Troubleshooting Slow Redox Reaction Kinetics: Strategies for Biomedical Research and Drug Development

This article provides a comprehensive guide for researchers and drug development professionals tackling the pervasive challenge of slow redox reaction kinetics.

Troubleshooting Slow Redox Reaction Kinetics: Strategies for Biomedical Research and Drug Development

Abstract

This article provides a comprehensive guide for researchers and drug development professionals tackling the pervasive challenge of slow redox reaction kinetics. It explores the fundamental principles governing redox reactions and the molecular origins of kinetic bottlenecks, from sluggish charge transfer to material degradation. The content details advanced methodological approaches, including in operando analytical techniques and the application of redox mediators and nanocatalysts, directly applicable to enhancing reaction rates in electrochemical biosensing and pharmaceutical analysis. A dedicated troubleshooting framework offers targeted strategies to overcome common issues like overpotential, shuttle effects, and interfacial resistance. Finally, the article synthesizes validation protocols and comparative analyses of different optimization strategies, presenting a clear pathway for improving the sensitivity, efficiency, and reliability of redox-based applications in biomedical science.

Understanding Redox Kinetics: Principles and Bottlenecks in Biomedical Systems

Fundamental Principles of Redox Reactions and Electron Transfer

Frequently Asked Questions (FAQs)

Q1: What are the fundamental definitions of oxidation and reduction in electron transfer terms? A1: Redox reactions are chemical processes where reactants undergo a change in their oxidation states through the transfer of electrons [1].

- Oxidation is the loss of electrons by a substance, increasing its oxidation number [2].

- Reduction is the gain of electrons by a substance, decreasing its oxidation number [2].

- Memory Aid: Use the mnemonic OIL RIG – Oxidation Is Loss, Reduction Is Gain [2].

Q2: How can I quickly identify the oxidizing and reducing agents in a reaction? A2: Identify the elements that change oxidation states.

- The reducing agent is the species that is oxidized (loses electrons), causing another substance to be reduced [2].

- The oxidizing agent is the species that is reduced (gains electrons), causing another substance to be oxidized [2].

- Example: In the reaction

Fe + Cu²⁺ → Fe²⁺ + Cu, iron (Fe) loses electrons and is the reducing agent, while the copper ion (Cu²⁺) gains electrons and is the oxidizing agent [2].

Q3: What does the term "sluggish redox kinetics" mean in practical terms? A3: Sluggish kinetics refers to a slow rate of the electron transfer process and associated chemical transformations in a redox reaction. This often manifests in electrochemical systems as [3] [4]:

- High overpotential: A larger than expected voltage gap between charge and discharge.

- Low capacity at high current densities: Significant drop in capacity when the battery is charged or discharged rapidly.

- Poor rate capability: The system cannot maintain performance under high power demands.

Q4: What are common chemical strategies to improve slow redox kinetics? A4: Research focuses on interface and reaction pathway engineering. Common strategies include:

- Redox Mediators (RMs): Soluble, redox-active molecules that shuttle electrons between the electrode and the solid active material, enhancing reaction kinetics and reversibility [5].

- Electrolyte Additives: Molecules that modify the electrode-electrolyte interface, promoting favorable reaction pathways, reducing energy barriers, and forming protective layers [3].

- Electrode Activation: Thermal or chemical treatments that increase the electrochemical activity of electrode materials (e.g., increasing surface functional groups on graphite felt) [6].

Troubleshooting Guide: Slow Redox Kinetics

This guide addresses common problems, their potential causes, and investigative steps.

| Problem Observed | Potential Causes | Diagnostic Steps & Solutions |

|---|---|---|

| High Overpotential | • Slow electron transfer kinetics at electrode.• High resistance in the cell.• Non-conductive decomposition products on electrode. | • Perform Electrochemical Impedance Spectroscopy (EIS) to measure cell resistance.• Introduce a suitable redox mediator to facilitate electron transfer [5]. |

| Rapid Capacity Fade | • Irreversible side reactions.• Active material dissolution.• Unstable electrode-electrolyte interface. | • Analyze electrolyte composition post-cycling.• Use an electrolyte additive to form a stable Solid-Electrolyte Interphase (SEI) [3]. |

| Poor Rate Performance | • Sluggish ion diffusion in the electrolyte or electrode.• Slow reaction kinetics of active material (e.g., anionic redox) [4]. | • Use Galvanostatic Intermittent Titration Technique (GITT) to measure diffusion coefficients [4].• Optimize electrode architecture for shorter ion diffusion paths. |

Experimental Protocols for Kinetic Analysis

Protocol 1: Evaluating Redox Mediators (RMs)

Objective: To test the efficacy of a candidate RM in improving the charge transfer kinetics of a slow redox reaction.

Background: RMs are soluble species that undergo reversible redox reactions. They diffuse to the electrode surface, get oxidized/reduced, and then chemically oxidize/reduce the active material, effectively shuttling electrons and boosting kinetics [5].

Materials:

- Electrochemical cell (e.g., coin cell or flow cell).

- Working and counter electrodes specific to your system (e.g., sulfur cathode, zinc anode).

- Electrolyte with and without the candidate RM.

- Potentiostat/Galvanostat.

Methodology:

- Prepare two identical cells: one with a baseline electrolyte and one with the electrolyte containing a defined concentration of the RM [5].

- Perform cyclic voltammetry (CV) at multiple scan rates. A decrease in the peak separation (ΔEp) in the RM-containing cell indicates improved kinetics and lower overpotential.

- Conduct galvanostatic charge-discharge (GCD) tests at various current densities. An increase in capacity retention at higher rates confirms enhanced rate capability [3].

- Cycle the cells over multiple cycles. Improved cycling stability with the RM suggests it helps maintain reaction reversibility.

Expected Outcome: The cell with the effective RM will show lower overpotential, higher capacity at high currents, and better cycling stability compared to the baseline cell.

Protocol 2: Interface Engineering with Electrolyte Additives

Objective: To investigate how an electrolyte additive modifies the electrode interface to boost redox kinetics.

Background: Additives can adsorb onto electrode surfaces, coordinate with ions, and form functional interphases, thereby altering the reaction pathway and energy barrier [3].

Materials:

- Similar setup to Protocol 1.

- Electrolyte additive (e.g., Tetramethylurea - TTMU, as used in Zn-S batteries [3]).

Methodology:

- Characterize the electrode surface morphology and composition before testing using techniques like SEM or XPS.

- Compare the electrochemical performance of cells with and without the additive using CV and GCD, as described in Protocol 1.

- Use techniques like X-ray Absorption Near Edge Structure (XANES) to study changes in the electronic structure and charge transfer processes at the interface [4].

- Post-cycle, characterize the electrode surfaces again to identify the composition and properties of any newly formed interphases.

Expected Outcome: A effective additive will lead to more uniform nucleation of products, a lower voltage gap, and the formation of a stable SEI, as evidenced by electrochemical data and post-mortem analysis [3].

Research Reagent Solutions

The following table details key reagents used to address slow redox kinetics.

| Reagent / Material | Function / Application | Key Consideration |

|---|---|---|

| Tetramethylurea (TTMU) | Electrolyte additive that adsorbs on cathode, coordinates ions, and alters reaction pathway to lower energy barrier and promote uniform nucleation [3]. | Concentration-dependent effects; typically used at ~10% by volume [3]. |

| Iodide/Iodine (I⁻/I₂) | Inorganic redox mediator that shuttles electrons in systems like aqueous Zn-S batteries, reducing voltage hysteresis [5]. | Can cause a shuttle effect, leading to self-discharge if not properly managed [5]. |

| Iron (II/III) Complexes | Inorganic redox mediators used in various flow battery systems to enhance the kinetics of other redox couples [5]. | Redox potential must be strategically positioned between the anode and cathode reactions. |

| Thermally Activated Graphite Felt | Electrode material for flow batteries; thermal activation introduces functional groups that boost electrochemical activity and kinetics [6]. | Optimal activation conditions (e.g., 400°C for 7 hours) are critical for performance [6]. |

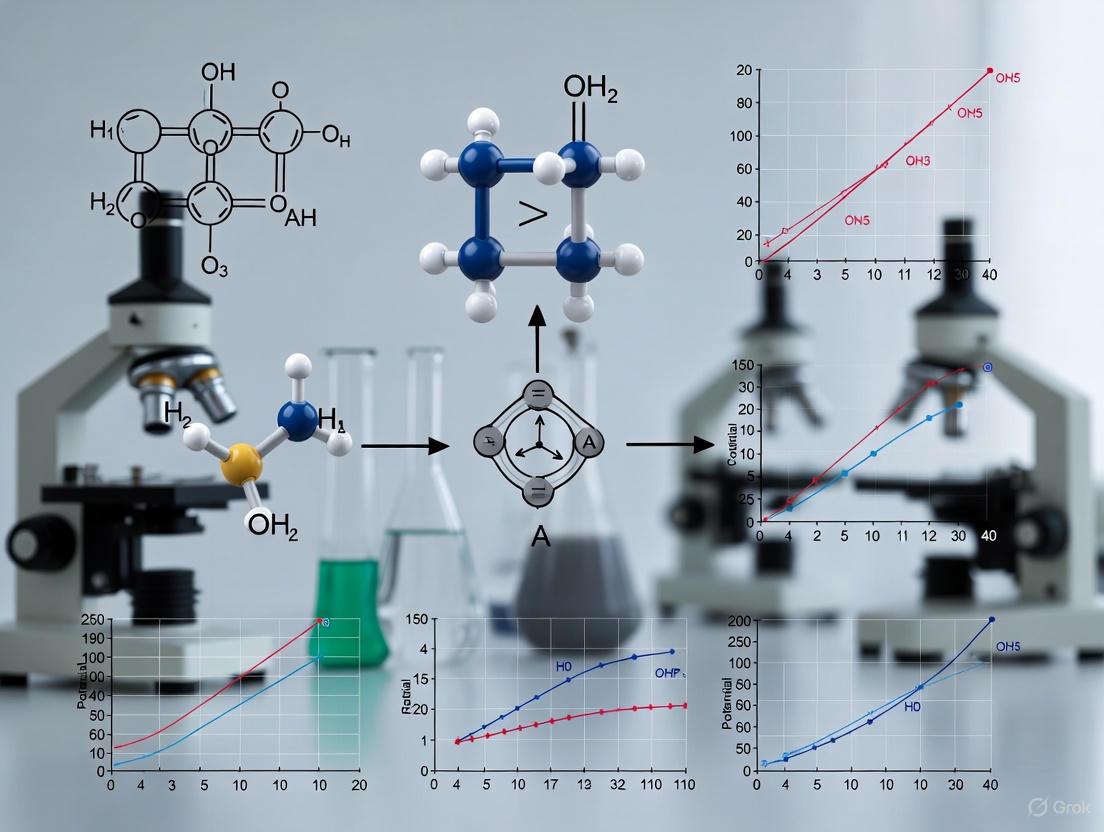

Workflow and Pathway Visualizations

Redox Mediator Mechanism

Kinetic Troubleshooting Workflow

Sluggish kinetics in electrochemical systems refer to the slow rate of redox (reduction-oxidation) reactions, which can severely limit the performance, efficiency, and practicality of devices like batteries, fuel cells, and electrolyzers. These kinetics determine how quickly electrons are transferred during oxidation and reduction processes. [7] Understanding and troubleshooting these limitations requires a fundamental grasp of three primary sources: overpotential, mass transport, and activation barriers.

The Three Main Types of Overpotential

Overpotential (η) is the voltage difference between a reaction's thermodynamically determined potential and the potential at which it is experimentally observed to proceed at a measurable rate. It represents the extra energy required to drive a reaction and is a direct measure of energy inefficiency. [8] [9] The total overpotential in a system is the sum of three key components:

- Activation Overpotential (

η_act): This is the overpotential required to overcome the activation energy barrier of the electron transfer step at the electrode-electrolyte interface. It dominates at low current densities and is described by the Butler-Volmer equation and Tafel equation. [10] [11] [9] It is strongly influenced by the electrocatalyst's activity, often quantified by the exchange current density (i_0). [10] - Concentration Overpotential (

η_conc): This arises from the depletion of reactants at the electrode surface (or accumulation of products) due to slow mass transport, creating a concentration gradient. It becomes significant at high current densities. [11] [9] - Ohmic Overpotential (

η_ohmic): This is the simple voltage drop (IR_drop) due to the electrical resistance of the cell components, including the electrolyte, electrodes, and contacts. It has a linear relationship with current. [11] [9]

The diagram below illustrates how these overpotentials contribute to the total voltage loss in a typical electrochemical cell, such as a fuel cell, across different current density regions.

Key Factors Influencing Redox Reaction Kinetics

The overall rate of a redox reaction is governed by several factors that can interact in complex ways: [7]

- Temperature: Increased temperature provides higher kinetic energy to reactants, leading to more frequent and energetic collisions, which helps overcome the activation energy barrier.

- Concentration: Higher reactant concentrations generally lead to more frequent collisions and a faster reaction rate.

- Surface Area: In heterogeneous reactions (e.g., on a catalyst surface), a greater surface area provides more active sites for the reaction to occur.

- Catalysts: Substances that increase the reaction rate without being consumed. They work by providing an alternative reaction pathway with a lower activation energy. [7]

- Nature of Reactants: The intrinsic chemical properties of the reacting species determine how readily they participate in electron transfer.

Troubleshooting FAQs and Guides

FAQ 1: How Can I Determine Which Type of Overpotential is Limiting My Experiment?

Answer: The dominant type of overpotential can often be identified by analyzing a polarization curve (a plot of cell voltage vs. current density) and using electrochemical impedance spectroscopy (EIS).

Check the Polarization Curve: Different overpotentials dominate in distinct regions of the curve. [11]

- Initial Voltage Drop: A sharp voltage drop at very low current densities is characteristic of activation polarization.

- Linear Voltage Decrease: A steady, linear decrease in voltage with increasing current is typically due to ohmic losses.

- Rapid Voltage Drop-Off: A sudden, severe voltage drop at high current densities signals significant concentration polarization.

Use Electrochemical Impedance Spectroscopy (EIS): This technique can help separate these losses more quantitatively. For instance, one study used EIS to show that a cathode exhibited charge-transfer-limited features (activation control), while an anode displayed mass-transfer-limited features. [12]

FAQ 2: My Reaction is Slow Even with a Good Catalyst. Could Mass Transport Be the Issue?

Answer: Absolutely. Even with a highly active catalyst, the overall reaction rate can be limited if reactants cannot reach the active sites quickly enough, or if products are not removed efficiently. This is known as a mass transport limitation. [7]

Troubleshooting Steps:

- Increase Agitation or Flow Rate: If possible, enhance mixing in the electrolyte to reduce the diffusion layer thickness at the electrode surface.

- Optimize Electrode Architecture: Use electrodes with higher porosity or more open structures to facilitate the inward and outward flow of species. [7] Designing 3D porous structures can dramatically improve mass transport.

- Check Reactant Concentration: Ensure the bulk concentration of reactants is sufficient. In some cases, increasing concentration can help, but the surface area and porosity of the electrode must be adequate to handle the flux.

FAQ 3: What Experimental Methods Can I Use to Measure Slow Reaction Kinetics?

Answer: Several established methods are suitable for studying reactions that occur on timescales of minutes to hours. [13]

The table below summarizes common techniques for analyzing slow reaction kinetics.

Table 1: Experimental Methods for Studying Slow Kinetics

| Method | Principle of Operation | Ideal for Measuring | Key Parameters/Equipment |

|---|---|---|---|

| Optical Absorption (Spectrophotometry) [13] | Tracks concentration change of a colored reactant or product by measuring light absorption (Beer's Law). | Reactions involving a colored species. | Absorbance, Wavelength, Cuvette path length, Spectrophotometer. |

| pH Measurement [13] | Monitors the production or consumption of hydrogen ions (H⁺) using a pH meter. | Reactions that produce or consume acids/bases. | pH meter, pH electrode. |

| Electrical Conductance (Conductimetry) [13] | Measures the solution's ability to conduct electricity, which changes with ion concentration. | Reactions that change the total ionic concentration of the solution. | Conductivity cell, AC bridge to avoid electrolysis. |

| Gas Evolution Measurement [13] | Tracks the volume or pressure change of a gas produced or consumed in the reaction. | Reactions involving gaseous reactants or products. | Gas syringe, pressure sensor, precision balance (for mass loss). |

| Light Scattering (Nephelometry) [13] | Monitors the formation of a solid precipitate by measuring the scattering of light. | Reactions that result in the formation of a fine precipitate. | Nephelometer, or a simple marked-paper setup. |

Case Study: Troubleshooting Sluggish Kinetics in a Zinc-Iodine Battery

A study on aqueous Zinc-Iodine (Zn-I₂) batteries provides an excellent real-world example of diagnosing and solving kinetic limitations. The "shuttle effect" of polyiodides was causing slow redox kinetics and capacity loss. [14]

The Problem: The dissociation of iodine (I₂) into polyiodides (Iₙ⁻) led to these species dissolving and shuttling between the cathode and anode, resulting in low Coulombic efficiency and sluggish apparent kinetics.

The Diagnosis: The issue was a combination of poor mass transport control (unwanted movement of species) and an insufficient activation barrier to prevent shuttling.

The Solution: Using a functional binder, gelatin, to modify the electrode interface.

- Mechanism 1 (Electrostatic Interaction): The positively charged regions in gelatin provided an electrostatic attraction to the negatively charged polyiodides, physically confining them (addressing mass transport). [14]

- Mechanism 2 (Electron Donor): The electron-rich regions in gelatin could donate electrons to form physical or even covalent bonds with iodine species, changing the reaction pathway and lowering the activation barrier for the desired redox reaction. [14]

Outcome: This dual approach dramatically boosted the iodine redox kinetics, resulting in a high reversible capacity even after 3,000 cycles and exceptional stability over 30,000 cycles. [14]

Essential Experimental Protocols

Protocol 1: Constructing and Analyzing a Potentiostatic Polarization Curve

This protocol is fundamental for diagnosing overpotentials and overall cell health. [11]

Workflow for Polarization Curve Analysis

Detailed Steps:

- Cell Setup and Stabilization: Assemble your electrochemical cell and allow it to reach a stable open-circuit voltage (OCV). Ensure all operating conditions (temperature, pressure, reactant flow rates, humidity) are stable and maintained throughout the test. [11]

- Step-wise Current Application: Using a potentiostat or galvanostat, apply a constant current load to the cell. Start from open-circuit and increase the current in small, discrete steps. [11]

- Equilibrium Waiting: After each current step, wait a predetermined time (e.g., 15-30 minutes for smaller cells, longer for larger systems) for the cell voltage and internal conditions (heat, water balance) to stabilize at the new load. This is critical for accurate data. [11]

- Data Recording: Once the voltage is stable, record the average current and the average voltage over the last 5 minutes of the step.

- Data Analysis and Plotting: Plot the measured cell voltage against the applied current density. Analyze the curve to identify the three distinct regions of loss as shown in the theoretical diagram above.

Protocol 2: Using a Hydrogen Reference Electrode to Separate Anode/Cathode Overpotentials

For a more detailed diagnosis, this advanced protocol allows for the separation of losses at the anode and cathode.

Objective: To accurately measure the individual contributions of the anode and cathode overpotentials to the total cell voltage loss.

Materials:

- Standard electrochemical cell setup.

- A hydrogen reference electrode embedded in the cell configuration.

- Key for Accuracy: Use an intentionally thick polymer electrolyte membrane and a low-catalyst-loaded working electrode to slow down the reaction and amplify the overpotential signal for clearer measurement. [12]

Procedure:

- Cell Configuration: Set up the cell with the hydrogen reference electrode placed in a location where it can probe the potential within the membrane.

- I-V and EIS Measurement: Run current-voltage (I-V) measurements while simultaneously using the reference electrode to monitor the potential of each electrode half. Perform electrochemical impedance spectroscopy (EIS) to analyze the non-ohmic overpotentials in detail. [12]

- Data Separation: The reference electrode allows you to determine the potential of each electrode versus a known reference. You can then separate the total overpotential (

η_total) into its components: [12]- Anode overpotential (

η_anode) - Cathode overpotential (

η_cathode) - Ohmic loss (

IR_drop)

- Anode overpotential (

Expected Outcome: This method revealed in one study that the cathode hydrogen evolution reaction (HER) had a larger non-ohmic overpotential than the anode hydrogen oxidation reaction (HOR), which was attributed to different rate-determining steps in their reaction mechanisms (Volmer-Heyrovsky vs. Volmer-Tafel). [12]

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Kinetic Studies

| Reagent/Material | Function in Kinetic Studies | Application Example |

|---|---|---|

| Gelatin Binder [14] | Functional binder that suppresses shuttle effect via electrostatic interaction and acts as an electron donor to boost redox kinetics. | Improving cycle life and rate capability in Zinc-Iodine batteries. |

| Phenolic Resin (APF) [15] | Encapsulating material for photocatalysts; modulates surface electronic structure to eliminate reaction energy barriers for intermediates. | Enhancing charge dynamics in photocatalytic H₂O₂ production. |

| Platinum Nanoparticles / High-Surface-Area Carbon | High-activity electrocatalyst to lower activation overpotential for reactions like Hydrogen Oxidation/Evolution (HOR/HER). | Standard catalyst in fuel cell and electrolyzer research. [12] |

| Nafion Membrane | Polymer electrolyte membrane; provides proton conductivity but can also influence kinetics when forming films on catalysts. [12] | Used as standard electrolyte in PEM fuel cells and electrolyzers. |

| TEMPO | A kinetically facile (outer-sphere) redox mediator with a very high standard rate constant, minimizing activation overpotential. [10] | Used in redox flow batteries for comparisons or as a mediator. |

Molecular and Interfacial Origins of Kinetic Limitations

Frequently Asked Questions

What are the fundamental signs of kinetic limitations in my electrochemical experiments? Common signs include a significant drop in capacity when you increase the charge/discharge rate (poor rate performance), large voltage gaps between charge and discharge curves (high polarization), and poor cycle life. Quantitatively, a low capacity retention at high C-rates (e.g., only 54 mAh/g at 3C versus 230 mAh/g at 0.1C) is a key indicator of sluggish kinetics [4].

Why is my high-capacity cathode material performing poorly at high power? Even materials with high theoretical capacity can be limited by slow reaction kinetics. This is often not a simple bulk ionic diffusion issue. In systems utilizing anionic redox (oxygen redox), the rate-determining step can be a slow, time-consuming charge transfer process between the anion and the metal center, exhibiting prolonged characteristic timescales (e.g., ~113.8 minutes) [4]. This inherently limits the speed of the redox reaction.

How can I distinguish between slow ionic diffusion and slow charge transfer kinetics? Use a combination of techniques. Galvanostatic Intermittent Titration Technique (GITT) measures apparent diffusion barriers. However, pairing it with methods like X-ray Absorption Near Edge Structure (XANES) can reveal slower, underlying electronic processes. If GITT shows a high barrier while XANES reveals a slow ligand-to-metal charge transfer, the charge transfer is likely the fundamental bottleneck [4].

My sodium-ion battery cathode has high residual alkali. How does this impact kinetics? Uneven sodium distribution in layered oxide cathodes leads to residual alkali (e.g., Na2CO3/NaOH) on the surface. This reactive layer increases interfacial resistance, causes side reactions with the electrolyte, and blocks ion transport pathways, collectively degrading kinetics and cycle life [16].

Troubleshooting Guides

Problem 1: Poor Rate Performance in Li-rich or Disordered Rock Salt Cathodes

Potential Cause: Sluggish anionic redox kinetics and slow charge transfer.

- Diagnosis Steps:

- Perform rate capability tests from 0.1C to high rates (e.g., 3C, 5C). A sharp capacity drop suggests kinetic limitations [4].

- Use GITT at different temperatures to calculate the activation energy for Li+ migration. A high barrier (>1.0 eV) indicates sluggish diffusion [4].

- Conduct ex situ or operando XANES after charging to a high-voltage (anionic redox) state. Let the sample relax and re-measure. A shift in the absorption edge over time (e.g., ~113 minutes) confirms a slow electronic charge transfer process between O and Ni, which is the molecular origin of the sluggish kinetics [4].

- Solutions:

- Material Synthesis: Employ synthesis methods that achieve atomic-level mixing of cations to create a more homogeneous bonding network. One-step spray pyrolysis can reduce Na+ migration barriers (e.g., to 1.127 eV) compared to traditional solid-state methods [16].

- Cation Coupling: Design materials where anionic redox is coupled with a fast cationic redox center (e.g., Co) to enhance the overall kinetics of the oxygen redox process [4].

Problem 2: Sluggish Redox Kinetics in Room-Temperature Sodium-Sulfur (RT Na-S) Battery Cathodes

Potential Cause: Low electronic conductivity of S/Na2S and slow conversion kinetics of sodium polysulfides (NaPSs).

- Diagnosis Steps:

- Check for a large overpotential in the charge/discharge profiles, particularly in the low-voltage plateaus corresponding to the conversion of long-chain to short-chain NaPSs [17].

- Observe if the cell exhibits a rapid capacity fade and low Coulombic efficiency, which indicates severe polysulfide shuttle effect exacerbated by slow conversion kinetics [17].

- Solutions:

- Conductive Scaffolds: Use porous carbon hosts with high surface area to improve electron transport and physically confine sulfur and polysulfides [17].

- Catalyst Incorporation: Introduce catalytic materials (e.g., single-atom metals, metal oxides, sulfides, nitrides, or MXenes) into the carbon host. These catalysts chemisorb polysulfides and lower the energy barrier for their decomposition, significantly accelerating the redox kinetics [17].

Problem 3: Interfacial Degradation and High Resistance in Layered Oxide Cathodes

Potential Cause: Residual alkali formation and unstable cathode-electrolyte interface.

- Diagnosis Steps:

- Measure the pH of the cathode powder after exposure to air; a highly basic pH indicates significant residual alkali (LiOH, Li2CO3 or Na2CO3, NaOH) [16].

- Use electrochemical impedance spectroscopy (EIS). A large and growing semicircle in the mid-to-high-frequency range indicates increasing interfacial resistance [16].

- Solutions:

- Synthetic Control: Replace the traditional "two-step" solid-state method with a one-step spray pyrolysis process. This uses spatially confined microdroplets as microreactors to achieve atomic-level homogeneity of Li/Na and transition metals, reducing residual alkali by over 60% [16].

- Surface Modifications: As a secondary measure, apply surface coatings (e.g., Al2O3) or perform gentle acid washing to remove surface residues. Note that these address the symptom, not the root cause like synthetic control does [16].

Experimental Protocols for Kinetic Characterization

Protocol 1: Galvanostatic Intermittent Titration Technique (GITT)

Purpose: To determine the apparent chemical diffusion coefficient of ions (Li+, Na+) in electrode materials. Materials: Electrochemical cell (coin or pouch cell), potentiostat/galvanostat with GITT capability, constant-temperature chamber. Procedure [4]:

- Assemble a half-cell with your material as the working electrode and Li/Na metal as the counter/reference electrode.

- At a desired state of charge, apply a constant current pulse for a short time (e.g., 30 minutes).

- Allow the cell to relax at open-circuit voltage for a sufficiently long time (e.g., 4 hours) until the voltage stabilizes.

- Repeat steps 2 and 3 through the entire charge/discharge profile.

- Data Analysis: The diffusion coefficient (D) can be calculated using the simplified equation:

( D = \frac{4}{\pi\tau} \left( \frac{nm Vm}{S} \right)^2 \left( \frac{\Delta Es}{\Delta Et} \right)^2 )

where

τis the current pulse duration,n_m,V_m, andSare the molar number, molar volume, and active area of the material, andΔE_sandΔE_tare the steady-state voltage change and transient voltage change during the pulse, respectively.

Protocol 2: Probing Charge Transfer Kinetics via Relaxation XANES

Purpose: To directly observe the time scale of electronic charge transfer between anions and metals after oxidation. Materials: Synchrotron XANES beamline, ex situ or operando electrochemical cells, high-voltage charger. Procedure [4]:

- Charge the electrode to a specific high voltage where anionic redox is expected (e.g., 4.8 V vs. Li/Li+).

- Immediately disassemble the cell in an inert atmosphere and recover the cathode material (for ex situ).

- Rapidly transfer the sample to the XANES spectrometer and collect a spectrum for the metal edge (e.g., Ni K-edge) as quickly as possible.

- Let the sample relax at open-circuit (or a moderate temperature) inside the spectrometer and collect successive XANES spectra over time (e.g., every 10-30 minutes).

- Data Analysis: Monitor the shift in the absorption edge position or the white line intensity over time. A gradual shift confirms an ongoing electronic charge transfer. The time constant of this process can be extracted by fitting the spectral changes, revealing the intrinsic kinetic limitation of the anionic redox reaction.

The Scientist's Toolkit: Research Reagent Solutions

Table 1: Essential Materials for Investigating and Improving Redox Kinetics

| Research Reagent | Function & Application | Key Rationale |

|---|---|---|

| Metal Acetates/Nitrates (e.g., Ni, Fe, Mn Acetate) [16] [4] | Precursors for cathode synthesis via sol-gel or spray pyrolysis. | Allows for atomic-level mixing with sodium/lithium sources, promoting compositional homogeneity and faster ion kinetics [16]. |

| Sodium Acetate (with excess) [16] [4] | Sodium source for Na-ion cathode materials. | Excess (e.g., 5 wt%) compensates for high-temperature volatilization. Atomic-level mixing reduces surface residual alkali [16]. |

| Poly(2-acrylamido-2-methylpropane sulfonic acid) [18] | Grafting polymer for functionalizing carbon nanotube (CNT) conductive agents. | Enhances Li⁺ transport, stabilizes interfaces via unique cathode-anode crosstalk, and mitigates Li dendrite formation in metal batteries [18]. |

| Single-Atom Metal Catalysts (on carbon supports) [17] | Catalytic additives for S cathodes in RT Na-S batteries. | Provide maximal active sites per mass to adsorb polysulfides and catalytically accelerate their conversion kinetics, reducing shuttle effect [17]. |

| Metal Oxides/Nitrides (e.g., MoO2, VN) [17] | Polar catalytic materials for sulfur hosts. | Chemisorb polysulfide intermediates, lower the energy barrier for their decomposition, and boost redox kinetics of S cathodes [17]. |

Table 2: Key Quantitative Metrics for Identifying Kinetic Limitations

| Technique | Measured Parameter | Typical Value Indicating a Problem | Example from Literature |

|---|---|---|---|

| Rate Performance Test | Capacity Retention at High C-rate | ~23% retention at 3C vs. 0.1C [4] | Li1.17Ti0.58Ni0.25O2 (LTNO) DRX cathode [4]. |

| GITT | Activation Energy (Ea) for Ion Migration | > 1.0 eV [16] [4] | Ea of 1.127 eV for Na+ migration in O3-type cathode; higher values indicate more sluggish diffusion [16]. |

| Relaxation XANES | Characteristic Charge Transfer Time | Prolonged time (~113.8 min) [4] | Slow ligand-to-metal (O to Ni) charge transfer in LTNO cathode, fundamental origin of slow oxygen redox [4]. |

| Surface Analysis | Residual Alkali Content | High surface residue (61.73% higher in traditional synthesis) [16] | Solid-state method vs. one-step spray pyrolysis for NaNi1/3Fe1/3Mn1/3O2 [16]. |

Visualization of Concepts and Workflows

Charge Transfer Bottleneck in Anionic Redox

Experimental Workflow for Kinetic Diagnosis

The Impact of Slow Kinetics on Biosensor Performance and Drug Efficacy

Core Concepts and Troubleshooting FAQs

What are the fundamental causes of slow kinetics in biosensors, and how do they impact performance?

Slow kinetics in biosensors primarily arise from two sources: the biochemical properties of the receptor-ligand interaction and inefficient electron transfer in redox-based sensors.

- In affinity-based biosensors (e.g., those using antibodies or aptamers), the binding kinetics are defined by the association rate (

k_on) and dissociation rate (k_off). High-affinity interactions, which are essential for detecting low-abundance analytes, typically have a slowk_off. The rate of equilibration (k_eq) is given byk_eq = k_on[T] + k_off. At low target concentrations[T], this results in long equilibration times, inherently limiting the sensor's ability to make rapid and sensitive measurements [19] [20]. - In enzyme-based electrochemical biosensors, slow kinetics often relate to Electron Transfer (ET) issues. Not all redox enzymes can transfer electrons directly (DET) to an electrode. The electronic coupling between the enzyme's active site and the electrode is crucial. Slow kinetics can result from poor orientation of the enzyme on the electrode surface, long electron tunneling distances, or electrostatic incompatibility, all of which hinder efficient electron transfer [21].

The performance impact is significant. Slow kinetics lead to:

- Long Response Times: The sensor takes too long to generate a stable signal.

- Poor Temporal Resolution: It cannot track rapid changes in analyte concentration, making it unsuitable for real-time monitoring.

- Inferior Rate Performance: In the context of battery research using materials with anionic redox reactions, sluggish kinetics directly result in poor rate capability and low capacity at higher current densities [4].

Our drug discovery program is targeting an enzyme. Why should we investigate binding kinetics beyond simple IC50 values?

Relying solely on IC50 values, which represent potency at equilibrium, provides an incomplete picture and can be misleading for lead optimization. The binding kinetics—specifically the association and dissociation rates—offer a deeper, more mechanistic understanding that can critically influence drug efficacy and safety [22] [23].

- Drug-Target Residence Time: The dissociation rate constant (

k_off) defines the residence time (RT = 1/k_off). A long residence time means the drug remains bound to its target for an extended period, even after free drug concentrations have declined in the systemic circulation. This can lead to a prolonged pharmacodynamic effect, allowing for less frequent dosing and potentially reducing off-target side effects [22] [23]. - Differentiating Compound Mechanisms: Detailed mechanistic enzymology can reveal if a compound is a simple competitive inhibitor, a slow-binding inhibitor, or an irreversible inactivator. This information is crucial for understanding the mechanism of action required for efficacy and for guiding the chemical optimization of lead compounds [22].

We are observing low signal intensity and slow response in our SPR experiments. What are the primary optimization strategies?

Surface Plasmon Resonance (SPR) is highly sensitive to kinetic parameters. Low signal and slow response can be addressed by optimizing both the experimental setup and the molecular system [24] [25].

- Optimize Ligand Immobilization: Low ligand density on the sensor chip can cause a weak signal. Conversely, excessively high density can cause steric hindrance and mass transport limitations, which distort kinetic measurements. Titrate the ligand during immobilization to find an optimal density. Also, ensure the ligand is correctly oriented and active on the chip surface [25].

- Address Mass Transport and Flow Rates: If the association rate is limited by the diffusion of the analyte to the sensor surface rather than the binding event itself, the calculated kinetics will be inaccurate. Increasing the flow rate can help overcome mass transport limitations and reveal the true binding kinetics [25].

- Buffer Optimization: The buffer composition can significantly impact binding. Adjusting pH, ionic strength, or adding surfactants (e.g., Tween-20) can reduce non-specific binding and improve the signal-to-noise ratio. Ensure compatibility between your buffer and the sensor chip chemistry [25].

Troubleshooting Guides

Guide: Tackling Slow Electron Transfer in Enzyme-Based Biosensors

Problem: An amperometric biosensor exhibits a low catalytic current, a slow response time, and a signal that fails to reach a steady state quickly.

Investigation and Solution Pathway:

Identify the ET Generation: Determine which generation of biosensor you are working with. This defines the troubleshooting path [21].

- First-Generation: Relies on the detection of a product/substrate (e.g., H₂O₂). Slow kinetics may be due to enzyme inactivation or mass transfer limitations.

- Second-Generation: Uses a dissolved or polymer-bound redox mediator. Slow kinetics suggest an inefficient shuttling process. Check the mediator's redox potential and its compatibility with the enzyme's cofactor.

- Third-Generation (DET): Aims for a direct electrical connection between the enzyme and electrode. Slow kinetics are the primary challenge.

For DET Biosensors, Focus on the Bioelectrode Interface:

- Enzyme Orientation: The enzyme must be immobilized so that its electron transfer site is oriented toward and in close proximity to the electrode surface. Use electrostatic interactions or specific surface chemistries (e.g., self-assembled monolayers) to promote favorable orientation [21].

- Electrode Nanostructuring: Increase the effective surface area and create favorable binding sites using nanomaterials like carbon nanotubes, graphene, or gold nanoparticles. This can enhance the electronic coupling and the local concentration of the enzyme [21].

- Exploit Cationic Effects: For negatively charged enzymes like cellobiose dehydrogenase (CDH), adding divalent cations (e.g., Ca²⁺, Mg²⁺) to the buffer can improve the internal electron transfer (IET) rate within the enzyme and modify the interaction with the electrode, boosting the catalytic current by up to five times [21].

Experimental Protocol: Optimizing Immobilization with Cations

- Objective: To enhance the DET signal of a dehydrogenase enzyme (e.g., CDH or FDH) via cationic promotion.

- Materials: Purified enzyme, electrochemical cell, potentiostat, nanostructured electrode (e.g., pyrolytic graphite or gold nanoparticle-modified), buffer (e.g., 0.1 M phosphate, pH 7.0), CaCl₂ or MgCl₂ stock solution.

- Procedure:

- Immobilize the enzyme on the electrode surface via a method of your choice (e.g., drop-casting, adsorption).

- Perform cyclic voltammetry in a non-turnover buffer (without substrate) to confirm DET, observing quasi-reversible redox peaks.

- Switch to a turnover condition by adding the enzyme's substrate (e.g., cellobiose for CDH).

- Record the catalytic current.

- Add small aliquots of CaCl₂ stock solution to the electrochemical cell to achieve incremental concentrations (e.g., 1 mM, 5 mM, 10 mM).

- After each addition, allow the system to stabilize and record the catalytic current again.

- Plot the catalytic current versus cation concentration to identify the optimum.

Guide: Implementing a Pre-Equilibrium Approach for Real-Time Biosensing

Problem: A high-affinity biosensor is too slow to track physiologically relevant, rapid fluctuations in a low-abundance analyte (e.g., a hormone like insulin).

Investigation and Solution Pathway:

Diagnose the Kinetic Bottleneck: Characterize your receptor's kinetics. High affinity (

K_D) is often achieved through a very slow dissociation rate (k_off), which dictates a slow equilibration time. For real-time tracking, this is the core problem [19] [20].Shift from Equilibrium to Pre-Equilibrium Sensing: Abandon the requirement to wait for the binding reaction to reach steady state. Instead, use the dynamics of the binding process itself to calculate the target concentration instantaneously [19] [20].

Apply the Target Estimation Algorithm (TEA): The law of mass action provides the framework. The target concentration

T(t)at any timetcan be calculated using:T(t) = [ dy(t)/dt + k_off * y(t) ] / [ k_on * (1 - y(t)) ]wherey(t)is the bound fraction anddy(t)/dtis its rate of change.Mitigate Noise: The pre-equilibrium method is sensitive to signal noise because it relies on the rate of change. To maximize the signal-to-noise ratio (SNR), you may need to select or engineer a receptor with faster kinetics (

k_onandk_off) that are optimized for the expected frequency of concentration changes in your target analyte [19] [20].

Experimental Protocol: Pre-Equilibrium Measurement Workflow

- Objective: To continuously measure a changing analyte concentration without reaching binding equilibrium.

- Materials: Biosensor with immobilized receptor, flow cell or microfluidic system to control sample delivery, real-time detection instrument (e.g., SPR, fluorescence).

- Procedure:

- Pre-Calibration: Determine the kinetic parameters of your receptor (

k_onandk_off) in a separate, controlled experiment. - Real-Time Data Collection: Expose the sensor to the dynamically changing sample. Continuously measure the binding signal (e.g., RU in SPR, fluorescence intensity).

- Data Processing: In real-time, calculate the bound fraction

y(t)and, using a smoothing or derivative filter, compute its time derivativedy(t)/dt. - Concentration Calculation: Feed

y(t),dy(t)/dt, and the pre-determinedk_onandk_offinto the TEA to output the estimated target concentrationT(t). - Validation: Validate the approach using samples with known, dynamically changing concentrations.

- Pre-Calibration: Determine the kinetic parameters of your receptor (

The following diagram illustrates the logical workflow and key decision points for implementing this pre-equilibrium approach.

Essential Data and Reagent Tables

Quantitative Data on Kinetic Scenarios

Table 1: Impact of Kinetic Parameters on Biosensor and Drug Performance

| Parameter / Scenario | Typical Values / Range | Impact of Slow Kinetics | Potential Mitigation Strategy |

|---|---|---|---|

| Biosensor Equilibration Time | Minutes to hours for high-affinity, low-concentration targets [19] | Prevents real-time monitoring of analyte fluctuations [19]. | Use pre-equilibrium analysis; select receptors with faster k_off [19] [20]. |

| Drug-Target Residence Time (RT) | RT = 1/k_off; can range from seconds to hours [23]. |

A long RT can prolong pharmacological effect, but an overly long RT may increase risk of off-target toxicity [22]. | Optimize chemical structure during lead optimization to fine-tune k_off [22]. |

| Anionic Redox Kinetics (in DRX Cathodes) | Charge transfer characteristic time: 113.8 min [4]. | Inferior rate performance (e.g., 54 mAh/g at 3C vs. 230 mAh/g at 0.1C) [4]. | Couple anionic redox with fast cationic redox; material engineering to facilitate charge transfer [4]. |

| Thiol-Disulfide Exchange Kinetics | Thermodynamically favored but kinetically slow [26]. | Delayed drug release from redox-responsive nanocarriers in the tumor microenvironment [26]. | Use alternative, faster redox-sensitive bonds (e.g., diselenide); tailor linker chemistry [26]. |

The Scientist's Toolkit: Key Research Reagents and Materials

Table 2: Essential Reagents for Investigating and Overcoming Slow Kinetics

| Item | Function / Application | Troubleshooting Context |

|---|---|---|

| Divalent Cations (Ca²⁺, Mg²⁺) | Promotes internal electron transfer (IET) and improves interfacial contact in DET-type biosensors [21]. | Add to assay buffer to boost catalytic current for certain dehydrogenases (e.g., CDH, FDH) [21]. |

| Redox Mediators (e.g., Ferrocene derivatives, PQQ) | Shuttles electrons between the enzyme's active site and the electrode in MET-based biosensors [21]. | Use when DET cannot be achieved; select a mediator with a redox potential matching the enzyme's cofactor [21]. |

| High-Sensitivity SPR Sensor Chips (e.g., CM5) | Provides a carboxylated dextran matrix for high-density ligand immobilization [25]. | Employ for studying low-affinity or low-abundance interactions where signal intensity is a problem [24] [25]. |

| Surfactants (e.g., Tween-20) | Reduces non-specific binding to sensor surfaces and assay components [25]. | Add at low concentrations (e.g., 0.005-0.05%) to running buffer in SPR or other binding assays to improve data quality [25]. |

| Redox-Sensitive Linkers (e.g., Disulfide bonds) | Used to engineer drug nanocarriers that release their payload in the reducing environment of the tumor microenvironment [26]. | The slow kinetics of thiol-disulfide exchange can be a limitation; consider this in nanocarrier design for controlled release [26]. |

Advanced Experimental Protocols

Detailed Protocol: Determining Binding Kinetics via Surface Plasmon Resonance (SPR)

This protocol outlines the steps for characterizing the binding kinetics (k_on, k_off) and affinity (K_D) of a molecular interaction using SPR [23].

- Objective: To obtain quantitative association and dissociation rate constants for a ligand-analyte pair.

- Principle: SPR measures changes in the refractive index at a sensor surface, reporting the mass of molecules binding to (associating) and leaving (dissociating) an immobilized ligand in real-time.

Materials:

- SPR instrument (e.g., Biacore series)

- Appropriate sensor chip (e.g., CM5 for amine coupling, NTA for His-tagged proteins, SA for biotinylated ligands) [25]

- Ligand and analyte in purified form

- Running buffer (HBS-EP is common: 10 mM HEPES, 150 mM NaCl, 3 mM EDTA, 0.05% surfactant P20, pH 7.4)

- Regeneration solution (e.g., 10 mM Glycine-HCl, pH 2.0-3.0)

- Coupling reagents: EDC, NHS, and a quenching agent (e.g., ethanolamine)

Step-by-Step Workflow:

- System Preparation: Prime the instrument with filtered and degassed running buffer. Dock the sensor chip.

- Ligand Immobilization:

- Activate: Inject a mixture of EDC and NHS over the desired flow cell to activate the carboxyl groups on the dextran matrix.

- Inject Ligand: Dilute the ligand in a low-salt buffer (e.g., sodium acetate, pH 4.0-5.5) and inject it over the activated surface. Aim for an appropriate immobilization level (Response Units, RU) to avoid mass transport issues.

- Quench: Inject ethanolamine to block any remaining activated ester groups.

- Reference Surface: Prepare a reference flow cell by activating and quenching without ligand, or by immobilizing an irrelevant protein.

- Kinetic Experiment:

- Association Phase: Serially inject a range of analyte concentrations (e.g., 3-fold serial dilutions spanning values above and below the expected

K_D) over the ligand and reference surfaces at a constant flow rate (e.g., 30 µL/min). Monitor the binding response over time. - Dissociation Phase: After the injection ends, continue flowing running buffer to monitor the dissociation of the complex.

- Surface Regeneration: Inject a regeneration solution to completely remove the bound analyte without damaging the immobilized ligand. Return the baseline to its original level.

- Association Phase: Serially inject a range of analyte concentrations (e.g., 3-fold serial dilutions spanning values above and below the expected

- Data Analysis:

- Reference Subtraction: Subtract the signal from the reference flow cell from the ligand flow cell data.

- Global Fitting: Fit the entire set of sensograms (binding curves for all analyte concentrations) simultaneously to a 1:1 Langmuir binding model using the SPR instrument's software. This global fitting provides the best estimates for the association rate constant (

k_on), the dissociation rate constant (k_off), and from them, the equilibrium dissociation constant (K_D = k_off / k_on).

The following diagram visualizes this multi-step experimental workflow.

Advanced Techniques and Catalytic Strategies to Accelerate Redox Reactions

In Situ and In Operando Analytical Tools for Real-Time Kinetic Monitoring

Troubleshooting Guides

Guide 1: Poor Signal-to-Noise Ratio in Spectroscopic Measurements

Problem: Data from in-situ vibrational spectroscopy (IR, Raman) or X-ray absorption spectroscopy (XAS) has a low signal-to-noise ratio, obscuring the detection of reaction intermediates.

- Potential Cause 1: Suboptimal reactor design leading to weak probe-catalyst interaction.

- Solution: Redesign the reactor to minimize the path length of the spectroscopic beam through the electrolyte while maximizing the beam's interaction area with the catalyst surface. For GI-XRD, this minimizes signal attenuation from the liquid phase and improves the signal from the catalyst [27].

- Potential Cause 2: Low concentration of short-lived intermediates.

- Solution: Modify the operando reactor to bring the analytical probe closer to the catalyst surface. For example, depositing the catalyst directly onto a pervaporation membrane in a DEMS setup significantly reduces the path length for intermediates to reach the mass spectrometer, enhancing detection probability and signal strength [27].

- Potential Cause 3: Inappropriate measurement timescale.

- Solution: Optimize data acquisition settings to capture faster kinetic events. Ensure the reactor design itself does not introduce long response times that obscure short-lived species [27].

Guide 2: Discrepancy Between Operando Results and Benchmarking Performance

Problem: Insights on active sites or mechanisms derived from operando experiments do not correlate with the catalyst's performance in standard benchmarking tests.

- Potential Cause 1: Mass transport limitations in the operando cell.

- Solution: Analyze the hydrodynamic conditions of your operando reactor. Many operando reactors use planar electrodes in batch configurations, which can suffer from poor reactant transport and pH gradients compared to flow cells or gas diffusion electrodes used in benchmarking. This can alter the local reaction environment and lead to misinterpretation of kinetics [27].

- Potential Cause 2: A "mismatch" between characterization and real-world conditions.

- Solution: Strive to co-design reactors that meet both the requirements of the analytical technique and realistic catalytic conditions. For instance, adapt zero-gap reactor configurations, common in high-performance applications like fuel cells, by incorporating beam-transparent windows to enable relevant operando XAS or other measurements [27].

Guide 3: Ambiguous Assignment of Spectral Signals

Problem: Unable to definitively assign spectroscopic signals (e.g., in IR, Raman, or XAS) to specific catalyst structures or reaction intermediates.

- Potential Cause 1: Overlap of signals from multiple species.

- Solution: Perform control experiments without the reactant or without the catalyst to establish a baseline and identify which signals are relevant to the catalytic reaction [27].

- Potential Cause 2: Lack of reference data for novel intermediates.

- Potential Cause 3: Complex electronic or geometric structural changes.

- Solution: Complement experimental data with theoretical modelling, such as Density Functional Theory (DFT) calculations. Simulated spectra for proposed structural models can be directly compared to experimental data to validate assignments and strengthen mechanistic conclusions [28].

Frequently Asked Questions (FAQs)

FAQ 1: What is the fundamental difference between in-situ and operando characterization?

- Answer: In-situ techniques probe the catalyst under simulated reaction conditions (e.g., applied potential, in solvent). Operando techniques go a step further by simultaneously measuring the catalytic activity and the catalyst structure under the same, realistic conditions, enabling a direct correlation between structure and function [27].

FAQ 2: Why is it crucial to monitor catalyst structure and reaction intermediates in real-time?

- Answer: Catalyst structures, especially in redox reactions, are often dynamic. They can undergo evolution in phase, valence state, and coordination under reaction conditions. Similarly, reaction intermediates are transient. Real-time monitoring with in-situ/operando techniques is therefore essential to identify the true active sites and capture short-lived species, preventing misinterpretations that can arise from post-reaction (ex-situ) analysis [28].

FAQ 3: Which in-situ/operando techniques are best for identifying the active sites in oxygen reduction reaction (ORR) catalysts?

- Answer: A combination of techniques is often required. In-situ X-ray absorption spectroscopy (XAS) can track changes in the electronic and geometric structure (e.g., oxidation state, coordination environment) of metal centers in Pt-based or M-N-C catalysts. Vibrational spectroscopy like Raman or IR can monitor the adsorption and desorption of oxygen-containing intermediates (O₂, OOH, O, OH) on the catalyst surface, providing indirect evidence of the active sites [28].

FAQ 4: What are common pitfalls when designing an operando electrochemical experiment?

- Answer: Two major pitfalls are:

- Ignoring Mass Transport: Using a reactor with poor mass transport (e.g., a simple batch cell) can create a local environment at the catalyst surface that is not representative of high-performance devices, leading to incorrect mechanistic conclusions [27].

- Over-interpretation of Data: Conclusively proving a mechanism from a single technique is difficult. Claims should be supported by a set of complementary experiments, multi-modal analysis, and theoretical support to avoid overreach [27].

Protocol 1:In-situX-ray Absorption Spectroscopy (XAS) for Electrocatalysts

Objective: To determine the electronic structure and local coordination environment of a metal center in a catalyst under operating conditions.

- Cell Setup: Use a spectro-electrochemical cell with an X-ray transparent window (e.g., Kapton film). Integrate a standard three-electrode system (working, counter, reference electrode).

- Electrode Preparation: Deposit the catalyst powder as a thin, uniform film on a conductive carbon cloth or glassy carbon electrode.

- Electrolyte: Introduce a relevant electrolyte (e.g., 0.1 M KOH for ORR) ensuring it covers the electrode.

- Data Collection:

- Apply a series of constant potentials relevant to the reaction (e.g., from open-circuit voltage to reducing/oxidizing potentials).

- At each held potential, collect XAS data (both XANES and EXAFS regions) at the absorption edge of the metal of interest (e.g., Pt L₃-edge for Pt catalysts).

- Simultaneously record the electrochemical current to correlate structural changes with activity.

- Data Analysis:

- XANES: Analyze the edge position and white-line intensity to track oxidation state changes.

- EXAFS: Fit the oscillations to extract coordination numbers and bond distances, revealing geometric changes.

Protocol 2: Differential Electrochemical Mass Spectrometry (DEMS)

Objective: To identify and quantify volatile reaction intermediates and products in real-time.

- Cell Setup: Use a DEMS cell where the working electrode is in close proximity to a porous membrane (e.g., PTFE) that leads to the vacuum chamber of a mass spectrometer.

- Electrode Preparation: For the fastest response time, deposit the catalyst directly onto the pervaporation membrane to minimize the diffusion path for volatile species [27].

- Calibration: Calibrate the mass spectrometer signal for relevant masses (e.g., m/z = 2 for H₂, 44 for CO₂, 22 for CH₃CH₂OH fragments) using standard solutions or gases.

- Data Collection:

- Perform electrochemical techniques such as cyclic voltammetry or chronoamperometry.

- Simultaneously monitor the intensity of selected mass signals.

- Data Analysis: Correlate peaks in mass signal intensity with specific applied potentials or current features to identify the potential-dependent formation of products.

| Technique | Typical Measurable Parameters | Key Quantitative Outputs | Time Resolution | Spatial Resolution |

|---|---|---|---|---|

| XAS (XANES/EXAFS) | Oxidation state, coordination number, bond distance | Edge shift (eV), coordination number (N), bond distance (Å) | Seconds to minutes | ~1 mm (typically bulk-average) [27] |

| IR Spectroscopy | Identity and concentration of surface adsorbates | Wavenumber (cm⁻¹), absorbance / reflectance | Milliseconds to seconds | Diffraction-limited (~µm) |

| Raman Spectroscopy | Molecular vibrations, crystal phases, stress | Wavenumber (cm⁻¹), intensity / count rate | Seconds | Diffraction-limited (~µm) |

| EC-MS | Identity and quantity of volatile products/elements | Mass-to-charge ratio (m/z), ion current (A) | Sub-second to seconds | N/A (bulk effluent) |

� Visualization of Workflows

Diagram 1: Decision Framework for Technique Selection

Diagram 2: Operando Reactor Design Logic

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function | Example Application |

|---|---|---|

| Isotope-Labeled Reactants (e.g., ¹⁸O₂, D₂O) | Shifts vibrational frequencies in IR/Raman, allowing definitive assignment of signals from specific intermediates [28]. | Confirming the identity of O-O stretching modes in ORR intermediates. |

| Ion-Selective Membranes | Key component of potentiometric sensors, allowing selective detection of specific ions (H⁺, Na⁺, etc.) in solution [29]. | Monitoring pH changes in the catalyst microenvironment during reaction. |

| Piezoelectric Polymers (e.g., PVDF) | Core material for self-powered mechanical sensors; generates electrical signal in response to pressure or strain [29]. | Integrating stress/strain sensing in catalytic reactors. |

| Mediators / Electron Acceptors | Synthetic redox mediators used in 2nd-generation enzyme sensors to shuttle electrons, overcoming oxygen dependence [29]. | Electrochemical detection of non-electroactive species. |

| Nanostructured Electrodes (e.g., Au nanonets, MXenes) | Increase the electroactive surface area (ESA) without enlarging physical size, boosting sensitivity for small sample volumes [29]. | Detecting low concentrations of analytes in tiny volumes (e.g., tears, interstitial fluid). |

Implementing Soluble Redox Mediators for Enhanced Electron Shuttling

Frequently Asked Questions (FAQs)

Q1: What is a redox mediator and how does it fundamentally work? A redox mediator is a soluble molecule that acts as a mobile electron shuttle, facilitating charge transfer between solid electrode surfaces and solid reactants (like Li₂O₂ in batteries) or microorganisms in biogeochemical systems [30]. It operates through a reversible redox pair (RM RM⁺ + e⁻). The mediator is oxidized at the electrode surface, diffuses to the reactant, oxidizes it, and is regenerated in the process, thereby reducing activation energy barriers and improving reaction kinetics [30].

Q2: My experiment with Lithium-Sulfur batteries shows a high charging overpotential. Can a redox mediator help? Yes. A high charging overpotential often indicates sluggish oxidation kinetics of solid Li₂S. Introducing a redox mediator with a redox potential higher than that of Li₂S can significantly lower this barrier [30]. For example, decamethylferrocene has been shown to reduce the Li₂S oxidation potential to as low as 2.9 V, thereby increasing discharge capacity and cycling performance [30]. The mediator oxidizes at the cathode and then chemically oxidizes the Li₂S.

Q3: Why is my system's performance still poor after adding a redox mediator? Several factors could be at play:

- Insufficient Concentration: The mediator concentration may be below the critical threshold needed for effective electron shuttling. For instance, in microbial ferrihydrite reduction, a minimum dissolved organic carbon content is required for acceleration [31].

- Improper Redox Potential: The mediator's formal potential must be appropriately positioned between the electron donor and acceptor. Its ionization energy should be compared to the formation energy of the reactant (e.g., Li₂O₂) for suitability [30].

- Mediator Instability: The mediator might be decomposing over cycles. Selecting stable molecules like certain phenazines or using insoluble bifunctional catalysts like PTMA can mitigate this [30].

- Slow Charge Transfer: In systems involving anionic redox (e.g., in DRX cathodes), the intrinsic charge transfer between oxygen and metals can be slow, limiting the benefit a mediator can provide [4].

Q4: Can I use naturally occurring substances as redox mediators? Yes. Humic substances (HS), which are abundant in nature, are excellent natural electron shuttles [30] [32]. They contain quinone functional groups that undergo reversible redox reactions. Studies show that HS can significantly enhance denitrification in sediments and reduce greenhouse gas emissions by facilitating complete electron transfer [32]. Their low molecular weight fractions are particularly effective at accessing soil micropores [31].

Q5: How do I choose the right redox mediator for my specific application? Selection should be based on several key properties, summarized in the table below. The mediator should have a well-defined electron stoichiometry, a known formal potential situated between your donor and acceptor, fast electron transfer kinetics, and stability in both oxidized and reduced forms [30].

Research Reagent Solutions

Table 1: Common Redox Mediators and Their Key Characteristics

| Mediator Name | Primary Application | Key Property/Function | Example Redox Couple |

|---|---|---|---|

| Dimethylphenazine [30] | Aprotic Li-O₂ Batteries | Organic mediator with low overpotential and high stability. | RM RM⁺ + e⁻ |

| PTMA (Poly(2,2,6,6-tetramethylpiperidinyloxy-4-yl methacrylate)) [30] | Li-O₂ Batteries | Insoluble bifunctional catalyst; also protects carbon cathode from degradation. | N-O• N=O⁺ |

| Decamethylferrocene [30] | Li-S Batteries | Effectively lowers the potential barrier for Li₂S oxidation. | Fe³⁺ Fe²⁺ |

| Lithium Iodide [30] | Li-S Batteries | Mobile catalyst for oxidizing Li₂S. | I⁻/I₃⁻ |

| Humic Substances (HS) [32] | Bioremediation, Microbial Fuel Cells | Natural electron shuttle containing quinone groups; enhances denitrification. | Quinone/Hydroquinone |

| Flavins (e.g., Riboflavin) [33] | Microbial Extracellular Electron Transfer | Biogenic molecule produced by bacteria like Shewanella for abiotic electron shuttling. | - |

| ACNQ (2-amino-3-carboxyl-1,4-napthoquinone) [33] | Microbial Extracellular Electron Transfer | Soluble analogue of menaquinone; identified in Shewanella oneidensis. | Quinone/Hydroquinone |

Troubleshooting Guides

Issue 1: Inefficient Electron Shuttling & Low Acceleration

Problem: The addition of a redox mediator does not yield the expected improvement in reaction rate or reduction in overpotential.

Investigation and Resolution Protocol:

Verify Mediator Concentration:

- Action: Measure the concentration of your dissolved mediator. Compare it against known effective thresholds from literature.

- Data Interpretation: For humic substances, electron transfer capacity (measured as Maximum Power Density in MFCs) increases linearly with HS concentration [32]. For low molecular weight HA, a threshold above ~2.3 mg C/L was needed to accelerate microbial ferrihydrite reduction [31].

- Solution: Systemically increase the mediator concentration and monitor performance.

Check the Redox Potential:

- Action: Characterize the formal potential (E'₀) of your mediator via cyclic voltammetry.

- Data Interpretation: The mediator's potential must lie between those of the electron-donating and electron-accepting half-reactions [30]. For Li-S batteries, mediators must have a potential higher than that of Li₂S.

- Solution: Select a different mediator with a more suitably positioned redox potential.

Assess Mediator Stability:

- Action: Perform post-experiment analysis (e.g., HPLC, UV-Vis) to check for mediator decomposition.

- Data Interpretation: A loss of the characteristic spectroscopic signature indicates degradation.

- Solution: Consider more stable alternatives, such as polymeric mediators like PTMA or exploring different molecular structures based on ionization energy calculations [30].

Issue 2: Sluggish Kinetics in Anionic Redox Systems

Problem: Poor rate performance is observed in systems relying on anionic redox reactions (e.g., Li-rich or cation-disordered cathodes), even with a mediator.

Investigation and Resolution Protocol:

Diagnose the Rate-Limiting Step:

- Action: Use techniques like Galvanostatic Intermittent Titration Technique (GITT) at different temperatures to probe kinetics [4].

- Data Interpretation: A strong temperature dependence of overpotential in the anionic redox region suggests kinetic limitations beyond simple ion diffusion.

- Solution: The slow step may be the intrinsic ligand-to-metal charge transfer (e.g., between O and Ni). A redox mediator may not directly speed this up. Focus on material design to enhance this charge transfer [4].

Characterize Charge Transfer Kinetics:

- Action: Use X-ray Absorption Near Edge Structure (XANES) with sample relaxation to track charge transfer over time [4].

- Data Interpretation: A prolonged characteristic time for charge transfer (e.g., 113.8 minutes observed in LTNO cathodes) confirms it as the fundamental bottleneck [4].

- Solution: Consider strategies like coupling oxygen redox with a fast cationic redox partner (e.g., Co) to enhance overall kinetics [4].

Quantitative Data for Experimental Design

Table 2: Key Quantitative Parameters for Redox Mediator Systems

| Parameter | System / Mediator | Reported Value / Threshold | Significance |

|---|---|---|---|

| Electron Shuttling Critical Distance [31] | Low MW Humic Acids (LHA) | 117.2 nm | Defines the maximum effective range for electron shuttling. |

| Effective TOC Threshold [31] | LHA (<3500 Da) for Fe(III) reduction | > ~2.3 mg C/L | Minimum dissolved organic carbon to initiate acceleration. |

| Charge Transfer Time [4] | Li₁.₁₇Ti₀.₅₈Ni₀.₂₅O₂ (LTNO) cathode | 113.8 min | Highlights intrinsic kinetic limitation of anionic redox. |

| Contrast for Visualization | Diagrams & Text | ≥ 4.5:1 (large text) / ≥ 7:1 (small text) [34] [35] | Ensures accessibility and clarity for all readers. |

Experimental Protocols

Protocol A: Evaluating Redox Mediator Efficacy in an Electrochemical Cell

Objective: To test the ability of a candidate soluble redox mediator to reduce charging overpotential in a Li-S battery configuration.

Materials:

- Candidate redox mediator (e.g., Dimethylphenazine, LiI)

- Standard electrolyte (e.g., 1M LiTFSI in DOL/DME)

- Li₂S/C composite cathode

- Lithium metal anode

- Coin cell hardware (CR2032)

- Celgard-type separator

- Glove box (H₂O, O₂ < 0.1 ppm)

- Battery cycler

Methodology:

- Electrolyte Preparation: Dissolve the redox mediator in the standard electrolyte at a specified concentration (e.g., 0.1 M).

- Cell Assembly: Assemble coin cells in an argon-filled glove box using the Li₂S cathode, lithium anode, separator, and the prepared electrolyte.

- Electrochemical Testing:

- Perform galvanostatic charge-discharge cycling between defined voltage limits (e.g., 1.5 - 3.0 V vs. Li/Li⁺) at various C-rates.

- Record the charge profiles, specifically noting the potential at which Li₂S oxidation begins.

- Data Analysis:

- Compare the charging overpotential and capacity retention of cells with and without the redox mediator.

- A successful mediator will show a significant decrease in the charging plateau voltage and higher reversible capacity [30].

Protocol B: Assessing Electron Shuttling in a Microbial System

Objective: To determine the impact of humic substances as electron shuttles on microbial ferrihydrite reduction.

Materials:

- Shewanella oneidensis MR-1 culture

- Humic substances (e.g., Leonardite HA)

- Ferrihydrite (Fe(III) oxide)

- Low-carbon growth medium

- Anaerobic chamber

- Centrifuge and filtration units (for LMWF separation)

Methodology:

- Mediator Preparation: Separate low molecular weight fractions (LMWF) of HA via membrane dialysis (e.g., <3500 Da) [31].

- Experimental Setup: Set up serum bottles inside an anaerobic chamber with growth medium, ferrihydrite, and Shewanella oneidensis MR-1.

- Test Conditions:

- Control: No HS added.

- Test: Amended with LMWF of HA.

- Incubation and Monitoring: Incate bottles and periodically sample the aqueous phase. Measure Fe(II) production over time using the ferrozine assay.

- Data Analysis: Calculate the Fe(III) reduction rate increased coefficient (α). An α > 1 confirms the electron shuttling effect of the added HS [31].

Visual Workflows and Pathways

Electron Shuttling in a Battery System

Electron Shuttling in a Microbial System

Troubleshooting Logic for Poor Mediator Performance

Nanostructured Catalysts and Single-Atom Designs for Optimal Active Sites

Frequently Asked Questions (FAQs)

Q1: What are the key advantages of single-atom catalysts (SACs) over traditional nanoparticle catalysts? Single-atom catalysts maximize atomic utilization because individual metal atoms are anchored on a supporting material, making every metal atom a potential active site. This structure often leads to superior catalytic activity and selectivity compared to nanoparticles, and can also reduce the amount of expensive noble metals required [36].

Q2: My electrochemical cell shows a strange voltammogram with drawn-out waves. What could be the cause? This problem often lies with the working electrode surface. It may be contaminated with a layer of polymer or adsorbed material that partially blocks the electrochemical response. The solution is to recondition the electrode through polishing, or chemical, electrochemical, or thermal treatment [37].

Q3: Why is slow kinetics a significant problem in catalytic systems like CO2 sorbents? Slow kinetics can severely limit the efficiency of a process. For example, in a high-temperature CO2 capture agent like lithium orthosilicate (Li4SiO4), a product shell of lithium carbonate forms a diffusion-limiting barrier around the unreacted core, dramatically slowing down the sorption rate [38].

Q4: How can I confirm that my potentiostat and leads are functioning correctly before troubleshooting the cell? Perform a dummy cell test. Disconnect the electrochemical cell and replace it with a 10 kOhm resistor. Connect the reference and counter electrode leads together on one side and the working electrode lead to the other. Run a CV scan from +0.5 V to -0.5 V at 100 mV/s. The result should be a straight line intersecting the origin with currents of ±50 μA. A correct response indicates the instrument is fine and the problem is with the cell itself [37].

Q5: What is a common source of residual metal contamination, and how can it be removed? Residual metal contamination, such as palladium or nickel, often comes from the metal catalysts used in cross-coupling reactions (e.g., Suzuki, Sonogashira, Buchwald-Hartwig). These residual metals can be removed using specialized metal scavengers like SiliaMetS Thiol, DMT, or Imidazole, depending on the specific metal [39].

Troubleshooting Guides

Issue 1: Slow Reaction Kinetics

Slow kinetics can stem from mass transfer limitations, poor accessibility of active sites, or low intrinsic activity.

- Potential Causes and Solutions:

- Diffusion Limitations: A common cause is the formation of a diffusion barrier around active sites. For example, a lithium carbonate shell on a Li4SiO4 sorbent blocks CO2 access.

- Solution: Design nanostructured materials with a network of pores so that most of the active material is on the surface, minimizing diffusion paths [38].

- Inactive Catalyst Centers: In single-atom catalysts, the metal atoms may not be properly activated or coordinated.

- Solution: Carefully select the biomass precursor and synthesis strategy to control the carbon structure and metal-carbon coordination environment, which directly influences catalytic performance [36].

- Sub-Optimal Reaction Conditions: The kinetics of a reaction are highly sensitive to conditions like pH and reactant ratios.

- Solution: Use kinetic modeling to simulate and optimize initial molar ratios of reactants, pH, and dosing regimes for your specific process [40].

- Diffusion Limitations: A common cause is the formation of a diffusion barrier around active sites. For example, a lithium carbonate shell on a Li4SiO4 sorbent blocks CO2 access.

Issue 2: High Catalyst Loading or Rapid Deactivation

This issue increases costs and reduces the practicality of the catalytic process.

- Diagnosis and Resolution:

- Check Catalyst Efficiency: Inefficient catalysts require higher loadings to achieve acceptable reaction rates.

- Solution: Transition to more efficient catalyst designs like Single-Atom Catalysts (SACs), which offer high activity with minimal metal loading [36].

- Analyze Catalyst-Support Interaction: The support material (e.g., alumina, silica, carbon) can markedly affect catalyst performance and stability.

- Solution: Systematically functionalize the support (e.g., SBA-15 silica with zirconia or titania) and characterize it to tune the catalyst's properties and improve its stability [38].

- Investigate Leaching: Metal atoms can leach from the support into the solution, deactivating the catalyst.

- Solution: For SACs, ensure strong anchoring of metal atoms on the support. Using biomass-derived carbon supports with tailored surface properties can enhance stability [36].

- Check Catalyst Efficiency: Inefficient catalysts require higher loadings to achieve acceptable reaction rates.

Issue 3: Excessive Noise in Electrochemical Measurements

Noise can obscure the true electrochemical signal, making data interpretation difficult.

- Systematic Check:

- Inspect Connections: Noise is frequently caused by poor contacts at electrode connections or instrument connectors (e.g., from rust or tarnish).

- Corrective Action: Polish the lead contacts or replace them entirely.

- Shielding: Place the entire electrochemical cell inside a Faraday cage to shield it from external electromagnetic interference [37].

Data Presentation

Table 1: Common Cross-Coupling Reactions and Associated Metal Scavengers

| Reaction Name | Primary Use | Common Catalyst | Effective Scavenger for Residual Metal |

|---|---|---|---|

| Suzuki-Miyaura [39] | Coupling aryl halides with aryl boronic acids | Pd(PPh₃)₄ | SiliaMetS Thiol, SiliaMetS DMT, SiliaMetS Imidazole |

| Sonogashira [39] | Coupling terminal alkynes with aryl halides | Pd / Cu (co-catalyst) | SiliaMetS DMT (for Pd and Cu) |

| Kumada [39] | Coupling aryl and alkenyl halides | NiDPPPCl₂ | SiliaMetS Triamine, SiliaMetS DMT |

| Buchwald-Hartwig Amination [39] | Forming C-N bonds | Pd (with various ligands) | SiliaMetS Thiol, SiliaMetS Thiourea |

Table 2: Research Reagent Solutions for Catalyst Development

| Reagent/Material | Function in Research | Application Context |

|---|---|---|

| Lithium Orthosilicate (LOS) [38] | High-temperature CO₂ capture agent | Process intensification for hydrogen production. |

| SBA-15 Mesoporous Silica [38] | Tunable support material for functionalizing with acidic sites (e.g., zirconia) or as a drug delivery vehicle. | Catalyst design for tuning acid strength; controlled release of therapeutic molecules. |

| Biomass Precursors [36] | Renewable, abundant source for fabricating carbon-based supports for Single-Atom Catalysts (SACs). | Sustainable synthesis of high-performance SACs. |

| SiliaMetS Metal Scavengers [39] | Removal of residual metal impurities from reaction products after catalytic synthesis. | Purification of products, especially in pharmaceutical API synthesis. |

Experimental Protocols

Protocol 1: Dummy Cell Test for Potentiostat Validation

This protocol verifies the proper function of your potentiostat and leads before blaming the electrochemical cell [37].

- Turn off the potentiostat.

- Disconnect all leads from the electrochemical cell.

- Replace the cell with a 10 kOhm resistor (the "dummy cell").

- Connect the reference and counter electrode leads together to one side of the resistor.

- Connect the working electrode lead to the other side of the resistor.

- Turn on the potentiostat and run a Cyclic Voltammetry (CV) scan from +0.5 V to -0.5 V with a scan rate of 100 mV/s.

- Expected Result: The resulting voltammogram should be a straight line that passes through the origin (0 V, 0 A) with maximum currents of ±50 μA.

Protocol 2: Synthesis of Nanostructured Sorbents for Improved Kinetics

This methodology outlines the solution to slow kinetics in CO₂ sorbents by creating a nanostructured material [38].

- Material Synthesis: Employ various synthesis methods (e.g., templating) to create a lithium orthosilicate (LOS)-like material with an intrinsic network of meso- and macropores.

- Characterization:

- Use Nitrogen Adsorption to confirm the high surface area and porous structure.