible, irreversible, and quasireversible electron transfer process from the waveform output? A: Diagnose the electrochemical reversibility by analyzing the SWV peak shape and position.

| Parameter | Reversible System | Irreversible System | Quasireversible System |

|---|---|---|---|

| Peak Symmetry | Symmetrical | Asymmetrical (sharper on one side) | Intermediate |

| Peak Width at Half Height (Ep/2) | ~90/n mV | > 90/n mV | Variable |

| Forward/Reverse Peak Separation | Coincident (single peak) | Separate peaks | Small separation |

| Effect of SW Frequency (f) | Peak potential constant with increasing f | Peak shifts significantly with f | Moderate shift with f |

Diagnostic Table: SWV Signatures for Reaction Reversibility.

Q4: Our modern potentiostat software offers advanced digital filtering. When and how should we apply smoothing filters to voltammetric data without introducing artifacts? A: Apply smoothing after data collection, never as a substitute for proper experimental noise reduction.

- Use Case: Apply mild Savitzky-Golay filtering (2nd order polynomial, 5-15 points) to reduce high-frequency random noise.

- Avoid: Over-filtering (using too many points) which distorts peak height, width, and area. Always compare raw and filtered data. Never filter data used for quantitative calibration without verifying the calibration curve is unaffected.

Experimental Protocol: Quantifying an Antibiotic via Adsorptive Stripping Voltammetry (AdSV)

This protocol overcomes the limitations of classical polarography for non-electroactive organic molecules by employing an adsorption preconcentration step.

Title: Quantification of Tetracycline in Serum Filtrate.

1. Reagents & Solutions:

- Supporting Electrolyte: 0.1 M Ammonium Acetate Buffer (pH 4.7). Adjust pH with acetic acid.

- Standard Stock Solution: 1.0 mM Tetracycline in 0.01 M HCl. Store at 4°C in the dark.

- Serum Sample Preparation: Mix 1 mL of human serum with 1 mL of acetonitrile to precipitate proteins. Vortex for 1 min, centrifuge at 10,000 rpm for 10 min. Filter the supernatant (0.45 µm nylon) and dilute 1:5 with the supporting electrolyte.

2. Instrumentation:

- Potentiostat with triple-electrode capability.

- Working Electrode: Hanging Mercury Drop Electrode (HMDE).

- Reference Electrode: Ag/AgCl (3 M KCl).

- Counter Electrode: Platinum wire.

- Cell: 10 mL voltammetric cell with magnetic stirrer.

3. AdSV Procedure: 1. Pipette 9.0 mL of supporting electrolyte into the cell. Purge with nitrogen for 8 minutes. 2. Conditioning: At the HMDE, apply -0.2 V for 30 s with stirring to clean the surface. 3. Preconcentration: Add 1.0 mL of prepared sample or standard. While stirring, adsorb the analyte onto the HMDE at an adsorption potential (Eads) of 0.0 V for a controlled time (tads = 60 s). 4. Equilibration: Stop stirring. Allow the solution to become quiescent for 15 s. 5. Stripping Scan: Initiate a negative-going square wave voltammetric scan from 0.0 V to -1.2 V. * Frequency: 25 Hz * Pulse amplitude: 25 mV * Step potential: 5 mV 6. Cleaning: After the scan, apply -1.2 V for 10 s with stirring to desorb any remaining material. 7. Replication: Perform triplicate measurements for each standard and unknown.

4. Data Analysis: * Measure the peak reduction current near -0.85 V (vs. Ag/AgCl). * Construct a calibration curve (Peak Current vs. Tetracycline Concentration) from standard additions. * Use the linear regression equation to calculate the unknown concentration, accounting for the sample preparation dilution factor.

The Scientist's Toolkit: Essential Research Reagent Solutions

| Item | Function in Modern Voltammetry |

|---|---|

| High-Purity Supporting Electrolyte (e.g., KCl, KNO₃, buffer salts) | Minimizes solution resistance, defines pH, eliminates migration current, and can complex interferents. |

| Electrode Polishing Kit (Alumina slurries: 1.0, 0.3, 0.05 µm) | Ensures a reproducible, clean, and active electrode surface, critical for reproducibility. |

| Inert Gas Supply (N₂ or Ar, ≥99.99%) with Gas Dispersion Tube | Removes electroactive interference from dissolved O₂, essential for trace analysis and negative potential windows. |

| Hg(II) Standard Solution (for Mercury Film Electrodes) | Used to form in-situ or ex-situ thin mercury films on substrates like glassy carbon for stripping analysis. |

| Standard Addition Spike Solutions | Contains known concentrations of target analyte; used for the method of standard additions to correct for complex matrix effects. |

Visualization: Modern Electrochemical Workflow & Evolution

Diagram Title: Evolution from Classical to Modern Electrochemical Methods.

Diagram Title: Standard Workflow for a Modern Stripping Voltammetry Experiment.

Modern Electrochemical Techniques: Principles and Real-World Applications in Drug Development

Troubleshooting Guides & FAQs

Q1: My DPP measurement shows a high, unstable baseline drift. What could be the cause and solution?

A: Baseline drift in DPP is often caused by changes at the working electrode surface or temperature fluctuations.

- Cause 1: Contaminated Electrode. Adsorption of sample matrix components.

- Solution: Clean the electrode thoroughly according to the manufacturer's protocol (e.g., polish with alumina slurry, sonicate in solvent, electrochemical cleaning cycles).

- Cause 2: Unstable Reference Electrode Potential. A clogged junction or depleted filling solution.

- Solution: Check the reference electrode. Ensure the junction is free-flowing and refill with fresh electrolyte.

- Cause 3: Temperature Variation. Electrode kinetics and diffusion coefficients are temperature-sensitive.

- Solution: Perform experiments in a thermostated cell. Allow sufficient time for temperature equilibration after sample introduction.

Q2: The DPP peak current is not proportional to analyte concentration in my calibration. What should I check?

A: Loss of linearity indicates system limitations or experimental error.

- Check 1: Pulse Parameters. Excessive pulse amplitude or width can cause peak broadening and non-linear response. Reduce pulse amplitude (e.g., to 25-50 mV) and duration (e.g., 50 ms).

- Check 2: Adsorption Effects. At higher concentrations, analyte or its reduction product may adsorb to the electrode, blocking sites. Examine the electrode surface post-experiment. Consider using a different electrode material (e.g., glassy carbon instead of mercury).

- Check 3: Solution Resistance (IR Drop). In low-conductivity solutions, uncompensated resistance distorts the applied potential. Add an inert supporting electrolyte (e.g., 0.1 M KCl, KNO₃) to increase conductivity. Use the instrument's IR compensation feature if available.

Q3: I observe multiple unexplained peaks in my DPP scan. How do I identify if they are interference or artifacts?

A: Systematic experimentation is required to identify peak sources.

- Step 1: Run a Blank. Perform a DPP scan on the deoxygenated supporting electrolyte alone. Any remaining peaks are from impurities in the electrolyte or electrode.

- Step 2: Check for Oxygen. Dissolved oxygen produces two irreversible reduction peaks (~-0.1 V and ~-0.9 V vs. Ag/AgCl). Purge with high-purity nitrogen or argon for at least 8-10 minutes before scanning.

- Step 3: Test for Metal Ion Impurities. Trace metals in reagents can reduce at specific potentials. Use ultra-pure reagents and consider pre-electrolysis or chelation.

- Step 4: Vary Scan Parameters. Change the pulse amplitude. Genuine faradaic peaks will shift in potential and change height predictably; charging current artifacts will not.

Q4: My mercury drop electrode (HMDE or MFE) shows erratic current steps or "spikes" during the pulse. How can I fix this?

A: This is typically a mechanical or electrical issue with the mercury drop dispenser.

- Fix 1: Check Mercury Capillary. Ensure the capillary is not partially clogged. Gently clean the tip as per manual. For static mercury drop electrodes (SMDE), ensure the drop size control settings are consistent.

- Fix 2: Secure Electrical Connections. Check all cables connecting the electrode to the potentiostat. Loose connections cause current spikes.

- Fix 3: Isolate from Vibration. Physical vibration of the hanging mercury drop causes current noise. Place the instrument on a vibration-damping platform and avoid disturbances during measurement.

Key Quantitative Data for DPP Optimization

Table 1: Effect of Key Instrumental Parameters on DPP Signal

| Parameter | Typical Optimal Range | Effect on Peak Current (ip) | Effect on Peak Width (W₁/₂) | Comment |

|---|---|---|---|---|

| Pulse Amplitude (ΔE) | 25 - 50 mV | Increases linearly with ΔE up to ~50 mV | Increases proportionally | Higher ΔE increases sensitivity but degrades resolution. |

| Pulse Duration (t_p) | 40 - 60 ms | Proportional to t_p⁻¹/² | Minimal direct effect | Shorter t_p increases current but requires faster electronics. |

| Scan Rate (dE/dt) | 1 - 5 mV/s | Increases with √(scan rate) | Minimal increase | Faster scans save time but may increase charging current. |

| Drop Time (t_d) | 0.5 - 2 s | Increases with t_d^(2/3) for HMDE | No effect | Synchronize pulse with end of drop life for max reproducibility. |

| Supporting Electrolyte Concentration | ≥ 0.1 M | No direct effect | No direct effect | Minimizes IR drop and migrational current. |

Table 2: Comparison of Polarographic Techniques in Drug Analysis

| Technique | Limit of Detection (Typical) | Resolution | Resistance to Capacitive Current | Key Advantage for Thesis Context |

|---|---|---|---|---|

| Classical DC Polarography | ~1 × 10⁻⁵ M | Poor | Low | Baseline for comparison; suffers from large charging current. |

| Normal Pulse Polarography (NPP) | ~1 × 10⁻⁶ M | Good | Medium | Reduces charging current vs. DC; less sensitive than DPP. |

| Differential Pulse Polarography (DPP) | ~1 × 10⁻⁸ M | Excellent | High | Superior sensitivity via current sampling pre- & post-pulse. |

| Square Wave Polarography (SWV) | ~1 × 10⁻⁸ M | Excellent | Very High | Faster than DPP; effective rejection of background. |

Experimental Protocol: Standard DPP Determination of a Pharmaceutical Compound

Title: Determination of Nitroimidazole Antibiotic in Serum Using DPP.

Objective: To quantify trace levels of metronidazole (a nitroimidazole drug reducible at the mercury electrode) in a simulated serum matrix, overcoming matrix interference limitations of DC polarography.

Materials: See "The Scientist's Toolkit" below.

Procedure:

- Supporting Electrolyte Preparation: Prepare 0.05 M Britton-Robinson buffer (pH 7.0) containing 0.1 M KNO₃ as the supporting electrolyte.

- Standard Solutions: Prepare a 1.0 mM stock solution of metronidazole in purified water. Prepare serial dilutions in the supporting electrolyte to cover a concentration range of 0.05 µM to 10 µM.

- Sample Preparation (Simulated Serum): To 1.0 mL of drug-free serum, add a known volume of metronidazole stock. Deproteinize by adding 2.0 mL of acetonitrile, vortex for 1 min, and centrifuge at 10,000 rpm for 10 min. Transfer the supernatant, evaporate under nitrogen at 40°C, and reconstitute the residue in 5.0 mL of supporting electrolyte.

- Deoxygenation: Transfer 10 mL of standard or prepared sample into the polarographic cell. Purge with nitrogen gas for 10 minutes to remove oxygen. Maintain a nitrogen blanket over the solution during measurement.

- Instrument Setup:

- Working Electrode: HMDE (Drop size: Medium, Drop time: 1 s).

- Reference Electrode: Ag/AgCl (3 M KCl).

- Counter Electrode: Platinum wire.

- DPP Parameters: Initial E: -0.2 V, Final E: -1.0 V, Scan rate: 2 mV/s, Pulse amplitude: 50 mV, Pulse duration: 50 ms, Sample period: 20 ms (pre- and post-pulse).

- Measurement: Initiate the scan. The reduction of the nitro group will produce a peak near -0.55 V vs. Ag/AgCl.

- Calibration & Analysis: Measure the peak height (in µA) for each standard. Plot peak height vs. concentration to generate a calibration curve. Determine the unknown concentration from the curve.

Visualizations

Title: DPP Experimental Workflow

Title: How DPP Overcomes DC Polarography's Key Limitation

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for DPP Experiments in Drug Development

| Item | Function & Rationale |

|---|---|

| High-Purity Mercury | For the working electrode (HMDE, MFE). Must be triple-distilled to eliminate trace metal impurities that cause interfering reduction peaks. |

| Inert Gas Supply (N₂ or Ar) | For deoxygenation of the analyte solution. Oxygen reduction peaks are major interferents. Gas must be passed through a scrubber to remove residual O₂. |

| Supporting Electrolyte (e.g., 0.1 M KCl, Buffer) | Minimizes solution resistance (IR drop) and eliminates migrational current by carrying the bulk of the charge. Provides controlled pH. |

| Standard Reference Electrode (Ag/AgCl, SCE) | Provides a stable, known reference potential for accurate control of the working electrode potential. Requires regular maintenance. |

| Electrode Polishing Kit (Alumina Slurries) | For solid electrodes (e.g., glassy carbon). Essential for reproducible surface renewal to maintain consistent electron transfer kinetics. |

| Ultra-Pure Water (18.2 MΩ·cm) | Prevents introduction of ionic contaminants and electroactive impurities that contribute to high background noise. |

| Faradaic Cage / Vibration Table | Isolates the sensitive mercury electrode from external vibrations, which cause noise and drop instability. |

Troubleshooting Guides & FAQs

Q1: During SWV analysis of a pharmaceutical compound, I observe a distorted peak shape with significant tailing. What could be the cause and how can I resolve it?

A: This is often due to adsorption of the analyte or its product onto the electrode surface. This is a critical limitation when moving from classical DC polarography to SWV for complex samples. To resolve:

- Clean the electrode meticulously using the protocol in the Experimental Protocols section.

- Implement an electrode conditioning step (e.g., applying a conditioning potential) between scans.

- Consider modifying the electrode surface (e.g., with a self-assembled monolayer) to prevent non-specific adsorption.

- Optimize the SWV frequency. Lower frequencies may reduce adsorption artifacts but compromise speed.

Q2: My calibration curve is non-linear at low concentrations, preventing accurate LOD determination. How can I improve low-concentration performance?

A: Non-linearity often stems from non-faradaic background currents dominating the signal. To overcome this for low detection limits:

- Optimize SWV parameters: Increase the step potential (ΔE_s) to 5-10 mV and use a moderate frequency (f) of 10-25 Hz. This enhances signal-to-background ratio.

- Employ background subtraction: Always run a blank buffer solution under identical conditions and subtract its voltammogram.

- Use a differential current measurement: Ensure your instrument is correctly plotting ΔI (Iforward - Ireverse). This inherently cancels capacitive background.

- Switch to a quieter electrode: A glassy carbon or boron-doped diamond electrode often has a lower background than mercury in certain potentials.

Q3: The SWV signal decreases irreproducibly with successive scans. What is causing this fouling?

A: This indicates electrode passivation or fouling, a common hurdle in drug development analyses. Solutions include:

- Implement a mechanical/chemical cleaning protocol between each measurement (see toolkit).

- Add an electrochemical cleaning/activation step (e.g., +1.4V for 60s in NaOH for glassy carbon) to your experimental workflow.

- Reduce the accumulation time if using an accumulation step to minimize surface loading.

- Consider a different electrolyte or pH to keep the analyte or product soluble.

Q4: How do I choose the optimal SWV frequency for a new analyte?

A: The optimal frequency balances sensitivity and resolution. Perform a frequency study:

- Start at 10 Hz and increase to 100 Hz or the maximum where the electrode kinetics support.

- Plot Peak Current vs. Square Root of Frequency. A linear relationship indicates a reversible, diffusion-controlled system ideal for SWV.

- Deviation from linearity at higher frequencies suggests quasi-reversible or slow kinetics, a limitation of fast SWV. In this case, use a lower frequency (e.g., 25-50 Hz) to prevent peak broadening and potential shift.

Data Presentation

Table 1: Optimized SWV Parameters for Low Detection Limit Analysis vs. Classical DC Polarography

| Parameter | Classical DC Polarography (Typical) | Modern SWV (Optimized for LOD) | Effect on Analysis |

|---|---|---|---|

| Scan Rate | 5 mV/s | Effective Scan Rate: 500 mV/s* | 100x faster analysis. |

| Current Sampling | Total Faradaic + Capacitive | Differential (Forward - Reverse) | Cancels capacitive background, lowers noise. |

| Detection Limit (Typical) | ~1 × 10⁻⁶ M | ~1 × 10⁻⁸ M | 100x lower LOD achievable. |

| Signal Output | Wave-shaped | Peak-shaped | Improved resolution for multi-analyte mixtures. |

| Kinetic Info | Limited | Extracted from f-dependence | Allows study of electrode kinetics. |

*Calculated as ΔE_s × f (e.g., 10 mV × 50 Hz = 500 mV/s).

Table 2: Troubleshooting SWV Parameters for Common Issues

| Symptom | Probable Cause | Primary Parameter to Adjust | Recommended Action |

|---|---|---|---|

| Broad, low peaks | Quasi-reversible kinetics | Frequency (f) | Decrease frequency (e.g., to 15-25 Hz). |

| Noisy baseline | High capacitive current | Amplitude (E_sw) | Decrease pulse amplitude (e.g., to 15-25 mV). |

| Poor peak separation | Low resolution | Step Potential (ΔE_s) | Decrease step potential (e.g., to 2-5 mV). |

| Peak potential shifts with frequency | Slow kinetics | Frequency (f) & Model | Lower f; use standard addition, not calibration. |

| Asymmetric peaks | Adsorption or fouling | Conditioning Protocol | Clean electrode; add rest period at start potential. |

Experimental Protocols

Protocol 1: Standard SWV Optimization for Trace Drug Analysis

- Objective: Determine an unknown concentration of an electroactive drug metabolite with low detection limit.

- Electrode: Glassy Carbon Working Electrode (3 mm), Ag/AgCl reference, Pt counter.

- Electrolyte: 0.1 M Phosphate Buffer Saline, pH 7.4.

- Method:

- Electrode Preparation: Polish the GCE with 0.05 µm alumina slurry on a microcloth. Rinse thoroughly with deionized water and sonicate for 1 minute in ethanol, then in water.

- Baseline Acquisition: Place the electrode in the blank buffer solution. Deoxygenate with N₂ or Ar for 10 minutes. Apply the SWV parameters: Estart = 0.0 V, Eend = +0.8 V, ΔEs = 5 mV, f = 25 Hz, Esw = 25 mV. Record the background voltammogram.

- Standard Addition: Add known aliquots of the drug metabolite stock solution to the cell. After each addition, purge briefly with inert gas (30s), and run the SWV scan under identical conditions.

- Data Analysis: Measure the net peak current (after blank subtraction). Plot peak current vs. added concentration. Perform linear regression to determine the unknown concentration from the x-intercept.

Protocol 2: Electrode Cleaning & Conditioning for Irreproducible Signals

- Objective: Restore electrode activity after fouling from complex biological samples.

- Method (for Glassy Carbon Electrode):

- Mechanical Polish: Polish sequentially with 1.0 µm and 0.05 µm alumina slurry on a clean polishing pad. Rinse copiously with DI water.

- Electrochemical Clean (in 0.1 M NaOH): Cycle the potential between -0.8 V and +1.4 V vs. Ag/AgCl at 100 mV/s for 20 cycles in fresh 0.1 M NaOH.

- Electrochemical Activation (in Analyte Buffer): Transfer to the background electrolyte (e.g., PBS). Apply a constant potential at +1.5 V for 30s, then -1.0 V for 10s.

- Stabilization: Run 5-10 cyclic voltammograms in the clean electrolyte between the analytical potential limits at 50 mV/s until a stable baseline is achieved.

Mandatory Visualization

Title: SWV Optimization for Overcoming DC Polarography Limits

Title: SWV Troubleshooting Decision Tree

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Advanced SWV Experiments

| Item | Function in SWV Experiment | Key Consideration for Low LOD |

|---|---|---|

| Glassy Carbon (GC) Electrode | Standard working electrode for anodic oxidations in drug analysis. | Must be polished to a mirror finish before each experiment to ensure reproducibility. |

| Boron-Doped Diamond (BDD) Electrode | Alternative working electrode with extremely low background current and wide potential window. | Ideal for analytes at extreme potentials or in complex matrices to reduce noise. |

| 0.05 µm Alumina Polishing Slurry | For mechanical abrasion and cleaning of solid electrode surfaces. | Essential for removing adsorbed contaminants and exposing a fresh, active electrode surface. |

| High-Purity Supporting Electrolyte (e.g., PBS, Acetate Buffer) | Provides ionic conductivity, controls pH, and defines the electrochemical window. | Must be prepared with ultrapure water and high-grade salts to minimize faradaic impurities. |

| Oxygen Scavenger (N₂ or Ar Gas) | For deoxygenation of the solution to remove dissolved O₂, which creates interfering reduction waves. | Critical for analysis at negative potentials (reductions). Purge for ≥10 minutes. |

| Redox Internal Standard (e.g., Potassium Ferricyanide) | A well-behaved, reversible redox couple to verify electrode performance and SWV parameter setup. | Use to test new parameters or after electrode modification to confirm system is working. |

| Electrochemical Cell Cleaning Solution (e.g., 50% HNO₃) | For deep cleaning of glassware/cells to prevent cross-contamination at trace levels. | Soak cell and lids when changing analytes or after concentrated samples. |

Technical Support Center: Troubleshooting & FAQs

FAQ 1: Why is my baseline current unstable or noisy during the pre-concentration step in Anodic Stripping Voltammetry (ASV)?

- Answer: An unstable baseline is often caused by contamination, improper electrode conditioning, or dissolved oxygen. First, ensure all glassware and cells are rigorously cleaned with 50% HNO₃ (v/v, trace metal grade) and ultrapure water (≥18.2 MΩ·cm). Condition the working electrode (e.g., mercury film or bismuth) by applying multiple cyclic voltammetry scans in the clean supporting electrolyte. Always deoxygenate the solution by purging with high-purity nitrogen or argon for at least 10 minutes before analysis and maintain a blanket of gas during the pre-concentration step.

FAQ 2: I am getting poor reproducibility between replicates in Cathodic Stripping Voltammetry (CSV) for organic molecules. What could be the issue?

- Answer: Poor reproducibility in CSV often stems from inconsistent electrode surface renewal or non-equilibrium adsorption. For hanging mercury drop electrodes (HMDE), ensure a fresh drop is formed with consistent size for each run. Control the adsorption time and stirring rate precisely. If using a solid electrode, implement a standardized electrochemical cleaning and polishing protocol between runs (e.g., 0.05 µm alumina slurry on a microcloth pad, followed by sonication in water). Verify the pH and ionic strength of your buffer are identical across runs, as adsorption is highly dependent on these parameters.

FAQ 3: How can I resolve overlapping peaks in the stripping step for a mixture of metals?

- Answer: Peak overlap can be addressed by optimizing the deposition potential, using differential pulse waveforms, or modifying the electrolyte. Use the following table to guide electrolyte selection:

Table 1: Common Supporting Electrolytes for Resolving Metal Ion Mixtures in ASV

| Electrolyte | Typical Composition | Optimal for Separating | Notes |

|---|---|---|---|

| Acetate Buffer | 0.1 M CH₃COONa, pH 4.5-5.5 | Pb²⁺, Cd²⁺, Zn²⁺ | Classic electrolyte for Bi or Hg film electrodes. |

| HCl | 0.1 M HCl | Cu²⁺, Pb²⁺, Cd²⁺, Sn²⁺ | Enhances separation of Sn and Cd. |

| CA/NaOH w/ Hg³⁺ | 0.1 M Sodium Citrate, 0.5 M NaOH, 2 ppm Hg²⁺ | Simultaneous detection of Cu, Pb, Cd, Zn | Highly alkaline electrolyte for Zn analysis. |

| KCl | 0.1 M KCl | Tl⁺, Pb²⁺, Cd²⁺ | Simple electrolyte for fundamental studies. |

FAQ 4: My calibration curve is non-linear, especially at very low concentrations. How do I fix this?

- Answer: Non-linearity at ultra-trace levels indicates potential loss of analyte via adsorption to container walls or incomplete deposition/stripping. Acidify samples to pH <2 with ultra-pure HNO₃ for metal analysis. Use containers pre-treated with the sample (pre-soaked). Ensure the deposition time is appropriate for the concentration range; for very low concentrations (< 1 µg/L), longer deposition times may be required, but be mindful of mercury drop saturation or film overloading. Verify the linear range of your specific electrode/configuration with standard additions.

Experimental Protocols

Protocol 1: Standard Addition Method for Ultra-Trace Pb²⁺ and Cd²⁺ in Water by ASV

Objective: To quantitatively determine sub-ppb levels of Pb²⁺ and Cd²⁺ in an aqueous sample. Materials: See "The Scientist's Toolkit" below. Method:

- Electrode Preparation: Polish the glassy carbon working electrode (GCE) sequentially with 1.0 and 0.05 µm alumina slurry on a microcloth. Rinse thoroughly with ultrapure water. Electroplate a mercury film by placing the polished GCE in a deoxygenated solution of 50 mg/L Hg(NO₃)₂ in 0.1 M KNO₃ (pH 2). Deposit at -1.0 V vs. Ag/AgCl for 300 s with stirring.

- Sample Preparation: Acidify 10 mL of filtered water sample with 20 µL of concentrated ultrapure HNO₃. Transfer to the electrochemical cell.

- Deoxygenation: Purge the solution with nitrogen for 10 minutes.

- Pre-concentration/Deposition: With continued N₂ blanket and stirring, deposit the metals onto the Hg/GCE at -1.2 V for 120 s.

- Stripping: After a 15 s equilibration period (no stirring), run a Differential Pulse Anodic Stripping Voltammetry (DPASV) scan from -1.2 V to -0.2 V (pulse amplitude: 50 mV, pulse width: 50 ms, step potential: 4 mV).

- Standard Additions: Repeat steps 4-5 after each of three sequential standard additions (e.g., 20 µL of a 10 mg/L Pb²⁺/Cd²⁺ standard). Plot peak current vs. added concentration to determine the original sample concentration.

Protocol 2: CSV Detection of Naphthalene Derivatives via Nitroso Functionalization

Objective: To pre-concentrate and detect 1-Naphthol via its electroactive nitroso-derivative. Materials: See "The Scientist's Toolkit" below. Method:

- Derivatization: To your sample (or standard), add sodium nitrite (NaNO₂) and HCl to final concentrations of 1 mM and 0.1 M, respectively. Let react for 5 minutes to form the nitroso compound.

- Electrode Setup: Use a freshly extruded HMDE. Parameters: Drop size = medium.

- Adsorption/Pre-concentration: Transfer the derivatized solution to the cell, deoxygenate for 5 min. With stirring, hold the potential at +0.1 V (vs. Ag/AgCl) for 60 s to adsorb the nitroso compound onto the mercury electrode.

- Stripping: After a 10 s rest, initiate a cathodic scan from +0.1 V to -0.7 V using Square Wave Voltammetry (SWV) (frequency: 25 Hz, amplitude: 25 mV, step potential: 4 mV). The reduction of the nitroso group produces a peak around -0.3 to -0.5 V.

- Quantification: Use the standard addition method as described in Protocol 1.

Diagrams

Diagram 1: ASV Workflow for Metal Detection

Diagram 2: CSV Principle for Organic Molecules

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Reagents and Materials for Stripping Analysis

| Item | Function/Description | Critical Notes |

|---|---|---|

| Ultrapure Water (≥18.2 MΩ·cm) | Solvent for all solutions; minimizes background ionic contamination. | Use a dedicated system with sub-boiling distillation or equivalent. |

| Trace Metal Grade Acids (HNO₃, HCl) | Sample acidification, electrolyte preparation, and glassware cleaning. | Essential to prevent exogenous metal contamination. |

| High-Purity Inert Gas (N₂ or Ar, 99.999%) | Decxygenation of electrochemical cell solutions. | Oxygen removal is critical to prevent interfering reduction currents. |

| Supporting Electrolyte Salts (e.g., KCl, Acetate Buffer) | Provides ionic conductivity and controls pH/complexation. | Choose based on target analytes (see Table 1). Use highest purity available. |

| Standard Solutions (Single/Multi-element, 1000 mg/L) | For calibration via standard addition method. | Dilute daily or weekly from stock; use acidified matrix matching solutions. |

| Working Electrode (Hg Film/Bi Film on GCE, HMDE, SPCFE) | Site of pre-concentration and redox reaction. | Choice depends on analyte (metals vs. organics) and required sensitivity. |

| Alumina Polishing Slurries (1.0, 0.3, and 0.05 µm) | Renewing the surface of solid working electrodes (GCE, Au, Pt). | Essential for reproducibility. Follow polish-rinse-sonicate protocol. |

Cyclic Voltammetry (CV) for Mechanistic Studies of Drug Redox Behavior

Technical Support Center: Troubleshooting CV Experiments in Drug Development

This support center is framed within the thesis context: Overcoming limitations of classical DC polarography research, which lacks multi-step mechanistic insight and suffers from mercury electrode limitations. CV provides a powerful alternative for elucidating complex drug redox mechanisms.

Frequently Asked Questions (FAQs)

Q1: My CV for a drug compound shows no redox peaks, only a capacitive current. What could be wrong? A: This is a common issue when moving from theoretical DC polarography conditions. Probable causes and solutions:

- Electrode Surface Fouling: The drug or excipient adsorbs, blocking electron transfer. Solution: Implement a rigorous electrode cleaning protocol (see Protocol 1).

- Incorrect Potential Window: The redox event may occur outside your scanned range. Solution: Consult literature on similar functional groups or perform a preliminary wide scan (-2.0 V to +2.0 V vs. Ag/AgCl, if solvent/electrolyte allows).

- Slow Electron Transfer Kinetics: The reaction is inherently slow at your chosen electrode material. Solution: Increase scan rate; a shift in peak potential with scan rate will confirm a quasi-reversible or irreversible process. Consider a different working electrode (e.g., glassy carbon over platinum).

Q2: I observe multiple, poorly defined peaks that change with repeated cycling. How do I interpret this? A: This indicates complex behavior beyond a simple reversible couple, highlighting CV's advantage over DC polarography.

- Chemical Step Following Electron Transfer (EC Mechanism): The initial redox product undergoes a chemical reaction (e.g., dimerization, decomposition), altering the species for the reverse scan. Solution: Perform scan rate studies and digital simulation to fit the mechanism.

- Surface-Confined Process: The drug strongly adsorbs to the electrode, creating thin-layer cell behavior. Solution: Compare peaks at different concentrations; peak current will scale linearly with scan rate (not its square root) for an adsorbed species.

- Electrode Passivation: The reaction products form an insulating film. Solution: Use rotating disk electrode (RDE) experiments to convect products away from the surface.

Q3: How do I distinguish between a pH-dependent proton-coupled electron transfer (PCET) and a simple electron transfer? A: This is a key mechanistic study where CV excels. Solution: Conduct a systematic pH study. Plot the formal potential (E°) vs. pH. A slope of ~-59 mV/pH (at 25°C) indicates a 1e–/1H+ process. A slope of ~-118 mV/pH indicates a 1e–/2H+ process. A pH-independent potential indicates a simple electron transfer.

Q4: My peak currents are not reproducible between days or electrode preparations. A: This addresses the reproducibility limitation of classical methods.

- Inconsistent Electrode History: Solution: Adopt a standardized, documented activation and cleaning procedure before each experiment (see Protocol 1).

- Uncontrolled Oxygen: Dissolved O2 can participate in side reactions. Solution: Deoxygenate solutions with inert gas (Ar/N₂) for at least 15 minutes prior to scans and maintain a blanket during experiments.

- Unstable Reference Electrode Potential: Solution: Regularly check and replenish the reference electrode filling solution. Use a secondary reference (e.g., Ferrocene/Ferrocenium couple) to report potentials.

Troubleshooting Guides

Issue: Irreproducible Peak Potentials

| Possible Cause | Diagnostic Test | Corrective Action |

|---|---|---|

| Unstable Junction Potential | Measure potential of a standard redox couple (e.g., 1 mM Ferrocene). | Replenish reference electrode salt bridge; use a double-junction reference electrode. |

| Poor Electrical Contact | Check cell resistance in potentiostat software. | Clean all contacts, ensure working electrode is tightly seated. |

| Uncompensated Resistance (Ru) | Observe increased peak separation at high scan rates. | Use the potentiostat's current interrupt or positive feedback iR compensation. |

Issue: Distorted, Asymmetric Peak Shapes

| Possible Cause | Diagnostic Test | Corrective Action |

|---|---|---|

| Excessive Uncompensated Resistance | Peak broadening and separation >59/n mV for reversible system. | Reduce electrolyte concentration; use a smaller electrode; improve iR compensation. |

| Non-Nernstian Behavior / Slow Kinetics | Perform scan rate study. Peak potential shifts with scan rate. | Model data with digital simulation to determine rate constant (k°). |

| Background Current Subtraction Issue | Run blank electrolyte CV and subtract from data. | Ensure proper background subtraction in analysis software. |

Detailed Experimental Protocols

Protocol 1: Standard Activation & Cleaning of a Glassy Carbon Working Electrode

- Polishing: On a clean microcloth, prepare a slurry of 0.05 μm alumina powder in deionized water. Polish the electrode surface using firm, figure-8 patterns for 60 seconds.

- Rinsing: Rinse thoroughly with copious amounts of deionized water from a wash bottle to remove all alumina particles.

- Sonication: Submerge the electrode in a beaker of deionized water or ethanol and sonicate for 1-2 minutes to remove adhered particles.

- Electrochemical Activation: In clean, deoxygenated 0.1 M H₂SO₄ or PBS (pH 7.4), perform cyclic voltammetry between -0.5 V and +1.5 V (vs. Ag/AgCl) at 100 mV/s for 20-50 cycles until a stable background is achieved.

- Final Rinse: Rinse with deionized water and the intended solvent immediately before use.

Protocol 2: Determining the Number of Electrons (n) in a Reversible Redox Process This protocol overcomes the quantitative limitations of DC polarography.

- Record a CV of the drug at a slow scan rate (e.g., 20-50 mV/s) to ensure reversible, diffusion-controlled behavior.

- Record a CV of a known standard (e.g., 1 mM Potassium ferricyanide, n=1) under identical conditions (cell, electrode, scan rate).

- Measure the peak current (Ip) for both the drug and the standard.

- For a reversible system, Ip is given by the Randles-Ševčík equation: Ip = (2.69×10⁵) n^(3/2) A D^(1/2) C ν^(1/2) Since A, ν are constant, and assuming D (diffusion coefficient) is similar: ndrug = nstandard * (Ipdrug / Ipstandard)^(2/3).

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in CV Drug Studies |

|---|---|

| Glassy Carbon Electrode | Standard, versatile working electrode with a wide potential window; inert for most organic drug molecules. |

| Ag/AgCl (3M KCl) Reference Electrode | Provides a stable, reproducible reference potential for aqueous and mixed solvent systems. |

| High-Purity Tetrabutylammonium Hexafluorophosphate (TBAPF₆) | Common supporting electrolyte for non-aqueous (DMSO, ACN) studies; wide electrochemical window, good solubility. |

| Phosphate Buffered Saline (PBS) pH 7.4 | Biologically relevant supporting electrolyte for studying drug behavior under physiological conditions. |

| Ferrocene/Ferrocenium (Fc/Fc⁺) Redox Couple | Internal potential standard for non-aqueous experiments; used to reference potentials and report vs. SHE. |

| Nitrogen (N₂) or Argon (Ar) Gas Cylinder | For deoxygenating solutions to prevent interference from O₂ reduction/oxidation peaks. |

Visualization: Experimental Workflows & Mechanisms

Title: CV Mechanistic Investigation Workflow for Drug Redox

Title: EC Mechanism Common in Drug Degradation

Technical Support Center: Troubleshooting & FAQs

Question 1: Why am I observing a non-linear calibration curve for my API using differential pulse polarography (DPP), and how can I correct it? Answer: A non-linear curve often indicates electrode fouling, non-Nernstian behavior, or analyte concentration exceeding the linear dynamic range. First, ensure your API is fully soluble and stable in the supporting electrolyte. Clean the mercury drop electrode meticulously between runs using the recommended electrochemical cleaning cycle. Dilute your samples to ensure concentrations fall within the 1x10⁻⁵ to 1x10⁻⁷ M range typical for DPP linearity. If the issue persists, consider adding a surfactant like Triton X-100 (0.001-0.01% w/v) to suppress maxima, but ensure it does not interact with your API.

Question 2: How do I resolve poor peak resolution between two structurally similar APIs in a mixture analysis? Answer: Poor resolution arises from overlapping reduction peaks. Optimize your pulse parameters: increase Pulse Amplitude (e.g., from 25 mV to 50 mV) to enhance peak separation and adjust the Scan Rate (slower rates improve resolution). Modify the supporting electrolyte composition and pH to differentially shift the half-wave potentials (E₁/₂) of the APIs. A pH shift of 1-2 units can significantly alter E₁/₂ for pH-dependent reductions. If available, switch to Square Wave Polarography (SWP) for inherently better resolution.

Question 3: What causes high background noise and a drifting baseline in my DC polarogram, and how can I minimize it? Answer: High noise and drift are commonly caused by dissolved oxygen, impurities in the supporting electrolyte, or temperature fluctuations. Decxygenate your solution rigorously by purging with high-purity nitrogen or argon for a minimum of 10-15 minutes before analysis and maintain a blanket during runs. Use the highest grade salts (e.g., ACS Reagent Grade) for electrolyte preparation and consider pre-electrolysis to remove trace metals. Ensure consistent thermostating of the cell at ± 0.5 °C. Implement digital filtering (e.g., Savitzky-Golay) during data processing.

Question 4: My mercury drop electrode shows unstable current. What are the steps to diagnose and fix this? Answer: Unstable current (drop noise) indicates issues with the capillary or mercury purity. Follow this protocol:

- Check Drop Time: Manually time the drop detachment. If irregular, clean the capillary: immerse in concentrated nitric acid (1:1 HNO₃/H₂O) for 30 minutes, rinse with copious deionized water, then dry.

- Inspect Mercury Reservoir: Ensure no air bubbles are in the tubing or capillary head.

- Purify Mercury: If suspicion exists, clean the mercury by passing it through a dilute HNO₃ (10%) wash followed by multiple deionized water washes in a fine-pore filter funnel.

- Check Electrical Connections: Ensure all contacts to the electrode stand are clean and tight.

Table 1: Comparison of Polarographic Techniques for API Quantification

| Technique | Typical LOD (M) | Linear Dynamic Range (M) | Key Advantage | Primary Limitation |

|---|---|---|---|---|

| Classical DC Polarography | ~1x10⁻⁵ | 1x10⁻⁵ – 1x10⁻³ | Robust, simple instrumentation | High LOD, capacitive current interference |

| Differential Pulse Polarography (DPP) | ~1x10⁻⁷ | 1x10⁻⁷ – 1x10⁻⁵ | Excellent sensitivity, reduced capacitive current | Slower than SWP |

| Square Wave Polarography (SWP) | ~1x10⁻⁸ | 1x10⁻⁸ – 1x10⁻⁶ | Very fast, excellent sensitivity & resolution | More complex parameter optimization |

Table 2: Optimized DPP Parameters for Common API Functional Groups

| API Functional Group | Supporting Electrolyte | Recommended pH | Pulse Amplitude (mV) | Approx. E₁/₂ vs. SCE (V) |

|---|---|---|---|---|

| Nitroaromatics | 0.1 M Phosphate Buffer | 7.0 | 50 | -0.3 to -0.6 |

| Azo Compounds | Britton-Robinson Buffer | 3.0 | 25 | -0.2 to -0.4 |

| Carbonyls | 0.05 M LiCl in Methanol | N/A | 50 | -1.8 to -2.2 |

| Halogenated Compounds | 0.1 M Tetraethylammonium iodide | N/A | 50 | -1.5 to -2.5 |

Experimental Protocols

Protocol 1: Standard Method for API Assay Using Differential Pulse Polarography

- Solution Preparation: Dissolve precisely weighed API in the chosen deoxygenated supporting electrolyte (e.g., 0.1 M phosphate buffer, pH 7.0). Prepare a series of 5-7 standard solutions across the expected concentration range.

- Instrument Setup: Configure the polarograph: Drop Time = 1 s, Scan Rate = 5 mV/s, Pulse Amplitude = 50 mV, Pulse Duration = 50 ms. Set initial and final potentials based on preliminary scans.

- Decxygenation: Transfer 10 mL of standard solution to the polarographic cell. Purge with nitrogen gas for 12 minutes. Maintain a nitrogen blanket above the solution during the run.

- Measurement: Initiate the potential scan. Record the DPP polarogram. Measure the peak current (Ip) for each standard.

- Calibration: Plot Ip (µA) vs. API concentration (M). Perform linear regression to obtain the calibration equation.