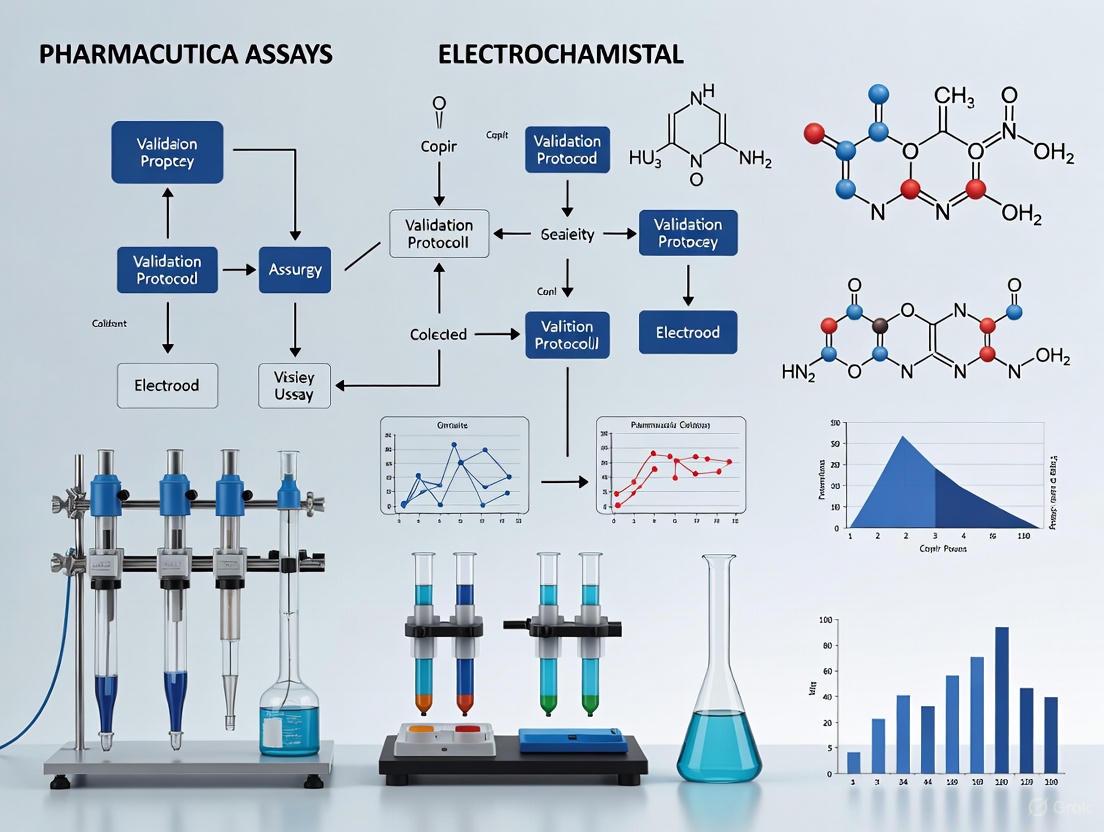

A Comprehensive Guide to Validation Protocols for Electrochemical Pharmaceutical Assays

This article provides a structured framework for developing and executing robust validation protocols for electrochemical assays in pharmaceutical development.

A Comprehensive Guide to Validation Protocols for Electrochemical Pharmaceutical Assays

Abstract

This article provides a structured framework for developing and executing robust validation protocols for electrochemical assays in pharmaceutical development. Tailored for researchers, scientists, and drug development professionals, it bridges foundational regulatory requirements with advanced electrochemical applications. The content spans from core validation principles and methodological design to advanced troubleshooting and comparative analysis with traditional techniques. The guide aims to equip readers with the knowledge to ensure data integrity, meet regulatory standards, and leverage the advantages of electrochemical methods for drug analysis, stability testing, and clinical diagnostics.

Building the Foundation: Core Principles of Pharmaceutical Validation and Electrochemistry

The Role of Validation in Pharmaceutical Quality Assurance

In the highly regulated pharmaceutical industry, validation and qualification serve as critical processes for ensuring product quality, safety, and efficacy. While often used interchangeably, these terms represent distinct but interconnected concepts with specialized applications in pharmaceutical quality assurance. Validation is defined as the documented evidence that a process consistently produces results meeting predetermined specifications and requirements [1] [2]. In contrast, qualification represents the documented process of ensuring that equipment or systems are correctly installed and operate according to their design specifications [1] [3].

This distinction can be summarized by a fundamental rule of thumb: equipment is qualified, while processes are validated [3]. One qualifies equipment, utilities, and instruments, while one validates manufacturing processes, cleaning procedures, analytical methods, and computer systems [3]. Crucially, processes are validated using equipment that has been properly qualified, establishing qualification as the essential foundation for successful validation activities [1] [3].

Within pharmaceutical quality assurance, these processes form a systematic framework that spans the entire product lifecycle, from development through distribution, providing documented scientific proof of consistent performance that regulatory agencies require for product approval [2] [4].

Key Differences Between Qualification and Validation

Conceptual Framework and Regulatory Basis

The pharmaceutical industry operates under stringent regulatory frameworks where qualification and validation activities are mandatory requirements rather than optional exercises. Regulatory bodies including the Food and Drug Administration (FDA) and European Medicines Agency (EMA) require proof that both equipment and processes meet strict standards [1] [2]. The FDA emphasizes a lifecycle validation approach, requiring companies to plan, perform, and monitor validation throughout a product's life [1]. For computerized systems, the FDA highlights the use of GAMP 5 validation guidelines to manage risks effectively [1].

The EMA governs qualification and validation through Annex 15 of the EU Good Manufacturing Practice (GMP) guidelines, which provides specific rules for equipment, utilities, and process validation within the European Union [1]. Additionally, the International Council for Harmonisation (ICH) guidelines help establish a common language for global pharmaceutical practices, supporting harmonization across countries and regions [1] [5]. These guidelines define how to manage cleaning validation, computer system validation, and change control processes, with clear acceptance criteria showing when processes are effective and safe [1].

Comparative Analysis: Qualification vs. Validation

The table below summarizes the key distinctions between qualification and validation in pharmaceutical environments:

| Aspect | Qualification | Validation |

|---|---|---|

| Primary Focus | Proves equipment is installed and operates correctly [1] | Demonstrates a process consistently produces expected results [1] |

| Application Scope | Equipment, utilities, instruments, ancillary systems [3] | Processes, procedures, methods (cleaning, manufacturing, analytical) [1] [3] |

| Timing | Occurs before full process validation begins [1] | Follows equipment qualification [1] |

| Documentation | Protocols, test scripts, reports for equipment [2] | Broader documentation throughout the validation lifecycle [2] |

| Objective | Ensure equipment/systems are fit for intended use [2] | Ensure reliability and consistency of process results [2] |

| Failure Impact | Generally carries smaller GMP consequences [1] | Failures carry significant GMP compliance implications [1] |

Validation of Analytical Methods for Pharmaceutical Analysis

ICH Validation Framework and Adaptation for Radiopharmaceuticals

For analytical methods used in pharmaceutical analysis, the International Conference on Harmonisation (ICH) provides a comprehensive validation framework adopted by regulatory agencies worldwide. The ICH guideline defines key validation parameters including accuracy, precision, specificity, linearity, and range [5]. However, standard ICH guidelines do not fully address all specific tests required for specialized pharmaceutical products like radiopharmaceuticals, necessitating adapted approaches [5].

The European Association of Nuclear Medicine (EANM) has developed specific guidelines for validating analytical methods for radiopharmaceuticals, modifying the ICH requirements to address unique characteristics including radioactivity measurement and decay considerations [5]. The adapted validation parameters for radioanalytical methods include:

- Radioactivity Content (Assay): Validation through instrument qualification, with accuracy assured by calibration using sources traceable to national standards [5]

- Radionuclide Identity: Established by assessing physical characteristics of radionuclide emissions, with half-life determinations providing additional identification confirmation [5]

- Specificity: Must confirm unless tests rule out relevant quantities of interfering impurities, considering possible attenuation from matrix and geometry effects [5]

Experimental Protocol: Analytical Method Validation

For analytical methods used in pharmaceutical quality control, a typical validation protocol follows these key stages:

- Validation Plan Development: Outline scope, approach, and resources required for the validation process [2]

- User Requirements Specification (URS) Definition: Define user needs and expectations from the validated system or process [2]

- Design Qualification (DQ): Verify that the system or process design meets user requirements [2]

- Installation Qualification (IQ): Ensure proper installation according to specifications [2]

- Operational Qualification (OQ): Confirm the system or process functions as intended under normal operating conditions [2]

- Performance Qualification (PQ): Demonstrate consistent performance within predetermined specifications and tolerances [2]

- Validation Reporting: Summarize activities, results, and conclusions [2]

The experimental workflow for this validation protocol can be visualized as follows:

Electrochemical Methods in Pharmaceutical Analysis: A Validation Case Study

Experimental Data: Validation of Electrochemical Assay for Carvedilol

Electrochemical methods have emerged as valuable tools for pharmaceutical analysis due to their affordability, sensitivity, and environmental advantages [6]. A recent study demonstrated the application of electroanalytical techniques for assessing compatibility and stability of carvedilol (CRV), a non-selective blocker of α and β adrenergic receptors used for hypertension and heart failure treatment [6].

The research investigated CRV compatibility with various lipid excipients using voltammetric and electrochemical impedance spectroscopy techniques. The experimental results showed significant variations in anodic peak potential (ΔEp1a) when CRV was combined with different excipients, indicating changes in the overpotential required for electrochemical oxidation [6].

The table below summarizes key experimental data from the carvedilol electrochemical compatibility study:

| Excipient | Anodic Peak Potential (Ep1a) | Peak Current (Ip1a) | Potential Shift (ΔEp1a) |

|---|---|---|---|

| CP Control | 0.625 ± 0.025 V | 1.881 ± 0.285 µA | --- |

| Oleic Acid | 0.670 ± 0.004 V | 5.679 ± 0.283 µA | 0.045 V |

| Sesame Oil | 0.689 ± 0.062 V | 1.937 ± 0.236 µA | 0.064 V |

| Canola Oil | 0.706 ± 0.048 V | 2.013 ± 0.490 µA | 0.081 V |

| Safflower Oil | 0.727 ± 0.006 V | 4.089 ± 0.179 µA | 0.102 V |

| Plurol Isostearic | 0.919 ± 0.001 V | 3.105 ± 0.523 µA | 0.294 V |

| Compritol | 0.930 ± 0.010 V | 0.205 ± 0.056 µA | 0.305 V |

| Stearic Acid | 1.043 ± 0.015 V | 4.850 ± 1.816 µA | 0.418 V |

The positive ΔEp1a values indicated that greater overpotential was required for CRV electrochemical oxidation in the presence of lipophilic excipients, suggesting a lower tendency to undergo oxidative chemical reaction [6]. Stearic acid showed the greatest anode peak potential variation and was considered a suitable excipient for CRV formulation, with CRV demonstrating highest stability at room temperature and 50°C when mixed with stearic acid (7% w/w) [6].

Research Reagent Solutions for Electrochemical Pharmaceutical Analysis

The table below details essential materials and their functions used in electrochemical compatibility studies:

| Reagent/Material | Function in Experimental Protocol |

|---|---|

| Carbon Paste Electrodes | Serve as the working electrode for voltammetric measurements [6] |

| Lipid Excipients | Test substances for drug compatibility assessment [6] |

| Plurol Isostearic | Liquid lipophilic excipient with inherent electroactivity [6] |

| Stearic Acid | Solid excipient that alters electrodic properties [6] |

| Mineral Oil | Agglutinating system component in carbon paste preparation [6] |

| Graphite Powder | Conductive material for electrode preparation [6] |

| Potassium Ferri/Ferrocyanide | Redox probe for electrochemical impedance spectroscopy [6] |

The Validation Lifecycle in Pharmaceutical Quality Systems

The Qualification Foundation: IQ, OQ, PQ

Equipment qualification forms the essential foundation for process validation, consisting of three sequential stages:

- Installation Qualification (IQ): Verifies that equipment is installed correctly according to design specifications and manufacturer requirements [1] [2]

- Operational Qualification (OQ): Confirms that equipment functions as intended under expected operating conditions, verifying all controls, alarms, and settings respond appropriately [1] [2]

- Performance Qualification (PQ): Demonstrates that equipment consistently performs according to specifications during actual production operations, proving real-world performance matches expectations [1] [2]

This sequence builds trust in equipment reliability and supports subsequent validation activities. Skipping any qualification step risks major compliance issues during regulatory audits [1].

Process Validation and Continuous Verification

Once equipment is qualified, process validation demonstrates that manufacturing processes consistently produce products meeting predetermined quality attributes. The FDA emphasizes a lifecycle approach to validation, requiring ongoing verification throughout the product's life [1]. This includes:

- Prospective Validation: Conducted before commercial distribution for new products [2]

- Concurrent Validation: conducted during routine production [2]

- Retrospective Validation: Based on historical data for established products [2]

- Revalidation: Performed periodically or when significant changes occur [2]

The relationship between commissioning, qualification, and validation activities throughout the equipment and process lifecycle is illustrated below:

Validation remains a cornerstone of pharmaceutical quality assurance, providing documented evidence that processes consistently produce products meeting quality standards. Through proper qualification of equipment and validation of processes, pharmaceutical manufacturers can ensure product quality, safety, and efficacy while maintaining regulatory compliance. The case study of electrochemical methods for carvedilol analysis demonstrates how validation principles apply to modern analytical techniques, highlighting the importance of method validation in pharmaceutical development. As the industry evolves, the lifecycle approach to validation continues to provide a framework for maintaining product quality from development through commercial manufacturing, ultimately protecting patient safety and product integrity.

Essential Components of a Regulatory-Compliant Validation Protocol

Analytical method validation is the formal, systematic process of demonstrating that an analytical procedure is suitable for its intended purpose, ensuring the reliability, accuracy, and consistency of test results. For pharmaceutical research, particularly in the development of electrochemical assays, a robust validation protocol is not merely a best practice but a regulatory requirement. Guidelines from the International Council for Harmonisation (ICH), the U.S. Food and Drug Administration (FDA), and the European Medicines Agency (EMA) provide a framework for the key components that must be evaluated to prove a method's suitability [7] [8]. This process provides confidence that the data generated is of high quality, directly impacting the safety and efficacy evaluations of pharmaceutical products.

The level of validation required is guided by the method's Context of Use (COU) [9]. For electrochemical assays used in drug development, the standards are rigorous. A well-structured validation protocol template serves as a roadmap, detailing the validation criteria, documentation requirements, team responsibilities, and timelines [8]. This guide outlines the essential components of a regulatory-compliant protocol, provides experimental methodologies for key tests, and compares different analytical approaches, with a specific focus on the needs of researchers developing electrochemical pharmaceutical assays.

Core Validation Parameters and Regulatory Framework

A regulatory-compliant validation protocol must systematically assess a set of core performance characteristics. The ICH Q2(R2) guideline categorizes these parameters based on the type of analytical procedure (e.g., identification, testing for impurities, assay) [7]. The following table summarizes the essential components and their definitions.

Table 1: Essential Validation Parameters as Defined by ICH Guidelines

| Validation Parameter | Definition and Purpose |

|---|---|

| Specificity/Selectivity | The ability to assess the analyte unequivocally in the presence of components that may be expected to be present, such as impurities, degradants, or matrix components [10]. |

| Accuracy | The closeness of agreement between the value which is accepted as a conventional true value or an accepted reference value and the value found. This measures the exactness of the method [8] [10]. |

| Precision | The closeness of agreement between a series of measurements obtained from multiple sampling of the same homogeneous sample under the prescribed conditions. It is typically subdivided into repeatability, intermediate precision, and reproducibility [10]. |

| Detection Limit (LOD) | The lowest amount of analyte in a sample that can be detected, but not necessarily quantitated, as an exact value [10]. |

| Quantitation Limit (LOQ) | The lowest amount of analyte in a sample that can be quantitatively determined with suitable precision and accuracy [10]. |

| Linearity | The ability of the method (within a given range) to obtain test results that are directly proportional to the concentration (amount) of analyte in the sample [10]. |

| Range | The interval between the upper and lower concentrations (amounts) of analyte in the sample for which it has been demonstrated that the analytical procedure has a suitable level of precision, accuracy, and linearity [10]. |

| Robustness | A measure of the method's capacity to remain unaffected by small, but deliberate, variations in method parameters (e.g., pH, temperature, mobile phase composition) and provides an indication of its reliability during normal usage [10]. |

The choice of a comparative method is a critical factor in validation. When possible, a reference method with documented correctness should be used. In this case, any observed differences are attributed to the test method. More commonly, a routine comparative method is used, and large, medically unacceptable differences must be carefully interpreted with the aid of additional experiments [11].

Experimental Design and Methodologies

The Comparison of Methods Experiment

A cornerstone of method validation is the comparison of methods experiment, which estimates the systematic error, or bias, of the new method against a comparative method using real patient specimens [11].

- Purpose: To estimate inaccuracy by analyzing patient samples by both the new (test) method and a comparative method. The goal is to understand the systematic differences at critical medical decision concentrations [11].

- Experimental Design:

- Specimen Number and Selection: A minimum of 40 different patient specimens is recommended. The quality of specimens is paramount; they should cover the entire working range of the method and represent the expected spectrum of diseases. For assessing specificity, 100-200 specimens may be needed [11].

- Replication and Timeframe: While single measurements are common, duplicate measurements are advantageous for identifying errors. The experiment should be conducted over a minimum of 5 days, and ideally 20 days, to incorporate routine source variation [11].

- Specimen Stability: Specimens must be analyzed within a stability-defined window (e.g., two hours) to ensure differences are due to analytical error and not specimen degradation [11].

The workflow below illustrates the key stages of a comparison of methods experiment.

Statistical Analysis of Comparison Data

Data visualization is the first critical step in analysis. A difference plot (Bland-Altman plot) is used when methods are expected to show one-to-one agreement, while a comparison plot (scatter plot) is used for other cases [11] [12]. These graphs help identify outliers and visual patterns of error.

For numerical estimates of systematic error, the statistical approach depends on the data range:

- Wide Analytical Range: Use linear regression analysis to obtain the slope and y-intercept of the line of best fit. The systematic error (SE) at a critical medical decision concentration (Xc) is calculated as:

Yc = a + bXc, thenSE = Yc - Xc[11]. A correlation coefficient (r) of ≥0.99 is desirable for reliable estimates [11]. - Narrow Analytical Range: Calculate the average difference (bias) between the two methods using a paired t-test approach [11].

Table 2: Comparison of Statistical Methods for Method Validation

| Analysis Method | Best Use Case | Key Outputs | Advantages | Limitations |

|---|---|---|---|---|

| Linear Regression | Methods with a wide analytical range (e.g., glucose, cholesterol) [11]. | Slope, Y-intercept, Standard Error of the Estimate (Sy/x) [11]. | Allows estimation of bias at multiple decision levels; reveals constant/proportional error [11]. | Requires a wide data range; sensitive to outliers; assumes no error in the comparative method [11] [12]. |

| Bland-Altman Difference Plot | Evaluating agreement between two methods, especially when the comparative method is not a reference [13]. | Mean difference (bias), Limits of Agreement [12]. | Visually intuitive; does not assume one method is correct; good for assessing bias magnitude [13] [12]. | Less useful for characterizing proportional error across the range without further analysis. |

| Paired t-test (Bias) | Methods with a narrow analytical range (e.g., sodium, calcium) [11]. | Mean difference (bias), Standard Deviation of differences [11]. | Simple to compute and interpret. | Provides only a single estimate of average bias, not concentration-dependent error [11]. |

Practical Implementation and Reagent Solutions

Successful validation requires careful planning of essential materials and reagents. For an electrochemical assay, the following "Research Reagent Solutions" are critical.

Table 3: Essential Research Reagent Solutions for Electrochemical Assay Validation

| Reagent/Material | Function in Validation | Key Considerations |

|---|---|---|

| Reference Standard | Serves as the benchmark for accuracy and linearity assessments. The known purity and concentration are the basis for all quantitative measurements. | Must be of certified and high purity; traceability to a primary reference material is essential for regulatory compliance. |

| Electrochemical Sensor/Electrode | The transducer that converts a chemical response into a measurable electrical signal. | Material (e.g., glassy carbon, gold), surface area, and modification (e.g., with enzymes, nanoparticles) define specificity and sensitivity. |

| Supporting Electrolyte | Carries current in the electrochemical cell and controls ionic strength, which can affect electron transfer kinetics and signal. | Composition, pH, and buffer concentration must be controlled and specified as part of robustness testing. |

| Pharmaceutical Matrix | The placebo or blank formulation that mimics the drug product without the active ingredient. | Used in specificity testing to demonstrate no interference, and in accuracy (recovery) experiments by spiking with the analyte. |

| Quality Control (QC) Samples | Samples with known concentrations (low, mid, high) used to monitor the performance of the assay during validation runs. | Used to verify precision (repeatability and intermediate precision) and stability throughout the validation. |

Navigating Regulatory Guidance and Recent Updates

Adherence to regulatory guidelines is non-negotiable. The foundational document is ICH Q2(R2), which outlines the validation of analytical procedures for drug substances and products [7]. In the US, the FDA provides further guidance, which has recently been updated.

A notable change is the FDA's January 2025 issuance of the "Bioanalytical Method Validation for Biomarkers" guidance. While concise, it directs the use of ICH M10 for biomarker bioanalysis, a guideline that itself explicitly states it does not apply to biomarkers [9]. This creates a point of confusion for the industry. The European Bioanalytical Forum (EBF) has highlighted the lack of reference to Context of Use (COU) in this new guidance [9]. The takeaway for researchers is that ICH M10 can be a starting point, but the validation approach must be tailored to the specific objectives of the analysis, whether for a biomarker or an electrochemical drug assay, and justified accordingly [9].

Method validation is not a one-time event. The EPA emphasizes that all methods must be validated and peer-reviewed before being issued, and laboratories are responsible for ensuring minimum validation criteria are met [14]. Furthermore, methods should be revalidated whenever there are significant changes to the method or the instrument, and their performance should be monitored continuously [8].

Electroanalysis has emerged as a critical tool in the pharmaceutical industry, offering versatile and sensitive methods for drug analysis and quality control. These techniques measure electrical properties such as current, voltage, and charge to detect and quantify chemical species with high sensitivity and selectivity, even in complex matrices like biological fluids and formulated products [15]. The fundamental advantage of electrochemical methods lies in their ability to provide rapid, cost-effective analysis with minimal sample volumes, making them indispensable for drug development, therapeutic monitoring, and environmental surveillance of pharmaceutical residues [15].

Within this domain, three primary sensor techniques form the cornerstone of modern electrochemical analysis: potentiometric, amperometric, and conductometric sensors. Each operates on distinct principles and offers unique advantages for specific pharmaceutical applications. This guide provides a comprehensive comparison of these techniques, supported by experimental data and validation protocols essential for researchers and drug development professionals working with electrochemical pharmaceutical assays.

Fundamental Principles and Comparative Analysis

Operational Principles

Potentiometric sensors measure the potential difference between two electrodes (working and reference) without drawing any current. This potential develops at the electrode interface and follows the Nernst equation, relating the measured potential to the logarithm of the target ion's concentration. Common examples include ion-selective electrodes (ISEs) used for measuring pH and specific ions in pharmaceutical formulations [15]. These sensors typically employ polymeric membranes containing ionophores that selectively recognize target ions [16].

Amperometric sensors operate by applying a constant potential and measuring the resulting current generated from the redox reaction of an analyte at the electrode surface. The current produced is directly proportional to the concentration of the target species. These sensors typically consist of a working electrode, a counter electrode, and often a reference electrode [17]. The redox current is measured under controlled conditions, making these sensors highly accurate and reliable for continuous monitoring applications [17].

Conductometric sensors measure changes in the electrical conductivity of a solution resulting from electrochemical reactions or ionic interactions. While less prominently featured in the search results, these sensors detect alterations in ionic strength between electrodes and are valuable for certain pharmaceutical applications where conductivity changes correlate with analyte concentration.

Comparative Performance Characteristics

Table 1: Comparative Analysis of Electrochemical Sensor Techniques

| Parameter | Potentiometric Sensors | Amperometric Sensors | Conductometric Sensors |

|---|---|---|---|

| Measured Quantity | Potential (voltage) | Current | Conductivity |

| Reference Electrode Required | Yes [17] | Not necessarily [17] | No |

| Sensitivity | High for ions (Nernstian slope ~59 mV/decade for monovalent ions) [16] [18] | Very high (current directly proportional to concentration) [17] | Moderate |

| Selectivity | High with ion-selective membranes [16] [18] | High with specific redox potentials and recognition elements [17] | Generally low |

| Response Time | Typically seconds (e.g., 7-8 seconds [19]) | Fast (rapid redox reactions) [17] | Fast |

| Detection Limit | ~10⁻⁸ M achievable [18] [19] | Very low (ppm or ppb level) [17] [20] | Varies with application |

| Dynamic Range | Wide (e.g., 10⁻⁷-10⁻² M [19]) | Wide [17] | Limited |

| Primary Applications | Ion concentration measurement, pH sensing, drug detection [16] [19] | Gas sensing, dissolved species, biosensors [17] | Overall ionic content, reaction monitoring |

Table 2: Recent Experimental Performance Data from Sensor Studies

| Sensor Type | Target Analyte | Linear Range | Detection Limit | Response Time | Reference |

|---|---|---|---|---|---|

| Potentiometric (TPM) | Pb²⁺ | N/A | 1.5 × 10⁻⁸ M | N/A | [18] |

| Potentiometric (BAPTA) | Ca²⁺ | 0.1-1 mM | N/A | N/A | [16] |

| Potentiometric (PVC-printed) | Oxytrol | 1.0 × 10⁻⁷ – 1.0 × 10⁻² M | 5.0 × 10⁻⁸ M | 7-8 seconds | [19] |

| Amperometric (General) | Gases, dissolved species | Wide range | ppm or ppb level | Fast response | [17] |

Experimental Protocols for Sensor Validation

Sensor Selection Workflow

Detailed Methodologies for Key Techniques

Potentiometric Sensor Development and Validation

The development of a novel potentiometric sensor for pharmaceutical analysis typically follows a structured experimental protocol, as demonstrated in recent research on oxytrol detection [19]:

Sensor Fabrication:

- Printed PVC Sensor: Prepared using polyvinyl chloride (PVC) polymer matrix with specific ionophores (e.g., MoPA, WPA) and plasticizers (e.g., DOP, DBP, TOCP) in optimized ratios (e.g., 1:1:1:3 for graphene-enhanced sensors)

- Carbon Paste Sensor: Prepared using graphite, graphene, plasticizer, and PVC with ion-pairing agents

- Electrode Conditioning: Submersion in standard analyte solutions with stirring before measurement

Calibration Protocol:

- Prepare standard solutions across concentration range (e.g., 1.0 × 10⁻⁹ – 1.0 × 10⁻² mol L⁻¹)

- Immerse sensor and double-junction Ag/AgCl reference electrode in solutions

- Record EMF readings under continuous stirring

- Plot potential vs. logarithm of concentration to establish calibration curve

- Determine slope (mV/decade), linear range, and limit of detection (LOD)

Validation Parameters:

- pH Studies: Evaluate sensor performance across pH range (e.g., 2.5-7.5)

- Response Time: Measure time to reach stable potential (e.g., 7-8 seconds)

- Selectivity Testing: Determine selectivity coefficients against interfering ions using separate solution method (SSM) and Nicolsky-Eisenmann equation [16]

- Lifetime Assessment: Monitor performance over extended period (e.g., 70 days for PVC-printed sensors)

- Accuracy Testing: Compare with standard methods (e.g., HPLC) using standard addition and calibration methods

Amperometric Sensor Experimental Protocol

Based on recent advances in amperometric technology [17], standard experimental protocols include:

Sensor Configuration:

- Utilize three-electrode system: working electrode (e.g., Pt, modified electrodes), counter electrode, and reference electrode

- Select appropriate electrolyte (aqueous solutions or ionic liquids)

- Apply optimized constant potential to working electrode

Calibration and Measurement:

- Dissolve analyte in appropriate electrolyte

- Apply fixed potential and measure steady-state current

- Record current response at increasing analyte concentrations

- Plot calibration curve of current vs. concentration

- Determine sensitivity, linear range, and detection limit

Key Performance Validations:

- Repeatability: Multiple measurements at same concentration

- Reproducibility: Different sensors and days

- Interference Studies: Test structurally similar compounds

- Long-term Stability: Continuous operation over specified period

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Research Reagents and Materials for Electrochemical Sensor Development

| Reagent/Material | Function/Application | Examples/Notes |

|---|---|---|

| Ionophores | Selective target recognition in potentiometric sensors | MoPA, WPA, Na-TPB for oxytrol sensors [19]; BAPTA for Ca²⁺ sensors [16] |

| Polymer Matrices | Sensor membrane support | PVC for printed sensors [19]; conducting polymers like polythiophenes [16] |

| Plasticizers/Solvent Mediators | Enhance membrane flexibility and ion transport | DOP, DBP, TOCP [19] |

| Ionic Liquids | Electrolyte materials for amperometric sensors | [Bmpy][NTf2], [Bmim][NTf2] for H₂ sensors [20] |

| Electrode Materials | Working electrode substrates | Platinum, gold, carbon paste, screen-printed electrodes [17] [19] |

| Reference Electrodes | Stable potential reference | Ag/AgCl, double-junction designs [19] |

| Nanomaterials | Enhance sensitivity and surface area | Graphene, carbon nanotubes, metal nanoparticles [17] [19] |

| Molecular Recognition Elements | Improve selectivity | Enzymes, antibodies, molecularly imprinted polymers [17] |

Advanced Validation Pathways in Pharmaceutical Applications

Sensor Validation Workflow

Application-Specific Validation Protocols

Pharmaceutical Formulation Analysis: For drug quantification in formulations, potentiometric sensors have demonstrated exceptional performance. Recent research on oxytrol detection achieved accuracy of 97.94-99.72% compared to reference HPLC methods, with recovery percentages of 98.00-99.27% in real samples including canned drinks and natural juices [19]. Validation includes:

- Analysis of variance (ANOVA) for statistical validation

- Standard addition methods to account for matrix effects

- Design Expert software for optimization and model validation

- Specificity testing against common excipients and impurities

Biological Monitoring Applications: For implantable sensors monitoring biomarkers, as demonstrated with Ca²⁺ sensors for detecting inflammation [16]:

- Nernstian response verification in physiological concentration ranges

- Selectivity testing against biologically relevant interferents (e.g., Mg²⁺ for Ca²⁺ sensors)

- Biocompatibility assessment for in vivo applications

- Stability testing in simulated biological fluids

Environmental Pharmaceutical Monitoring: For detection of pharmaceutical residues in environmental samples:

- Low detection limit verification for trace analysis

- Robustness testing across varying environmental conditions

- Cross-validation with standard environmental monitoring methods

- Matrix effect studies in different water sources

The selection of appropriate electrochemical sensor technology depends critically on the specific pharmaceutical analysis requirements. Potentiometric sensors offer exceptional selectivity for ionic drugs and biomarkers with well-established validation protocols. Amperometric sensors provide superior sensitivity for continuous monitoring applications, particularly with advancements in nanomaterials and molecular recognition elements. Conductometric sensors, while less selective, offer simple and cost-effective solutions for specific pharmaceutical applications.

The experimental data and validation protocols presented provide researchers with a framework for implementing these techniques in pharmaceutical development and quality control. As the field advances, integration of these sensors with miniaturized systems, artificial intelligence for data analysis, and innovative materials will further expand their applications in pharmaceutical research and personalized medicine.

In the modern pharmaceutical industry, the demand for rapid, sensitive, and cost-effective analytical techniques has never been greater. Electrochemical assays have emerged as powerful tools that meet these demands, offering distinct advantages over conventional methods like chromatography and spectrophotometry. Within the critical framework of validation protocols for pharmaceutical assay research, these techniques provide a reliable pathway for drug development, quality control, and therapeutic drug monitoring. This guide objectively compares the performance of electrochemical assays against traditional techniques, highlighting their operational advantages and applicability in real-world pharmaceutical settings. The integration of advanced materials and artificial intelligence is further propelling electrochemical methods to the forefront of pharmaceutical analysis, enabling unprecedented levels of sensitivity and speed while maintaining rigorous validation standards [15] [21].

Comparative Analysis: Electrochemical Assays vs. Traditional Techniques

Electrochemical techniques offer a compelling alternative to traditional methods, balancing high performance with practical operational benefits. The tables below provide a structured comparison of key analytical parameters and operational characteristics.

Table 1: Comparison of Analytical Performance Characteristics

| Analytical Parameter | Electrochemical Assays | High-Performance Liquid Chromatography (HPLC) | Enzyme-Linked Immunosorbent Assay (ELISA) | Spectrophotometry |

|---|---|---|---|---|

| Typical Detection Limit | Sub-nanomolar to picomolar range [22] [23] | Nanomolar range [24] | Nanomolar range [25] | Micromolar range [24] |

| Sample Volume Required | Microliters (µL) [15] [26] | Milliliters (mL) [24] | Microliters to milliliters [25] | Milliliters (mL) [24] |

| Analysis Time | Seconds to minutes [25] [23] | Minutes to hours [22] [24] | Hours [25] [24] | Minutes |

| Multi-analyte Detection | Possible with advanced sensors & AI [21] | Yes, with specific detectors | Possible with multiplex kits | Limited |

| Suitability for Real-Time Monitoring | Excellent [15] [26] | Poor | Poor | Poor |

Table 2: Comparison of Operational and Economic Factors

| Operational Factor | Electrochemical Assays | High-Performance Liquid Chromatography (HPLC) | Enzyme-Linked Immunosorbent Assay (ELISA) | Spectrophotometry |

|---|---|---|---|---|

| Instrument Cost & Footprint | Low cost; portable and miniaturized formats available [23] [24] | Very high cost; large, benchtop instruments [22] | Moderate cost; requires plate readers [25] | Low to moderate cost; benchtop instruments |

| Operational Cost Per Test | Low (minimal reagents) [15] | High (expensive solvents, columns) [22] | Moderate (costly antibodies and kits) [25] | Low |

| Sample Preparation | Minimal often required [15] [24] | Extensive required (extraction, filtration) [22] [27] | Moderate required [25] | Simple to moderate |

| User Skill Requirement | Low to moderate, especially with automated systems [24] | High, requires trained experts [22] [25] | Moderate [25] | Low |

| Portability for Point-of-Care | Excellent [23] [24] | Not portable | Limited portability | Limited portability |

Experimental Protocols and Validation

The advantages of electrochemical assays are grounded in well-established and robust experimental methodologies. The following protocols detail the core processes for sensor preparation and quantitative detection, which are fundamental to achieving validated results.

Protocol 1: Sensor Preparation and Modification for Tyrosine Kinase Inhibitor (TKI) Detection

This protocol outlines the development of a nanomaterial-modified sensor for the detection of Anticancer Drugs like Imatinib, demonstrating the material innovations that enhance sensitivity [23].

- Electrode Pretreatment: Clean the glassy carbon electrode (GCE) by polishing with alumina slurry (0.05 µm) on a microcloth, followed by sequential sonication in ethanol and deionized water for 1 minute each to remove adsorbed particles.

- Nanocomposite Modification: Prepare a homogeneous dispersion of graphene oxide (GO) and multi-walled carbon nanotubes (MWCNTs) in dimethylformamide (DMF). Deposit a precise volume (e.g., 5 µL) of this nanocomposite onto the GCE surface and allow it to dry under an infrared lamp. This layer enhances the electroactive surface area and electron transfer kinetics [22].

- Polymer Electropolymerization: Immerse the modified electrode in a solution containing the monomer (e.g., aniline or pyrrole) and a supporting electrolyte. Perform cyclic voltammetry (CV) over a set potential window for a predetermined number of cycles to grow a conductive polymer film on the electrode. This film provides a stable matrix and can be engineered for selective recognition.

- Sensor Characterization: Use cyclic voltammetry (CV) and electrochemical impedance spectroscopy (EIS) in a standard redox probe solution (e.g., 5 mM K₃[Fe(CN)₆]/K₄[Fe(CN)₆]) to characterize the modification steps. A decrease in peak separation in CV and a lower charge-transfer resistance (Rct) in EIS confirm successful modification and improved electrode performance [26].

Protocol 2: AI-Enhanced Immunoassay for Staphylococcal Enterotoxin B (SEB)

This protocol illustrates the integration of electrochemical detection with immunoassay specificity and machine learning for robust quantification, a cutting-edge approach to overcoming variability [25].

- Antibody Immobilization:

- Pretreat a gold screen-printed electrode (SPE) with β-Mercaptoethylamine to form a self-assembled monolayer (SAM).

- Activate the SAM by incubating with 2.5% glutaraldehyde, which acts as a crosslinker.

- Immobilize the specific SEB antibodies onto the activated surface by incubation for 1 hour, followed by rinsing to remove unbound antibodies.

- Antigen Capture and Detection:

- Apply the sample (20 µL) containing the SEB antigen to the modified electrode and incubate for a short period (e.g., 10-15 minutes) to allow for specific antigen-antibody binding.

- Perform cyclic voltammetry (CV) in a solution of 5 mM K₃[Fe(CN)₆] as a redox marker. The binding of the antigen hinders electron transfer, resulting in measurable changes in the CV curve.

- Machine Learning-Enhanced Data Analysis:

- Feature Extraction: From each CV curve, extract multiple feature parameters (e.g., peak current, peak potential, peak separation, half-peak width, and charge transfer resistance) rather than relying on a single parameter.

- Model Training and Prediction: Use a multivariate linear regression algorithm to train a model on a dataset where these features are linked to known SEB concentrations. This model learns to predict the target concentration from new CV data, mitigating noise from electrode batch variations and experimental conditions. This approach has achieved an R² score of 0.999 for SEB prediction [25].

The workflow for this AI-enhanced quantitative detection is summarized below.

Key Electrochemical Techniques and Their Signaling Pathways

Different electrochemical techniques are selected based on the analytical requirement. The diagram below illustrates the decision-making pathway for selecting the most appropriate technique in a pharmaceutical context.

- Cyclic Voltammetry (CV): Used primarily for qualitative analysis to study redox mechanisms and reaction kinetics of pharmaceutical compounds. It involves sweeping the potential linearly and measuring the current response [22] [15].

- Differential Pulse Voltammetry (DPV): A highly sensitive quantitative technique. It applies small amplitude pulses on a linear ramp, which minimizes the contribution of capacitive current, leading to a lower background and superior signal-to-noise ratio for trace-level detection [22] [15].

- Amperometry: Measures current at a fixed potential over time. It is ideal for continuous monitoring and is the cornerstone of biosensors, such as those for glucose monitoring, due to its simplicity and rapid response [22] [26].

- Stripping Voltammetry: An extremely sensitive technique for metal ions and certain organic molecules. It involves a pre-concentration step where the analyte is deposited onto the electrode, followed by a stripping step that generates a highly sensitive analytical signal [26].

The Scientist's Toolkit: Essential Research Reagent Solutions

The performance of electrochemical assays is dependent on the careful selection of reagents and materials. The following table details key components and their functions in a typical sensor development workflow.

Table 3: Essential Reagents and Materials for Electrochemical Assay Development

| Item | Function/Application | Example in Protocol |

|---|---|---|

| Screen-Printed Electrodes (SPEs) | Disposable, portable, and mass-producible platforms for decentralized analysis. Often feature integrated working, reference, and counter electrodes [25]. | Used as the base platform in the AI-enhanced SEB immunoassay [25]. |

| Glassy Carbon Electrodes (GCEs) | A versatile and widely used electrode material with a broad potential window and good electrocatalytic properties for foundational research [22]. | Used as the base electrode for modification in the TKI sensor protocol [23]. |

| Carbon Nanotubes (CNTs) & Graphene Oxide (GO) | Nanostructured carbon materials that enhance electrode surface area, improve electron transfer kinetics, and can serve as scaffolds for immobilizing biorecognition elements [22]. | Form the nanocomposite layer in the TKI sensor to boost sensitivity [23]. |

| Potassium Ferricyanide (K₃[Fe(CN)₆]) | A common redox probe used in electrochemical characterization to study electron transfer efficiency and sensor surface properties via CV and EIS [25] [26]. | Used as the electrolyte in both CV characterization and the SEB immunoassay [25]. |

| Specific Antibodies | Biorecognition elements that provide high specificity for immunoassays by binding to a unique target antigen (e.g., a toxin or biomarker) [25] [21]. | Immobilized on the SPE surface for specific capture of SEB [25]. |

| Glutaraldehyde | A homobifunctional crosslinker used to covalently immobilize biomolecules (like antibodies) onto activated electrode surfaces, ensuring stable attachment [25]. | Used to activate the SAM layer for antibody immobilization in the SEB assay [25]. |

| Molecularly Imprinted Polymers (MIPs) | Synthetic polymer receptors with tailor-made cavities for a specific template molecule, offering an alternative to biological receptors with potentially greater stability [22]. | Can be used as a robust recognition element for small molecule drugs [22]. |

Electrochemical assays present a formidable combination of speed, sensitivity, and cost-effectiveness that aligns perfectly with the evolving needs of the pharmaceutical industry. The experimental data and comparative analysis confirm their capability to deliver highly sensitive and rapid quantification for a wide range of analytes, from small-molecule drugs to complex biomarkers, while significantly reducing operational costs and complexity. When developed and applied within rigorous validation protocols, these assays transition from promising research tools to reliable mainstays for pharmaceutical analysis. The ongoing integration of novel nanomaterials and artificial intelligence promises to further enhance their robustness, reproducibility, and scope, solidifying their role in advancing drug development and personalized medicine.

Defining the Scope and Objective for Your Electrochemical Validation Study

In the highly regulated field of pharmaceutical sciences, the validity of every analytical result is paramount. Electrochemical assays have emerged as powerful tools for drug analysis, offering high sensitivity, selectivity, and cost-effectiveness for quantifying active pharmaceutical ingredients (APIs), monitoring metabolites, and ensuring product stability [15]. Unlike traditional techniques like chromatography, electroanalytical methods often require minimal sample preparation and provide opportunities for real-time monitoring and portable diagnostics [15]. However, their reliability for regulatory decision-making hinges on a rigorously defined and executed validation process. This guide provides a structured framework for establishing the scope and objectives of your electrochemical validation study, ensuring the generation of robust, reproducible, and defensible data.

Core Principles of electrochemical assay validation

A validation master plan outlines the overall philosophy and requirements for validation activities, while the validation protocol specifies the exact operating conditions, process limits, and acceptance criteria for a given assay [28]. For electrochemical methods, the core objective of validation is to demonstrate that the procedure is suitable for its intended purpose, providing evidence that the assay is reliable, consistent, and accurate within its defined scope.

Key questions to define the scope include:

- What is the specific analyte? (e.g., API, impurity, metabolite)

- What is the intended application? (e.g., quality control, dissolution testing, pharmacokinetic studies)

- What is the required sensitivity and dynamic range?

- What sample matrices will be encountered? (e.g., bulk powder, formulated product, biological fluids)

Comparing Electroanalytical Techniques for Pharmaceutical Assays

Selecting the appropriate technique is a foundational step in scoping your validation study. Different electrochemical methods offer distinct advantages and limitations. The table below provides a comparative overview of common techniques to guide your selection.

Table 1: Comparison of Key Electroanalytical Techniques in Pharmaceutical Analysis

| Technique | Best Use Cases | Key Advantages | Key Limitations | Typical Detection Limits |

|---|---|---|---|---|

| Cyclic Voltammetry (CV) | Mechanistic studies, redox potential determination, reaction kinetics [15]. | Provides rich qualitative data on electrochemical behavior [15]. | Less suitable for precise quantification of trace analytes [15]. | Micromolar (µM) range [15]. |

| Pulse Voltammetry (DPV, SWV) | Trace analysis, detection in complex matrices (e.g., serum, urine) [15]. | High sensitivity, low detection limits, reduced background current [15]. | More complex instrumentation and data analysis than CV. | Nanomolar (nM) to picomolar (pM) range [15]. |

| Electrochemical Impedance Spectroscopy (EIS) | Label-free biosensing, surface characterization, binding kinetics, corrosion science [29]. | Highly sensitive to surface phenomena, non-destructive. | Complex data interpretation requiring equivalent circuit modeling [29]. | Varies widely with application. |

| Potentiometry | Ion activity measurement (e.g., pH, specific ions in formulations) [15]. | Simple, low-cost, direct measurement of ion concentration. | Can be susceptible to interference from other ions. | Varies with ion-selective electrode. |

Defining validation objectives and performance criteria

Once the analytical technique is selected, the validation objectives must be translated into measurable performance criteria, as outlined in the table below.

Table 2: Key Validation Parameters and Recommended Acceptance Criteria

| Validation Parameter | Objective | Recommended Experimental Approach | Typical Acceptance Criteria |

|---|---|---|---|

| Specificity/Selectivity | Demonstrate that the method can accurately measure the analyte in the presence of excipients, impurities, or matrix components. | Compare analyte response in pure standard vs. spiked sample matrix (e.g., placebo formulation, biological fluid). | No significant interference at the retention time/peak of the analyte. Recovery of 98-102%. |

| Linearity & Range | Establish a proportional relationship between analyte concentration and response. | Analyze a minimum of 5 concentrations across the intended range in duplicate. | Correlation coefficient (R²) ≥ 0.990. |

| Accuracy | Assess the closeness of the measured value to the true value. | Spike and recover the analyte at multiple levels (e.g., 80%, 100%, 120%) within the range. | Mean recovery of 98-102%. |

| Precision (Repeatability) | Evaluate the agreement under the same operating conditions over a short interval. | Analyze multiple replicates (n≥6) of a homogeneous sample at 100% of the test concentration. | Relative Standard Deviation (RSD) ≤ 2.0%. |

| Intermediate Precision (Ruggedness) | Demonstrate the reliability of the method when used by different analysts, on different days, or with different instruments. | Perform the assay on the same sample set in a different laboratory/analyst/day. | RSD between two sets ≤ 3.0%. |

| Robustness | Evaluate the method's capacity to remain unaffected by small, deliberate variations in method parameters. | Intentional variation of parameters (e.g., pH of buffer, deposition time, temperature). | The method continues to meet system suitability criteria. |

| Limit of Detection (LOD) / Quantification (LOQ) | Determine the lowest amount of analyte that can be detected or quantified with acceptable accuracy and precision. | Signal-to-noise ratio (3:1 for LOD, 10:1 for LOQ) or based on the standard deviation of the response. | LOD: Signal/Noise ≥ 3. LOQ: Signal/Noise ≥ 10 and RSD ≤ 5%. |

Experimental protocol: Validation of an API using differential pulse voltammetry

This detailed protocol provides a template for a typical validation exercise using the sensitive technique of Differential Pulse Voltammetry (DPV).

Materials and Reagents

- Electrochemical Workstation: Potentiostat with DPV capability.

- Working Electrode: Glassy Carbon Electrode (GCE), 3 mm diameter.

- Counter Electrode: Platinum wire.

- Reference Electrode: Ag/AgCl (3 M KCl).

- Analytical Standards: High-purity API and potential interferents.

- Supporting Electrolyte: Phosphate buffer saline (PBS), pH 7.4.

- Test Samples: Placebo formulation and finished product.

Electrode Preparation and Experimental Setup

- Polishing: Before each measurement, polish the GCE surface with 0.05 µm alumina slurry on a microcloth, followed by rinsing with deionized water.

- Activation: Electrochemically clean the electrode by performing cyclic voltammetry in a clean supporting electrolyte (e.g., 10 cycles from -0.2 V to +0.8 V at 100 mV/s) until a stable background is obtained.

- Setup: Transfer the cell containing 10 mL of supporting electrolyte and de-aerate with nitrogen gas for 10 minutes. Maintain a nitrogen blanket during measurements.

DPV Parameter Optimization

- Initial Conditions: Set the following DPV parameters as a starting point: Initial Potential: 0 V; Final Potential: +0.8 V; Pulse Amplitude: 50 mV; Pulse Width: 50 ms; Scan Rate: 20 mV/s.

- Robustness Testing: Systematically vary parameters one at a time (e.g., pulse amplitude ±10 mV, pH of buffer ±0.2 units) to establish optimal and robust conditions.

Validation Procedure

- Linearity and Range: Prepare a standard curve with at least five concentrations of the API within the expected range (e.g., 1-50 µM). Run each concentration in triplicate and plot the peak current versus concentration.

- Accuracy (Recovery): Prepare placebo formulations spiked with known quantities of the API at three levels (80%, 100%, 120% of the target concentration). Analyze these samples (n=3 for each level) and calculate the percentage recovery.

- Precision: Analyze six independent preparations of a sample at 100% of the test concentration. Calculate the mean, standard deviation, and relative standard deviation (RSD).

- Specificity: Record DPV scans of (a) the supporting electrolyte, (b) a placebo solution, (c) a standard API solution, and (d) the finished product. Confirm the absence of overlapping peaks in the placebo at the API's peak potential.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Materials and Reagents for Electrochemical Validation

| Item | Function / Rationale | Example / Specification |

|---|---|---|

| Supporting Electrolyte | To carry current and control ionic strength/pH, which critically affects redox potentials. | Phosphate Buffered Saline (PBS), Acetate buffer. High-purity salts. |

| Electrode Polishing Kit | To ensure a fresh, reproducible electrode surface for each measurement, crucial for precision. | Alumina or diamond slurry (0.05-0.3 µm), microcloth polishing pads. |

| Internal Standard | A compound with similar electrochemical properties used to normalize signal and correct for variations. | Not always applicable, but can be a structural analog of the analyte. |

| Standard Reference Material | A substance with a certified purity and concentration to establish method accuracy. | Certified API standard from a recognized supplier (e.g., USP). |

| Surface Modifiers | To enhance selectivity, sensitivity, or prevent fouling (e.g., Nafion, nanomaterials). | Carbon nanotubes, graphene oxide, molecularly imprinted polymers. |

Workflow diagram for assay validation

The following diagram illustrates the logical workflow for defining the scope and executing a validation study, from initial concept to final report.

A well-defined scope and clear objectives are the bedrock of a successful electrochemical validation study. By systematically selecting the appropriate analytical technique, translating objectives into measurable performance criteria and conducting experiments with detailed protocols, researchers can build a compelling case for the reliability of their electrochemical assays. This rigorous approach not only ensures data integrity but also streamlines the path toward regulatory compliance, ultimately accelerating drug development and enhancing the quality of pharmaceutical products. The integration of advanced materials and intelligent data analysis promises to further refine these validation paradigms, solidifying the role of electroanalysis as a cornerstone of modern pharmaceutical research [15].

From Theory to Practice: Developing and Applying Validated Electrochemical Methods

The reliability of electrochemical assays in pharmaceutical research hinges on the rigorous validation of key analytical parameters. Accuracy, precision, linearity, and range form the cornerstone of this process, ensuring that methods consistently produce trustworthy data for drug development, quality control, and regulatory approval. This guide objectively compares established and emerging electrochemical techniques against traditional chromatographic methods, providing a detailed analysis of their performance in assessing these critical parameters. Supported by experimental data and standardized protocols, this review equips researchers with the knowledge to select and implement appropriate validation strategies, enhancing the robustness and acceptance of electrochemical assays in pharmaceutical sciences.

Analytical method validation provides documented evidence that a laboratory procedure is fit for its intended purpose, ensuring the reliability, consistency, and accuracy of data used in pharmaceutical decision-making [30]. For electrochemical assays used in drug analysis, this process verifies that the method can accurately and precisely measure an analyte—such as an active pharmaceutical ingredient (API) or its metabolite—in a specific biological or pharmaceutical matrix [15]. Regulatory agencies, including the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA), mandate validated analytical procedures to guarantee product quality, safety, and efficacy, as outlined in harmonized guidelines like ICH Q2(R2) [31] [7] [30].

The selection of validation parameters is driven by the method's specific application, a principle known as "fitness for purpose" [32]. The United States Pharmacopeia (USP) categorizes analytical procedures and defines their validation requirements. For quantitative assays of APIs or major components (Category I) and impurity testing (Category II), a comprehensive set of parameters including accuracy, precision, linearity, and range must be demonstrated [30]. This review focuses on these four fundamental parameters, providing a comparative guide for their determination in electrochemical pharmaceutical analysis.

Core Principles and Definitions

Accuracy is defined as the closeness of agreement between a measured value and a value accepted as either a conventional true value or an accepted reference value [32] [33]. It is typically expressed as percent recovery of a known, spiked amount of analyte and reflects the method's freedom from systematic error (bias).

Precision measures the degree of scatter among a series of measurements obtained from multiple sampling of the same homogeneous sample under prescribed conditions [32] [33]. It is a measure of random error and is usually evaluated at three levels: repeatability (intra-assay), intermediate precision (inter-day, inter-analyst), and reproducibility (between laboratories).

Linearity is the ability of the method to elicit test results that are directly, or by a well-defined mathematical transformation, proportional to the concentration of analyte in samples within a given range [33] [30]. It is assessed by plotting a calibration curve of signal response against analyte concentration.

Range is the interval between the upper and lower concentrations of analyte in the sample for which it has been demonstrated that the analytical procedure has a suitable level of precision, accuracy, and linearity [30]. The range is typically derived from the linearity study and must encompass the expected concentrations in real samples.

The following diagram illustrates the logical relationship and workflow between these four core validation parameters.

Comparative Performance of Analytical Techniques

Electrochemical techniques are gaining prominence in pharmaceutical analysis due to their high sensitivity, rapid response, cost-effectiveness, and portability compared to conventional methods like chromatography and spectroscopy [22] [15]. The table below provides a quantitative comparison of these techniques for assessing key validation parameters.

Table 1: Performance Comparison of Analytical Techniques for Key Validation Parameters

| Analytical Technique | Typical Accuracy (% Recovery) | Precision (%RSD) | Linearity (Correlation Coefficient, R²) | Wide Dynamic Range | Key Applications in Pharma |

|---|---|---|---|---|---|

| Cyclic Voltammetry (CV) | 98-102% | 1.5-3% | >0.995 | 2-3 orders of magnitude | Mechanistic studies, redox behavior, electrode characterization [22] [15] |

| Differential Pulse Voltammetry (DPV) | 97.5-102.5% | 0.8-2% | >0.998 | 3-5 orders of magnitude | Trace analysis, API quantification in formulations, impurity detection [22] [15] |

| Square Wave Voltammetry (SWV) | 98-101% | 0.5-1.5% | >0.999 | 4-6 orders of magnitude | Ultra-trace detection, drug metabolite monitoring [15] |

| High-Performance Liquid Chromatography (HPLC) | 99-101% | 0.5-1.5% | >0.999 | 2-3 orders of magnitude | Assay, stability testing, impurity profiling [30] |

Key Insights from Comparative Data

- High Sensitivity Techniques: Pulse voltammetric methods like DPV and SWV demonstrate superior sensitivity and lower detection limits compared to CV, making them more suitable for quantifying low-abundance analytes like impurities or drugs in biological fluids [15]. Their pulsed measurement approach minimizes capacitive background current, significantly enhancing the signal-to-noise ratio [22].

- Accuracy in Complex Matrices: While HPLC consistently shows high accuracy, modern electrochemical sensors modified with nanomaterials (e.g., graphene, carbon nanotubes, metal-organic frameworks) can achieve comparable recovery rates, even in complex matrices like serum or wastewater, by mitigating fouling and improving selectivity [34] [22].

- Precision and Robustness: Electrochemical methods generally exhibit slightly higher relative standard deviation (%RSD) than HPLC, often due to greater sensitivity to minor variations in electrode surface regeneration, electrolyte pH, and temperature [15]. Automated systems and robust electrode modification protocols are key to improving precision [31].

Experimental Protocols for Parameter Assessment

Protocol for Accuracy (Recovery) Assessment

The most common technique for determining accuracy in pharmaceutical analysis is the spike recovery method [32].

- Sample Preparation: Prepare a minimum of three sets of samples at concentrations spanning the intended range (e.g., 80%, 100%, 120% of the target concentration), each in triplicate [32].

- Spiking: For each concentration level, a known quantity of a pure reference standard of the analyte is added (spiked) into the blank matrix (e.g., placebo formulation, synthetic biological fluid).

- Analysis and Calculation: Analyze both the spiked and un-spiked (if applicable) samples using the electrochemical method (e.g., DPV). The recovery (%) is calculated as:

(Measured Concentration / Theoretical Concentration) × 100%. The mean recovery across all concentrations should typically fall within 98-102% for an API assay [30].

Protocol for Precision (Repeatability) Assessment

Precision is evaluated by analyzing multiple replicates of a homogeneous sample.

- Sample Homogenization: Ensure a single, homogeneous sample is prepared at 100% of the target concentration.

- Replicate Analysis: Perform a minimum of six independent analyses of this sample using the same electrochemical procedure, same analyst, and same equipment on the same day.

- Statistical Analysis: Calculate the mean, standard deviation (SD), and relative standard deviation (RSD) of the measured concentrations or peak currents. For an API assay, the %RSD should generally be less than 2% [30].

Protocol for Linearity and Range Assessment

This experiment establishes the relationship between analyte concentration and the electrochemical signal (e.g., peak current in DPV).

- Calibration Standards: Prepare a series of standard solutions with at least five to six concentration levels, spaced evenly across the anticipated range.

- Analysis: Analyze each standard in triplicate using the optimized electrochemical method.

- Calibration Curve: Plot the mean response (y-axis) against the concentration (x-axis). Perform linear regression analysis to determine the slope, y-intercept, and correlation coefficient (R²).

- Acceptance Criteria: A linear relationship is demonstrated by a correlation coefficient (R²) typically greater than 0.995 [33] [30]. The range is validated as the interval over which this linearity is maintained, and acceptable accuracy and precision are confirmed.

The workflow for this integrated assessment is visualized below.

The Scientist's Toolkit: Key Research Reagent Solutions

The performance of electrochemical assays is heavily dependent on the materials used for electrode modification and signal enhancement. The following table details essential reagents and their functions.

Table 2: Essential Research Reagents for Electrochemical Pharmaceutical Assays

| Reagent/Material | Function in Assay Development | Specific Application Example |

|---|---|---|

| Carbon Nanotubes (Single/Multi-Walled) | Enhance electron transfer kinetics and increase electroactive surface area; improve sensitivity [34] [22]. | Detection of heavy metals in drug substances or antibiotic residues [34]. |

| Graphene & Graphene Oxide | Provide a high surface-area platform for biomolecule immobilization; excellent conductivity [22]. | Base material for sensors detecting NSAIDs like diclofenac [22]. |

| Metal Nanoparticles (Gold, Platinum) | Catalyze redox reactions; facilitate signal amplification; enable surface functionalization [22]. | Functionalization with aptamers for selective antibiotic detection [22]. |

| Molecularly Imprinted Polymers (MIPs) | Create synthetic, highly selective recognition sites for target molecules; mimic antibody binding [22]. | Selective detection of a specific API in complex biological matrices [22]. |

| Ion-Selective Electrodes (ISEs) | Measure ion activity (concentration) in solution without drawing current; used in potentiometry [15]. | Monitoring specific ions (e.g., pH) critical to pharmaceutical formulation stability [15]. |

| Buffer Salts (e.g., PBS, Acetate) | Maintain constant pH and ionic strength, ensuring reproducible electrochemical reaction conditions [6]. | Standard electrolyte for assessing drug-excipient compatibility of carvedilol [6]. |

The rigorous validation of accuracy, precision, linearity, and range is non-negotiable for the adoption of electrochemical methods in regulated pharmaceutical environments. As demonstrated, advanced electrochemical techniques, particularly pulse voltammetry coupled with nanomaterial-modified sensors, can achieve performance metrics comparable to, and in some cases surpassing, traditional chromatographic methods, especially for trace analysis and point-of-care applications. The experimental protocols and comparative data provided in this guide serve as a foundational framework for researchers to validate their assays robustly. Future advancements in standardization, coupled with the integration of artificial intelligence for data analysis [31] [15], will further solidify the role of electroanalysis as a reliable, sensitive, and cost-effective pillar of modern pharmaceutical analysis.

The determination of the Limit of Detection (LOD) and Limit of Quantitation (LOQ) is fundamental to the validation of analytical procedures in pharmaceutical sciences. These parameters define the lowest concentrations of an analyte that can be reliably detected and quantified, respectively, establishing the sensitivity and applicability of an analytical method [35]. Despite their crucial importance in regulatory compliance and method validation, the absence of a universal protocol for establishing these limits has led to varied approaches among researchers and analysts [35] [36]. This guide objectively compares predominant methodologies for determining LOD and LOQ, with particular emphasis on their application in validating electrochemical pharmaceutical assays, a field gaining prominence due to its cost-effectiveness, rapid analysis capabilities, and high sensitivity [15] [37].

Core Methodologies for Determining LOD and LOQ

Several methodologies are recognized by international guidelines, such as the International Conference on Harmonisation (ICH) Q2(R2), for determining LOD and LOQ [7] [38]. Each approach has distinct advantages, limitations, and optimal use cases, which are critical for selecting the most appropriate method for a given analytical technique.

Methodological Comparison

The table below summarizes the key characteristics of the primary approaches for determining LOD and LOQ.

Table 1: Comparison of Major Approaches for Determining LOD and LOQ

| Methodology | Basis of Determination | Typical LOD Value | Typical LOQ Value | Key Advantages | Key Limitations |

|---|---|---|---|---|---|

| Standard Deviation of Blank/Response & Slope [36] | Statistical | ( \text{LOD} = 3.3\sigma/S ) | ( \text{LOQ} = 10\sigma/S ) | Objective, statistically rigorous; does not require low-concentration samples. | Can provide underestimated values; relies on homoscedasticity (constant variance) [35]. |

| Signal-to-Noise (S/N) [36] [38] | Instrumental | S/N = 2 or 3 | S/N = 10 | Simple, intuitive, and widely applicable in chromatography. | Calculation method for noise is not standardized; can be instrument-dependent and somewhat arbitrary [38]. |

| Visual Evaluation [36] [38] | Empirical/Subjective | Lowest concentration visually detected | Lowest concentration visually quantified | Technically simple and straightforward. | Highly subjective and operator-dependent; lacks statistical rigor [38]. |

| Uncertainty Profile [35] | Statistical & Graphical (Tolerance Interval) | Intersection of uncertainty profile and acceptability limits. | Provides a precise estimate of measurement uncertainty; gives a realistic and relevant assessment. | Computationally complex; requires a robust experimental design. | |

| Accuracy Profile [35] | Graphical (Accuracy & Tolerance Interval) | Intersection of accuracy profile and acceptability limits. | Directly links LOD/LOQ to method accuracy; reliable assessment. | Computationally complex. |

Advanced Graphical and Statistical Approaches

Beyond the classical methods, advanced strategies like the Uncertainty Profile and Accuracy Profile offer more comprehensive validation tools. These graphical approaches are based on computing β-content tolerance intervals, which define an interval that contains a specified proportion (β) of the population with a specified degree of confidence (γ) [35]. A method is considered valid within a concentration range where its uncertainty or accuracy profile falls entirely within pre-defined acceptability limits (λ). The LOQ is then determined as the lowest concentration where this condition is met, found by calculating the intersection point of the upper (or lower) tolerance interval limit and the acceptability limit [35]. These methods are noted for providing realistic and relevant assessments of a method's capabilities compared to classical strategies [35].

Experimental Protocols and Performance Data

The theoretical principles of these methodologies are best understood through their practical implementation in analytical studies.

Experimental Protocol: HPLC-UV for Sotalol in Plasma

A comparative study implemented multiple strategies to determine LOD and LOQ for an HPLC method analyzing sotalol in plasma [35].

- Methodology: The study compared a classical strategy (based on statistical parameters of the calibration curve) with graphical tools (accuracy profile and uncertainty profile).

- Key Findings: The classical strategy provided underestimated values for LOD and LOQ. In contrast, the uncertainty and accuracy profiles yielded values of the same order of magnitude and were deemed more realistic and relevant for assessing the method's true performance [35].

Experimental Protocol: Electroanalysis vs. HPLC for Octocrylene

A direct comparison of electroanalysis and chromatography for detecting octocrylene (OC) in water matrices demonstrates how the analytical technique influences sensitivity [37].

- Electrochemical Method: A Glassy Carbon Sensor (GCS) was used with Differential Pulse Voltammetry (DPV). The cell consisted of a GCS working electrode, Ag/AgCl reference electrode, and platinum counter electrode. The electrolyte was a Britton-Robinson buffer solution (pH 6). The GCS surface was polished before and after each measurement.

- Chromatographic Method: Analysis was performed using an Ultimate 3000 HPLC system with a C18 column in isocratic mode (80/20 acetonitrile/water eluent).

- Performance Data: The experimental LOD and LOQ values for each technique are summarized below.

Table 2: Experimental LOD and LOQ Values for Octocrylene Determination [37]

| Analytical Technique | Limit of Detection (LOD) | Limit of Quantitation (LOQ) |

|---|---|---|

| Electroanalysis (GCS) | 0.11 ± 0.01 mg L⁻¹ | 0.86 ± 0.04 mg L⁻¹ |

| High-Performance Liquid Chromatography (HPLC) | 0.35 ± 0.02 mg L⁻¹ | 2.86 ± 0.12 mg L⁻¹ |

The data shows that the electroanalytical method achieved significantly lower (approximately 3 times) detection and quantification limits compared to HPLC for this specific application, highlighting its superior sensitivity for quantifying recalcitrant organic compounds like octocrylene [37].

The Scientist's Toolkit: Key Reagents and Materials

The following table details essential materials and reagents commonly used in the development and validation of electrochemical pharmaceutical assays.

Table 3: Essential Research Reagent Solutions for Electroanalytical Assays

| Item | Function/Application | Example from Literature |

|---|---|---|

| Glassy Carbon Electrode (GCE) | A common working electrode known for its low adsorption, high conductivity, and wide potential window. | Used as the sensor for quantifying octocrylene [37]. |

| Britton-Robinson (BR) Buffer | A universal buffer solution used to maintain a specific pH in the electrochemical cell, which is critical for analyte stability and reaction kinetics. | Used as the electrolyte at pH 6 for OC determination [37]. |

| Supporting Electrolyte (e.g., NaCl) | Increases the conductivity of the solution and minimizes the migration current, ensuring the signal is primarily based on diffusion. | Used in solutions to mimic swimming pool water conditions [37]. |

| Internal Standard (e.g., Atenolol) | A compound added in a constant amount to samples and calibrators to correct for variability during sample preparation and analysis. | Used in the HPLC method for sotalol in plasma to improve precision [35]. |

| Reference Electrode (e.g., Ag/AgCl) | Provides a stable and reproducible reference potential against which the working electrode's potential is controlled. | Used as the reference electrode in the three-electrode cell for OC detection [37]. |

Workflow and Decision Pathway

The process of determining LOD and LOQ, from method selection to final validation, can be visualized as the following workflow. This diagram integrates the core concepts of the uncertainty profile method for establishing the valid quantitative domain.

Selecting an appropriate method for determining LOD and LOQ is critical for establishing the credibility and regulatory compliance of an analytical procedure. While classical and instrumental methods like standard deviation and signal-to-noise ratio offer simplicity, advanced graphical tools like the uncertainty profile provide a more robust and realistic assessment of a method's quantitative capabilities by incorporating measurement uncertainty directly into the validation process [35]. The demonstrated performance of electroanalytical techniques, offering lower detection limits compared to traditional HPLC for specific pharmaceutical compounds like octocrylene, positions electroanalysis as a powerful and sensitive alternative for pharmaceutical analysis [15] [37]. The choice of methodology should be guided by the nature of the assay, regulatory requirements, and the intended use of the analytical data, ensuring that the reported LOD and LOQ truly reflect the method's sensitivity and reliability.

System Suitability and Electrode Conditioning for Reliable Performance