Redox Initiators for Polymerization: A Comparative Review of Mechanisms, Biomedical Applications, and Future Directions

This article provides a comprehensive comparative analysis of redox initiation systems for polymerization, tailored for researchers and drug development professionals.

Redox Initiators for Polymerization: A Comparative Review of Mechanisms, Biomedical Applications, and Future Directions

Abstract

This article provides a comprehensive comparative analysis of redox initiation systems for polymerization, tailored for researchers and drug development professionals. It explores the fundamental mechanisms of redox pairs, details modern synthetic methodologies like RAFT and SI-ATRP, and addresses key challenges in optimization and scalability. A critical validation of system performance is presented, comparing efficiency, biocompatibility, and applicability across various biomedical contexts, including drug delivery and antimicrobial polymers. The review synthesizes these insights to guide the selection and design of next-generation redox initiators for advanced therapeutic applications.

Understanding Redox Initiation: Core Mechanisms and Initiator Pair Classifications

Fundamental Principles of Redox Radical Generation

Redox radical generation is a foundational process in both chemical synthesis and biological systems, operating on the principle of electron transfer between oxidizing and reducing agents to produce highly reactive radical species. In biological contexts, this process is governed by a sophisticated "redox code" that organizes life's essential oxidation-reduction reactions, maintaining a delicate balance between oxidative signaling and damage [1] [2]. Meanwhile, in synthetic chemistry, particularly in polymerization research, redox initiation provides a powerful method for generating free radicals under mild conditions through one-electron transfer reactions [3]. This comparative guide examines the fundamental principles, mechanisms, and experimental approaches to redox radical generation across biological and synthetic contexts, providing researchers with a structured framework for selecting and optimizing redox initiator systems.

The core principle uniting these diverse fields is the electron transfer event that creates radical species with unpaired electrons. In biological systems, reactive oxygen species (ROS) such as superoxide (O₂•⁻) and hydrogen peroxide (H₂O₂) function as key redox signaling molecules when maintained at physiological levels, but can cause oxidative stress when this balance is disrupted [4]. In polymer science, redox initiators like the persulfate-bisulfite system or metal-peroxide couples generate radicals that kickstart chain-growth polymerizations at remarkably low temperatures compared to thermal initiation [3]. Understanding the comparative mechanisms, advantages, and limitations of these systems enables researchers to strategically employ redox chemistry across applications ranging from pharmaceutical development to advanced materials synthesis.

Core Principles and Generation Mechanisms

The Biological "Redox Code" and Homeodynamics

Biological systems maintain redox balance through four fundamental principles termed the "redox code." First, bioenergetics, catabolism, and anabolism are organized through high-flux NADH and NADPH systems operating near equilibrium with central metabolic fuels. Second, macromolecular structure and activities are linked to these systems through kinetically controlled sulfur switches in the redox proteome. Third, activation and deactivation cycles of H₂O₂ production support redox signaling for differentiation and development. Fourth, redox networks form an adaptive system that responds to environmental changes [1].

This framework operates not as a static homeostasis but as a dynamic "redox homeodynamics" where continuous monitoring and reprogramming of redox fluctuations occurs. This is exemplified by mitochondrial cristae, which reshape at timescales of seconds to accommodate redox changes [1]. The biological redox landscape encompasses both redox eustress (physiological, signaling functions) and oxidative distress (damaging pathways), with the balance determined by spatiotemporal control of radical generation and elimination [1] [4].

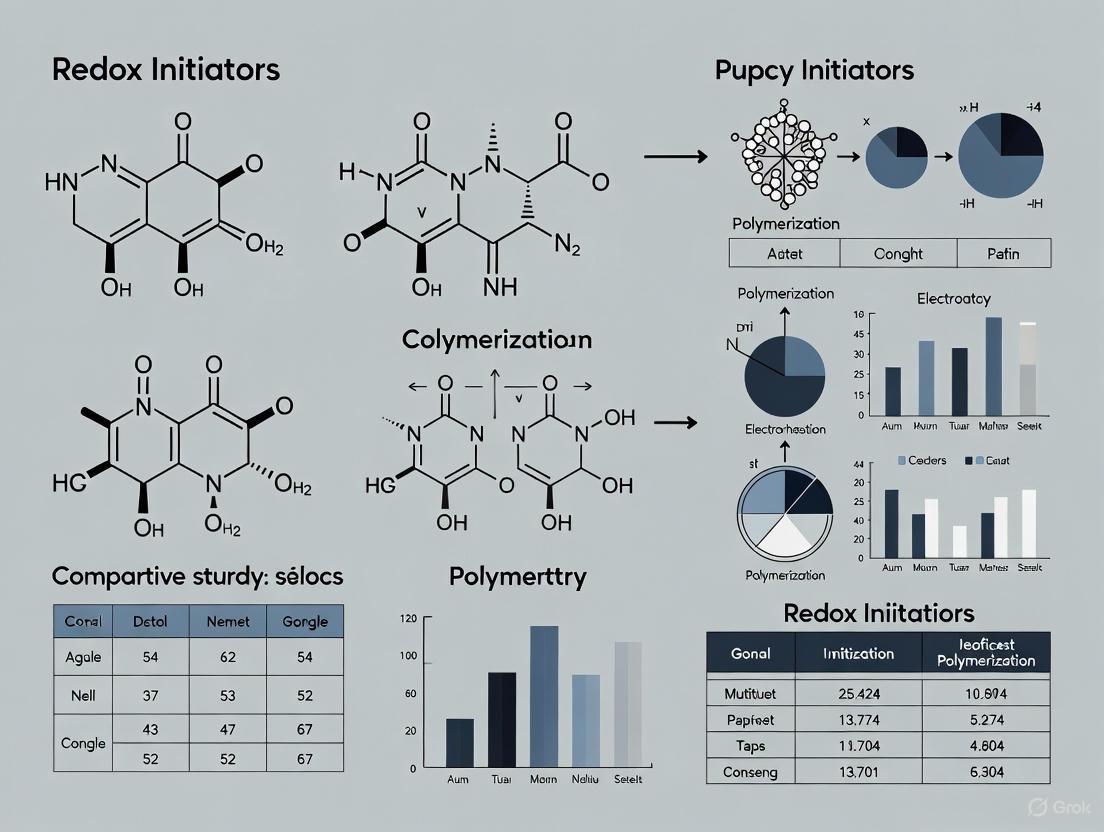

Figure 1: Comparative Pathways of Redox Radical Generation in Biological and Synthetic Contexts

Chemical Redox Initiation Mechanisms

In synthetic systems, redox initiation occurs through one-electron transfer reactions that generate radical species at substantially lower activation energies (40-80 kJ mol⁻¹) compared to thermal initiation (125-160 kJ mol⁻¹) [3]. This energy advantage enables radical generation under mild conditions, making redox initiation particularly valuable for temperature-sensitive applications. The classic Fenton's reagent reaction demonstrates this mechanism, where ferrous iron reacts with hydrogen peroxide: Fe²⁺ + H₂O₂ → Fe³⁺ + OH⁻ + •OH [3]. The generated hydroxyl radical (•OH) then initiates polymerization or participates in other chemical reactions.

Different redox pairs offer distinct advantages depending on the application requirements. For emulsion polymerizations, systems like potassium persulfate/potassium thiosulfate generate radicals that create grafting sites on polymer surfaces [5]. Recent research has also revealed that reactive redox radical species can form spontaneously at gas/water interfaces without applied bias or catalysts, as demonstrated at gas diffusion electrode interfaces [6]. This phenomenon, detected using electron paramagnetic resonance (EPR), highlights the complex interplay between interface chemistry and radical generation, suggesting potential applications in electrochemical systems and environmental chemistry.

Comparative Analysis of Redox Initiator Systems

Performance Comparison of Representative Redox Initiators

Table 1: Comparative Performance of Redox Initiator Systems in Polymerization

| Redox System | Optimal Temperature Range | Activation Energy | Radical Generation Rate | Key Applications | Advantages | Limitations |

|---|---|---|---|---|---|---|

| Ascorbic acid/tBHP/Fe³⁺ [7] | -1°C to 60°C | 40-80 kJ mol⁻¹ | Adjustable via catalyst (0.4-86% process time reduction) | Emulsion polymerization (vinyl acetate) | High conversion (90-99%), tunable kinetics | Component sensitivity requires precise control |

| DMA/BPO [8] | Room temperature | Low (ambient initiation) | Fast frontal propagation | Frontal polymerization (acrylates) | Bubble-free curing, ambient initiation | Short pot life (spontaneous polymerization) |

| Persulfate/Bisulfite [3] | 0-50°C | ~50 kJ mol⁻¹ | Rapid at low temperatures | Emulsion polymers, grafting | Rapid initiation, water-soluble | pH-dependent, can cause side reactions |

| Metal Chelates [3] | 20-70°C | Variable with metal | Controlled, sustained | Specialty polymers | Controlled release, tailored kinetics | Complex synthesis, potential metal contamination |

Biological vs. Synthetic Redox Systems

Table 2: Biological versus Synthetic Redox Radical Generation Systems

| Characteristic | Biological Redox Systems | Synthetic Redox Initiators |

|---|---|---|

| Primary Radical Sources | Mitochondrial ETC, NADPH oxidases, Enzymatic reactions [1] [4] | Peroxide decomposition, Persulfate activation, Metal-redox pairs [3] |

| Key Generated Species | Superoxide (O₂•⁻), Hydrogen peroxide (H₂O₂), Hydroxyl radical (•OH) [4] | Hydroxyl radical (•OH), Sulfate radical (SO₄•⁻), Carbon-centered radicals (R•) [3] |

| Regulation Mechanism | Antioxidant enzymes (SOD, catalase), Redox buffers (GSH/GSSG), Compartmentalization [1] | Component ratios, Catalyst concentration, pH adjustment, Temperature control [7] |

| Primary Functions | Signaling, Metabolic regulation, Immune defense [1] [4] | Polymerization initiation, Surface modification, Chemical synthesis [5] [3] |

| Spatial Organization | Compartmentalized (organelles, membrane microdomains) [1] | Phase-dependent (emulsion, interfacial, homogeneous) [5] [6] |

| Temporal Control | Second-to-minute signaling waves, Feedback loops [1] | Mix-initiated, Diffusion-controlled, Catalyst-dependent [7] |

Experimental Protocols and Methodologies

Redox-Initiated Emulsion Polymerization Protocol

The emulsion polymerization of vinyl acetate with neodecanoic acid vinyl ester using ascorbic acid/tert-butyl hydroperoxide/iron catalyst represents a well-characterized redox initiation system [7]. The detailed methodology begins with creating an initial charge containing water, emulsifier (Mowiol 4-88), and monomers, which is degassed with nitrogen for 30 minutes to remove oxygen, a known radical scavenger. The redox components are typically added after degassing: l-ascorbic acid (AsAc) as reducing agent, tert-butyl hydroperoxide (tBHP) as oxidant, and ammonium iron(III) sulfate dodecahydrate as catalyst.

The reaction proceeds with continuous nitrogen flushing to maintain an oxygen-free environment. Researchers can systematically vary parameters including the initiation temperature (-1°C to 60°C), tBHP concentration, and iron catalyst amount to control the polymerization kinetics and final product properties [7]. Key metrics for evaluation include conversion rate (measured gravimetrically), molecular weight and distribution (via GPC), particle size (dynamic light scattering), and glass transition temperature (DSC). This system demonstrates remarkable flexibility, achieving 90-99% conversion with process times adjustable from 2-240 minutes by modifying the redox component ratios while maintaining consistent product properties.

Detection and Quantification of Redox Radicals

Electron paramagnetic resonance (EPR) spectroscopy with spin trapping represents the gold standard for detecting and identifying short-lived radical species in both biological and synthetic systems. For investigating radical generation at gas diffusion electrodes (GDE), researchers employed 5,5-dimethyl-1-pyrroline N-oxide (DMPO) as a spin-trapping agent, circulating aqueous solutions through the GDE setup while feeding argon or oxygen gas [6]. After 20-40 minutes of operation, the solution was analyzed by EPR, revealing DMPO-OH and DMPO-H₂O⁺ adduct signals that confirmed the spontaneous generation of hydroxyl radicals and water radical cations without any applied bias or catalysts.

Complementary approaches for radical verification include ultraviolet-visible (UV-Vis) spectroscopy to track redox reactions. For example, the oxidation of I⁻ to I₃•⁻ or Fe(CN)₆⁴⁻ to Fe(CN)₆³⁻ produces characteristic absorbance increases measurable by UV-Vis [6]. In biological systems, specific fluorescent probes (e.g., H₂DCFDA for H₂O₂) coupled with microscopic techniques enable spatial resolution of radical generation, while genetically encoded biosensors provide real-time monitoring in live cells. For protein-specific redox changes, redox proteomics approaches using biotin-conjugated probes can identify and quantify cysteine oxidation across the proteome.

Figure 2: Experimental Workflow for Redox Radical Generation and Detection

The Scientist's Toolkit: Essential Research Reagents

Table 3: Essential Reagents for Redox Radical Research

| Reagent Category | Specific Examples | Primary Function | Application Context |

|---|---|---|---|

| Oxidizing Agents | tert-Butyl hydroperoxide (tBHP), Benzoyl peroxide (BPO), Potassium persulfate (KPS) | Generate radicals upon reduction, Accept electrons | Synthetic polymerization, Chemical synthesis [7] [8] |

| Reducing Agents | l-Ascorbic acid, N,N-Dimethylaniline (DMA), Potassium thiosulfate | Donate electrons to oxidants, Form radical species | Redox initiation, Graft polymerization [5] [7] |

| Catalysts | Ammonium iron(III) sulfate, Ferrous sulfate | Mediate electron transfer, Lower activation energy | Fenton chemistry, Ascorbate-peroxide systems [7] [3] |

| Spin Traps | 5,5-dimethyl-1-pyrroline N-oxide (DMPO) | Stabilize transient radicals for detection | EPR spectroscopy, Radical identification [6] [9] |

| Biological ROS Sources | Xanthine oxidase, NADPH oxidase | Generate physiological ROS | Cell signaling studies, Oxidative stress research [4] [9] |

| Radical Scavengers | Superoxide dismutase, Deferoxamine, Ascorbic acid | Quench specific radical species | Mechanism elucidation, Pathway inhibition [4] [9] |

The comparative analysis of redox radical generation systems reveals distinct advantages and optimal application contexts for different initiator types. For polymer scientists requiring low-temperature processing with controlled kinetics, ascorbic acid/tBHP/iron systems offer tunable reaction rates and high conversion without compromising product properties [7]. When bubble-free polymerization is critical, as in frontal polymerization applications, DMA/BPO redox couples provide effective initiation at ambient temperatures while eliminating gaseous byproducts [8]. For biological researchers, understanding the nuanced balance between redox signaling and oxidative stress requires tools that can detect specific radical species within complex cellular environments, where EPR with spin trapping and genetically encoded biosensors provide the necessary specificity [6] [4].

The fundamental principle unifying these diverse applications is the strategic exploitation of electron transfer reactions to generate reactive intermediates under controlled conditions. Future directions in redox initiation research include developing more environmentally benign redox pairs, achieving spatiotemporal control through external triggers like light or electrical fields, and creating bio-inspired systems that mimic the sophisticated redox homeostasis of living organisms. By understanding both the biological "redox code" and synthetic initiation mechanisms, researchers can design more efficient, specific, and controllable redox systems for applications ranging from drug development to advanced materials manufacturing.

Radical polymerization is a cornerstone of industrial polymer production, with approximately 45% of all polymer products manufactured using this method. A significant portion of these rely on redox initiation systems, which use the chemical energy stored in a reductant-oxidant pair to produce initiating radicals at ambient temperatures [10] [11]. This guide provides a comparative analysis of two classical redox pairs: metal-persulfate systems and peroxide-amine systems. These systems enable energy-efficient room-temperature activation, unrestricted product shape and size, and polymerization without light, making them indispensable for applications ranging from industrial manufacturing to biomedical fields such as dental biomaterials and drug delivery systems [10] [12].

The following sections compare the initiation mechanisms, performance characteristics, and experimental protocols for these systems, supported by quantitative data and visualization of their reaction pathways.

Key Characteristics and Applications

Table 1: Comparison of Classical Redox Initiator Systems

| Feature | Metal-Persulfate Systems | Peroxide-Amine Systems |

|---|---|---|

| Typical Oxidant | Persulfate (e.g., Sodium Persulfate) | Organic Peroxide (e.g., Benzoyl Peroxide - BPO) |

| Typical Reductant/Catalyst | Metal Salts (e.g., Fe²⁺) or Ascorbic Acid | Tertiary Aromatic Amine (e.g., N,N-Dimethylaniline) |

| Primary Mechanism | Metal oxidation and persulfate decomposition via inner-sphere electron transfer | SN2 attack by amine on peroxide, followed by homolysis |

| Activation Energy | 40–80 kJ/mol [13] | Varies with peroxide structure; lower with electron-withdrawing groups [10] |

| Typical Temperature Range | -1°C to 87°C (wide range achievable) [13] | Ambient conditions (room temperature) |

| Key Advantages | Water-soluble; suitable for emulsion polymerization; wide temperature range | Metal-free; biocompatible; effective in solvent-free bulk polymerizations |

| Common Applications | Emulsion polymers (e.g., polyvinyl acetate for paints, adhesives) [13] | Structural adhesives, dental resins, biomaterials, hydrogels for drug delivery [10] [12] [11] |

Visualization of Reaction Mechanisms

Figure 1: Comparative reaction mechanisms of metal-persulfate and peroxide-amine redox initiation systems. The metal-persulfate system proceeds through electron transfer, while the peroxide-amine system follows a concerted SN2 attack followed by homolysis.

Performance Data and Experimental Evidence

Quantitative Performance Comparison

Table 2: Experimental Performance Data for Redox Initiation Systems

| Redox System | Specific Components | Polymerization Conditions | Monomer Conversion | Reaction Time | Key Findings |

|---|---|---|---|---|---|

| Amine-Peroxide | BPO + N,N-Dimethylaniline (DMA) | Ambient temperature, bulk polymerization | Not specified | Not specified | Radical generation rate: 1.3 × 10⁻¹¹ s⁻¹ [10] |

| Amine-Peroxide | p-Nitro-substituted BPO + DMA | Ambient temperature, bulk polymerization | Not specified | Not specified | Radical generation rate: 1.9 × 10⁻⁹ s⁻¹ (~150× faster than BPO) [10] |

| Metal-Persulfate | tBHP + AsAc + Fe-cat. (1:1:0.006 molar ratio) | 60°C initiation temperature, emulsion | 99% | ~15 minutes | 86% reduction in process time [13] |

| Metal-Persulfate | tBHP + AsAc + Fe-cat. (varied ratios) | -1°C to 60°C, emulsion | 90-99% | 2-240 minutes | Reaction rate adjustable without changing product properties [13] |

| Amine-Peroxide | BPO + N-phenyldiethanolamine | Ambient temperature, hydrogel fabrication | Not specified | Not specified | Suitable for thermolabile bioactive agents (peptides, proteins) [12] |

Factors Influencing Performance

Peroxide Structure in Amine Systems: Electron-withdrawing groups (e.g., nitro groups) on benzoyl peroxide significantly increase initiation rates by lowering both SN2 and homolysis barriers. Conversely, electron-donating groups decrease initiation rates [10] [14].

Component Ratios in Metal-Persulfate Systems: Varying the catalyst (Fe³⁺) amount adjusts reaction rate without changing product properties like molecular weight, particle size, or glass transition temperature. However, changing tert-butyl hydroperoxide content directly affects molecular weight [13].

Temperature Dependence: Metal-persulfate systems offer a broad effective temperature range (-1°C to 87°C), while amine-peroxide systems primarily function at ambient temperatures, making each suitable for different application requirements [13] [11].

Detailed Experimental Protocols

Experimental Workflow for Redox-Initiated Polymerization

Figure 2: Generalized experimental workflow for redox-initiated polymerization, applicable to both metal-persulfate and peroxide-amine systems with specific modifications.

Protocol 1: Metal-Persulfate Initiated Emulsion Polymerization

This protocol adapts the method from Jacoba et al. for emulsion copolymerization of vinyl acetate and neodecanoic acid vinyl ester [13].

Materials and Reagent Preparation

- Monomer Mixture: Combine vinyl acetate (99% purity) and neodecanoic acid vinyl ester (Versa10, 99% purity) in desired ratio

- Redox System Components:

- Oxidizing Agent: tert-Butyl hydroperoxide (tBHP)

- Reducing Agent: L-Ascorbic acid (AsAc)

- Catalyst: Ammonium iron(III) sulfate dodecahydrate

- Stabilizer: Mowiol 4-88 as protective colloid

- Water: Deionized, degassed

Procedure

- Initial Charge Preparation: In reactor, combine water, stabilizer (Mowiol 4-88), and portion of monomer mixture

- Degassing: Purge with nitrogen gas for ≥30 minutes to remove oxygen

- Temperature Equilibration: Bring reaction mixture to target initiation temperature (-1°C to 60°C)

- Redox Initiator Addition: Simultaneously add solutions of:

- tBHP oxidant

- AsAc reducing agent

- Fe-catalyst solution

- Polymerization: Maintain temperature with continuous stirring; reaction typically completes in 2-240 minutes depending on component ratios and temperature

- Termination: Sample periodically for conversion analysis; stop reaction at desired conversion

Key Parameters for Optimization

- Molar Ratios: Vary tBHP:AsAc:Fe-catalyst ratios (e.g., 1:1:0.006) to control rate without affecting product properties

- Temperature Control: Effective from -1°C to 87°C; lower temperatures reduce chain transfer to polymer

- Conversion Monitoring: Track via gravimetric analysis or spectroscopy; typically achieves 90-99% conversion

Protocol 2: Amine-Peroxide Redox Polymerization

This protocol synthesizes functional block copolymers via redox-initiated RAFT emulsion polymerization, based on the work with β-ketoester functional monomers [15] [10].

Materials and Reagent Preparation

Macro-CTA Synthesis:

- Monomer: Poly(ethylene glycol) methyl ether methacrylate (PEGMA, Mn = 475 g/mol)

- Chain Transfer Agent: 4-Cyano-4-(ethylthiocarbonothioylthio) pentanoic acid (CEPA)

- Thermal Initiator: Azobisisobutyronitrile (AIBN), recrystallized from ethanol

- Solvent: 1,4-dioxane

Redox Block Copolymerization:

- Functional Monomer: 2-(Acetoacetoxy)ethyl methacrylate (AEMA), purified through basic alumina

- Redox Initiator System:

- Oxidant: Potassium persulfate (KPS), recrystallized from cold water

- Reductant: L-Ascorbic acid sodium salt (NaAs)

- Water: Deionized, degassed

Procedure

Macro-CTA Synthesis:

- Combine PEGMA, CEPA, AIBN, and 1,4-dioxane in round-bottom flask

- Degas with nitrogen for 45 minutes

- Heat at 70°C in oil bath for ~470 minutes (until ~80% conversion by ¹H NMR)

- Precipitate product in excess n-hexane, wash with diethyl ether, and dry under vacuum

Redox-Initiated RAFT Emulsion Polymerization:

- Combine PPEGMAₙ-CEPA macro-CTA and AEMA monomer in round-bottom flask

- Add calculated amount of water to achieve target solids content (e.g., 15% w/w)

- Degas with nitrogen for 20 minutes at 50°C

- Add degassed solutions of KPS (oxidant) and NaAs (reductant) to initiate polymerization

- React at 50°C; typical conversion >95% within 30 minutes

- Characterize resulting block copolymer assemblies (morphologies include spheres, worms, vesicles)

Key Parameters for Optimization

- Solids Content: Typically 10-50% w/w for PISA conditions

- Temperature: 25-50°C range; higher temperatures favor higher-order morphologies

- Macro-CTA DP: Molecular weight affects resulting morphology of self-assembled structures

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Research Reagents for Redox Initiation Studies

| Reagent Category | Specific Examples | Function | Application Notes |

|---|---|---|---|

| Persulfate Oxidants | Sodium persulfate, Potassium persulfate, Ammonium persulfate | Strong oxidizing agent; generates sulfate radicals | Water-soluble; can be activated by heat, transition metals, or base [16] [13] |

| Organic Peroxides | Benzoyl peroxide (BPO), tert-Butyl hydroperoxide, Cumene hydroperoxide | Radical generation through redox reaction with amines or metal complexes | BPO has limited shelf life; CHP more stable for formulation [10] [11] |

| Reducing Agents (Amines) | N,N-Dimethylaniline, N-Phenyldiethanolamine, N-(4-methoxyphenyl)pyrrolidine | Electron donors for peroxide reduction; generate initiating radicals | Tertiary aromatic amines most effective; toxicity varies [10] [12] [11] |

| Reducing Agents (Non-Amine) | L-Ascorbic acid, L-Ascorbic acid sodium salt | Metal-free reducing agent for persulfate systems | Biocompatible alternative; used with persulfates or peroxides [15] [13] |

| Metal Catalysts | Ferrous sulfate, Ferrous chloride, Ammonium iron(III) sulfate | Electron transfer mediators; activate persulfate decomposition | Optimal concentration critical; excess amounts can quench radicals [16] [13] |

| Chain Transfer Agents | 4-Cyano-4-(ethylthiocarbonothioylthio) pentanoic acid (CEPA) | Controls molecular weight and architecture in RAFT polymerization | Enables synthesis of block copolymers with precise structures [15] |

| Functional Monomers | 2-(Acetoacetoxy)ethyl methacrylate (AEMA), Glycidyl methacrylate | Provides reactive handles for post-polymerization modification | β-ketoester groups in AEMA enable diverse chemical transformations [15] |

Metal-persulfate and peroxide-amine redox pairs represent two distinct classes of initiation systems with complementary characteristics and applications. Metal-persulfate systems offer superior versatility in temperature range and are particularly advantageous for aqueous emulsion polymerizations, while peroxide-amine systems provide metal-free initiation under ambient conditions, making them valuable for biomedical applications and structural adhesives.

The choice between these systems depends on specific application requirements including temperature constraints, biocompatibility needs, monomer solubility, and desired polymerization rate. Recent advances in understanding their mechanistic pathways have enabled the rational design of improved initiators, such as peroxide derivatives with electron-withdrawing groups that demonstrate significantly accelerated kinetics. These developments continue to expand the capabilities of redox polymerization for emerging applications in biomedicine, advanced materials, and additive manufacturing.

Emerging Redox Systems for Controlled/Living Polymerization

Redox initiation systems, which generate free radicals through electron-transfer reactions under mild conditions, have long been instrumental in industrial polymerization processes such as low-temperature emulsion polymerizations [3]. Their ability to provide a rapid initiation rate with low activation energy (40–80 kJ mol⁻¹) minimizes side reactions and enables the production of high molecular weight polymers with high yield [3]. Traditionally applied in conventional free-radical polymerization, redox chemistry has now become a powerful component in the realm of Controlled/Living Radical Polymerization (CRP), enabling precise synthesis of polymers with complex architectures, tailored functionalities, and enhanced performance characteristics.

CRP techniques, including Atom Transfer Radical Polymerization (ATRP), Reversible Addition-Fragmentation Chain Transfer (RAFT), and Nitroxide-Mediated Polymerization (NMP), rely on establishing a dynamic equilibrium between active propagating chains and dormant species [17]. The integration of redox systems into these processes enhances control over polymerization, allows for operation under milder conditions, and facilitates the use of environmentally benign reagents. This guide provides a comparative analysis of emerging redox systems for CRP, presenting structured experimental data, detailed protocols, and essential resources to equip researchers with the practical knowledge needed to advance polymer science in fields ranging from drug delivery to materials engineering.

Comparative Analysis of Redox-Initiated CRP Techniques

The following table summarizes the key characteristics, performance data, and optimal application contexts for the major redox-initiated CRP techniques discussed in this guide.

Table 1: Comparative Overview of Emerging Redox Systems for Controlled/Living Polymerization

| Polymerization System | Redox Initiator / Mediator Components | Reaction Temperature | Key Quantitative Results | Primary Advantages | Ideal Applications |

|---|---|---|---|---|---|

| Redox-Initiated RAFT Emulsion PISA [15] | KPS / NaAsc (Ascorbic acid sodium salt) | 50 °C | Monomer conversion >95% within 30 min; Formation of worms, vesicles, spheres [15]. | Rapid kinetics; Morphological control; High solids content (10-50%); Surfactant-free [15]. | Bioimaging, drug delivery, nanoreactors [15]. |

| ATRP for Redox-Active Polymer Brushes [18] | - (SI-ATRP with Cu-based catalyst) | - | Dapp increased by 15.2%; k⁰ increased by 24.6% with grafted particle mediators [18]. | High grafting density; Control over MW and dispersity; Enhanced charge transport [18]. | Energy storage, redox flow batteries, modified electrodes [18]. |

| ATRP-Synthesized Enzyme Nanogels [19] | - (Surface-initiated ATRP) | - | Half-life at 50°C: 47-49 days (197x free enzyme); Sensitivity: 111 μA cm⁻² mM⁻¹ [19]. | Unprecedented enzyme stabilization; Prevents mediator leakage; High sensitivity [19]. | Biosensors, bioelectronics, stable enzymatic reactors [19]. |

| Traditional Redox Initiation (e.g., Fenton) [3] | H₂O₂ / Fe²⁺ | Ambient - 50 °C | Low activation energy (40-80 kJ/mol); High molecular weight polymers [3]. | Mild conditions; Short induction period; High yield [3]. | Industrial emulsion polymers, conventional plastics [3]. |

Experimental Protocols for Key Redox CRP Systems

Redox-Initiated RAFT Emulsion Polymerization-Induced Self-Assembly (PISA)

Objective: To synthesize functional block copolymer nano-assemblies with various morphologies using a redox initiation system at moderate temperature [15].

Materials:

- Monomer: 2-(Acetoacetoxy)ethyl methacrylate (AEMA), purified by passing through a column of basic alumina prior to use.

- Macro-CTA: Poly(poly(ethylene glycol) methyl ether methacrylate)-4-cyano-4-(ethylthiocarbonothioylthio) pentanoate (PPEGMA₁₂-CEPA).

- Redox Initiator System: Potassium persulfate (KPS, recrystallized from cold water) as oxidant and L-Ascorbic acid sodium salt (NaAsc) as reductant.

- Solvent: Deionized water.

Methodology:

- Solution Preparation: Dissolve the PPEGMA₁₂-CEPA macro-CTA and AEMA monomer in deionized water in a reaction vessel. The typical protocol for a target DP of 100 at 15% w/w monomer feeding is used [15].

- Initiation: Purge the solution with nitrogen to remove oxygen. Add the KPS and NaAsc to the reaction mixture to initiate polymerization.

- Polymerization: Maintain the reaction temperature at 50 °C with constant stirring. Monitor monomer conversion via ¹H NMR spectroscopy.

- Morphology Analysis: After polymerization (typically achieving >95% conversion in 30 minutes), analyze the resulting nano-objects using Transmission Electron Microscopy (TEM) and Dynamic Light Scattering (DLS) to identify morphologies such as spherical micelles, worm-like structures, and vesicles [15].

Critical Step: The molar ratio of the redox components and the molecular weight of the macro-CTA are crucial parameters that dictate the polymerization kinetics and the final morphology of the block copolymer assemblies.

Surface-Initiated ATRP for Redox-Active Polymer Brushes

Objective: To graft poly(2,2,6,6-tetramethyl-1-piperidinyloxy-4-yl methacrylate) (PTMA) from silica particles to create redox-active composite materials for enhanced charge transport [18].

Materials:

- Substrate: Silica particles.

- Initiator: ATRP initiator functionalized on silica surface.

- Monomer: 2,2,6,6-Tetramethyl-1-piperidinyloxy-4-yl methacrylate (TMA).

- Catalyst System: Copper(I) bromide and suitable ligand (e.g., PMDETA).

- Solvent: Acetonitrile with 0.1 M LiTFSI electrolyte.

Methodology:

- Surface Initiation: Functionalize silica particles with ATRP initiator, such as a bromoester group.

- Grafting-from Polymerization: Combine the initiator-functionalized particles, TMA monomer, Cu(I)Br catalyst, and ligand in the solvent. Allow the polymerization to proceed under controlled temperature and atmosphere.

- Characterization: Characterize the resulting SiO₂-PTMA particles using FTIR, XPS, and EPR spectroscopy to confirm polymer grafting and radical density. Determine molecular weights and grafting densities (e.g., 0.688 chains nm⁻² for 2.5 kDa grafts) [18].

- Electrochemical Testing: Disperse the SiO₂-PTMA particles in a solution of free PTMA polymer near its overlap concentration (C*). Use cyclic voltammetry to measure the apparent diffusion coefficient (Dapp) and electron transfer rate constant (k⁰), observing significant enhancements due to the grafted particles acting as redox mediators [18].

Mechanism and Workflow Diagrams

Redox CRP Equilibrium and Chain Extension

Redox CRP Equilibrium and Propagation

This diagram illustrates the fundamental mechanism of CRP. A dynamic equilibrium between dormant chains (Pn-X) and active radicals (Pn•) is maintained by a redox process (activation/deactivation). The active radical adds monomer units (M) during propagation (k_p), temporarily forming an extended radical (Pn+1•) before it is rapidly deactivated back to a dormant state, allowing for controlled chain growth [17].

Redox-Initiated RAFT PISA Workflow

Redox-Initiated RAFT PISA Experimental Flow

This workflow outlines the key steps in conducting a redox-initiated RAFT PISA synthesis [15]. The process begins with the dissolution of a water-soluble macromolecular chain transfer agent (Macro-CTA) and a hydrophobic monomer. After oxygen removal, the redox pair (e.g., KPS/NaAsc) is added to initiate the polymerization at a mild temperature (e.g., 50°C). As the hydrophobic block grows, it triggers in situ self-assembly, leading to a variety of nano-object morphologies. The final product can be further functionalized for advanced applications.

The Scientist's Toolkit: Essential Research Reagents

Table 2: Key Reagents and Materials for Redox-Controlled Polymerization Research

| Reagent / Material | Function / Role | Example from Research | Handling Notes |

|---|---|---|---|

| Potassium Persulfate (KPS) | Oxidizing component in redox pairs; generates sulfate radical anions [15]. | Used with NaAsc for RAFT emulsion PISA of AEMA [15]. | Often recrystallized from cold water before use [15]. Store dry. |

| Ascorbic Acid / Sodium Ascorbate (NaAsc) | Reducing agent in redox pairs; regenerates metal catalysts or consumes oxidizers [15] [19]. | Component in KPS/NaAsc initiator system; used for ATRP activator regeneration [15] [17]. | Oxygen-sensitive; prepare fresh solutions. |

| Copper(I) Bromide (CuBr) | Catalyst for ATRP; mediates the halogen atom transfer equilibrium [18] [19]. | Catalyst for SI-ATRP of PTMA from silica particles and enzyme nanogel synthesis [18] [19]. | Air-sensitive; must be handled under inert atmosphere. |

| Functional Monomers (AEMA, TMA) | Provide reactive handles (β-ketoester) or redox-active sites (TEMPO) for post-polymerization modification or electrochemical activity [15] [18]. | AEMA for post-modification with AIEgens; TMA for battery materials [15] [18]. | AEMA should be purified through basic alumina and stored at 4°C [15]. |

| Macromolecular Chain Transfer Agent (Macro-CTA) | Controls molecular weight and mediates the RAFT equilibrium; defines the solvophilic block in PISA [15]. | PPEGMA-CEPA for aqueous RAFT emulsion PISA [15]. | Synthesized and characterized (e.g., via ¹H NMR) prior to PISA. |

| N,N,N',N'',N''-Pentamethyldiethylenetriamine (PMDTA) | Ligand for ATRP catalyst; solubilizes copper in organic media and tunes its redox potential [19]. | Used in the ATRP synthesis of enzyme-polymer nanogels [19]. | Air-sensitive; often stored under nitrogen. |

The integration of redox chemistry with controlled/living polymerization strategies has created a versatile and powerful toolkit for polymer synthesis. As demonstrated, redox-initiated RAFT PISA allows for the efficient, one-pot production of functional nano-objects, while ATRP facilitates the precise grafting of redox-active polymers for energy applications and the stabilization of biomolecules for biosensing.

Future developments in this field are likely to focus on several key areas [20] [18] [21]. The drive for sustainability will accelerate the creation of bio-based and fully recyclable redox polymers, as exemplified by recent work on hydroquinone-substituted polyallylamines for aqueous batteries [22]. Furthermore, the exploration of novel redox-active monomers and mediators will expand the scope of accessible properties and applications. Finally, the scaling of these advanced redox CRP systems using continuous flow reactors and low-catalyst ATRP techniques (e.g., ARGET ATRP) will be crucial for translating these sophisticated materials from the research laboratory to industrial-scale production [17]. The continued synergy between redox chemistry and controlled polymerization promises to be a rich source of innovation for creating the next generation of functional polymeric materials.

The Role of Activators in Grafting Efficiency and Polymer Architecture

In polymer science, activators serve as crucial components in initiating systems that trigger and control grafting reactions, ultimately determining the efficiency of polymer attachment and the final architectural outcome. These chemical agents, particularly in redox initiation systems, operate under mild conditions by generating free radicals through electron transfer processes, thereby enabling controlled polymerization without external energy inputs like heat or light [23] [24]. The strategic selection of activators directly influences key parameters including grafting density, side-chain length distribution, and spatial uniformity, which collectively define the performance characteristics of grafted polymers in applications ranging from drug delivery to advanced composites [25] [23].

The broader thesis of comparative redox initiator research recognizes that beyond mere initiation efficiency, the choice of activator system fundamentally shapes the polymer architecture through its impact on reaction kinetics, radical stability, and side reactions. This guide provides an objective comparison of activator-assisted grafting methodologies, presenting experimental data to elucidate how different initiating systems govern grafting efficiency and architectural control across diverse polymer systems.

Grafting Methodologies: A Comparative Framework

Polymer grafting employs three principal methodologies, each with distinct mechanisms and architectural outcomes [25]:

- Grafting-to: Pre-synthesized polymer chains with reactive end-groups are attached to a functionalized substrate

- Grafting-from: Polymer chains grow from initiator sites immobilized on a substrate surface

- Grafting-through: Macromonomers with polymerizable end-groups are copolymerized with conventional monomers

A direct comparative study employing cellulose as a substrate revealed fundamental architectural differences between these approaches [26]. The grafting-from technique demonstrated superior control over polymeric content distribution, with polymer content increasing systematically with graft length (23 ≤ M(n) ≤ 87 kDa). In contrast, the grafting-to approach showed no correlation between graft length and surface content, which remained essentially constant across a similar molecular weight range (21 ≤ M(n) ≤ 100 kDa), indicating significant limitations in controlling surface architecture via this method [26].

Table 1: Comparative Analysis of Grafting Methodologies

| Parameter | Grafting-From | Grafting-To | Grafting-Through |

|---|---|---|---|

| Grafting Density | High (steric hindrance minimized during growth) | Limited by steric hindrance during attachment | Variable, depends on macromonomer reactivity |

| Architectural Control | Excellent control over graft length and distribution | Limited control over surface distribution | Moderate control, depends on copolymerization kinetics |

| Synthetic Complexity | Requires surface-bound initiators, polymerization control | Requires end-functionalized polymers, coupling chemistry | Requires synthetic preparation of macromonomers |

| Grafting Efficiency | Typically high initiation efficiency | Limited by steric factors, typically lower efficiency | High incorporation efficiency possible |

| Molecular Weight Distribution | Can be controlled via living polymerization | Predetermined by pre-synthesized chains | Depends on macromonomer purity and reactivity |

Redox Initiating Systems: Mechanisms and Efficiency

Redox initiating systems constitute a major class of activators in polymer grafting, operating through electron transfer between reducing (Red) and oxidizing (Ox) agents to generate radical species under mild conditions [23]. These systems typically feature activation energies below 80 kJ/mol, enabling polymerization at ambient to moderately elevated temperatures (0-45°C) without the energy-intensive heating required for thermal decomposition of conventional initiators (>120 kJ/mol activation energies) [23].

The redox cationic frontal polymerization (RCFP) system exemplifies advanced activator technology, combining stannous octoate (reducing agent) with iodonium salts (oxidizing agent) to enable rapid, intact curing of epoxy resins and composites [27]. This system addresses the limitation of conventional thermal radical initiators, which often cause decarboxylation and void formation in highly reactive cycloaliphatic epoxies. The redox couple effectively prevents foaming while maintaining a self-sustaining curing front, demonstrating the critical role of activator selection in minimizing structural defects [27].

Table 2: Performance Characteristics of Redox Initiating Systems

| Redox System Components | Optimal Temperature Range | Grafting Efficiency/Conversion | Key Architectural Outcomes |

|---|---|---|---|

| Stannous octoate/Iodonium salt [27] | 100-130°C | >95% (epoxy conversion) | Prevents decarboxylation, enables >50 vol% fiber composites |

| Fe²⁺/Peroxide (Fenton-type) [24] | Ambient temperature | Variable, pH-dependent | Enables hydrogel formation, moderate grafting density |

| Ascorbic acid-based systems [23] | Room temperature to 45°C | High in aqueous systems | Biocompatible grafts for drug delivery applications |

| Triethylboron/Oxygen [23] | Sub-ambient to ambient | Rapid initiation, variable control | Suitable for acrylate grafting, oxygen tolerance |

Experimental Comparison: Grafting-From vs. Grafting-To

Methodology and Experimental Protocol

A seminal comparative study established a rigorous experimental framework to evaluate grafting-from and grafting-to techniques on cellulose substrates [26]. The investigation employed:

- Grafting-from approach: Activators Regenerated by Electron Transfer Atom Transfer Radical Polymerization (ARGET ATRP)

- Grafting-to approach: Copper(I)-catalyzed azide-alkyne cycloaddition (CuAAC)

- Critical standardization: Polymers grafted-to surfaces were precisely matched in length to those grafted-from surfaces by utilizing free polymer formed parallel to the grafting-from reaction

Molecular weights of grafted polymers were determined after cleavage from substrates via size exclusion chromatography (SEC), confirming comparable ranges: free polymers for grafting-to (21 ≤ M(n) ≤ 100 kDa; 1.07 ≤ Đ(M) ≤ 1.26) versus grafted-from polymers (23 ≤ M(n) ≤ 87 kDa; 1.08 ≤ Đ(M) ≤ 1.31) [26].

Advanced characterization techniques included:

- High-resolution Fourier transform infrared microscopy (FT-IRM): Spatial distribution of polymer content

- X-ray photoelectron spectroscopy (XPS): Surface elemental composition

- Contact angle (CA) measurements: Surface wettability changes

- Field-emission scanning electron microscopy (FE-SEM): Surface morphology

Architectural and Efficiency Outcomes

The comparative data revealed significant architectural advantages for the grafting-from approach [26]. FT-IRM analysis demonstrated that grafting-from provided systematic control over polymer content by varying graft length, enabling precise surface tailoring. In contrast, grafting-to produced consistent polymer content regardless of graft length variations, indicating that steric hindrance during chain attachment limited architectural control.

The grafting-from approach achieved superior grafting density, as the growing chains could navigate steric limitations more effectively than pre-formed polymers attempting to access surface initiation sites [26]. This fundamental difference in mechanism translates to distinct architectural outcomes: grafting-from facilitates brush-like, high-density surfaces, while grafting-to typically yields lower-density, patchy architectures.

Advanced Activator Systems and Emerging Applications

Electrochemical Activation

Electrochemically mediated polymerization represents an emerging activator paradigm that substitutes electrons for chemical redox agents [24]. This approach offers exceptional control over radical generation through precise modulation of applied potential/current, enabling spatial and temporal control over grafting reactions. Electrografting techniques have successfully created surface-attached responsive gel layers and functionalized surfaces with applications in biosensing and smart materials [24].

The electro-initiated free radical polymerization (eFRP) of N-isopropylacrylamide (NIPAM) exemplifies this technology, where electrochemical control over radical generation directs the formation of thermoresponsive poly-NIPAM networks with potential in drug delivery and tissue engineering [24].

Polymer Assembly-Assisted Grafting (PAAG)

A novel grafting-to strategy demonstrates how activator selection combined with architectural design can overcome traditional limitations [28]. The PAAG method utilizes pre-formed polymer assemblies of poly(carboxybetaine methacrylate) and poly(butyl methacrylate) diblock and triblock copolymers, which spontaneously form ∼100 nm particles in solution prior to surface immobilization.

This approach achieved exceptional grafting density with film thickness of 10.96 nm on gold surfaces of surface acoustic wave (SAW) sensors, significantly outperforming conventional grafting-to methods [28]. The resulting coatings demonstrated excellent antifouling properties, reducing protein adsorption to 4.3° phase shift compared to 12° for bare gold surfaces, highlighting the practical implications of advanced grafting strategies.

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Research Reagent Solutions for Activator-Assisted Grafting

| Reagent/System | Function in Grafting Process | Experimental Considerations |

|---|---|---|

| Diaryliodonium Salts [23] [27] | Oxidizing component in redox cationic polymerization; generates strong Brønsted acids upon reduction | Light-sensitive; often paired with stannous octoate or ascorbic acid reducing agents |

| Stannous Octoate [27] | Reducing agent in redox couples; enables low-temperature epoxy curing | Miscible with various epoxy monomers; reduces required co-initiator concentrations |

| Copper(I)/Ligand Complexes [26] | Catalyzes azide-alkyne cycloaddition (CuAAC) in grafting-to approaches | Oxygen-sensitive; requires degassing or protective atmosphere |

| RAFT Agents [15] | Mediates controlled radical polymerization via reversible chain transfer | Enables molecular weight control in grafting-from; requires careful selection based on monomer |

| Azo-initiators [24] | Thermal radical generators for conventional free radical grafting | Half-life temperature critical for controlled initiation; can be combined with redox systems |

This comparative analysis demonstrates that activator selection profoundly influences both grafting efficiency and ultimate polymer architecture. Redox initiating systems offer distinct advantages for grafting-from approaches, enabling high-density brush architectures under mild conditions [26] [23]. In contrast, conventional grafting-to methods face inherent steric limitations that restrict architectural control, though innovative approaches like PAAG show promise in overcoming these constraints [28].

The experimental data presented establishes that strategic activator implementation must align with target architectural outcomes: grafting-from with redox initiation provides superior control over graft density and distribution, while emerging techniques including electrochemical activation and polymer assembly-assisted grafting offer complementary pathways for specific application requirements. These findings underscore the critical importance of activator chemistry in polymer architecture design, particularly for advanced applications in biomedical devices, drug delivery systems, and functional surfaces where precise interfacial control determines technological success.

Comparative Analysis of Reaction Kinetics and Activation Energies

In polymer reaction engineering, the kinetics of polymerization reactions and their associated activation energies are fundamental to understanding reaction rates, controlling polymer properties, and designing industrial processes. Free radical polymerization (FRP) constitutes over 50% of global polymer production, while controlled radical polymerization techniques, such as atom transfer radical polymerization (ATRP) and reversible addition-fragmentation chain transfer (RAFT) polymerization, have emerged as powerful methods for synthesizing polymers with precise architectures [29]. The activation energy (Ea) of these reactions represents the energy barrier that must be overcome for a specific reaction step to occur, directly influencing reaction rates and temperature dependencies. This guide provides an objective comparison of reaction kinetics and activation energies across different polymerization systems, supported by experimental data and detailed methodologies to assist researchers in selecting appropriate techniques for their specific applications.

Comparative Kinetic Parameters of Polymerization Systems

Table 1: Comparative Kinetic Parameters of Polymerization Systems

| Polymerization System | Typical Activation Energy Range (kJ mol⁻¹) | Polymerization Rate Profile | Gelation Behavior | Network Homogeneity |

|---|---|---|---|---|

| Conventional FRP | 18-39 (termination) [30] | Fast rate with early autoacceleration [31] | Early gel formation with significant intramolecular crosslinking [31] | Heterogeneous network with microgels [31] |

| RAFT Polymerization | Varies by chain transfer agent | Slower rate with mid-conversion autoacceleration [31] | Gelation near macro-gelation point; limited cyclization [31] | More homogeneous network structure [31] |

| ATRP | Specific values depend on catalyst system | Slowest rate with late autoacceleration [31] | Similar to RAFT; gels near macro-gelation point [31] | More homogeneous network structure [31] |

| Acrylate Polymerization (with backbiting) | Multiple activation energies for ECR, MCR, and PMR [32] | Complex kinetics due to multiple radical types [32] | Dependent on crosslinker density | Varies with propagation control |

Table 2: Experimentally Determined Activation Energies for Specific Systems

| System Studied | Activation Energy Value | Measurement Method | Experimental Conditions | Citation |

|---|---|---|---|---|

| Termination in dilute solution FRP of styrene | 25-39 kJ mol⁻¹ | Kinetic analysis with chemical initiation | Dilute solutions, low conversion [30] | [30] |

| Termination in bulk FRP of styrene | 18-24 kJ mol⁻¹ | Kinetic analysis with chemical initiation | Bulk polymerization [30] | [30] |

| Thermal degradation of PMMA (benzoyl peroxide initiated) | ~130 kJ mol⁻¹ | Thermogravimetric analysis | Free-radical polymerized PMMA [33] | [33] |

| Thermal degradation of anionically polymerized PMMA | 260 kJ mol⁻¹ | Thermogravimetric analysis | Anionically polymerized, saturated end-groups [33] | [33] |

Experimental Protocols for Kinetic Studies

Comparison of FRP, RAFT, and ATRP Gelation Behaviors

This protocol examines the kinetic differences between conventional free radical polymerization (FRP), reversible addition-fragmentation chain transfer (RAFT), and atom transfer radical polymerization (ATRP) when copolymerizing monovinyl and divinyl monomers, based on the study by ScienceDirect [31].

Materials and Reagents:

- Monomers: Oligo(ethylene glycol) methyl ether methacrylate (OEGMEMA) and oligo(ethylene glycol) dimethacrylate (OEGDMA)

- FRP System: Conventional free radical initiator (e.g., AIBN)

- RAFT System: RAFT chain transfer agent appropriate for methacrylates

- ATRP System: Copper(I) bromide catalyst, suitable initiator (e.g., methyl α-bromophenylacetate), and N,N,N,N-tetramethylethylenediamine ligand

Methodology:

- Prepare separate reaction mixtures for FRP, RAFT, and ATRP with identical monomer compositions (OEGMEMA with OEGDMA molar fractions of 2.56%, 5.26%, 8.11%, and 11.11%)

- Conduct polymerizations under controlled temperature conditions

- Monitor vinyl conversion versus time using appropriate analytical techniques (e.g., NMR spectroscopy)

- Determine gel points by measuring the abrupt increase in complex viscosity using rheological measurements

- Characterize network structure by solvent extraction to determine sol and gel fractions

Key Measurements:

- Polymerization rates and autoacceleration regions

- Conversion at gel point

- Evolution of network structure with conversion

- Homogeneity of the resulting networks

Determination of Activation Energy for Termination

This protocol describes the experimental approach to measure the activation energy of the termination reaction in radical polymerization, based on recent research published in PMC [30].

Materials and Reagents:

- Monomers: Styrene, methyl methacrylate, butyl methacrylate, or dodecyl methacrylate

- Initiators: AIBN or bis(3,5,5-trimethylhexanoyl) peroxide

- Solvents: Trifluorotoluene or ethylbenzene

Methodology:

- Conduct a series of homopolymerizations with different monomers using chemical initiators

- Perform polymerizations in solution at atmospheric pressure with varying temperatures

- Determine the overall termination rate coefficient (

) from measurements of the rate of polymerization - Calculate activation energy Ea(

) from the temperature dependence of using the Arrhenius approach - Analyze the chain-length-dependent termination (CLDT) using the composite model

Key Measurements:

- Polymerization rates at different temperatures

- Overall termination rate coefficients

- Activation energies for termination

- Chain-length dependence of termination

Pulsed Laser Polymerization for Propagation Rate Coefficients

This protocol outlines the use of pulsed laser polymerization (PLP) to determine propagation rate coefficients in acrylate polymerization, accounting for multiple radical types, based on recent research in Polymer Chemistry [32].

Materials and Reagents:

- Monomer: n-butyl acrylate

- Photoinitiator: 2,2-dimethoxy-2-phenylacetophenone

- Equipment: Pulsed laser system, size exclusion chromatography

Methodology:

- Utilize a laser beam to generate pulse-wise initiator radicals

- Allow radical chain growth during the dark time (Δt) between laser pulses

- Analyze the molecular weight distribution of the resulting polymer using SEC

- Determine the chain length (L) at the first inflection point of the SEC trace

- Calculate kp,app using the relationship: L = kp,app[M]0Δt, where [M]0 is initial monomer concentration

- Employ kinetic Monte Carlo simulations and DFT calculations to interpret results

Key Measurements:

- Molecular weight distributions from SEC

- Apparent propagation rate coefficients

- Contributions from end-chain radicals, mid-chain radicals, and propagated mid-chain radicals

- Backbiting and β-scission rate coefficients at higher temperatures

Visualization of Reaction Pathways and Kinetic Relationships

Polymerization Kinetic Pathways Comparison

Activation Energy Influencing Factors

The Scientist's Toolkit: Essential Research Reagents

Table 3: Research Reagent Solutions for Polymerization Kinetics Studies

| Reagent Category | Specific Examples | Function in Kinetic Studies | Application Notes |

|---|---|---|---|

| Conventional Initiators | AIBN, Benzoyl peroxide | Generate radicals for FRP; determine initiation kinetics | Decomposition rate coefficients depend on temperature and structure [29] |

| RAFT Agents | 4-Cyano-4-(ethylthiocarbonothioylthio) pentanoic acid (CEPA) | Mediate controlled radical polymerization via reversible chain transfer | Enables control over molecular weight and distribution; affects polymerization rate [15] |

| ATRP Components | Copper bromide, alkyl halide initiators, nitrogen-based ligands | Enable controlled radical polymerization via reversible deactivation | Catalyst system determines activation-deactivation equilibrium [31] |

| Redox Initiators | Potassium persulfate, L-ascorbic acid sodium salt | Generate radicals at lower temperatures via redox chemistry | Useful for temperature-sensitive systems; enables fast initiation [15] |

| Chain Transfer Agents | Lauryl mercaptan, various thiol compounds | Regulate molecular weight by terminating growing chains | Transfer constants vary with structure; affect kinetic chain length [29] |

| Monomer Types | Styrene, methacrylates, acrylates, divinyl crosslinkers | Determine propagation rate coefficients and network formation | Structure affects reactivity ratios and copolymerization kinetics [31] |

This comparative analysis demonstrates significant differences in reaction kinetics and activation energies across various polymerization systems. Conventional FRP exhibits faster polymerization rates but earlier gelation and more heterogeneous networks, while controlled techniques like RAFT and ATRP provide slower growth, delayed gelation, and more homogeneous structures. The activation energies for termination reactions range from 18-39 kJ mol⁻¹, varying with chain length dependencies and reaction conditions. Acrylate polymerizations present additional complexity due to the presence of multiple radical types with distinct propagation characteristics. These kinetic parameters fundamentally influence polymerization rates, network development, and final material properties, enabling researchers to select appropriate systems based on their specific application requirements in fields ranging from biomaterials to advanced coatings.

Synthesis and Implementation: Techniques and Biomedical Use Cases

The design of advanced functional materials often requires precise control over polymer architecture and surface properties. Among the various techniques available, graft copolymerization serves as a powerful method to impart a diverse range of functional groups to a polymer, enabling the creation of materials with tailor-made characteristics [34]. The modification of polymers through grafting has witnessed substantial growth, driven by the need for specialized materials in fields ranging from membrane science to biomedical applications [35] [34]. Two principal synthetic strategies—'grafting-from' and 'grafting-to'—have emerged as cornerstone approaches for constructing these hybrid materials. This guide provides an objective comparison of these methodologies, focusing on their performance characteristics, supported by experimental data, and framed within the context of redox initiator systems for polymerization research.

Fundamental Principles and Comparative Analysis

Graft copolymers consist of a primary polymer chain (the backbone) with secondary polymer chains (the branches or grafts) covalently attached. The technique used to create this structure profoundly influences the final properties of the material [35] [36].

The 'Grafting-to' Approach: This method involves pre-synthesizing polymer chains with reactive end-groups and subsequently attaching them to a functionalized backbone polymer [35]. The independent synthesis of the side chains allows for excellent control over their molecular weight and dispersity before the conjugation reaction.

The 'Grafting-from' Approach: This technique, also known as surface-initiated polymerization, utilizes initiating sites present on the backbone polymer to initiate the growth of new polymer chains directly from the surface [35] [37]. This method is particularly effective for achieving high grafting densities.

The 'Grafting-through' Approach: A third, less common strategy involves the copolymerization of a macromonomer (a polymer chain with a polymerizable end-group) with a conventional low molecular weight monomer [35] [36].

The following diagram illustrates the logical sequence and key differences between the 'grafting-from' and 'grafting-to' methodologies.

Diagram 1: A workflow comparing the 'Grafting-from' and 'Grafting-to' synthesis pathways.

The core distinction between these routes lies in the sequence of reactions and the resulting structural control. The table below summarizes the comparative advantages, disadvantages, and typical performance outcomes of each method.

Table 1: Comparative Analysis of 'Grafting-from' and 'Grafting-to' Methodologies

| Parameter | 'Grafting-from' Approach | 'Grafting-to' Approach |

|---|---|---|

| Grafting Density | Can achieve very high density due to minimal steric hindrance during polymer chain growth [36]. | Limited grafting density caused by steric hindrance from pre-formed polymer chains, which blocks reactive sites [36]. |

| Control over Graft Chain | Control can be challenging; relies on the efficiency of the surface-initiated polymerization. | Excellent control; graft chains are synthesized and characterized independently, allowing for precise molecular weight and low dispersity [36]. |

| Experimental Complexity | Often a two-step process (activation followed by polymerization). Requires careful optimization of the initiation step [37]. | Conceptually simple, but requires separate synthesis and purification of end-functionalized polymers prior to grafting [38]. |

| Compatibility with Redox Initiators | Highly compatible. Redox systems like Fe²⁺/KPS can generate free radicals directly on the backbone to initiate growth [35] [39]. | Less direct compatibility. Redox reactions are typically not involved in the final coupling step, which is often a conjugation reaction (e.g., NHS ester coupling) [38]. |

| Typical Grafting Yield | Can be very high (e.g., >350% reported for MMA onto chitin using FAS-KPS [39]). | Often lower, may require a large molar excess of polymer to achieve moderate conjugation levels (e.g., in polymer-protein conjugation [38]). |

| Common Applications | Membrane surface modification [40], creating anti-fouling coatings [37], water-absorbing materials. | Polymer-protein bioconjugates [38], functionalization of sensitive substrates, miktoarm star copolymers [36]. |

Experimental Protocols and Redox Initiator Performance

The choice of initiator system is critical in grafting polymerizations, particularly for the 'grafting-from' method. Redox initiators, which generate free radicals through electron-transfer reactions at moderate temperatures, are widely used to graft vinyl monomers onto various backbones [39] [34].

Exemplary Protocol: Grafting MMA onto Chitin

A comparative study investigated the relative reactivities of potassium persulfate (KPS) and the ferrous ammonium sulfate-potassium persulfate (FAS-KPS) redox system for grafting methyl methacrylate (MMA) onto chitin [39].

Detailed Methodology:

- Reaction Setup: The grafting was carried out in an aqueous medium. Chitin was dispersed in water, and the system was purged with nitrogen to create an inert atmosphere.

- Monomer Addition: A specified concentration of MMA monomer was added to the reaction vessel.

- Initiator System:

- System A: Potassium persulfate (KPS) alone.

- System B: Ferrous ammonium sulfate (FAS) combined with KPS (FAS-KPS redox pair).

- Polymerization: The reaction proceeded under optimized conditions of time and temperature. The study systematically varied parameters including initiator concentration, monomer concentration, chitin concentration, reaction time, and temperature to determine optimum grafting yields.

- Work-up and Analysis: The grafted product was isolated, purified to remove homopolymer (poly-MMA), and dried. Evidence of grafting was obtained through IR spectroscopy. The grafting yield (%) was calculated gravimetrically.

Key Quantitative Findings:

- Under optimum conditions, the KPS system yielded a grafting percentage of 94.5%.

- The FAS-KPS redox system was significantly more effective, achieving a dramatically higher grafting yield of 352% [39].

- The apparent activation energy for the FAS-KPS initiated grafting reaction was estimated to be 23 kcal/mol [39].

This experiment highlights the superior efficiency of redox initiator systems like FAS-KPS in 'grafting-from' polymerizations, as they generate radicals more efficiently at lower temperatures, leading to higher grafting yields.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Reagents for Grafting Polymerization with Redox Initiators

| Reagent / Material | Function in Grafting Polymerization | Exemplary Use Case |

|---|---|---|

| Potassium Persulfate (KPS) | A common oxidizing component in redox pairs; generates sulfate radical anions upon reduction [35]. | Used alone or as part of a redox pair (e.g., with FAS) to initiate free-radical grafting on polysaccharides like chitosan and chitin [39]. |

| Ferrous Ammonium Sulfate (FAS) | A reducing agent that reacts with persulfate to rapidly generate free radicals (e.g., SO₄⁻• and OH•) at room temperature [35] [39]. | FAS-KPS system for high-yield grafting of MMA onto chitin [39]. The radical generation can be represented as: Fe²⁺ + S₂O₈²⁻ → Fe³⁺ + SO₄²⁻ + SO₄⁻• [35]. |

| Ceric Ammonium Nitrate (CAN) | A strong one-electron oxidant that is particularly effective in creating active sites on polymer backbones containing hydroxyl groups (e.g., cellulose, chitosan) [39] [34]. | Initiation of acrylic acid grafting onto carboxymethyl chitosan [39]. |

| Chitin/Chitosan | Natural polysaccharide backbone rich in hydroxyl and amine functional groups, which can be activated by initiators for grafting [39] [36]. | A model substrate for evaluating the performance of different redox initiator systems in grafting vinyl monomers [39]. |

| Methyl Methacrylate (MMA) | A vinyl monomer commonly used in grafting studies to impart altered solubility, thermal, and mechanical properties to the backbone polymer [39]. | Monomer grafted onto chitin to study the relative efficiency of KPS vs. FAS-KPS initiator systems [39]. |

The experimental workflow for a typical 'grafting-from' process using a redox initiator system is detailed below.

Diagram 2: A detailed experimental workflow for a 'grafting-from' polymerization using a redox initiator system.

Application-Oriented Performance in Functional Materials

The choice between 'grafting-from' and 'grafting-to' is often dictated by the intended application of the final functional material, as each method bestows distinct performance advantages.

Membrane Separation Science: The 'grafting-from' technique is extensively used to modify liquid separation membranes. For instance, grafting hydrophilic polymers like poly(2-methacryloyloxyethyl phosphorylcholine) onto PVDF or PES membranes via surface-initiated polymerization significantly enhances their surface hydrophilicity [40] [37]. This modification improves water flux and imparts robust anti-fouling properties by creating a hydration layer that reduces protein and bacterial adhesion, a critical performance metric in wastewater treatment and desalination [40].

Conducting Polymers and Bioelectronics: Grafting methodologies can enhance the processability and performance of conducting polymers. The 'grafting-to' approach allows for the attachment of well-defined, soluble polymer chains onto a conjugated conducting backbone (e.g., polythiophene). This preserves the extended conjugation required for charge transport while improving solubility and enabling the fabrication of thin-film electronics [35] [34].

Adsorbents for Water Purification: A 'grafting-through' method was employed to functionalize graphene oxide (GO) with cationic polymers [41]. The GO was first modified with allylamine to introduce a polymerizable site, followed by radical polymerization. The resulting GO-polymer composite demonstrated a enhanced and selective adsorption capacity for anionic dyes like methyl orange and viruses, showcasing how controlled grafting can tailor a material's surface charge and functionality for specific adsorption applications [41].

Biomedical Conjugates: The 'grafting-to' strategy is the method of choice for creating polymer-protein bioconjugates, crucial for therapeutic applications like antibody-drug conjugates. In this context, well-defined polymers are synthesized separately (e.g., via RAFT polymerization) with end-groups such as N-hydroxysuccinimide or maleimide, which are then conjugated to lysine or cysteine residues on the protein [38]. This method provides the precise control over polymer properties necessary to maintain protein stability and function while modulating pharmacokinetics.

Both 'grafting-from' and 'grafting-to' methodologies offer powerful and complementary pathways for engineering functional materials. The 'grafting-from' approach, particularly when leveraged with efficient redox initiator systems like FAS-KPS, excels at producing high grafting densities and is ideal for modifying surfaces and creating dense polymer brushes for applications in membrane technology and adsorbents. In contrast, the 'grafting-to' approach provides superior control over graft chain architecture and is indispensable for applications requiring precise conjugation, such as in the development of polymer-biomolecule hybrids. The selection of the optimal grafting strategy must be guided by the specific performance requirements of the target application, balancing the need for grafting density, molecular control, and experimental feasibility.

Redox-Initiated RAFT Polymerization for Precision Macromolecular Design

Reversible addition-fragmentation chain-transfer (RAFT) polymerization has emerged as one of the most powerful reversible deactivation radical polymerization (RDRP) techniques, enabling precise control over molecular weight, architecture, and functionality of vinyl polymers. [42] [43] While traditional RAFT polymerization relies on thermal initiators such as azobisisobutyronitrile (AIBN), redox initiation systems (RISs) offer distinctive advantages for polymer synthesis under mild conditions, particularly for biomedical and materials applications requiring ambient temperature initiation and minimal side reactions. [44] [11] This comparison guide objectively evaluates the performance of emerging redox initiators against traditional radical initiation methods within the context of precision macromolecular design, providing researchers with experimental data and protocols for informed reagent selection.

Redox initiation operates through electron transfer reactions between oxidizing and reducing agents, generating free radicals at ambient or physiological temperatures without external energy input. [11] This characteristic makes RISs particularly valuable for synthesizing polymer-bioconjugates, formulating two-part adhesives, and producing thermally sensitive materials where conventional thermal initiators would cause degradation or uncontrolled polymerization. [44] [11] Recent research has focused on developing "peroxide-free and amine-free" redox systems that mitigate toxicity concerns while maintaining excellent reactivity profiles under challenging conditions such as aerobic environments. [44]

Comparative Analysis of Redox Initiating Systems

Performance Benchmarking of Contemporary RISs

Table 1: Quantitative Comparison of Redox Initiating Systems for Free Radical Polymerization

| Redox System Components | Gel Time (s) | Final Conversion (%) | Max Temp (°C) | Surface Curing | Stability (50°C) |

|---|---|---|---|---|---|

| Mn(acac)₂ / DPS (1/1 wt%) | 110 | 98% | 140 | Tack-free | 7 days stable |

| Cu(AAEMA)₂ / DPS (1/1 wt%) | 380 | 90% | 130 | Tack-free | 7 days stable |

| Fe(acac)₃ / DPS (1/1 wt%) | 900 | n.d. | 45 | Tacky | n.d. |

| Mn(acac)₃ / DPS (1/1 wt%) | 155 | 98% | 142 | Tack-free | Unstable |

| Traditional BPO/Amine | Variable | 85-95% | 110-130 | Often tacky | Poor (BPO decay) |

The performance data reveals significant advantages of metal complex/DPS systems over traditional benzoyl peroxide (BPO)/aromatic amine initiators. The Mn(acac)₂/DPS combination achieves exceptional final conversion (98%) with rapid gelation (110s) while maintaining excellent storage stability—addressing key limitations of conventional BPO systems, which suffer from ambient temperature decay and shelf-life limitations. [44] [11] Notably, these peroxide-free systems effectively overcome oxygen inhibition, enabling polymerization under aerobic conditions where traditional systems fail. [44]

Redox-Initiated RAFT Versus Alternative Activation Methods

Table 2: Comparison of RAFT Activation Techniques for Precision Polymerization

| Activation Method | Temp. Conditions | Temporal Control | Spatial Control | Oxygen Tolerance | Industrial Scalability |

|---|---|---|---|---|---|

| Redox Initiation | Ambient - 50°C | Limited | Limited | Moderate to High | Excellent |

| Thermal Initiation | 70-90°C | Limited | None | Poor | Good |

| Photoiniferter RAFT | Ambient | Excellent | Excellent | Poor | Challenging |

| PET-RAFT | Ambient | Excellent | Excellent | Good (with catalysts) | Moderate |

| Electro-RAFT | Ambient | Good | Limited | Moderate | Developing |

Redox-initiated RAFT occupies a unique position within the RAFT technique spectrum, offering mild temperature operation combined with excellent scalability. While photochemical methods provide superior spatiotemporal control, redox systems deliver practical advantages for industrial applications where light penetration limitations or catalyst removal present manufacturing challenges. [42] The recent development of redox systems functioning effectively under air dramatically expands their utility for biomedical applications and composite material production. [44]

Experimental Protocols and Methodologies

Redox-Initiated RAFT Emulsion Polymerization of β-Ketoester Functional Monomers

The synthesis of functional block copolymer assemblies via redox-initiated RAFT emulsion polymerization represents an advanced application of this technique. The following protocol adapted from recent research enables the production of poly(poly(ethylene glycol) methyl ether methacrylate)-b-PAEMA (PPEGMAn-PAEMAm) with various nano-object morphologies: [15]

Materials and Equipment:

- Macromolecular chain transfer agent (macro-CTA): PPEGMA₁₂-CEPA

- Functional monomer: 2-(acetoacetoxy)ethyl methacrylate (AEMA)

- Redox initiator system: Potassium persulfate (KPS) and L-ascorbic acid sodium salt (NaAs)

- Purification reagents: Basic alumina (for monomer purification), n-hexane, and diethyl ether

- Reaction system: Nitrogen-purged reactor with temperature control at 50°C

- Characterization: ¹H NMR spectroscopy, Transmission Electron Microscopy (TEM), Dynamic Light Scattering (DLS)

Step-by-Step Procedure:

- Monomer Preparation: Purify AEMA by passing through a basic alumina column to remove inhibitors. Store refrigerated at 4°C until use.

- Macro-CTA Synthesis: Prepare PPEGMA₁₂-CEPA via RAFT polymerization of PEGMA (Mn = 475 g/mol) using CEPA as chain transfer agent and AIBN initiation at 70°C in 1,4-dioxane. Precipitate the product in n-hexane, wash with diethyl ether, and dry under vacuum at 45°C. Verify degree of polymerization (DP = 12) via ¹H NMR.

- Redox-Initiated Emulsion Polymerization:

- Charge PPEGMA₁₂-CEPA (0.28 g) and AEMA monomer (targeting DP = 100) to the reactor with aqueous medium.

- Degas the system with nitrogen for 45 minutes.

- Initiate polymerization by adding the redox pair: KPS (oxidizing agent) and NaAs (reducing agent).

- Maintain reaction temperature at 50°C with continuous stirring.

- Reaction Monitoring: Track monomer conversion via ¹H NMR by sampling aliquots at timed intervals. Kinetic studies typically show >95% conversion within 30 minutes.

- Morphology Characterization: Analyze resulting nano-objects using TEM and DLS to identify worm-like, vesicular, and spherical morphologies dependent on macro-CTA molecular weight and monomer concentration.

- Post-Polymerization Modification: React β-ketoester functional groups with aggregation-induced emission (AIE) luminogens (e.g., TPE-NH₂) to create AIE-active polymer assemblies with strong aqueous fluorescence.

This methodology demonstrates the efficient synthesis of functional block copolymer assemblies at solids concentrations up to 15% w/w, achieving rapid monomer conversion (>95% within 30 minutes) with distinct polymerization phases driven by micelle formation and monomer depletion. [15]

Peroxide-Free Redox Initiation for Methacrylate Resins

Recent advances have introduced peroxide-free RISs combining diphenylsilane (DPS) with metal complexes. The following protocol demonstrates their application for methacrylate polymerization under aerobic conditions: [44]

Materials:

- Reducing agent: Diphenylsilane (DPS)

- Oxidizing agents: Mn(acac)₂, Cu(AAEMA)₂, or Fe(acac)₃

- Monomer: Methacrylate resin formulation

- Equipment: Optical pyrometer, RT-FTIR spectrometer, composite molds

Procedure:

- Formulate resin part containing methacrylate monomers and DPS (0.5-2.0 wt%).

- Prepare curative part with selected metal complex (0.5-2.0 wt%).

- Mix components at designed ratio (typically 1:1) under ambient atmosphere.

- Monitor polymerization progress via optical pyrometry (gel time, exotherm) and RT-FTIR (conversion).

- For composite preparation: Impregnate fiber mats (glass or carbon) with activated resin, layer, and cure under ambient conditions.

This peroxide-free system achieves tack-free surfaces with final methacrylate conversions exceeding 90% under air, overcoming a fundamental limitation of conventional radical polymerization. [44]