Advanced Fabrication of Solid-Contact Ion-Selective Electrodes: A Comprehensive Guide for Biomedical Research and Drug Development

This article provides a comprehensive examination of solid-contact ion-selective electrode (SC-ISE) fabrication, addressing the critical needs of researchers and drug development professionals.

Advanced Fabrication of Solid-Contact Ion-Selective Electrodes: A Comprehensive Guide for Biomedical Research and Drug Development

Abstract

This article provides a comprehensive examination of solid-contact ion-selective electrode (SC-ISE) fabrication, addressing the critical needs of researchers and drug development professionals. It explores the fundamental principles and advantages of SC-ISEs over traditional liquid-contact systems, including their miniaturization potential and enhanced stability. The content details advanced methodological approaches utilizing novel materials like conducting polymers, carbon nanotubes, and nanocomposites, with specific applications in pharmaceutical analysis and clinical monitoring. Practical troubleshooting guidance addresses common challenges such as potential drift and water layer formation, while validation protocols and comparative performance analyses against reference techniques like ICP-OES establish reliability standards. This integrated resource supports the development of robust, reproducible potentiometric sensors for biomedical and clinical applications.

Fundamentals of Solid-Contact ISEs: Principles, Components, and Advantages for Modern Sensing

Solid-contact ion-selective electrodes (SC-ISEs) represent a significant advancement in potentiometric sensing technology by eliminating the traditional inner filling solution. This architecture enables easier miniaturization, enhanced stability, and improved suitability for portable, wearable, and on-site analysis in environmental, industrial, and biomedical applications [1] [2]. This application note details the fundamental architecture, working principles, and experimental protocols for SC-ISE fabrication, providing researchers with a framework for developing these solid-state systems. The replacement of the liquid contact with a solid-contact (SC) layer that acts as an ion-to-electron transducer addresses inherent limitations of liquid-contact ISEs (LC-ISEs), including internal solution evaporation, osmotic pressure effects, and difficulties in miniaturization [1].

Fundamental SC-ISE Architecture and Working Principle

Core Components

The SC-ISE is a multi-layered structure consisting of three essential components [1] [2]:

- Conductive Substrate: The electron-conducting base (e.g., glassy carbon, metal, or screen-printed electrode) that provides the electrical connection.

- Solid-Contact (SC) Layer: The intermediary layer deposited on the conductive substrate, responsible for the crucial ion-to-electron transduction. It must possess both high ionic and electronic conductivity.

- Ion-Selective Membrane (ISM): The outermost layer that provides selective recognition of the target ion. It typically comprises a polymer matrix, a plasticizer, an ionophore (ion carrier), and an ion exchanger [1].

Working Principle

The operational principle is based on potentiometry, where the potential difference between the SC-ISE and a reference electrode is measured under negligible current flow [1] [2]. The total electromotive force (EMF) is the sum of all interfacial potentials. The key event is the specific recognition of the target ion by the ionophore in the ISM. The subsequent signal transduction occurs at the ISM/SC interface, which can proceed via two primary mechanisms [1]:

- Redox Capacitance Mechanism: Utilizes conducting polymers (CPs) like poly(3-octylthiophene) or polyaniline. The transduction involves reversible redox reactions accompanied by ion doping/de-doping, which provides a high redox capacitance to stabilize the potential [1].

- Electric Double-Layer (EDL) Capacitance Mechanism: Employs materials with a high specific surface area (e.g., 3D porous carbon, carbon nanotubes) to create a large double-layer capacitance at the ISM/SC interface, which stabilizes the potential [1] [3].

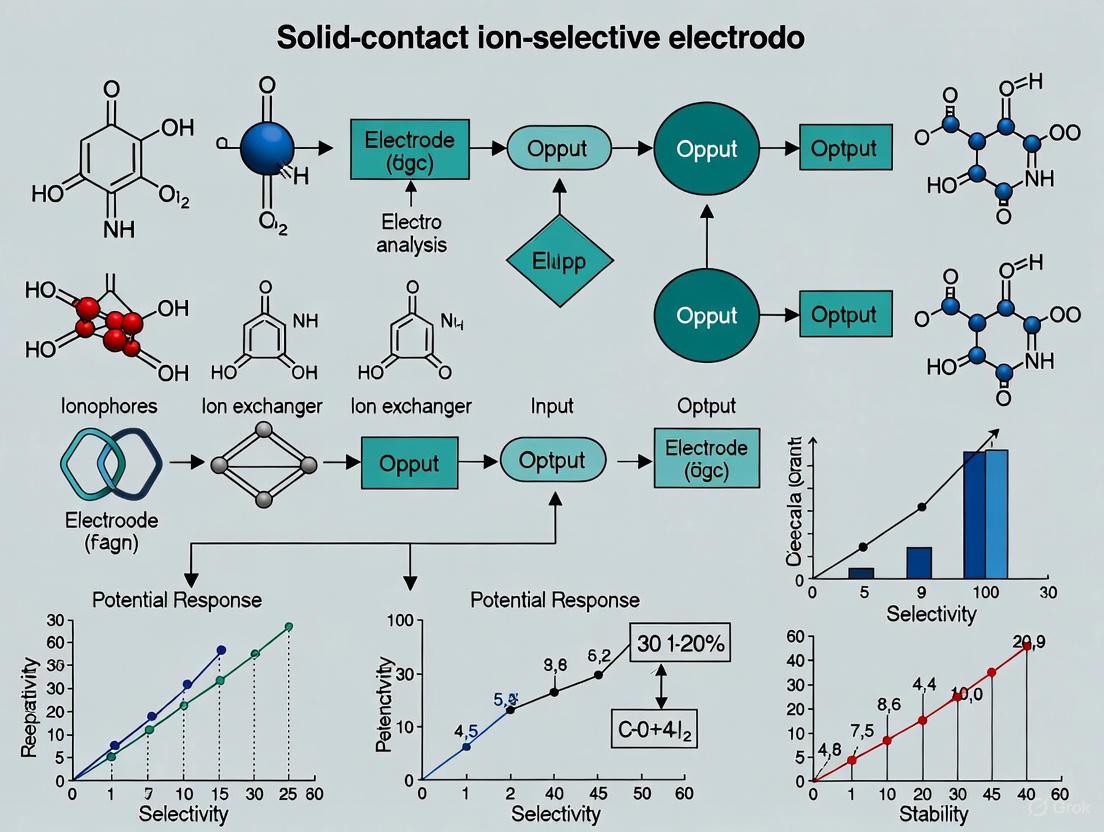

The following diagram illustrates the architecture and contrasts it with a traditional liquid-contact design.

The Scientist's Toolkit: Key Materials and Reagents

The performance of SC-ISEs is highly dependent on the materials used in their construction. The table below catalogues essential reagents and their functions.

Table 1: Key Research Reagents for SC-ISE Fabrication

| Component Category | Example Materials | Function | Key Characteristics |

|---|---|---|---|

| Solid-Contact Materials [3] [4] | Conducting Polymers (e.g., PEDOT, POT, PPer) | Ion-to-electron transduction via redox capacitance | High redox capacitance, mixed ionic/electronic conductivity |

| Carbon Nanomaterials (e.g., MWCNTs) | Ion-to-electron transduction via double-layer capacitance | High surface area, hydrophobicity, electrical conductivity | |

| Nanocomposites (e.g., MWCNTs/CuO NPs) | Combines properties of constituents for enhanced performance | Improved potential stability, reproducibility, temperature resistance [4] | |

| Ion-Selective Membrane Components [1] | Polymer Matrix (e.g., PVC) | Provides structural backbone for the membrane | Mechanical stability, compatibility with other components |

| Plasticizer (e.g., DOS, NOPE) | Confers plasticity and modulates membrane polarity | High lipophilicity, low volatility, governs ionophore selectivity | |

| Ionophore (e.g., Valinomycin for K⁺) | Selectively binds and extracts the target ion | High selectivity, strong complexation, sufficient hydrophobicity | |

| Ion Exchanger (e.g., NaTFPB, KTFPB) | Introduces fixed ionic sites for permselectivity | Enables Donnan exclusion, reduces interference, ensures conductivity |

Quantitative Performance of Select Solid-Contact Materials

The choice of solid-contact material directly impacts critical sensor parameters, including sensitivity, detection limit, and stability. The following table summarizes the performance of different SC materials for potassium ion-sensing under varying temperatures, based on a comparative study [4].

Table 2: Potentiometric Response of K⁺-SCISEs with Different Solid Contacts at Varying Temperatures [4]

| Electrode Designation | Temperature | Slope (mV/decade) | Detection Limit (M) | Potential Stability (µV/s) |

|---|---|---|---|---|

| GCE/PPer/ISM | 10 °C | ~56.18 (Theoretical) | Lowest at 10 °C | 0.11 |

| 23 °C | ~59.16 (Theoretical) | Lowest at 23 °C | 0.05 | |

| 36 °C | ~61.37 (Theoretical) | Lowest at 36 °C | 0.06 | |

| GCE/NC/ISM | 10 °C | ~56.18 (Theoretical) | Lowest at 10 °C | 0.12 |

| 23 °C | ~59.16 (Theoretical) | Lowest at 23 °C | 0.08 | |

| 36 °C | ~61.37 (Theoretical) | Lowest at 36 °C | 0.09 | |

| GCE/POT/ISM | 10 °C | Close to theoretical | Higher than PPer/NC | Not Specified |

| 23 °C | Close to theoretical | Higher than PPer/NC | Not Specified | |

| 36 °C | Close to theoretical | Higher than PPer/NC | Not Specified | |

| GCE/MWCNTs/ISM | 10 °C | Deviates from theoretical | Higher than PPer/NC | Not Specified |

| 23 °C | Deviates from theoretical | Higher than PPer/NC | Not Specified | |

| 36 °C | Deviates from theoretical | Higher than PPer/NC | Not Specified |

Experimental Protocol: Fabrication and Characterization of a SC-ISE

This protocol outlines the general procedure for fabricating a solid-contact ion-selective electrode, from substrate preparation to analytical characterization.

Electrode Fabrication Workflow

The sequential steps for constructing a SC-ISE are visualized in the following workflow.

Detailed Methodologies

Part A: Fabrication of the Solid-Contact Layer

Method 1: Drop-Casting of a Conducting Polymer

- Solution Preparation: Dissolve the conducting polymer (e.g., poly(3-octylthiophene-2,5-diyl), POT) in a suitable volatile organic solvent (e.g., tetrahydrofuran or chloroform) to form a homogeneous solution [1] [4].

- Deposition: Using a micropipette, deposit a precise volume (e.g., 5-10 µL) of the polymer solution onto the surface of the clean, prepared conductive substrate.

- Drying: Allow the solvent to evaporate completely at room temperature or under a gentle stream of an inert gas (e.g., nitrogen) to form a uniform, dry SC layer.

Method 2: Drop-Casting of Carbon Nanomaterials

- Dispersion Preparation: Disperse the nanomaterial (e.g., multi-walled carbon nanotubes, MWCNTs) in an organic solvent or water, often with the aid of surfactants or functionalization, to create a stable, homogeneous dispersion [4].

- Deposition and Drying: Deposit a known volume of the dispersion onto the substrate and allow it to dry, as described in Method 1.

Part B: Preparation and Application of the Ion-Selective Membrane

- ISM Cocktail Formulation: Precisely weigh the ISM components into a glass vial. A typical formulation for a 100 mg membrane might include [1]:

- 1.0 mg Ionophore (e.g., Valinomycin for K⁺)

- 0.5 mg Ion Exchanger (e.g., Potassium tetrakis[3,5-bis(trifluoromethyl)phenyl]borate, KTFPB)

- 32.5 mg Polymer Matrix (e.g., Polyvinyl Chloride, PVC)

- 66.0 mg Plasticizer (e.g., bis(2-ethylhexyl) sebacate, DOS)

- Dissolution: Add a suitable volume of tetrahydrofuran (THF, ~200-300 µL) to the vial and vortex until all components are fully dissolved, forming a homogeneous, viscous cocktail.

- Membrane Casting: Deposit a defined volume (e.g., 20-30 µL) of the ISM cocktail directly onto the solidified SC layer.

- Solvent Evaporation: Allow the THF to evaporate slowly at room temperature for at least 12 hours (or overnight) to form a smooth, defect-free ion-selective membrane.

Part C: Conditioning and Potentiometric Characterization

- Conditioning: Soak the newly fabricated SC-ISE in a solution of its primary ion (e.g., 0.01 M KCl for a K⁺-ISE) for approximately 24 hours before the first use. This critical step hydrates the membrane and establishes stable equilibrium conditions at all interfaces [3].

- Calibration Curve Measurement:

- Prepare a series of standard solutions of the primary ion across a broad concentration range (e.g., from 1 × 10⁻⁷ M to 1 × 10⁻¹ M) using a constant ionic strength background.

- Immerse the conditioned SC-ISE and an appropriate reference electrode (e.g., Ag/AgCl) in each standard solution from the lowest to the highest concentration.

- Measure the steady-state potential (EMF) for each solution.

- Plot the measured EMF (mV) versus the logarithm of the primary ion activity (log aᵢ). Perform linear regression on the linear portion of the plot to determine the slope (sensitivity, in mV/decade) and the lower limit of detection [3] [4].

- Stability and Reproducibility Assessment:

- Potential Drift: Measure the potential of the SC-ISE in a constant concentration solution over an extended period (e.g., 1 hour). The drift is calculated as the change in potential per unit time (e.g., µV/s or µV/h) [4].

- Reproducibility: Fabricate at least three electrodes in the same batch and compare their standard potentials (E⁰) and calibration slopes. High reproducibility is indicated by a low standard deviation of the E⁰ values [3].

Solid-contact ion-selective electrodes (SC-ISEs) represent a significant advancement over traditional liquid-contact ion-selective electrodes (LC-ISEs). While LC-ISEs suffer from limitations such as the evaporation and osmotic pressure effects of inner filling solutions, which hinder miniaturization and careful maintenance, SC-ISEs eliminate these issues by incorporating a solid-contact (SC) layer between the ion-selective membrane (ISM) and the electronic conduction substrate (ECS) [1]. This architecture allows SC-ISEs to possess the advantages of easy miniaturization, chip integration, portability, strong stability, and reliable detection in complex environments, making them highly suitable for portable, wearable, and intelligent detection devices in environmental, industrial, and biomedical applications [1].

The core components of an SC-ISE work in concert to convert a chemical signal (ion activity) into an electrical signal (potential). The ion-selective membrane is responsible for the selective recognition of target ions from the sample solution. The solid-contact layer acts as an ion-to-electron transducer, ensuring stable signal conversion. The conductive substrate serves as the electron conductor, relaying the signal to the measuring instrument [1]. Understanding the design, material selection, and fabrication of these three components is crucial for developing high-performance potentiometric sensors.

Ion-Selective Membranes (ISMs)

The ion-selective membrane is the cornerstone of sensor selectivity. It is a polymeric matrix that selectively interacts with the target ion, generating a membrane potential that correlates with the ion's activity in the sample solution [1].

Composition and Function

The ISM is typically composed of four key elements, each with a distinct function [1]:

- Polymer Matrix: Provides the physical backbone and mechanical properties for the membrane. Common materials include polyvinyl chloride (PVC), acrylic esters, polyurethane, polystyrene, and silicone rubber.

- Plasticizer: Improves the plasticity and fluidity of the membrane, and its polarity can optimize selectivity based on the ionophore. Examples are bis(2-ethylhexyl) sebacate (DOS), dibutyl phthalate (DBP), and 2-nitrophenyloctyl ether (NOPE).

- Ionophore: The key component for selectivity, responsible for specifically extracting the target ions from the sample into the membrane. These can be natural or synthetic molecules with functional groups that accommodate target ions.

- Ion Exchanger: Introduces oppositely charged sites into the membrane to facilitate ion exchange and ensure permselectivity. Common ion exchangers are sodium tetrakis(pentafluorophenyl) borate (NaTFPB) and potassium tetrakis[3,5-bis(trifluoromethyl)phenyl] borate (KTFPB).

Optimized Membrane Formulations

Recent research has demonstrated optimized membrane compositions for specific analytes. The table below summarizes key formulations from recent studies.

Table 1: Examples of Optimized Ion-Selective Membrane Formulations

| Target Ion | Polymer Matrix | Plasticizer | Ionophore | Ion Exchanger | Key Performance | Citation |

|---|---|---|---|---|---|---|

| Cadmium (Cd²⁺) | PVC | NPOE | Not specified | Not specified | Nernstian slope: 29.7 ± 0.4 mV/decade; LOD: 6.8×10⁻⁸ M | [5] |

| Silver (Ag⁺) | PVC | NPOE | Calix[4]arene | NaTFPB | Near-Nernstian slope: 61.0 mV/decade; LOD: 4.1×10⁻⁶ M; For Ag⁺ from SSD | [6] |

| Sodium (Na⁺) | 3D-printed polymer | Not specified | Sodium ionophore | Not specified | Nernstian slope: 57.1 mV/decade; LOD: 0.0024 mM | [7] |

| Potassium (K⁺) | PVC-based K-ISM | Not specified | Valinomycin | Not specified | Linear range: 10⁻⁵ to 10⁻¹ M; For veterinary medicine | [8] |

| Lithium (Li⁺) | Inorganic LATP plate (Li₁₊ₓ₊ᵧAlₓ(Ti,Ge)₂₋ₓSiᵧP₃₋ᵧO₁₂) | Not applicable (solid electrolyte) | Not applicable | Not applicable | Nernstian slope: 60.8 ± 0.5 mV/decade; LOD: 10⁻⁴.⁹ | [9] |

Solid-Contact Layers

The solid-contact layer is the heart of the SC-ISE, responsible for transducing ionic currents from the ISM into electronic currents in the conductive substrate. Its properties directly impact the sensor's potential stability, reproducibility, and sensitivity.

Transduction Mechanisms

Two primary transduction mechanisms are employed in SC-ISEs [1] [5]:

- Electric Double-Layer Capacitance: This mechanism relies on materials with a high specific surface area (e.g., carbon nanomaterials, MXenes) to form a capacitive interface at the SC/ISM boundary. The large capacitance helps to stabilize the potential and reduce drift [1] [8].

- Redox Capacitance: This mechanism utilizes materials with reversible redox properties (e.g., conducting polymers like PEDOT, functionalized COFs) to provide a well-defined interfacial potential. This enhances the reproducibility of the standard potential (E°) between electrodes [1] [5].

Recently, mixed-mechanism transducers that combine both large double-layer capacitance and defined redox activity have been developed to harness the benefits of both approaches [5].

Material Classes and Performance

Extensive research has been conducted on various materials for solid-contact layers. The following table compares the performance of different transducer materials.

Table 2: Performance Comparison of Solid-Contact Transducer Materials

| Transducer Material | Type/Mechanism | Key Advantages | Reported Performance | Citation |

|---|---|---|---|---|

| Graphene | Double-layer Capacitance | High hydrophobicity, high capacitance, excellent stability | Lowest potential drift, highest capacitance among carbon materials | [10] |

| DAAQ-TFP@rGO | Mixed (Redox + Capacitive) | Good redox activity from anthraquinone, high capacitance from rGO | Capacitance: 2.0 mF; Potential drift: 1.2 μV/h; Excellent E° reproducibility | [5] |

| Hydrophobic Ti₃C₂/AuNPs | Double-layer Capacitance | Prevents water layer, enhanced conductivity, integrated temp. sensor | Stable across 5-45°C; resists water layer formation | [8] |

| Multi-Walled Carbon Nanotubes (MWCNTs) | Double-layer Capacitance | High hydrophobicity, large surface area, efficient ion-electron transduction | Improved potential stability; prevented aqueous layer formation in Ag⁺-ISE | [6] |

| Conducting Polymers (e.g., PEDOT) | Redox Capacitance | High redox capacitance, both ionic and electronic conductivity | Well-defined interfacial potential, good reproducibility | [1] |

| LiFePO₄/FePO₄ | Redox Capacitance (Battery-inspired) | Extremely stable reference potential, high reproducibility | Potential variation: -3 to +6 mV over 17 days; Low device-to-device deviation | [9] |

Diagram 1: Core components of an SC-ISE and the primary ion-to-electron transduction mechanisms in the solid-contact layer.

Conductive Substrates

The conductive substrate forms the physical foundation of the SC-ISE and provides the electrical connection to the external measuring instrument. The choice of substrate is closely linked to the desired sensor architecture and application.

- Glassy Carbon Electrodes (GCEs): Offer a stable, polished surface for depositing solid-contact and membrane layers and are commonly used in laboratory prototypes [11].

- Screen-Printed Electrodes (SPEs): Planar, disposable, mass-producible sensors printed on ceramic or plastic substrates. They enable miniaturization, integration of multiple electrodes, and are ideal for low-cost, single-use applications in field and point-of-care testing [6] [8].

- 3D-Printed Substrates: An emerging technology that allows for the fabrication of fully customized, monolithic sensor geometries. For example, conductive substrates can be printed from carbon-infused polylactic acid (CB-PLA), offering new possibilities for rapid prototyping and complex design [7].

Detailed Experimental Protocols

Protocol: Fabrication of a Cd²⁺-ISE with a COF@rGO Solid Contact

This protocol is adapted from the work on a DAAQ-TFP@rGO-based cadmium ion-selective electrode [5].

5.1.1 Synthesis of DAAQ-TFP@rGO Composite

- Dissolve 178.2 mg of p-toluenesulfonic acid (PTSA) and 40.2 mg of 2,6-diaminoanthraquinone (DAAQ) powder in 15 mL of deionized water under vigorous stirring to form a yellow solution.

- Add this solution dropwise to 13 mL of a graphene oxide (GO) dispersion (5 mg/L) to obtain a homogeneous mixture.

- Add 23.4 mg of 1,3,5-triformylphloroglucinol (TFP) to the aforementioned dispersion, resulting in a viscous slurry.

- Transfer the mixture into a Teflon-lined autoclave and maintain it at 180 °C for 12 hours for a hydrothermal reaction.

- After cooling, collect the resulting solid product via filtration, wash it repeatedly with deionized water and ethanol, and dry it under vacuum at 60 °C overnight.

5.1.2 Electrode Fabrication

- Polish a glassy carbon electrode (GCE, 3 mm diameter) sequentially with 1.0 and 0.3 μm alumina slurries. Clean ultrasonically in deionized water and ethanol, then dry under a nitrogen stream.

- Prepare an ink by dispersing 2.0 mg of the DAAQ-TFP@rGO composite in 1.0 mL of a water/ethanol (1:1, v/v) mixture with 30 minutes of sonication.

- Drop-cast 8.0 μL of the ink onto the clean GCE surface and allow it to dry at room temperature, forming the solid-contact layer.

- Prepare the Cd²⁺ ion-selective membrane cocktail by dissolving 1.0 mg of ionophore, 0.55 mg of NaTFPB, 33.0 mg of PVC, and 65.0 mg of the plasticizer NPOE in 1.5 mL of tetrahydrofuran (THF).

- Drop-cast 80.0 μL of the membrane cocktail onto the surface of the modified GCE and air-dry overnight to form the ion-selective membrane.

5.1.3 Conditioning and Measurement

- Condition the fabricated Cd²⁺-ISE by soaking in a 1.0 × 10⁻³ M Cd(NO₃)₂ solution for at least 24 hours before use.

- Perform all potentiometric measurements against a conventional double-junction Ag/AgCl reference electrode.

- The electrode should exhibit a Nernstian slope of ~29.7 mV/decade in a linear range from 1.0 × 10⁻⁷ M to 7.9 × 10⁻⁴ M.

Protocol: Fabrication of a Fully 3D-Printed Na⁺-ISE

This protocol outlines the steps for creating a monolithic, fully 3D-printed sodium ion-selective electrode [7].

5.2.1 Printing Process

- Print the Conductive Substrate: Use a fused deposition modeling (FDM) 3D printer and a filament of carbon-infused polylactic acid (CB-PLA) to print the electrode body and conductive substrate. Optimize printing parameters (e.g., angle, thickness) to enhance transducer hydrophobicity.

- Print the Ion-Selective Membrane: Use a stereolithography (SLA) 3D printer to fabricate the Na⁺-ion-selective membrane directly onto the CB-PLA transducer. The photocurable resin for the SLA printer should be formulated with sodium ionophore, ion exchanger, and plasticizer.

5.2.2 Conditioning and Measurement

- Condition the fully assembled 3D-printed sensor in a NaCl solution.

- The optimized sensor should demonstrate a Nernstian slope of ~57.1 mV/decade for Na⁺ and a low potential drift of approximately 20 μV/h.

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Key Reagents and Materials for SC-ISE Fabrication

| Item Name | Function/Application | Specific Examples |

|---|---|---|

| Ionophores | Provides selectivity for the target ion. | Calix[4]arene (for Ag⁺), Valinomycin (for K⁺), Dibenzyl-14-crown-4 (for Li⁺), Cadmium ionophore |

| Ion Exchangers | Imparts permselectivity and facilitates ion exchange within the ISM. | Sodium tetrakis(pentafluorophenyl) borate (NaTFPB), Potassium tetrakis[3,5-bis(trifluoromethyl)phenyl] borate (KTFPB) |

| Polymer Matrices | Forms the structural backbone of the ion-selective membrane. | Polyvinyl Chloride (PVC), Acrylic esters, Polyurethane |

| Plasticizers | Provides membrane fluidity and modulates dielectric constant. | 2-Nitrophenyl octyl ether (NPOE), Bis(2-ethylhexyl) sebacate (DOS) |

| Solid-Contact Materials | Acts as an ion-to-electron transducer. | Graphene, Multi-walled Carbon Nanotubes (MWCNTs), DAAQ-TFP@rGO composite, PEDOT, Hydrophobic Ti₃C₂ Mxene/AuNPs |

| Conductive Substrates | Serves as the electron-conducting base for the sensor. | Glassy Carbon Electrodes (GCE), Screen-Printed Electrodes (SPEs), 3D-printed Carbon-PLA |

| Solvents | For dissolving membrane components and fabricating sensing cocktails. | Tetrahydrofuran (THF), Cyclohexanone |

Diagram 2: A generalized workflow for the fabrication of a solid-contact ion-selective electrode.

The performance of solid-contact ISEs is dictated by the synergistic interplay between their three core components: the ion-selective membrane, the solid-contact layer, and the conductive substrate. Recent material advances, such as mixed-mechanism transducers (e.g., DAAQ-TFP@rGO), hydrophobic nanocomposites (e.g., Ti₃C₂/AuNPs), and battery-inspired reference systems (e.g., LiFePO₄/FePO₄), have led to significant improvements in sensor stability, reproducibility, and selectivity [5] [8] [9]. Furthermore, innovative fabrication techniques like 3D printing are paving the way for customized, cost-effective, and mass-producible sensors [7]. A deep understanding of the materials and protocols outlined in this document provides researchers with a solid foundation for developing next-generation potentiometric sensors for demanding applications in healthcare, environmental monitoring, and industrial process control.

Solid-contact ion-selective electrodes (SC-ISEs) represent a significant evolution from traditional liquid-contact electrodes, enabling miniaturization, integration into wearable sensors, and use in various applications from clinical diagnostics to environmental monitoring [12]. The core innovation in SC-ISEs is the solid-contact layer that mediates between the ion-conducting selective membrane and the electron-conducting substrate. This layer performs the crucial ion-to-electron transduction, converting the chemical signal (ion activity) into an electrical signal (potential) that can be measured potentiometrically [12]. Two primary physical mechanisms govern this transduction: redox capacitance and electric double-layer (EDL) capacitance [12]. The choice of mechanism depends fundamentally on the properties of the solid-contact material used, with conducting polymers typically operating via redox capacitance and carbon-based materials often relying on EDL capacitance [12] [13]. Understanding the distinction between these mechanisms is essential for designing SC-ISEs with optimal potential stability, sensitivity, and robustness for specific applications.

Theoretical Foundations of Transduction Mechanisms

Redox Capacitance Mechanism

The redox capacitance mechanism operates in solid-contact materials that exhibit highly reversible redox behavior, with conducting polymers serving as the quintessential example [12]. In this mechanism, ion-to-electron transduction occurs through oxidation and reduction reactions within the solid-contact material itself. The thermodynamic foundation for this mechanism can be illustrated using poly(3,4-ethylenedioxythiophene) (PEDOT) doped with Y⁻ anions as a model system [12].

The overall ion-to-electron transduction reaction can be summarized as: PEDOT⁺Y⁻ (SC) + K⁺ (aq) + e⁻ (GC) ⇌ PEDOT (SC) + Y⁻ (ISM) + K⁺ (ISM) [12]

This overall reaction encompasses three distinct equilibrium potentials that establish at different interfaces:

- Electron transfer at the conductor/SC interface: Governed by the Nernst equation for the PEDOT⁺/PEDOT redox couple

- Ion transfer at the SC/ISM interface: Determined by the distribution of Y⁻ anions between the solid-contact and ion-selective membrane phases

- Ion transfer at the ISM/sample interface: Controlled by the selective recognition of the target ion (K⁺) [12]

The total measured potential (E) represents the sum of these three interfacial potentials, resulting in the familiar Nernstian response to the target ion activity [12]. A key advantage of this mechanism is that the potential is thermodynamically well-defined, contributing to enhanced potential stability of the electrode [12].

Electric Double-Layer Capacitance Mechanism

The electric double-layer capacitance mechanism functions through a physical separation of charge at the interface between the solid-contact material and the ion-selective membrane, forming an asymmetric capacitor [12]. This mechanism does not involve faradaic electron transfer reactions but rather relies on the electrostatic arrangement of charges at the interface [14].

In this system, one side of the capacitor consists of electronic charges (electrons or holes) in the solid-contact material, while the opposite side comprises ionic charges in the ion-selective membrane [12]. The resulting capacitance (C) is defined as C = ∂σ/∂E, where σ represents the surface charge density and E is the electrode potential [14]. The overall capacitance arises from the series connection of multiple capacitive components, including the metal phase capacitance (CM), dipole layer capacitance (Cdip), and Helmholtz ionic layer capacitance (CH), following the relationship: 1/Ci = 1/CM + 1/Cdip + 1/CH [14].

Materials that employ this mechanism typically possess high specific surface areas, such as carbon nanotubes, graphene, and other nanostructured carbon materials [13] [15]. The extensive surface area significantly enhances the double-layer capacitance without increasing the geometric projection of the solid contact, thereby improving the potential stability of the electrode [13]. The differential capacitance of the electrode/electrolyte interface exhibits a characteristic minimum at the potential of zero charge (pzc), which can be identified through capacitance versus potential measurements [14].

Comparative Analysis of Fundamental Principles

Table 1: Fundamental characteristics of transduction mechanisms

| Feature | Redox Capacitance | Electric Double-Layer Capacitance |

|---|---|---|

| Primary Materials | Conducting polymers (PEDOT, PANi) [12] | Carbon materials (MWCNTs, graphene) [16] [13] |

| Transduction Process | Faradaic (redox reactions) [12] | Non-faradaic (electrostatic) [12] |

| Thermodynamic Basis | Well-defined (Nernst equation) [12] | Defined by capacitance and charge separation [14] |

| Key Advantage | Thermodynamically defined potential [12] | High capacitance from large surface area [13] |

| Kinetic Considerations | Dependent on redox reaction rates | Limited by ion migration in double layer |

| Typical Capacitance Range | Moderate | High (e.g., 383.4 µF for graphene) [16] |

Diagram 1: Fundamental transduction mechanisms in SC-ISEs showing two primary pathways with their characteristic materials, thermodynamic bases, and advantages.

Experimental Assessment and Performance Comparison

Methodologies for Transducer Characterization

Chronopotentiometry for Potential Stability Assessment

Chronopotentiometry serves as a crucial technique for evaluating the potential stability of solid-contact transducers by applying a constant current and monitoring potential drift over time [16]. The protocol involves applying a small constant current (typically ±0.5-1 nA) to the electrode and recording the potential change over a specific duration (usually 5-60 seconds) [16]. The short-term potential drift (∆E/∆t) calculated as µV s⁻¹ provides a key metric for stability, with lower values indicating superior performance [16]. Additionally, this technique enables calculation of the total capacitance (C) using the formula C = i/(∆E/∆t), where i represents the applied current, and ∆E/∆t denotes the potential drift [16]. For instance, graphene-based transducers demonstrated exceptional capacitance of 383.4 ± 36.0 µF with minimal potential drift of 2.6 ± 0.3 µV s⁻¹ [16].

Electrochemical Impedance Spectroscopy (EIS) for Interface Analysis

EIS provides comprehensive characterization of the electrical properties at the transducer/membrane interface across a frequency spectrum [13]. The standard protocol involves applying a small amplitude AC voltage (typically 10 mV) across a frequency range from 0.1 Hz to 100 kHz while measuring the impedance response [13]. The resulting Nyquist plot enables extraction of crucial parameters including bulk resistance (Rb), double-layer capacitance (Cdl), geometric capacitance (Cg), and specific capacitance (Cp) through fitting to appropriate equivalent circuit models [13]. This technique proves particularly valuable for distinguishing between redox and EDL capacitance mechanisms based on the characteristic patterns in the impedance spectra.

Water Layer Test for Hydrophobicity Evaluation

The water layer test assesses the formation of undesirable aqueous layers between the ion-selective membrane and solid contact, which can compromise potential stability [17]. The experimental procedure involves exposing the electrode to solutions with significant primary ion activity differences (e.g., 0.1 M vs. 0.01 M) and monitoring potential drift over extended periods (hours to days) [17]. Electrodes with hydrophobic solid contacts that effectively prevent water layer formation demonstrate minimal potential drift in these tests, with studies showing successful implementations using materials like graphene and properly conditioned conducting polymers [16] [17].

Performance Comparison of Transducer Materials

Table 2: Experimental performance metrics of different transducer materials

| Transducer Material | Capacitance (µF) | Potential Drift (µV s⁻¹) | Slope (mV/decade) | Detection Limit (M) | Mechanism |

|---|---|---|---|---|---|

| Graphene | 383.4 ± 36.0 [16] | 2.6 ± 0.3 [16] | 61.9 ± 1.2 [16] | 10⁻⁵.⁵ [16] | EDL Capacitance [16] |

| MWCNTs | Not specified | 34.6 [13] | 56.1 ± 0.8 [13] | 3.8 × 10⁻⁶ [13] | EDL Capacitance [13] |

| PEDOT | Not specified | Not specified | -53.3 ± 0.5 (for Cl⁻) [17] | 6.03 × 10⁻⁶ (for Cl⁻) [17] | Redox Capacitance [12] |

| PEDOT:PSS | Not specified | Not specified | Near-Nernstian for multiple ions [18] | Varies by ion [18] | Redox Capacitance [18] |

| Nanocomposite (MWCNTs/CuO) | Not specified | 0.09-0.12 [4] | Near-Nernstian across temperatures [4] | Lowest values across temperatures [4] | Combined Mechanisms |

Diagram 2: Experimental assessment workflow for transducer materials showing three primary characterization techniques with their measured parameters and applications.

The Scientist's Toolkit: Essential Materials and Reagents

Transducer Materials

Table 3: Key research reagents for transducer fabrication

| Material Category | Specific Examples | Function | Key Characteristics |

|---|---|---|---|

| Conducting Polymers | PEDOT, PEDOT:PSS, PANi, POT [13] [4] | Redox capacitance transduction [12] | High electronic/ionic conductivity, reversible doping [12] |

| Carbon Nanomaterials | MWCNTs, graphene, rGO [16] [13] | EDL capacitance transduction [13] | High surface area, hydrophobicity [16] |

| Metal Oxides | Copper(II) oxide nanoparticles [4] | Transducer for specific ions | Selective interactions, stability |

| Nanocomposites | MWCNTs/CuO, conductive MOFs [15] [4] | Combined transduction mechanisms | Enhanced capacitance, stability across temperatures [4] |

| Ion-Selective Membranes | PVC, plasticizers (NPOE), ionophores [17] [18] | Selective ion recognition | Determines electrode selectivity [17] |

Protocol for Fabrication of Solution-Processable SC-ISEs

The following protocol outlines the fabrication of fully solution-processable SC-ISEs, adaptable for both redox and EDL capacitance-based systems:

Electrode Pretreatment: Clean the substrate electrode (e.g., screen-printed carbon or gold) with isopropyl alcohol followed by oxygen plasma treatment to ensure uniform surface properties [18].

Solid-Contact Application:

- For conducting polymers: Drop-cast 2.5 μL of PEDOT:PSS dispersion onto the sensing area and cure at 140°C for 5 minutes [18].

- For carbon nanomaterials: Disperse MWCNTs or graphene in appropriate solvents (e.g., DMF) and drop-cast onto the electrode surface, followed by drying at room temperature [16].

- Optional anion exchange: For anion-selective electrodes, immerse the PEDOT-based solid contact in a solution containing the target anion (e.g., Cl⁻ for chloride sensors) to exchange the dopant anion, significantly improving sensitivity [17].

Ion-Selective Membrane Application: Prepare the membrane cocktail by dissolving PVC, plasticizer (e.g., NPOE), ionophore, and ionic additives in tetrahydrofuran (THF) [17] [18]. Drop-cast the membrane solution onto the solid-contact layer and allow to dry at room temperature for 24 hours in a controlled environment [18].

Conditioning: Condition the completed SC-ISE in a solution containing the primary ion (e.g., 0.01 M KCl for potassium electrodes) for at least 2 hours before use [18]. For anion-exchanged electrodes, conditioning time may be significantly reduced [17].

Application-Oriented Material Selection and Protocol Optimization

Temperature Resistance Considerations

The performance of SC-ISEs under varying temperature conditions represents a critical consideration for applications in environmental monitoring and clinical diagnostics. Recent comparative studies have revealed significant differences in how transducer materials maintain performance across temperature ranges [4]. Electrodes modified with nanocomposites (MWCNTs/CuO) and specialized polymers (perinone polymer) demonstrated superior resistance to temperature changes, maintaining nearly Nernstian responses and stable detection limits across a temperature range from 10°C to 36°C [4]. These materials exhibited minimal potential drift (0.05-0.12 µV/s) across the tested temperature spectrum, outperforming single-component transducers [4]. This enhanced performance is attributed to the synergistic effects in composite materials, which combine the advantageous properties of individual components to create more robust transduction systems capable of withstanding environmental variations [4].

Application-Specific Selection Guidelines

The choice between redox capacitance and EDL capacitance mechanisms should be guided by the specific application requirements:

Wearable Health Monitoring: For sweat analysis applications requiring continuous monitoring, graphene-based transducers offer advantages due to their high capacitance (383.4 µF) and minimal potential drift (2.6 µV s⁻¹) [16] [12]. The hydrophobic nature of graphene effectively prevents water layer formation, enhancing long-term stability during prolonged wear [16].

Clinical Diagnostic Applications: For blood and urine analysis where temperature control is possible, PEDOT-based systems with optimized anion exchange protocols provide excellent sensitivity and near-Nernstian responses for anions like chloride [17]. The well-defined thermodynamic potential of redox-based systems offers measurement reliability for diagnostic purposes [12] [17].

Environmental Monitoring: For field applications with varying temperature conditions, nanocomposite transducers (e.g., MWCNTs/CuO) demonstrate superior temperature resistance, maintaining stable performance across a range from 10°C to 36°C [4]. This stability ensures reliable measurements without requiring strict temperature control.

Multi-ion Sensing Platforms: For systems requiring integration of multiple ion sensors, solution-processable materials like PEDOT:PSS enable facile fabrication through techniques like drop-casting, ensuring compatibility with different ion-selective membranes [18]. The consistent fabrication process across different ion channels improves measurement reproducibility.

Solid-contact ion-selective electrodes (SC-ISEs) represent a significant advancement over traditional liquid-contact ion-selective electrodes (LC-ISEs), addressing critical limitations related to miniaturization, portability, and operational stability [1]. The elimination of the internal filling solution in SC-ISEs through the incorporation of a solid-contact (SC) layer between the ion-selective membrane (ISM) and electronic conductor has enabled the development of robust, miniaturized sensors suitable for field-deployable, wearable, and point-of-care applications [1] [19]. This application note examines the fundamental advantages of SC-ISEs, provides quantitative performance data from recent research, and details standardized protocols for fabricating and characterizing these sensors to ensure reproducible performance across environmental, biomedical, and industrial applications.

Critical Advantages of SC-ISEs: Quantitative Evidence

The transition from liquid-contact to solid-contact architectures provides three interconnected advantages that dramatically expand the application scope of potentiometric sensors.

Miniaturization and Fabrication Flexibility

SC-ISEs enable unprecedented miniaturization and design flexibility through advanced manufacturing techniques. The removal of the internal liquid reservoir eliminates constraints on sensor size and shape, allowing integration with microfluidic systems [20] and fabrication using additive manufacturing technologies [7] [19]. Recent demonstrations include fully 3D-printed sodium sensors with stereolithographically printed ion-selective membranes and carbon-infused polylactic acid transducers [7], and microfluidic platforms integrating all-solid-state ISEs for simultaneous multi-ion detection in sub-millimeter channels [20]. Screen-printing and inkjet printing technologies further enable mass production of disposable or reusable electrode platforms with minimal material consumption [21] [22].

Enhanced Portability for Field Deployment

The solid-state construction of SC-ISEs enables true portability for field-based measurements without compromising analytical performance. These sensors operate effectively in resource-limited environments due to their minimal power requirements, simple instrumentation, and elimination of liquid reagents [23] [24]. Recent field studies demonstrate successful in-situ monitoring of nitrate, ammonium, potassium, and chloride in small and medium-sized rivers over extended deployment periods [23]. Similar platforms have been deployed for environmental monitoring of pharmaceuticals like ketoprofen in river water without sample pretreatment [24].

Operational Stability in Complex Environments

SC-ISEs exhibit remarkable stability across diverse challenging environments, including variable temperature, ionic strength, and complex biological matrices. The solid-contact layer prevents membrane detachment and provides hydrophobic protection against interfacial water layer formation [1]. Recent studies document stability achievements including minimal potential drift (~20 μV/hour for 3D-printed sensors [7]), sustained performance after prolonged dry storage (up to 28 days for screen-printed electrodes [21]), and reproducible signal accuracy even after one-month dry storage periods for nitrate sensors [25].

Table 1: Quantitative Performance Metrics of Recent SC-ISE Development

| Sensor Type | Target Ion | Linear Range | Sensitivity (Slope) | Stability / Lifetime | Application Context | Citation |

|---|---|---|---|---|---|---|

| All-solid-state potentiometric | Nitrate | N/A | N/A | Reproducibility of ± 3 mg/L after 3 months; stable after 1-month dry storage | Drinking water analysis | [25] |

| Screen-printed ISE | Na+, Ca2+ | N/A | 52.1 ± 2.0 mV/dec (Na+); 27.3 ± 0.8 mV/dec (Ca2+) | Stable intercept over 7 days; 28 days dry storage | Environmental (tap water, hydroponics) | [21] |

| Fully 3D-printed SC-ISE | Na+ | 240 μM–250 mM | 57.1 mV/decade | ~20 μV drift per hour | Biological fluids (human saliva) | [7] |

| Microfluidic all-solid-state | Ca2+, Na+, K+ | N/A | Near-Nernstian for Ca2+, Na+; sub-Nernstian for K+ | Response times of 3–5 min; stable in complex matrices | Salivary ion monitoring | [20] |

| Solid-contact electrodes | Ketoprofen | 1×10⁻⁵ M to 1×10⁻¹ M | -56.80 to -58.80 mV/decade | Effective in untreated river water | Pharmaceutical environmental monitoring | [24] |

Experimental Protocols

Protocol 1: Fabrication of Screen-Printed Solid-Contact ISEs

This protocol describes the fabrication of reusable, calibration-free screen-printed ion-selective electrodes based on carbon paste/PEDOT:PEDOT-SO3H back contacts, adapted from recent research demonstrating exceptional potential stability [21].

Materials and Equipment:

- Screen-printing equipment with appropriate mesh size

- Carbon-based conductive ink

- PEDOT:PEDOT-SO3H solution or commercial PEDOT:PSS

- Ion-selective membrane components: ionophore, ion exchanger, PVC, plasticizer

- Tetrahydrofuran (THF) for membrane solution preparation

- Substrate material (ceramic or plastic)

Procedure:

- Substrate Preparation: Clean substrate surface with isopropyl alcohol to remove contaminants.

- Electrode Printing: Screen-print carbon ink onto substrate in desired electrode pattern (typically 3-4 mm diameter working electrode).

- Solid-Contact Application: Apply PEDOT:PEDOT-SO3H solution to carbon working area via drop-casting or printing. Cure at 140°C for 5 minutes [20].

- Membrane Solution Preparation: Dissolve membrane components in THF: 1-2% ionophore, 0.5-1% ion exchanger, 30-33% PVC, 65-68% plasticizer.

- Membrane Deposition: Drop-cast optimized membrane cocktail onto solid-contact layer (typically 1.7-4.2 μL depending on formulation [20]).

- Conditioning: Soak prepared electrodes in conditioning solution (e.g., 4 M NaCl for Na+ sensors, 0.01 M CaCl2 for Ca2+ sensors) for 24 hours [20].

Quality Control:

- Verify electrode morphology by microscopy

- Confirm membrane thickness uniformity (target: 100-200 μm)

- Test potentiometric response in standard solutions before use

Protocol 2: Characterization of Sensor Stability and Reproducibility

This protocol standardizes the evaluation of SC-ISE stability under various storage and operational conditions, essential for validating sensor reliability in field applications [25] [21].

Materials and Equipment:

- Potentiometer with high-impedance input (>10¹² Ω)

- Reference electrode (e.g., Ag/AgCl with appropriate bridge electrolyte)

- Standard solutions of target ion across concentration range

- Temperature-controlled measurement cell

- Data acquisition system

Procedure:

- Calibration Curve Generation:

- Measure potential in standard solutions across concentration range (typically 10⁻⁷ to 10⁻¹ M)

- Record potential after stabilization (<1 mV change per minute)

- Perform triplicate measurements at each concentration

- Plot potential vs. logarithm of activity; calculate slope and intercept

Short-Term Stability Assessment:

- Immerse sensor in constant concentration solution

- Record potential continuously for 12-24 hours

- Calculate potential drift (μV/hour) from linear regression of potential vs. time

Long-Term Stability Testing:

- Perform weekly calibrations over 1-3 month period

- Store sensors under different conditions (dry, conditioned, various temperatures)

- Monitor changes in slope, intercept, and linear range

- Calculate reproducibility as standard deviation of repeated measurements

Dry Storage Recovery Test:

- Store sensors dry for extended periods (1-4 weeks)

- Recondition following original conditioning protocol

- Compare pre- and post-storage calibration parameters

- Quantify recovery time to stable potential reading

Data Analysis:

- Report slope, linear correlation coefficient (R²), and detection limit for each calibration

- Calculate mean reproducibility across multiple sensors (n≥3)

- Document drift rates under various operational conditions

The Scientist's Toolkit: Essential Materials for SC-ISE Development

Table 2: Key Research Reagent Solutions for SC-ISE Fabrication

| Material Category | Specific Examples | Function/Purpose | Application Notes |

|---|---|---|---|

| Conductive Substrates | Screen-printed carbon, Gold-sputtered PET, 3D-printed conductive PLA | Provides electronic conduction pathway | Choice affects cost, reproducibility, and manufacturing scalability [21] [20] |

| Solid-Contact Materials | PEDOT:PSS, Polypyrrole, Poly(3-octylthiophene) | Ion-to-electron transduction; prevents water layer formation | Critical for potential stability; PEDOT:PSS offers high capacitance [21] [1] |

| Polymer Matrices | Polyvinyl chloride (PVC), Acrylic esters, Polyurethane | Membrane backbone providing mechanical stability | PVC most common; alternatives offer improved biocompatibility [1] [24] |

| Plasticizers | DOS, o-NPOE, DOP, DBP | Imparts membrane fluidity; modulates dielectric constant | Affects selectivity and detection limit; concentration typically 65-68% [1] [24] |

| Ionophores | Valinomycin (K+), Bis(benzo-15-crown-5) (Na+), ETH 129 (Ca2+) | Selective target ion recognition | Hydrophobicity prevents leaching; determines selectivity pattern [20] [1] |

| Ion Exchangers | NaTFPB, KTFPB, KTPCIPB | Imparts permselectivity; reduces interference | Critical for Donnan exclusion; typically 0.5-1% of membrane [20] [1] |

Solid-contact ion-selective electrodes represent a transformative technology that successfully addresses the critical challenges of miniaturization, portability, and stability for potentiometric sensing. The protocols and materials detailed in this application note provide researchers with standardized methodologies for developing robust SC-ISEs suitable for environmental monitoring, point-of-care diagnostics, and industrial process control. As fabrication technologies continue to advance, particularly in 3D printing and nanomaterial integration, SC-ISEs are poised to become increasingly prevalent in field-deployable analytical platforms where their unique advantages offer compelling benefits over traditional sensing approaches.

Advanced Fabrication Techniques and Biomedical Applications: From Materials to Real-World Implementation

The evolution of ion-selective electrodes (ISEs) from conventional designs with internal solutions to all-solid-state architectures represents a significant advancement in electrochemical sensing [26]. Solid-contact ion-selective electrodes (SCISEs) eliminate the internal solution, enabling sensor miniaturization, simplified fabrication, and operational flexibility for in-field and point-of-care applications [4]. The core innovation in SCISEs lies in the solid-contact layer, which functions as an ion-to-electron transducer situated between the ion-selective membrane (ISM) and the electron-conducting substrate [26]. This layer is critical for achieving stable potential readings by facilitating efficient charge transfer across different phases within the electrode [27]. The selection of appropriate transducer materials directly governs key performance parameters including potential stability, detection limit, sensitivity, and resistance to environmental interferences such as oxygen, carbon dioxide, and light [27]. This document provides application notes and detailed protocols for fabricating high-performance SCISEs using three principal material classes: conducting polymers, carbon nanomaterials, and metal/metal oxide nanoparticles, contextualized within ongoing thesis research on advanced electrochemical sensor platforms.

Comparative Analysis of Transducer Materials

The selection of transducer materials significantly impacts the analytical performance, stability, and fabrication process of SCISEs. The table below provides a systematic comparison of the three primary material classes based on recent research findings.

Table 1: Comparative Analysis of Transducer Materials for Solid-Contact ISEs

| Material Class | Key Advantages | Inherent Limitations | Reported Performance Metrics | Fabrication Considerations |

|---|---|---|---|---|

| Conducting Polymers (e.g., PEDOT, POT, PANI) | Mixed ionic/electronic conductivity [27]; High redox capacitance [26]; Tunable hydrophobicity [27]. | Potential side reactions from electrical activity [27]; Variable long-term stability under oxidative stress [28]. | Potential drift: < 0.1 μV/s [4]; Capacitance: High (Redox) [26]; Contact Angle: ~140° (POT-CB) [27]. | Electropolymerization or drop-casting [27]; Requires doping for optimal conductivity [28]. |

| Carbon Nanomaterials (e.g., Graphene, CNTs, Carbon Black) | High double-layer capacitance [26]; Chemical inertness; High specific surface area [29]. | Susceptible to water layer formation without hydrophobization [27]; Dispersion stability can be challenging [27]. | Potential drift: 0.065 mV/h (Graphene) [30]; Capacitance: 0.9 mF (Graphene) [30]; LoD: 10⁻⁶ M (for NO₃⁻) [30]. | Drop-casting of dispersions [30]; Can be incorporated directly into the membrane (single-piece electrode) [30]. |

| Metal/Metal Oxide Nanoparticles (e.g., CuO, RuO₂) | High electrical capacity [26]; Good stability; Can enhance electron transfer kinetics. | Can be prone to aggregation; Some may have limited conductivity. | Potential drift: ~0.1 μV/s (CuO nanocomposite) [4]; Improved temperature resistance [4]. | Often used in nanocomposites [4]; Drop-casting or incorporation into pastes [26]. |

Detailed Material Profiles and Selection Guidelines

Conducting Polymers

Conducting polymers (CPs) are organic materials characterized by a conjugated π-electron backbone, which confers unique electronic properties and mixed ion-electron conduction capabilities ideal for solid-contact layers [28]. Their electrical conductivity can be finely adjusted through doping processes, and they offer inherent structural flexibility [28].

- Poly(3,4-ethylenedioxythiophene) (PEDOT): Frequently used doped with poly(styrene sulfonate) (PSS) or chloride ions. It demonstrates high conductivity, excellent stability, and high redox capacitance [26] [27]. A limitation is its broad electrical activity window, which may lead to potential drift from side reactions [27].

- Poly(3-octylthiophene) (POT): A highly hydrophobic polymer with significantly reduced participation in side reactions. Its drawbacks include lower redox capacitance and conductivity compared to PEDOT [27]. It is often combined with carbon materials to form composite transducers [27].

- Polyaniline (PANI) and Polypyrrole (PPy): Well-established conducting polymers with high stability and conductivity [26] [27]. Similar to PEDOT, they can exhibit electrical activity over a wide potential range.

Selection Guideline: PEDOT is suitable for applications requiring high capacitance and conductivity, while POT is preferable when extreme hydrophobicity is critical to prevent water layer formation. POT and PANI are promising for creating simplified single-piece electrodes where the polymer is dispersed directly within the ion-selective membrane [30].

Carbon Nanomaterials

Carbon nanomaterials are favored for their high specific surface area, which leads to high electrical double-layer capacitance, and their general chemical inertness [29].

- Carbon Black (CB): An inexpensive carbon material with a semi-graphitic structure, high porosity, and natural superhydrophobic behavior [27]. It forms stable dispersions and yields electrodes with high storage stability and resistance to O₂ and CO₂ interference [27].

- Graphene/Reduced Graphene Oxide: A two-dimensional material offering a very high surface area and excellent electrical conductivity. It has been shown to provide exceptional potential stability (e.g., 0.065 mV/h drift) and high capacitance (0.9 mF) in SCISEs [30].

- Carbon Nanotubes (CNTs): Both single-walled (SWCNTs) and multi-walled (MWCNTs) nanotubes create a conductive network, facilitating electron transfer. A cited study used MWCNTs to achieve a low detection limit of 2.31 × 10⁻⁶ M for nitrate ions [30].

Selection Guideline: Carbon Black offers a cost-effective solution with robust performance. Graphene is ideal for applications demanding the highest possible capacitance and stability. CNTs are excellent for creating conductive networks in composites. Their functionalization can enhance dispersion and tune properties for specific applications [29].

Metal and Metal Oxide Nanoparticles

Metal oxides are significant due to their high electrical capacity and mixed ion-electron conductivity [26]. They contribute to the development of all-solid-state sensors with competitive analytical performance.

- Copper(II) Oxide (CuO) Nanoparticles: Research shows that CuO nanoparticles, particularly in a nanocomposite with MWCNTs, can significantly improve a sensor's resistance to temperature changes, ensuring stable performance across a range from 10°C to 36°C [4].

- Ruthenium Oxide (RuO₂) and Manganese Oxide (MnO₂): These are among other metal oxides being explored for their high capacitance and catalytic properties in potentiometric sensors [26].

Selection Guideline: Metal oxides are particularly valuable in composite materials to enhance specific properties like temperature stability [4]. They are also effectively used as the sensing layer in screen-printed pH sensors or as components in paste electrodes [26].

Experimental Protocols

Protocol 1: Fabrication of a POT-Carbon Black Nanocomposite Solid-Contact K⁺-ISE

This protocol details the creation of a nanocomposite solid contact, combining the high hydrophobicity of POT with the high surface area of Carbon Black for a stable potassium ion-selective electrode [27].

Research Reagent Solutions:

- Poly(3-octylthiophene-2,5-diyl) (POT): Conductive polymer, provides mixed ion-electron conduction and high hydrophobicity.

- Carbon Black (CB): Nanomaterial, provides high specific surface area and double-layer capacitance.

- Tetrahydrofuran (THF): Anhydrous solvent, for dissolving POT and dispersing CB.

- Potassium Ion-Selective Membrane (ISM) Cocktail: Contains PVC (polymer matrix), plasticizer (e.g., DOS), ionophore (e.g., Valinomycin), and lipophilic salt (e.g., KTpClPB).

- Glassy Carbon (GC) Electrode: Electron-conducting substrate.

Procedure:

- Electrode Substrate Preparation: Polish a Glassy Carbon (GC) disk electrode sequentially with 1.0, 0.3, and 0.05 μm alumina slurry. Rinse thoroughly with deionized water and methanol, then dry under a stream of nitrogen gas [30].

- Nanocomposite Dispersion Preparation: Dissolve 2 mg of POT in 1 mL of THF. Add 1 mg of Carbon Black to the solution. Sonicate the mixture for 30-60 minutes to obtain a homogeneous, time-stable black suspension [27].

- Solid-Contact Layer Deposition: Drop-cast 5-10 μL of the POT-CB nanocomposite dispersion directly onto the polished surface of the GC electrode. Allow the solvent to evaporate completely at room temperature, forming a uniform solid-contact layer [27].

- Ion-Selective Membrane Deposition: Prepare the K⁺-ISM cocktail in THF. Drop-cast 60-100 μL of this cocktail onto the POT-CB-modified GC electrode. Allow the THF to evaporate slowly, preferably covered to prevent dust contamination, forming a robust polymeric membrane over the solid contact. The electrode should be conditioned by soaking in a 10⁻³ M KCl solution for at least 24 hours before use [4] [27].

Protocol 2: Fabrication of a Single-Piece Nitrate-Selective Electrode with Carbon Nanomaterials

This protocol describes a simplified method for creating a "single-piece" electrode, where the carbon nanomaterial is dispersed directly into the ion-selective membrane, omitting a separate solid-contact deposition step [30].

Research Reagent Solutions:

- Carbon Nanomaterial (Graphene, CB, or CNTs): Acts as the ion-to-electron transducer within the membrane.

- Nitrate Ion-Selective Membrane Cocktail: Contains PVC, plasticizer (e.g., o-NPOE), ionophore (e.g., Tridodecylmethylammonium nitrate), and tetrahydrofuran (THF) as solvent.

- Glassy Carbon (GC) Electrode: Electron-conducting substrate.

Procedure:

- Electrode Substrate Preparation: Prepare the GC electrode as described in Protocol 1, Step 1 [30].

- Modified Membrane Cocktail Preparation: In a glass vial, combine all components for the nitrate-selective membrane (33.2% PVC, 65% plasticizer, 1.1% ionophore, 0.7% lipophilic salt) and dissolve in THF. To this solution, add 4% (w/w) of your chosen carbon nanomaterial (e.g., graphene, CB, or CNTs). Sonicate the mixture to achieve a homogeneous dispersion of the nanomaterial within the cocktail [30].

- Membrane Deposition: Drop-cast 60 μL of the modified membrane cocktail directly onto the surface of the prepared GC electrode. Allow the THF to evaporate, forming a single-piece electrode where the transducer and sensing functions are integrated into a single layer. Condition the electrode in a 10⁻⁵ M KNO₃ solution for 24 hours before calibration and use [30].

SCISE Fabrication Workflow: This diagram illustrates the two primary fabrication pathways for Solid-Contact Ion-Selective Electrodes: the standard solid-contact approach (right) and the simplified single-piece method (left).

Characterization Methods and Performance Validation

Rigorous electrochemical characterization is essential to validate the performance of fabricated SCISEs. The following table outlines key techniques and their specific application in evaluating transducer materials.

Table 2: Key Electrochemical Characterization Techniques for SCISEs

| Technique | Primary Measured Parameters | Interpretation & Significance for SCISEs |

|---|---|---|

| Chronopotentiometry | Potential drift (ΔE/Δt) | Quantifies short-term potential stability. Lower drift values (e.g., < 1 μV/s) indicate a more stable solid contact, crucial for reliable measurements [27]. |

| Electrochemical Impedance Spectroscopy (EIS) | Charge transfer resistance (Rₑₜ), Double-layer capacitance (Cₑₗ) | Reveals the charge transfer efficiency at interfaces and the capacitive performance of the transducer. A low Rₑₜ and high Cₑₗ are desirable [30]. |

| Cyclic Voltammetry (CV) | Electrochemically Active Surface Area (EASA), Redox behavior | Assesses the effective surface area and confirms the redox activity of conducting polymers. A higher EASA suggests more active sites for charge transfer [27]. |

| Water Layer Test | Potential stability in alternating solutions | Evaluates the hydrophobicity and the risk of water layer formation between the membrane and substrate. A stable potential indicates a hydrophobic, water-layer-free contact [27]. |

| Potentiometric Calibration | Slope (mV/decade), Linear Range, Limit of Detection (LoD) | Determines the key analytical performance metrics of the sensor, including sensitivity and working range [4] [30]. |

The strategic selection and engineering of conducting polymers, carbon nanomaterials, and metal oxides are pivotal for advancing solid-contact ion-selective electrode technology. The current research trajectory emphasizes the development of composite and hybrid materials, such as POT-Carbon Black, which synergistically combine the benefits of individual components to overcome their respective limitations [27]. Furthermore, simplified fabrication approaches, like the single-piece electrode design where the transducer is incorporated directly into the membrane, present a promising path toward more manufacturable and robust sensors [30]. Future research within this thesis framework will focus on several key challenges: enhancing the long-term stability of these materials under high oxidative and reductive stress [28], improving the reproducibility of nanomaterial-based sensors [29], and systematically evaluating their performance across a wider range of environmental conditions, including variable temperature and pH [4]. Addressing these aspects is crucial for the transition of laboratory-scale SCISEs into reliable analytical tools for real-world applications in clinical diagnostics, environmental monitoring, and industrial process control.

Solid-contact ion-selective electrodes (SC-ISEs) represent a significant advancement in potentiometric sensing, offering advantages in miniaturization, portability, and stability compared to their liquid-contact counterparts [1]. The transition from laboratory-scale innovation to commercially viable products hinges on the development of robust, scalable, and reproducible fabrication protocols. Solution-processable fabrication methods have emerged as a cornerstone technology in this endeavor, enabling the deposition of functional layers through techniques that are cost-effective, amenable to mass production, and compatible with flexible substrates [31]. This application note details standardized protocols for the scalable production of SC-ISEs, framing them within the broader research context of advancing electrochemical sensor manufacturing.

The core challenge in SC-ISE fabrication lies in constructing a stable interface between the ion-selective membrane (ISM) and the underlying conductive substrate. Solution-based methods—including drop-casting, spin-coating, and various printing techniques—allow for precise control over this interface by facilitating the layer-by-layer assembly of specialized materials [32]. These protocols are designed to ensure that the final sensors exhibit high sensitivity, selectivity, and long-term stability, with minimal potential drift, which is critical for applications in point-of-care diagnostics, environmental monitoring, and wearable health devices [7] [1].

Experimental Protocols

This section provides detailed, step-by-step methodologies for two prominent solution-processable fabrication routes for SC-ISEs: a fully 3D-printed approach and a laser-induced graphene (LIG) based method.

Protocol 1: Fully 3D-Printed SC-ISE Fabrication

This protocol outlines the fabrication of a solid-contact sodium ion-selective electrode using a multi-material 3D-printing approach, creating a sensor with remarkable stability and Nernstian behavior [7].

Materials and Equipment

- Conductive Transducer Filament: Carbon-infused polylactic acid (CB-PLA)

- ISM Resin: Stereolithography (SLA) resin formulated for ion-selectivity (containing ionophore, ion-exchanger, plasticizer, and polymer matrix)

- 3D Printer 1: Fused deposition modeling (FDM) system capable of printing CB-PLA

- 3D Printer 2: Stereolithography (SLA) system

- Curing Station: UV curing chamber for post-processing SLA resins

- Electrochemical Workstation: For potentiometric characterization

Step-by-Step Procedure

Print Solid-Contact Transducer:

- Utilize the FDM printer to fabricate the conductive electrode body from CB-PLA filament.

- Critical Parameters: Optimize print angle and layer thickness to enhance transducer hydrophobicity, which is directly related to improved potential stability. A specific print angle of 45° and a layer thickness of 0.2 mm have been demonstrated to be effective [7].

Print Ion-Selective Membrane:

- Employ the SLA printer to directly print the Na+-selective membrane onto the surface of the CB-PLA transducer.

- The ISM resin should be formulated with sodium ionophore, sodium tetrakis [3,5-bis(trifluoromethyl)phenyl] borate (NaTFPB) as an ion-exchanger, and appropriate plasticizers.

Post-Processing:

- Cure the printed ISM in a UV curing chamber according to the resin manufacturer's specifications to achieve final polymerization.

Conditioning and Characterization:

- Condition the fully assembled 3D-printed sensor in a 0.01 M solution of NaCl for a minimum of 12 hours prior to use.

- Validate sensor performance by measuring the potential response across a series of standard Na+ solutions (e.g., 10⁻⁵ M to 10⁻¹ M).

Table 1: Performance Metrics of 3D-Printed Na+-SC-ISE

| Parameter | Value | Measurement Conditions |

|---|---|---|

| Slope (Sensitivity) | 57.1 mV/decade | Linear range: 240 μM – 250 mM |

| Limit of Detection (LOD) | 0.0024 mM | - |

| Limit of Quantification (LOQ) | 0.008 mM | - |

| Potential Drift | ~20 μV/hour | Long-term stability measurement |

| Selectivity Coefficient (log KpotNa+, K+) | -2.1 | Separate solution method |

Protocol 2: Laser-Induced Graphene (LIG) SC-ISE Patch Sensor Fabrication

This protocol describes the fabrication of a flexible, wearable patch sensor for simultaneous detection of Na⁺ and K⁺ in sweat, utilizing electrospinning and laser carbonization to create a highly stable, hydrophobic solid-contact layer [32].

Materials and Equipment

- MXene/PVDF Precursor Solution: Ti₃C₂Tₓ MXene dispersed in a solvent mixture of acetone and DMF, with added PVDF powder.

- Electrospinning Apparatus: Including syringe pump, high-voltage power supply, and collector drum.

- Laser Engraving System: CO₂ laser cutter.

- Substrate: Flexible polyimide tape (e.g., Kapton) or similar.

- ISM Cocktails: For Na⁺ and K⁺, based on a PVC-SEBS blend plasticized with DOS and containing respective ionophores and ion-exchangers.

- Reference Electrode: Ag/AgCl coated or printed.

Step-by-Step Procedure

Synthesize MXene (Ti₃C₂Tₓ):

- Selectively etch aluminum from 1.0 g of Ti₃AlC₂ (MAX phase) powder using a mixture of 12 mL HCl and 2 mL HF in 6 mL DI water. Stir at 35°C for 24 hours.

- Wash the resulting multilayer MXene repeatedly with DI water via centrifugation until the supernatant reaches a neutral pH (~6). Collect the sediment and dry it in a vacuum oven at 75°C [32].

Fabricate MXene@PVDF Nanofiber (MPNF) Mat:

- Prepare an electrospinning solution by dispersing the synthesized MXene powder in a binary solvent (acetone:DMF, 7:5 v/v) to achieve ~2.1 wt% MXene. Add PVDF powder to reach 12 wt% of the total solution mass. Stir at 55°C for 2 hours to achieve a homogeneous mixture.

- Load the solution into a syringe and electrospin onto a collector using an applied voltage of 18 kV, a flow rate of 2.0 mL/h, and a tip-to-collector distance of 12 cm.

- Dry the collected nanofibers in an oven at 50°C for 3 hours and carefully detach them from the collector [32].

Generate LIG@TiO₂ Electrode:

- Place the MPNF mat in a CO₂ laser engraver.

- Use laser irradiation to simultaneously convert the PVDF matrix into laser-induced graphene (LIG) and oxidize the surface of the MXene nanosheets to form in-situ anatase TiO₂ nanoparticles. This creates the MPNFs/LIG@TiO₂ hybrid solid-contact layer.

- Critical Parameter: Precisely adjust the laser power to control the degree of graphitization and TiO₂ formation, which tunes the electrode's conductivity, morphology, and hydrophobicity [32].

Deposit Ion-Selective Membranes:

- Drop-cast the respective Na⁺ and K⁺ ISM cocktails onto the designated LIG working electrodes.

- Allow the membranes to dry and stabilize under ambient conditions for at least 24 hours.

Sensor Validation:

- Test the sensors in simulated sweat or real human sweat samples.

- Calibrate against standard solutions to determine sensitivity and selectivity.

Table 2: Performance Metrics of LIG-based Na⁺ and K⁺ SC-ISEs

| Parameter | Na⁺ Sensor | K⁺ Sensor | Measurement Conditions |

|---|---|---|---|

| Slope (Sensitivity) | 48.8 mV/decade | 50.5 mV/decade | Physiologically relevant ranges |

| Potential Drift | 0.04 mV/hour | 0.08 mV/hour | Prolonged exposure to simulated sweat |

Workflow Visualization

The following diagram illustrates the logical sequence and parallel options for the scalable fabrication of SC-ISEs.

SC-ISE Fabrication Workflow

The Scientist's Toolkit: Key Research Reagent Solutions

The table below catalogs essential materials used in the solution-processable fabrication of SC-ISEs, as featured in the protocols above.

Table 3: Essential Reagents for SC-ISE Fabrication

| Reagent/Material | Function/Application | Key Characteristics |

|---|---|---|

| Carbon-infused PLA (CB-PLA) | Conductive transducer in 3D-printed SC-ISEs [7] | FDM-printable, serves as both electrode body and ion-to-electron transducer. |

| Ionophore (e.g., Sodium Ionophore X) | Molecular recognition element within the ISM [1] | Selectively complexes with target ion (e.g., Na⁺), determining sensor selectivity. |

| Polymer Matrix (e.g., PVC) | Structural backbone of the Ion-Selective Membrane (ISM) [33] [1] | Provides mechanical stability and hosts membrane components. |

| Plasticizer (e.g., DOS, NPOE) | Component of the ISM [33] [1] | Imparts mobility to ionophores and controls membrane polarity and dielectric constant. |

| Ion-Exchanger (e.g., NaTFPB) | Component of the ISM [1] | Introduces ionic sites into the membrane, critical for establishing Donnan exclusion and reducing interference. |

| Ti₃C₂Tₓ MXene | Precursor for LIG-based transducer [32] | 2D conductive material; enhances electrical conductivity and surface area in composite electrodes. |

| Poly(vinylidene fluoride) (PVDF) | Hydrophobic polymer for electrospinning [32] | Provides mechanical flexibility and hydrophobicity; precursor for LIG formation under laser irradiation. |

| Multi-Walled Carbon Nanotubes (MWCNTs) | Solid-contact transduction layer [33] | High hydrophobicity prevents water layer formation; excellent ion-to-electron transduction capability. |

| SEBS Block Copolymer | ISM additive [32] | Improves mechanical strength of PVC-based ISMs and suppresses water layer formation. |

The protocols detailed herein for 3D-printed and LIG-based SC-ISEs provide a robust foundation for the scalable and reproducible production of high-performance potentiometric sensors. The quantitative performance data, structured workflows, and comprehensive reagent information are intended to equip researchers and development professionals with the practical tools necessary to advance solid-contact ion-selective electrode fabrication from laboratory research to commercially viable products. The continued refinement of these solution-processable fabrication strategies is paramount to bridging the quality divide between lab-scale devices and mass-produced, reliable sensors for a wide array of applications.

Ion-selective electrodes (ISEs) represent a cornerstone of modern potentiometric sensing, with their performance critically dependent on the molecular recognition element—the ionophore. These host molecules are responsible for the selective complexation of target ions within the ion-selective membrane (ISM), forming the basis for analytical specificity in complex matrices [34] [35]. The integration strategy of the ionophore into the sensor architecture fundamentally governs key analytical parameters, including selectivity, detection limit, stability, and operational lifetime.

Recent advancements in ISE technology have expanded the traditional boundaries of ionophore application, moving beyond conventional hydrophobic ionophores in plasticized poly(vinyl chloride) membranes to include hydrophilic peptides on nanoporous scaffolds and metalloporphyrins in pulsed chronopotentiometric modes [36] [37]. Furthermore, the transition toward solid-contact ion-selective electrodes (SC-ISEs) has introduced new considerations for ionophore integration to prevent leaching and maintain potential stability while enabling miniaturization and field-portable applications [38] [21]. This application note details established and emerging protocols for ionophore integration, providing researchers with practical methodologies to enhance sensor selectivity for target analytes across clinical, environmental, and pharmaceutical domains.

Ionophore Integration Mechanisms and Material Selection

The mechanism of selectivity enhancement varies significantly with the ionophore integration strategy. Hydrophobic ionophores in polymeric membranes operate by facilitating selective ion partitioning from the aqueous sample into the organic membrane phase, with the resulting phase boundary potential governed by the relative stability constants of ion-ionophore complexes [35]. In contrast, ion-channel mimetic systems utilize solid-state nanopores modified with ion-selective ligands, where selectivity arises from both complexation thermodynamics and steric constraints within the confined nanopore geometry [37]. Pulsed potentiometric methods achieve enhanced selectivity through kinetic discrimination, where differences in ion extraction rates during current pulses enable separation of thermodynamically preferred interferents [36].

The table below summarizes the key ionophore classes and their corresponding integration strategies for enhanced selectivity:

Table 1: Ionophore Classes and Their Integration Strategies

| Ionophore Class | Target Ions | Integration Strategy | Selectivity Mechanism | Representative Example |

|---|---|---|---|---|

| Metalloporphyrins | Anions (Cl⁻, Salicylate) | Polymeric membrane with lipophilic salts | Thermodynamic affinity & pulsed mode kinetic discrimination | In(III)tetraphenylporphyrin [36] |

| Hydrophobic Synthetic Ionophores | Cations (K⁺, Na⁺, Ca²⁺, Pb²⁺) | Plasticized PVC or plasticizer-free copolymer membranes | Selective complexation in hydrophobic phase | Valinomycin (K⁺), Calcium Ionophore IV [39] |

| Hydrophilic Peptides | Cations (Cu²⁺) | Functionalized gold nanopores | Complexation in confined, tuned nanoenvironment | Cys-Gly-Gly-His tripeptide [37] |

| Conducting Polymers | Multiple ions | Solid-contact layer | Ion-to-electron transduction & stabilized potential | PEDOT:PSS, Poly(3-octylthiophene) [38] [39] |

The successful implementation of these strategies requires careful consideration of the supporting membrane matrix. While poly(vinyl chloride) plasticized with dos remains widely used, plasticizer-free copolymers (e.g., methylmethacrylate-decylmethacrylate) have gained prominence for improving stability and reducing undesirable ion fluxes [39]. For solid-contact electrodes, the ion-to-electron transducer material—whether conducting polymers, carbon nanomaterials, or composite structures—must form a hydrophobic interface with the ISM to prevent water layer formation, a primary source of potential drift [38] [21].

Experimental Protocols

Protocol 1: Chloride-Selective Electrode with In(III)-Porphyrin for Pulsed Chronopotentiometry

This protocol describes the fabrication of a chloride-selective electrode using an In(III)-porphyrin-based ionophore, designed to overcome salicylate interference via pulsed chronopotentiometric measurement [36].

Reagents and Materials

- High molecular weight poly(vinyl chloride) (PVC)

- Plasticizer: o-nitrophenyl octyl ether (o-NPOE)

- Lipophilic salt: Tetradodecylammonium tetrakis(4-chlorophenyl) borate (ETH 500)

- Ionophore precursor: In(III)TPPCl (prepared from meso-tetraphenylporphyrin)

- Counterion source: Potassium tetrakis[3,5-bis(trifluoromethyl)phenyl] borate (KTFPB)