EQCM-D: A Comprehensive Guide to Combined Electrochemical and Gravimetric Analysis for Redox Studies

This article explores the powerful synergy of Quartz Crystal Microbalance with Dissipation monitoring (QCM-D) and electrochemistry, known as Electrochemical QCM-D (EQCM-D), for advanced redox research.

EQCM-D: A Comprehensive Guide to Combined Electrochemical and Gravimetric Analysis for Redox Studies

Abstract

This article explores the powerful synergy of Quartz Crystal Microbalance with Dissipation monitoring (QCM-D) and electrochemistry, known as Electrochemical QCM-D (EQCM-D), for advanced redox research. Tailored for researchers and drug development professionals, we cover the foundational principles of QCM-D mass/viscoelasticity sensing and electrochemical redox reactions. The scope extends to practical methodologies for studying processes like metal deposition/stripping and biomolecular interactions, alongside troubleshooting for experimental optimization. The article also addresses data validation against complementary techniques and the significant implications of this combined approach for developing biosensors, optimizing battery interfaces, and probing redox biology in biomedical applications.

Understanding the Core Principles: QCM-D, Electrochemistry, and Their Redox Synergy

Quartz Crystal Microbalance with Dissipation Monitoring (QCM-D) is a powerful, surface-sensitive analytical technique that provides real-time, label-free analysis of molecular interactions at the nanoscale. By simultaneously measuring changes in mass and viscoelastic properties, QCM-D offers unique insights for researching electrochemical redox processes, biomolecular interactions, and material deposition. This application note details the core principles and provides specific protocols for applying QCM-D in electrochemical studies, with a focus on investigating redox mechanisms.

Core Principles and Measurement Outputs

QCM-D functions as a highly sensitive balance that operates by exciting a piezoelectric quartz crystal sensor to oscillate at its resonant frequency. The technology detects two primary parameters:

- Frequency Shift (Δf): A decrease in resonant frequency indicates mass uptake on the sensor surface, while an increase signifies mass loss [1] [2]. The relationship between frequency shift and mass change for thin, rigid layers is described by the Sauerbrey equation [1].

- Dissipation Shift (ΔD): This parameter quantifies the energy loss in the system [1]. An increase in dissipation indicates the formation of a soft, viscoelastic layer that dissipates energy, whereas a minimal change suggests the formation of a rigid, Sauerbrey-like film [2].

The combination of these measurements allows researchers to distinguish between rigid mass adsorption and the formation of hydrated, soft layers in real time [1]. Table 1 summarizes the interpretation of these key parameters.

Table 1: Interpretation of QCM-D Output Parameters

| Parameter | Change | Physical Meaning | Implied Layer Property |

|---|---|---|---|

| Frequency (Δf) | Decrease | Mass Increase (Adsorption/Binding) | - |

| Increase | Mass Decrease (Desorption/Etching) | - | |

| Dissipation (ΔD) | Significant Increase | High Energy Loss | Soft, Viscoelastic |

| Minimal Change | Low Energy Loss | Rigid |

QCM-D in Electrochemical Research (EQCM-D)

The integration of QCM-D with electrochemistry, known as Electrochemical QCM-D (EQCM-D), creates a powerful tool for investigating redox-active systems [3]. This combination allows for the direct correlation of electrochemical stimuli (e.g., applied potential or current) with the resulting mass and viscoelastic changes at the sensor surface, which also acts as the working electrode [3].

Benefits of EQCM-D include:

- Real-time Monitoring: Simultaneously track current/potential with mass and structural changes [3].

- Direct Correlation: Link specific electrochemical events (e.g., an oxidation peak in a voltammogram) to precise mass uptake or loss [3] [4].

- Unique Insights: Uncover reaction mechanisms, such as ion insertion/expulsion in conducting polymers or metal deposition/stripping, that are inaccessible by either technique alone [3] [4].

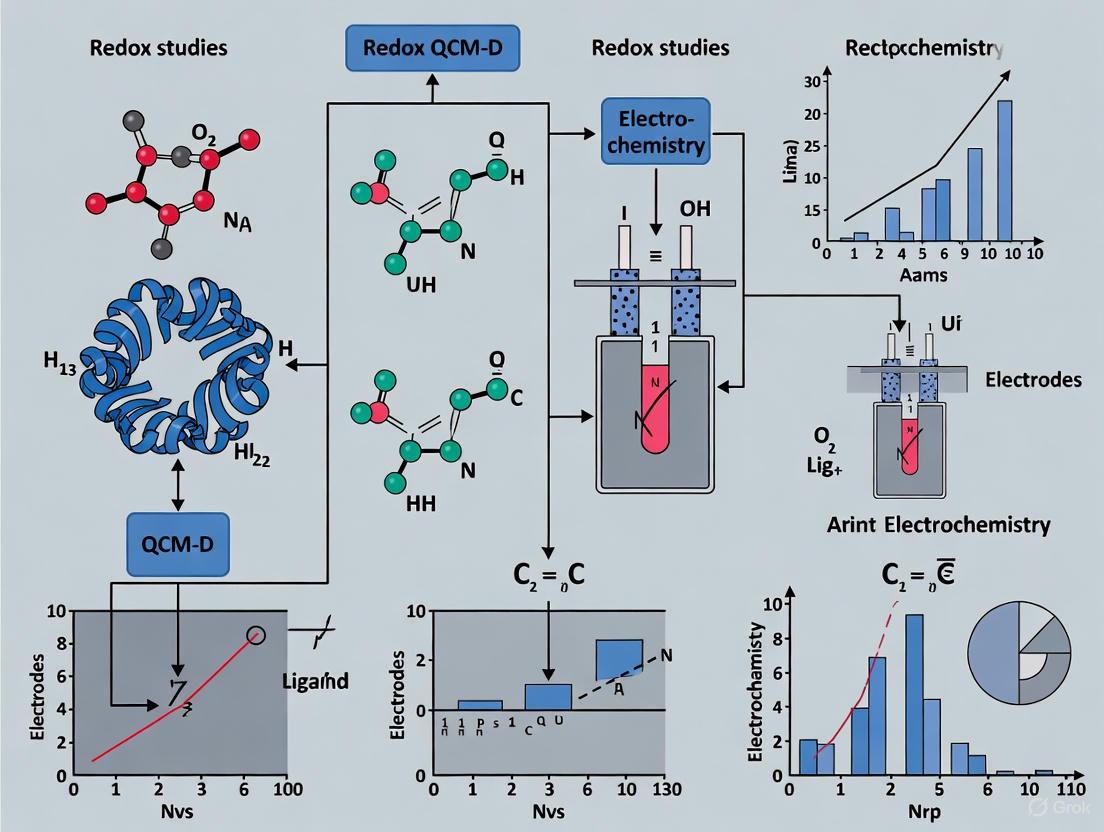

The diagram below illustrates a generalized workflow for an EQCM-D experiment.

Application Note: Investigating Copper Redox Deposition and Stripping

This protocol demonstrates how EQCM-D can be used to quantitatively study the electrodeposition and stripping of copper, a classic redox process.

Experimental Objective

To simultaneously monitor the mass and viscoelastic changes during the electrochemical reduction (deposition) and oxidation (stripping) of copper on a gold QCM-D sensor surface [3].

Research Reagent Solutions

Table 2: Essential Reagents and Materials

| Item | Function / Role | Specifications / Notes |

|---|---|---|

| Gold-coated QCM-D Sensor | Working Electrode | Provides a conductive, clean surface for deposition and mass detection. |

| Copper Salt Solution | Electrolyte & Metal Source | e.g., 0.1 M CuSO₄ in a supporting electrolyte like H₂SO₄. |

| Potentiostat/Galvanostat | Electrochemical Control | Applies controlled potential or current to drive redox reactions. |

| QCM-D Instrument with Flow Module | Mass & Viscoelasticity Monitoring | Enables simultaneous measurement of Δf and ΔD. Must be compatible with electrochemistry. |

| Reference Electrode | Potential Reference | e.g., Ag/AgCl. Essential for applying accurate potentials. |

| Counter Electrode | Completes Circuit | e.g., Platinum wire. |

Step-by-Step Protocol

- System Setup: Place the gold sensor in the EQCM-D flow cell and connect it as the working electrode. Insert the reference and counter electrodes. Ensure the cell is properly sealed and connected to the fluidics system.

- Baseline Establishment: Flow a blank supporting electrolyte solution (e.g., dilute H₂SO₄) through the cell until stable frequency (Δf) and dissipation (ΔD) baselines are achieved. This ensures a clean, stable starting point.

- Solution Introduction: Introduce the copper-containing electrolyte solution (e.g., 0.1 M CuSO₄ in H₂SO₄) under a constant, non-reactive flow or in a static condition.

- Simultaneous Data Acquisition: Initiate the electrochemical method (e.g., cyclic voltammetry scanning between positive and negative potentials) while simultaneously recording QCM-D data (Δf and ΔD at multiple overtones) and electrochemical data (current and potential).

- Data Analysis:

- During the negative potential sweep, copper ions (Cu²⁺) are reduced to solid copper (Cu⁰) on the sensor. This will appear as a large negative frequency shift (Δf), indicating mass gain. The minimal change in dissipation (ΔD) confirms the formation of a rigid metal layer [3].

- During the positive potential sweep, the solid copper is oxidized back to Cu²⁺ ions, which dissolve into solution. This is observed as a positive frequency shift (Δf), indicating mass loss [3].

Quantitative Data Interpretation

Table 3 summarizes the expected QCM-D responses during the key stages of the copper redox cycle.

Table 3: Expected QCM-D Responses for Copper Redox Cycling

| Electrochemical Step | Expected Δf | Expected ΔD | Interpretation |

|---|---|---|---|

| Cu²⁺ Reduction (Deposition) | Large Decrease | Minimal Increase | Rigid mass loading onto the sensor surface. |

| Cu⁰ Oxidation (Stripping) | Large Increase | Minimal Change | Rigid mass removal from the sensor surface. |

| Completion of Cycle | Return to Near Baseline | Return to Near Baseline | Process is reversible; little to no residual mass. |

Advanced Application: Probing Viscoelastic Changes in Actomyosin Networks

Beyond rigid layers, QCM-D excels at characterizing soft, hydrated biological systems. The following diagram outlines a protocol for studying the mechanics of reconstituted cytoskeletal networks.

Key Experimental Observations:

- The formation of an actin filament network on the sensor surface leads to a negative Δf and a positive ΔD, characteristic of a soft, viscoelastic layer [5].

- Subsequent addition of myosin II motors can alter the viscoelasticity. Increased cross-linking and contractile forces from myosin can lead to a decrease in ΔD, indicating a stiffening of the network [5].

- Introducing ATP (which induces myosin's weakly bound state) typically causes network relaxation and an increase in ΔD (softening), while ADP promotes a strongly bound state, potentially maintaining stiffness [5].

QCM-D is an indispensable technique for researchers requiring nanoscale insight into mass and viscoelastic changes. Its unique ability to provide real-time, label-free data on both rigid and soft materials makes it particularly powerful when combined with electrochemistry. The detailed protocols for copper redox cycling and actomyosin mechanics provided here demonstrate its versatility across physical and life sciences, enabling a deeper understanding of complex surface interaction phenomena.

The Quartz Crystal Microbalance with Dissipation Monitoring (QCM-D) is a powerful analytical technique that has transformed the study of interfacial processes in electrochemistry. This technology functions by applying an alternating current to a piezoelectric quartz crystal disc, inducing oscillations at a characteristic resonant frequency [2]. When mass is added to or removed from the crystal's surface, the frequency changes, similarly to how a guitar string's pitch depends on its thickness [2]. The integration of QCM-D with electrochemistry creates a powerful hybrid technique, the Electrochemical Quartz Crystal Microbalance (EQCM-D), which enables simultaneous monitoring of both mass changes and viscoelastic properties at an electrode surface during redox reactions [6]. This combined approach provides unique insights into electron transfer processes, particularly for complex systems involving polymers, biomolecules, and energy storage materials, where mass transport and structural rearrangements play critical roles in electrochemical performance.

For researchers in drug development and materials science, EQCM-D offers a label-free, real-time investigative tool that goes beyond traditional electrochemical measurements. It can detect nanogram-level mass changes [7] while providing information on the viscoelastic character of the adlayer—whether it is rigid and tightly bound or soft and hydrated [8] [2]. This is particularly valuable when studying non-rigid biological layers or polymer films that undergo structural transformations during oxidation and reduction cycles.

Table 1: Key Quantitative Parameters in QCM-D Electrochemical Studies

| Parameter | Typical Values/Units | Interpretation in Electrochemical Context |

|---|---|---|

| Frequency Shift (Δf) | Hz | Indicates mass change at electrode surface; negative shift during mass gain (e.g., adsorption, film formation) [7] |

| Dissipation Shift (ΔD) | Dimensionless (x10⁻⁶) | Reflects viscoelastic properties and structural changes; increase suggests softer, more dissipative layer formation [8] |

| Fundamental Frequency | 5-9 MHz (common range) | Determines base sensitivity; thinner crystals have higher fundamental frequencies [8] [9] |

| Mass Sensitivity | ~17.7 ng·cm⁻²/Hz (for 5 MHz crystal) | Mass change per unit frequency shift under Sauerbrey conditions [7] |

| Harmonics Measured | 3rd, 5th, 7th, 9th, 11th, 13th | Multiple overtones enable viscoelastic modeling and layer characterization [8] [2] |

Fundamental Principles and Theoretical Framework

Piezoelectric Effect and Mass Sensing

The operational principle of QCM-D technology centers on the piezoelectric properties of quartz crystals. Quartz generates an electrical charge when mechanically stressed and deforms mechanically when exposed to an electric field [2]. This property stems from its crystal structure, which lacks a center of symmetry. In standard QCM-D configuration, AT-cut quartz crystals are used because they produce a pure thickness shear mode oscillation where the two surfaces of the crystal move in an anti-parallel fashion [2]. When an alternating electric field is applied via metal electrodes (typically gold) sputtered onto the crystal surfaces, the quartz oscillates at its resonant frequency, which is determined by its physical thickness [2].

The relationship between mass change and frequency shift was first quantified by Sauerbrey in 1959, establishing the foundational equation for QCM technology [7]. The Sauerbrey equation states:

Δm = -C × (Δf/n)

where Δm is the mass change per unit area, Δf is the measured frequency shift, n is the harmonic number, and C is a constant that depends on the properties of the quartz crystal (for a standard 5 MHz crystal, C ≈ 17.7 ng·cm⁻²/Hz) [7] [2]. This linear relationship applies specifically to thin, rigid, and evenly distributed mass layers where the added mass oscillates synchronously with the crystal surface.

Dissipation Monitoring and Viscoelasticity

A critical advancement in QCM technology came with the integration of dissipation monitoring (QCM-D), which provides essential information about the viscoelastic properties of surface layers. The dissipation factor (D) quantifies the energy loss in the oscillating system and is defined as:

D = Edissipated / (2π × Estored)

where Edissipated is the energy dissipated during one oscillation cycle and Estored is the energy stored in the oscillating system [7]. The QCM-D technique determines this parameter by monitoring the decay of the crystal's oscillation after the driving power is switched off [7]. For rigid, elastic layers that faithfully follow the crystal oscillation, the decay is slow, and the dissipation value is low. In contrast, soft, viscoelastic layers cause rapid decay of oscillation and higher dissipation values due to internal energy losses [2].

This capability to simultaneously measure frequency and dissipation shifts makes QCM-D particularly valuable for studying electrochemical processes involving non-rigid layers such as conducting polymers, biomolecular films, or hydration layers that undergo structural changes during redox reactions. The multiple harmonic data available in modern QCM-D instruments further enables sophisticated modeling of film properties using viscoelastic models [8].

Integration with Electrochemical Systems

When combined with electrochemical techniques, QCM-D transforms into EQCM-D, where the quartz sensor functions as both the mass sensor and the working electrode in an electrochemical cell [6]. This configuration enables direct correlation of faradaic currents with mass changes at the electrode-electrolyte interface. During redox processes, the technique can detect mass changes associated with ion insertion/ejection, solvent transport, film deposition, or molecular adsorption/desorption [10] [6]. The simultaneous measurement of dissipation provides additional insight into structural rearrangements, swelling, or compaction of electroactive films during oxidation and reduction.

Diagram: EQCM-D System Configuration for Redox Studies. The quartz crystal serves as both mass sensor and working electrode, enabling simultaneous monitoring of mass changes and faradaic currents.

Research Reagents and Materials Toolkit

Table 2: Essential Research Reagents and Materials for EQCM-D Redox Studies

| Category | Specific Examples | Function in EQCM-D Experiments |

|---|---|---|

| QCM-D Sensors | Gold-coated AT-cut quartz crystals (5-9 MHz) | Serve as both piezoelectric mass sensors and working electrodes [9] |

| Redox-Active Molecules | TEMPO derivatives (4-OH-TEMPO), conductive polymers (polypyrrole) | Model compounds for studying electron transfer processes and mass changes [10] [11] |

| Biomolecules | Fibronectin, proteins, DNA | Investigate redox-controlled biomolecular adsorption and conformation changes [6] [7] |

| Electrolyte Salts | NaCl, NaClO₄ (0.5-2.0 M concentration) | Provide ionic conductivity and maintain electrochemical stability [6] [11] |

| Surface Modification Agents | 3-mercaptopropionic acid, fibronectin, self-assembled monolayers | Functionalize electrode surfaces for specific molecular interactions [6] [9] |

| Cell Cultures | Cardiomyocytes, fibroblasts, NIH-3T3 cells | Study cell-electrode interactions and redox biology in drug screening [6] [9] |

Experimental Protocols and Methodologies

Protocol: Investigating Redox-Controlled Protein Adsorption

Objective: To study potential-dependent fibronectin adsorption onto conductive polymer surfaces using EQCM-D [6].

Materials and Equipment:

- EQCM-D instrument with electrochemical module

- Gold-coated quartz crystals (5-9 MHz)

- Conductive copolymer (PEDOT-co-PDLLA)

- Fibronectin solution (50-100 μg/mL in buffer)

- Electrolyte: 0.5 M NaCl in deionized water

- Three-electrode setup: Ag/AgCl reference electrode, graphite counter electrode

- Potentiostat for electrical stimulation

Procedure:

- Sensor Preparation: Clean gold electrodes with piranha solution (3:1 H₂SO₄:H₂O₂) for 20 seconds, rinse thoroughly with deionized water, and dry under nitrogen stream [9].

- Polymer Coating: Deposit conductive copolymer (PEDOT-co-PDLLA) onto the sensor surface via electrochemical polymerization or spin-coating to create a uniform film.

- Baseline Establishment: Mount the modified sensor in the EQCM-D flow chamber and establish stable frequency and dissipation baselines with electrolyte flow (0.5 M NaCl, 100 μL/min).

- Electrical Stimulation: Apply controlled potentials (+0.5 V or -0.125 V vs. Ag/AgCl) to the working electrode using the potentiostat.

- Protein Adsorption: Introduce fibronectin solution (50 μg/mL in 0.5 M NaCl) to the flow system while maintaining applied potential.

- Real-time Monitoring: Record simultaneous changes in frequency (Δf), dissipation (ΔD), and electrochemical current for 60-90 minutes.

- Rinsing Phase: Switch to pure electrolyte solution to remove loosely adsorbed proteins while continuing measurements.

- Data Analysis: Compare mass adsorption under different potentials using the Sauerbrey relationship for rigid layers or Voigt modeling for viscoelastic layers.

Key Parameters:

- Temperature control: 25°C ± 0.1°C

- Flow rate: 100 μL/min

- Applied potentials: +0.5 V, -0.125 V, and open circuit potential (control)

- Fundamental frequency: 5 MHz with monitoring of 3rd, 5th, and 7th overtones

Expected Outcomes: The study typically reveals enhanced fibronectin adsorption under electrical stimulation, with greater mass uptake at positive potentials (+0.5 V) [6]. Dissipation data may indicate conformational changes, with unfolded protein structures promoting better cell adhesion [6].

Protocol: Monitoring Passivation Dynamics During Organic Molecule Oxidation

Objective: To characterize electrode passivation during electrooxidation of 4-hydroxy-TEMPO (HT) using combined EQCM-D and electrochemical analysis [11].

Materials and Equipment:

- EQCM-D with rotating disk electrode capability

- Glassy carbon, Pt, or Au working electrodes on quartz crystals

- 4-hydroxy-TEMPO (0.002-2 M concentration range) in 0.5 M NaCl

- Control: TEMPO without hydroxyl group (0.05 M)

- Polishing supplies: alumina slurry (1 μm, 0.3 μm, 0.05 μm)

Procedure:

- Electrode Preparation: Polish working electrodes sequentially with 1 μm, 0.3 μm, and 0.05 μm alumina slurry, followed by ultrasonication in ethanol and deionized water [11].

- Solution Preparation: Prepare HT solutions across concentration range (0.002-2 M) in 0.5 M NaCl, degas with argon for 15 minutes.

- Passivation Studies: Perform cyclic voltammetry (scan rates: 0.5-1000 mV/s) while simultaneously monitoring frequency and dissipation changes.

- Surface Characterization: After passivation, analyze electrode surface using ex situ techniques: XPS, electron microscopy.

- Comparative Analysis: Repeat experiments with TEMPO control to isolate hydroxyl group effects.

- Self-Cleaning Investigation: At intermediate HT concentrations, monitor potential-induced removal of passivation layer.

Key Parameters:

- Scan rates: 0.5 mV/s to 1000 mV/s to simulate different battery operation conditions

- HT concentrations: 0.002 M to 2 M (near solubility limit)

- Multiple electrode materials: glassy carbon, Pt, Au

- Temperature: 25°C

Expected Outcomes: This protocol demonstrates concentration-dependent and scan rate-dependent passivation behavior, with formation of a polymeric-type layer composed of HT-like subunits [11]. The dissipation data reveals the viscoelastic nature of the passivation layer, while frequency changes quantify mass accumulation. The control experiments with TEMPO confirm the critical role of the hydroxyl moiety in passivation chemistry.

Diagram: General Workflow for EQCM-D Redox Experiments. The protocol involves sequential steps from sensor preparation to data analysis, with continuous multi-parameter monitoring.

Data Analysis and Interpretation

Quantitative Data Treatment

The rich dataset generated by EQCM-D experiments requires sophisticated analysis approaches that correlate electrochemical activity with mass and structural changes. For rigid, thin films where the Sauerbrey equation applies, the mass change can be directly calculated from frequency shifts. However, most electrochemical systems involving polymers or biomolecules require more complex modeling due to their viscoelastic nature.

The Voigt model is commonly employed to extract quantitative parameters from viscoelastic layers, using frequency and dissipation data from multiple harmonics [8]. This model treats the adsorbed film as a viscoelastic layer characterized by thickness, density, shear viscosity, and shear elasticity. The equations developed by Voinova et al. enable calculation of these parameters through fitting to experimental Δf and ΔD values across several overtones [8].

Table 3: Interpretation of Combined EQCM-D and Electrochemical Data

| Electrochemical Signal | QCM-D Response | Interpretation |

|---|---|---|

| Anodic current peak | Negative Δf, small ΔD | Oxidative deposition of rigid film; electron transfer coupled with mass accumulation [10] |

| Cathodic current peak | Positive Δf, decreasing ΔD | Reductive dissolution or desorption; mass release with structural compaction [10] |

| Small faradaic current | Large negative Δf, increasing ΔD | Non-faradaic processes dominate; extensive swelling or hydration changes [6] |

| Continuous current | Progressive negative Δf | Gradual passivation layer formation; surface blocking through film growth [11] |

| Current oscillation | Oscillating Δf and ΔD | Dynamic processes; cyclic adsorption/desorption or structural rearrangements [9] |

Case Study: Cardiomyocyte Contraction Monitoring for Drug Screening

QCM-D technology has been successfully applied to monitor the beating function of primary cardiomyocytes for drug screening applications [9]. In this innovative approach, cardiomyocytes are cultured directly on QCM-D sensors, and their mechanical contractions are detected as frequency and dissipation shifts.

Experimental Setup:

- Primary cardiomyocytes from neonatal SD rats cultured on fibronectin-modified gold electrodes

- 9 MHz AT-cut quartz crystals with optimal self-assembly modification

- Combined QCM and electrical impedance spectroscopy (EIS) monitoring

- Drug treatments: isoprenaline (positive inotropic drug) and verapamil (negative inotropic drug)

Data Analysis Method: The cell-induced frequency changes are analyzed to calculate beating rate (BR), beating amplitude (BA), and rhythm irregularity indices. The QCM technique demonstrates high sensitivity for detecting drug-induced changes in cardiomyocyte contraction, with results consistent with traditional electrical impedance measurements [9]. This application highlights the potential of QCM-D for preclinical cardiotoxicity screening and pharmaceutical development.

Applications in Advanced Research Domains

Energy Storage Materials Development

EQCM-D has emerged as a valuable technique for investigating fundamental processes in energy storage materials, particularly for flow battery applications [11]. Studies of nitroxide-radical molecules like TEMPO and its derivatives have revealed crucial passivation behavior that impacts battery performance and longevity. Research demonstrates that 4-hydroxy-TEMPO (HT) exhibits unusual surface passivation during electrooxidation in concentrated electrolytes, forming a polymeric-type layer over the electrode surface [11]. This passivation is concentration-dependent and scan rate-dependent, with greater film formation at higher concentrations and lower scan rates.

The QCM-D methodology provides unique insights into these passivation dynamics by quantifying mass accumulation during oxidation cycles while correlating with electrochemical signals. This approach has identified that the hydroxyl moiety in HT mediates the passivation chemistry, as TEMPO without this functional group shows minimal surface film formation [11]. These findings have direct implications for designing stable redox-active molecules for grid-scale energy storage applications.

Controlled Drug Delivery Systems

The EQCM-D platform enables detailed investigation of drug incorporation and release from conductive polymer matrices [10]. In one application, researchers studied the electrochemically controlled binding and release of chlorpromazine from a composite polypyrrole/melanin film [10]. The QCM-D provided direct measurement of mass changes during drug loading and release phases, while cyclic voltammetry correlated these mass transitions with oxidation and reduction events.

This approach revealed new information on ion dynamics under in situ conditions, demonstrating how electrical stimulation triggers drug release through electrochemical switching of the polymer matrix [10]. The combination of mass sensing and electrochemical control provides a powerful tool for optimizing stimulus-responsive drug delivery systems, with potential applications in neural interfaces, implantable devices, and targeted therapeutics.

Biomolecular Interactions at Functionalized Interfaces

EQCM-D technology advances the study of redox-controlled biomolecular interactions at functionalized interfaces. Research has demonstrated that electrical stimulation significantly enhances fibronectin adsorption onto conductive copolymer surfaces (PEDOT-co-PDLLA), with greater adsorption observed at +0.5 V compared to -0.125 V or open circuit potential [6]. Furthermore, the dissipation data suggests that fibronectin binds to the copolymer interface in an unfolded conformation, which promotes better fibroblast adhesion and development [6].

These findings have important implications for designing bioelectrodes and tissue engineering scaffolds where controlled protein adsorption is critical for biocompatibility and functionality. The ability to precisely manipulate molecular interactions through applied potentials, while monitoring both quantitative mass changes and structural properties, opens new possibilities for intelligent biointerfaces that dynamically respond to electrical signals.

The Electchemical Quartz Crystal Microbalance with Dissipation monitoring (EQCM-D) is a powerful analytical technique that integrates two complementary methodologies: electrochemistry and mass/viscoelasticity sensing. This combination allows researchers to obtain simultaneous, real-time data on both the electrochemical reactions and the corresponding mass and structural changes occurring at an electrode surface. The fundamental principle underpinning this technology is the synergistic relationship between these measurement types, enabling the investigation of complex interfacial processes that neither technique could elucidate in isolation [3]. In the context of redox studies, this integration is particularly valuable as it directly correlates electron transfer events with material fluxes and morphological transformations.

The core of the EQCM-D system is a piezoelectric quartz crystal sensor that also serves as the working electrode in an electrochemical cell. The QCM-D component operates by applying an oscillating electric field across the quartz crystal, causing it to resonate at a characteristic frequency. When mass is deposited on or removed from the electrode surface, it changes the resonance frequency (Δf) of the crystal, providing gravimetric information with nanogram sensitivity. Simultaneously, the energy dissipation (ΔD) reveals information about the viscoelastic properties (rigidity or softness) of the surface layer. The electrochemical half of the system controls or measures the potential and current, characterizing redox reactions, electron transfer processes, and charge states [3] [12]. This simultaneous measurement capability provides a comprehensive window into electrochemical processes, making EQCM-D an indispensable tool for researchers investigating mechanisms in battery development, electrocatalysis, corrosion science, and biomolecular interactions.

Key Applications in Redox Studies

The application of EQCM-D in redox studies provides unprecedented insights into the molecular mechanisms of electrochemical reactions. The following table summarizes the primary areas where EQCM-D delivers critical information:

| Application Area | Key Insights Provided by EQCM-D | Representative Systems |

|---|---|---|

| Ion (de)insertion in Electrodes | Mass change per electron transfer (MPE); ion-solvent coupling; co-insertion behavior [12]. | Battery electrode materials (e.g., Li-ion, Na-ion) [12]. |

| Nucleation & Growth | Rigidity of deposited layers; kinetics of deposition/stripping; identification of intermediate states [3] [12]. | Metal electrodeposition (e.g., Cu); alkali metal anodes [3] [12]. |

| Interfacial Reaction & Reconstruction | Formation dynamics, evolution, and mechanical properties of interphases (e.g., SEI, CEI) [12] [13]. | Solid electrolyte interphase (SEI) on anodes [12] [13]. |

| Redox-Active Polymers | Mechanisms of charge compensation (ion vs. proton transfer); solvent fluxes; polymer reconfiguration [14]. | Conducting polymers (e.g., poly(o-toluidine), polyaniline) [14]. |

| Inorganic Redox Systems | Stoichiometry of redox switching; identity of charge-compensating ions; solvent coupling [15]. | Prussian blue and its analogs [15]. |

Case Study: Copper Redox Cycling

A quintessential example that demonstrates the power of EQCM-D is the study of copper reduction and oxidation (Cu²⁺ + 2e⁻ ⇌ Cu⁰). In this experiment, the electrochemical data (cyclic voltammogram) shows the current associated with the reduction and oxidation peaks, while the simultaneously collected QCM-D data displays a mass increase (negative frequency shift) during copper deposition and a mass decrease (positive frequency shift) during copper dissolution [3].

- Experimental Data: During deposition, a rigid copper layer forms, indicated by a frequency shift of up to 500-600 Hz and a relatively small dissipation shift [3].

- Unique Insight: The electrochemical current alone cannot quantify the amount of material deposited, and the mass signal alone cannot confirm the redox state of the copper. Only the combined data confirms that the electron transfer is directly linked to the formation and removal of solid, rigid copper metal, and allows for the precise calculation of the mass change per electron transferred [3].

Case Study: Prussian Blue Redox Switching

A study on Prussian blue (PB) films highlights EQCM-D's ability to unravel complex ion and solvent transport mechanisms. The redox switching of PB involves the insertion and expulsion of ions to maintain electroneutrality. EQCM-D measurements revealed that water transfer is decoupled from and opposite to potassium ion (K⁺) transfer during cycling [15].

- Quantitative Findings: The mole ratio of water to potassium (ρ) was approximately -0.5 at a scan rate of 0.010 V s⁻¹, meaning about half a water molecule was expelled per K⁺ ion inserted [15].

- Mechanistic Elucidation: The study further demonstrated that this ratio depends on pH and electrolyte composition. At pH 2.7, proton transfer competes with K⁺ transfer, while in other electrolytes, anion transfer can compete with cation movement [15]. This level of mechanistic detail is inaccessible to purely electrochemical techniques.

Case Study: Conducting Polymer Redox

Research on poly(o-toluidine) films in perchloric acid used a combined EQCM and Probe Beam Deflection (PBD) instrument to distinguish between the fluxes of protons, anions, and solvent. The EQCM detected mass changes from all species, while PBD was primarily sensitive to ions. This complementary approach revealed that the first redox process involved exchanges of both protons and anions, and that the degree of film hydration profoundly affected the ion exchange ratio [14]. This case underscores EQCM-D's value in deconvoluting the contributions of different mobile species in redox reactions, especially in soft, hydrated materials.

Experimental Protocols

Protocol 1: Investigating Metal Electrodeposition/Stripping

Aim: To characterize the kinetics, mass changes, and rigidity of a deposited metal layer (e.g., copper) using EQCM-D coupled with cyclic voltammetry.

Materials and Reagents:

- EQCM-D System equipped with an electrochemical flow cell.

- Sensor Crystals: Gold-coated quartz crystals (e.g., 5 MHz), which serve as the working electrode.

- Counter Electrode: Platinum wire or mesh.

- Reference Electrode: Ag/AgCl or Saturated Calomel Electrode (SCE).

- Electrolyte Solution: 0.1 M CuSO₄ in 0.1 M H₂SO₄ (or another supporting electrolyte). Solutions should be prepared with high-purity water and analytical grade salts.

Procedure:

- Setup: Place the gold sensor in the flow cell and connect the electrochemical leads. Introduce the electrolyte solution and ensure no bubbles are trapped on the sensor surface.

- Baseline Stabilization: Flow the electrolyte through the cell while monitoring the frequency (f) and dissipation (D) signals until a stable baseline is achieved (drift < 1 Hz/min).

- Experiment Execution:

- In the software, set up a method that synchronizes the electrochemical and QCM-D measurements.

- Program a cyclic voltammetry method, for example, scanning between -0.3 V and +0.6 V vs. Ag/AgCl for 5 cycles at a scan rate of 50 mV/s.

- Simultaneously, initiate QCM-D monitoring, recording f and D at multiple overtones (e.g., 3rd, 5th, 7th).

- Data Collection: The system will output a voltammogram (current vs. potential) and synchronized plots of Δf and ΔD vs. time or potential.

- Post-measurement Rinse: Flush the cell with a clean supporting electrolyte to remove copper ions and prevent further deposition.

Data Analysis:

- Correlate the cathodic current peak with the negative Δf shift (mass increase) to confirm copper deposition.

- Correlate the anodic current peak with the positive Δf shift (mass loss) to confirm copper stripping.

- The small ΔD changes during deposition indicate the formation of a rigid, well-adhered layer. A large ΔD would suggest a soft or viscoelastic deposit.

- Use the Sauerbrey equation to convert the frequency shift to mass change, and correlate this with the charge passed to calculate mass per electron (MPE), which should correspond to the atomic mass of copper divided by 2 electrons (~31.8 ng/µC).

Protocol 2: Probing Ion and Solvent Flux in a Redox Film

Aim: To determine the identity of charge-compensating ions and the accompanying solvent flux during the redox cycling of a surface-bound film (e.g., Prussian blue or a conducting polymer).

Materials and Reagents:

- EQCM-D System with electrochemical cell.

- Sensor Crystals: Appropriate working electrode (e.g., gold, ITO).

- Electrodes: Pt counter electrode and suitable reference electrode.

- Film Preparation Solutions: For Prussian blue: solutions of FeCl₃ and K₃Fe(CN)₆, or a solution for electrochemical deposition [15].

- Electrolyte Solutions: Various potassium salt solutions (e.g., 0.1 M K₂SO₄, KCl) at different pH levels to probe ion-specific effects [15].

Procedure:

- Film Fabrication: First, deposit a thin film of the redox-active material (e.g., Prussian blue) onto the sensor surface. This can be done electrochemically by cycling the potential or holding at a deposition potential in a solution of the precursors [15].

- EQCM-D Measurement:

- Place the modified sensor in the cell and introduce the electrolyte of interest (e.g., 0.1 M K₂SO₄).

- Use cyclic voltammetry (e.g., scanning between 0.2 V and 1.0 V vs. SCE) to repeatedly switch the film between its oxidized and reduced states.

- Record the current, potential, and the simultaneous f and D changes.

- Solution Variation: Repeat the measurement in different electrolytes (e.g., changing the anion from sulfate to chloride) or at different pH values to observe changes in the mass response.

- Scan Rate Variation: Perform experiments at different scan rates (e.g., 10 mV/s and 100 mV/s) to probe kinetic effects on ion/solvent transport.

Data Analysis:

- Plot the mass change (Δm) against the charge (Q) transferred during the redox half-cycle. The slope of this plot, d(Δm)/dQ, is the mass change per electron.

- Compare the experimental mass-per-electron value to the molar masses of potential moving ions (e.g., K⁺ ~ 39 g/mol, Cl⁻ ~ 35.5 g/mol, H₃O⁺ ~ 19 g/mol). A value lower than the ion's mass suggests solvent is expelled upon ion insertion, while a higher value suggests solvent is co-inserted.

- By testing different electrolytes, you can deduce whether cations, anions, or both are moving to compensate charge. For example, if the mass response is identical in KCl and K₂SO₄, K⁺ is likely the dominant moving ion.

Visualization of the EQCM-D Workflow and Data Synergy

The following diagram illustrates the integrated process of an EQCM-D experiment and how data from the two techniques are combined to provide unique insights.

The Scientist's Toolkit: Essential Research Reagents and Materials

Successful execution of EQCM-D experiments requires careful selection of materials and reagents. The following table details key components and their functions in typical redox studies.

| Item | Function/Description | Application Notes |

|---|---|---|

| QCM-D Sensor (Working Electrode) | Piezoelectric quartz crystal with conductive coating (e.g., Au, Pt, ITO). Serves as the substrate for reactions and mass sensing. | Gold is common for general use; ITO is chosen for optical transparency; material must be compatible with the electrochemical window [3] [15]. |

| Reference Electrode | Provides a stable and known reference potential (e.g., Ag/AgCl, SCE). | Critical for accurate potential control in three-electrode setups. Choice depends on electrolyte compatibility [3] [15]. |

| Counter Electrode | Completes the electrical circuit in the electrochemical cell (e.g., Pt wire/mesh). | Must be inert and have a surface area larger than the working electrode to avoid being rate-limiting [3]. |

| Supporting Electrolyte | Electrochemically inert salt (e.g., KCl, K₂SO₄, NaClO₄) at high concentration (0.1-1.0 M). | Carries current and minimizes resistive drop (iR drop). Ion type and concentration can influence the mechanism [15]. |

| Redox-Active Species | The molecule or ion of interest that undergoes electrochemical reaction (e.g., Cu²⁺, Prussian blue film, conducting polymer). | Can be in solution or pre-deposited as a film on the sensor. Purity is essential for reproducible results [3] [15]. |

| Solvent | High-purity water or organic solvent (e.g., propylene carbonate, acetonitrile). | Must dissolve electrolytes and analytes, and be free of contaminants that could adsorb on the sensor or react. |

| Binder Materials | (For composite electrodes) Polymers like PVDF or Nafion to adhere active material particles to the sensor. | Used in battery research to create model composite electrodes; should be electrochemically inert in the potential range of study [13]. |

Electrochemical Quartz Crystal Microbalance with Dissipation Monitoring (EQCM-D) is a powerful analytical technique that combines the mass and viscoelastic sensing capabilities of QCM-D with the controlled perturbation and monitoring functions of electrochemistry. This synergy allows researchers to answer complex questions that neither technique could address alone by providing a direct correlation between electrochemical reactions (current and potential) and the resulting mass, structural, and viscoelastic changes at the electrode surface in real-time [3]. When an electrical potential difference is applied to drive an identifiable chemical change, the QCM-D simultaneously measures the consequent changes in resonant frequency (Δf), related to mass, and energy dissipation (ΔD), related to the viscoelastic properties of the adlayer [3]. This combination is particularly powerful for studying redox-active systems, where electron transfer processes often involve mass transport, ion exchange, and significant structural rearrangements of the material at the electrode interface.

Fundamental Principles and Key Parameters

QCM-D Core Signals: Frequency (Δf) and Dissipation (ΔD)

The operational principle of QCM-D is based on the piezoelectric properties of an AT-cut quartz crystal. When an alternating voltage is applied, the crystal oscillates at its resonant frequency. Any mass attached to or removed from the sensor surface causes a shift in this resonant frequency (Δf). The relationship between frequency shift and mass change for a thin, rigid, and evenly distributed film is described by the Sauerbrey equation:

Δm = - (C • Δf) / n

Where Δm is the change in mass per unit area, C is a constant dependent on the properties of the quartz crystal (e.g., ~17.7 ng/(cm²•Hz) for a 5 MHz crystal), and n is the overtone number (1, 3, 5, ...) [7] [2] [16]. Simultaneously, the QCM-D measures the energy dissipation (ΔD), which quantifies the dampening of the oscillating motion after the driving voltage is switched off. The dissipation factor is defined as the energy dissipated per oscillation cycle divided by the total energy stored in the system (D = Edissipated / (2π Estored)) [7] [17]. A high dissipation indicates a soft, viscous, and water-rich layer that deforms under shear stress and dissipates energy, whereas a low dissipation indicates a rigid, elastic layer that moves in sync with the crystal oscillation [2] [18].

Electrochemical Parameters: Current and Potential

In the combined EQCM-D setup, the QCM-D sensor also acts as the working electrode in an electrochemical cell. This allows for the control and measurement of two key electrochemical parameters:

- Potential (E): The electrical potential applied to the working electrode relative to a reference electrode (e.g., Ag/AgCl). Controlling the potential dictates the thermodynamics of the redox reactions at the electrode-electrolyte interface.

- Current (I): The electrical current measured as a result of the applied potential. The current is proportional to the rate of the electron transfer (redox) reaction.

The combination of these signals provides a multidimensional view of electrochemical processes, revealing not just electron transfer, but also associated mass changes and structural dynamics.

Correlation of Multimodal Data

The power of EQCM-D lies in the direct, real-time correlation of these independent data streams. For instance, during a redox reaction:

- A current peak in a cyclic voltammogram indicates a Faradaic electron transfer process.

- A concurrent negative frequency shift (Δf) indicates a mass increase at the electrode, suggesting, for example, the incorporation of ions from the electrolyte to maintain charge neutrality during oxidation.

- The accompanying dissipation shift (ΔD) reveals whether the incorporated mass is rigidly bound (small ΔD) or forms a soft, viscous layer (large ΔD) [3] [19].

Table 1: Interpretation of Correlated EQCM-D Signals during Redox Events.

| Electrochemical Signal | Frequency Shift (Δf) | Dissipation Shift (ΔD) | Composite Interpretation |

|---|---|---|---|

| Anodic (Oxidation) Current Peak | Negative (decrease) | Small Increase | Rigid deposition of material (e.g., metal) or insertion of small, rigidly bound ions [3]. |

| Anodic (Oxidation) Current Peak | Negative (decrease) | Large Increase | Uptake of solvent and ions, leading to the formation of a soft, swollen, viscoelastic polymer film [19]. |

| Cathodic (Reduction) Current Peak | Positive (increase) | Small Decrease | Removal of a rigid mass from the electrode surface (e.g., metal stripping or ion expulsion from a rigid matrix) [3]. |

| Cathodic (Reduction) Current Peak | Positive (increase) | Large Decrease | Loss of a soft, viscous layer from the electrode interface (e.g., de-doping and collapse of a polymer film) [19]. |

Experimental Protocol: EQCM-D for a Model Redox System

The following protocol details an experiment for studying the electrodeposition and stripping of copper, a classic model system for EQCM-D [3].

Research Reagent Solutions and Essential Materials

Table 2: Key Reagents and Materials for EQCM-D Copper Redox Studies.

| Item | Function / Relevance | Example / Specification |

|---|---|---|

| EQCM-D Instrument | Core apparatus for simultaneous electrochemical and gravimetric/viscoelastic measurements. | Q-Sense QCM-D with electrochemical module (e.g., QEM 401) [3]. |

| Potentiostat/Galvanostat | Instrument for applying controlled potentials and measuring resulting currents. | Integrated system or external potentiostat (e.g., BioLogic) [19]. |

| Gold-coated QCM-D Sensor | Serves as both the piezoelectric mass sensor and the working electrode. | AT-cut, 5 MHz fundamental frequency, sputtered with gold electrodes (e.g., QSX 301) [3] [2]. |

| Copper Sulfate (CuSO₄) | Source of Cu²⁺ ions for the redox reaction (Cu²⁺ + 2e⁻ ⇌ Cu⁰). | 1-10 mM in supporting electrolyte [3]. |

| Sulfuric Acid (H₂SO₄) | Provides a supporting electrolyte to ensure sufficient conductivity and a low pH to prevent copper hydrolysis. | 0.1 - 0.5 M aqueous solution [3]. |

| Platinum Counter Electrode | Completes the electrical circuit in the electrochemical cell. | High-purity platinum wire or mesh. |

| Reference Electrode | Provides a stable, known potential reference for the working electrode. | Ag/AgCl (in 3M KCl) or Saturated Calomel Electrode (SCE). |

Step-by-Step Procedure

- Sensor Preparation: Clean the gold-coated QCM-D sensor using a standard protocol (e.g., 10 minutes in a 5:1:1 mixture of Milli-Q water, ammonia hydroxide (25%), and hydrogen peroxide (30%) at 75°C). Rinse thoroughly with Milli-Q water and dry under a stream of nitrogen gas.

- Instrument Setup: Mount the clean sensor in the EQCM-D electrochemical flow cell or chamber. Connect the potentiostat leads to the sensor (working electrode), the platinum wire (counter electrode), and the reference electrode.

- Baseline Establishment: Flow the supporting electrolyte solution (e.g., 0.1 M H₂SO₄) through the cell at a constant rate (e.g., 0.1 mL/min). Allow the system to stabilize until the frequency (f) and dissipation (D) signals reach a stable baseline. Maintain a constant temperature (e.g., 25 ± 0.1 °C) throughout the experiment [2].

- Experimental Execution:

- In the instrument software, configure the QCM-D to monitor multiple overtones (e.g., n = 3, 5, 7) and set the electrochemical technique to Cyclic Voltammetry.

- Set the scan parameters: for example, a potential window of -0.3 V to +0.6 V vs. Ag/AgCl and a scan rate of 50 mV/s. Perform 5-10 consecutive cycles.

- Initiate the simultaneous measurement. The instrument will now record current (I) vs. potential (E), frequency (Δf) vs. time, and dissipation (ΔD) vs. time.

- Data Collection: The raw data will consist of three synchronized data streams: the voltammogram (I vs. E), and the QCM-D responses (Δf and ΔD vs. time for each overtone).

Workflow and Data Correlation

The following diagram illustrates the logical workflow of the EQCM-D experiment and how the different data streams are generated and correlated.

Diagram 1: EQCM-D Experimental Data Workflow.

Data Analysis and Interpretation

Quantitative Analysis of Copper Deposition/Stripping

Using the model protocol, the collected data can be quantitatively analyzed. For the copper system, during the cathodic (negative-going) potential sweep, Cu²⁺ ions are reduced to solid copper (Cu⁰) that deposits on the sensor electrode. This is observed as a cathodic current peak and a concurrent large negative frequency shift (e.g., -500 to -600 Hz) [3]. The small dissipation shift confirms the formation of a rigid metal layer. The mass of deposited copper can be calculated using the Sauerbrey equation, typically applied to the fundamental frequency (n=1) or an average of several overtones.

During the subsequent anodic (positive-going) sweep, the copper is oxidized back to Cu²⁺ ions, which dissolve into the solution. This is seen as an anodic current peak and a positive frequency shift of equal magnitude to the deposition shift, indicating complete mass removal [3]. The data can be summarized in a table for easy comparison across cycles.

Table 3: Example Quantitative Data from EQCM-D Analysis of Copper Redox Cycling.

| Cycle Number | Reduction Peak Current (mA) | Δf during Deposition (Hz) | Calculated Mass (ng/cm²) | Oxidation Peak Current (mA) | Δf during Stripping (Hz) | Mass Efficiency (%) |

|---|---|---|---|---|---|---|

| 1 | -1.25 | -580 | 1026 | 1.28 | +582 | 100.3 |

| 2 | -1.24 | -575 | 1017 | 1.26 | +576 | 100.2 |

| 3 | -1.23 | -572 | 1012 | 1.25 | +573 | 100.2 |

Advanced Application: Conducting Polymer Redox Switching

A more complex application involves the study of conducting polymers, such as polypyrrole. The diagram below illustrates the distinct mechanistic steps and their corresponding signatures in the current, frequency, and dissipation data during one voltammetric cycle.

Diagram 2: Signaling Pathway for Polymer Redox Cycling.

As shown in Diagram 2, the process involves:

- Doping (Oxidation): As the potential is swept positively, the polymer backbone is oxidized. To maintain electroneutrality, anions from the electrolyte are inserted into the polymer film, causing a mass increase (negative Δf) and a modest change in dissipation [19].

- Polymer Growth (at high potentials): At sufficiently positive vertex potentials, the monomer itself is oxidized, leading to further polymerization and a significant, irreversible mass increase (strong negative Δf slope) [19].

- De-doping (Reduction): When the potential is swept back negatively, the polymer is reduced, and the anions are expelled, resulting in a mass decrease (positive Δf) [19].

The dissipation shifts throughout this process provide critical insight into the changing viscoelasticity of the polymer film as it swells with solvent and ions during doping and de-swells during de-doping.

The correlation of frequency (Δf) and dissipation (ΔD) shifts with electrochemical current and potential provides an unparalleled, multi-parameter view of interfacial processes during redox reactions. As detailed in these application notes, EQCM-D can quantitatively distinguish between simple, rigid deposition/stripping (as in the copper model) and complex, viscoelastic transformations (as in conducting polymers). The protocols and data analysis frameworks provided here serve as a foundational guide for researchers applying this powerful technique to advance studies in battery technology, electrocatalysis, corrosion science, and bio-electrochemistry. By moving beyond simple mass detection to include mechanical properties and their coupling to electrochemical driving forces, EQCM-D offers a pathway to deeper mechanistic understanding and more intelligent material and device design.

The Quartz Crystal Microbalance with Dissipation monitoring (QCM-D) is a powerful, surface-sensitive analytical technique that provides real-time information about molecular interactions at interfaces. At the core of this technology lies the piezoelectric sensor, a quartz crystal that enables the conversion of electrical energy into mechanical energy and vice versa. This sensor's unique properties make it indispensable for studying soft and thick films, going beyond the capabilities of traditional QCM, which is primarily limited to characterizing thin and rigid films [20].

The piezoelectric effect, discovered by Pierre and Jacques Curie in 1880, describes the ability of certain materials to generate an electrical charge in response to applied mechanical stress [21]. Quartz is the preferred piezoelectric material in QCM applications due to its low acoustic wave resistance, high shear modulus, and excellent chemical stability [21]. In a QCM-D sensor, a thin quartz crystal disk is sandwiched between two electrodes. When an alternating voltage is applied to these electrodes, the piezoelectric effect causes the crystal to oscillate at its resonance frequency in a thickness-shear mode [20].

Fundamental Principles of QCM-D Operation

From QCM to QCM-D: Measuring Frequency and Dissipation

Traditional QCM measures only changes in the resonance frequency (Δf) of the quartz crystal, which relates primarily to mass adsorption on the sensor surface according to the Sauerbrey equation [21]. QCM-D advances this technology by simultaneously measuring two parameters: the resonance frequency (f) and the energy dissipation (D) [20]. The dissipation parameter quantifies the energy losses in the system, which provides crucial information about the viscoelastic properties of the adsorbed layer.

The QCM-D technique typically employs a "pinging" approach, where the crystal is set to oscillate by applying an alternating voltage, and then the driving power is rapidly switched off. The oscillation decay is monitored, with the decay time being inversely proportional to the dissipation factor [20]. This dual measurement capability allows researchers to distinguish between rigid, well-coupled masses that follow the Sauerbrey relationship and soft, viscoelastic layers that require more complex modeling for interpretation.

Table 1: Key Parameters Measured in QCM vs. QCM-D

| Parameter | Traditional QCM | QCM-D | Significance |

|---|---|---|---|

| Frequency (Δf) | Measured | Measured | Relates to mass changes at sensor surface |

| Dissipation (ΔD) | Not measured | Measured | Quantifies energy loss, indicates viscoelastic properties |

| Data Output | Mass adsorption | Mass, thickness, viscoelastic properties | More comprehensive layer characterization |

| Application Scope | Rigid, thin films | Soft, thick, viscoelastic films | Extended to biological samples, polymers, hydrogels |

The Sauerbrey Equation and Beyond

For thin, rigid, and uniformly adsorbed films, the relationship between frequency shift and mass change is described by the Sauerbrey equation:

$$\Delta fn = -n \frac{2f{0,n}^2}{\sqrt{\muq \rhoq}} \Delta m_a$$ [21]

Where Δfn is the change in resonant frequency at the n-th harmonic, f{0,n} is the resonant frequency at the n-th harmonic, μq is the shear modulus of quartz, ρq is the quartz density, and Δm_a is the areal mass change.

For non-rigid films that dissipate energy, the Sauerbrey equation becomes insufficient, and the additional dissipation data collected by QCM-D enables the application of viscoelastic modeling to extract more accurate information about mass, thickness, and mechanical properties of the adsorbed layer [20].

The Piezoelectric Sensor as a Working Electrode in EQCM-D

Integration of Electrochemistry with QCM-D

The combination of QCM-D with electrochemistry, known as Electrochemical QCM-D (EQCM-D), creates a powerful tool for investigating electrochemical processes at interfaces. In this configuration, the piezoelectric sensor does double duty: it functions as both the mass sensor and the working electrode in an electrochemical cell [3]. This dual functionality enables direct correlation between electrochemical reactions and the resulting mass and viscoelastic changes at the electrode-electrolyte interface.

The EQCM-D setup allows researchers to apply controlled potentials or currents to the sensor/working electrode while simultaneously monitoring the resulting mass changes and structural modifications of the surface layer. This capability is particularly valuable for studying processes such as electrodeposition, redox reactions in polymer films, corrosion, and electrochemical transformations of biological molecules [3].

Table 2: Electrochemical Techniques Compatible with EQCM-D

| Technique | Primary Control Parameter | Typical Applications in EQCM-D |

|---|---|---|

| Cyclic Voltammetry | Potential | Studying redox reactions, deposition/stripping processes |

| Galvanostatic Cycling | Current | Battery material research, electroplating studies |

| Amperometric Cycling | Potential | Catalyst research, electrochemical sensors |

| Impedance Spectroscopy | AC Potential | Interface characterization, film properties |

Experimental Evidence: Copper Deposition and Stripping

A representative EQCM-D experiment demonstrates the reduction and oxidation of copper. When copper is reduced to solid copper on the sensor surface (functioning as the working electrode), the QCM-D data shows a substantial negative frequency shift of 500-600 Hz, indicating mass deposition. The relatively small dissipation shift confirms rigid deposition. When the copper is oxidized again, the process reverses, with frequency returning toward baseline as mass leaves the electrode surface [3].

This simultaneous electrochemical and gravimetric monitoring provides insights that neither technique could deliver alone. The electrochemical data reveals charge transfer processes, while the QCM-D data quantifies the mass changes and structural properties of the deposited layer, enabling a comprehensive understanding of the electrochemical processes [3].

Experimental Protocols for EQCM-D Studies

Sensor Preparation and Setup

Materials and Reagents:

- QCM-D sensors with gold electrodes (often with Ti adhesion layer)

- Electrochemical cell specifically designed for EQCM-D

- Reference electrode (Ag/AgCl or calomel)

- Counter electrode (platinum wire or mesh)

- Electrolyte solutions appropriate for the system under study

- Purge gas (e.g., nitrogen or argon) for deoxygenation

Procedure:

- Sensor Cleaning: Clean the piezoelectric sensor following manufacturer protocols, typically including UV-ozone treatment, plasma cleaning, or chemical cleaning sequences.

- Baseline Establishment: Mount the sensor in the electrochemical cell and establish a stable frequency and dissipation baseline in the electrolyte solution.

- Electrochemical Setup: Position reference and counter electrodes to ensure proper electrochemical cell configuration without interfering with sensor oscillation.

- Experimental Sequence: Initiate simultaneous electrochemical control and QCM-D monitoring according to the experimental design.

Simultaneous EQCM-D Measurement Protocol

For Electrodeposition Studies (e.g., Copper):

- Initialization: Set up the QCM-D to monitor multiple harmonics (typically 3rd, 5th, and 7th) while configuring the potentiostat for cyclic voltammetry.

- Potential Cycling: Program potential cycles appropriate for the redox system under study (e.g., for copper: cycle between potentials where reduction and oxidation occur).

- Simultaneous Data Collection: Initiate both QCM-D and electrochemical measurements simultaneously to ensure temporal correlation.

- Data Analysis: Correlate current peaks in voltammograms with frequency and dissipation changes to identify mass deposition/removal and structural changes.

Diagram 1: EQCM-D Experimental Workflow

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Essential Materials for EQCM-D Research

| Material/Reagent | Function/Application | Technical Considerations |

|---|---|---|

| Quartz Sensors with Gold Electrodes | Piezoelectric substrate and working electrode | Ti adhesion layer preferred over Cr for electrochemical stability [21] |

| Reference Electrodes (Ag/AgCl) | Provide stable reference potential for electrochemical control | Choose appropriate reference based on electrolyte compatibility |

| Counter Electrodes (Pt wire/mesh) | Complete electrochemical circuit without reaction interference | High surface area preferred to minimize polarization |

| Electrolyte Solutions | Provide ionic conductivity for electrochemical measurements | Purify to remove contaminants; degas for oxygen-sensitive systems |

| Redox-Active Molecules | Subjects for electrochemical-QCM-D studies | Vary from metal ions (Cu²⁺) to organic molecules and polymers |

| Viscoelastic Modeling Software | Data analysis for soft films | Required for interpreting dissipation data from non-rigid layers |

Advanced Applications in Redox Studies

The unique capabilities of EQCM-D make it particularly valuable for redox studies in various research domains:

Battery and Energy Research: EQCM-D enables real-time monitoring of electrode-electrolyte interfaces during charge-discharge cycles, providing insights into solid-electrolyte interphase (SEI) formation, lithium plating, and degradation mechanisms [3] [22].

Electrocatalyst Characterization: Researchers can correlate electrochemical signals with mass changes during catalytic reactions, distinguishing between adsorption processes, reaction intermediates, and product formation [3].

Polymer Redox Systems: For electroactive polymers such as polyaniline, EQCM-D can monitor ion and solvent fluxes during redox switching, providing crucial information about doping mechanisms and viscoelastic property changes [23].

Biomolecular Electrochemistry: The technique enables studies of redox proteins and biomolecules at electrode surfaces, monitoring both electron transfer and associated conformational changes through dissipation monitoring [3].

Diagram 2: Information Integration in EQCM-D

The piezoelectric sensor serves as the fundamental component that enables the sophisticated capabilities of the QCM-D system, particularly when extended to electrochemical applications. Its dual role as both a mass sensor and working electrode in EQCM-D configurations provides researchers with a unique window into interfacial processes, allowing direct correlation between electrochemical reactions and the resulting mass and structural changes. This powerful combination continues to advance research in fields ranging from energy storage and materials science to biological redox systems, making it an indispensable tool for modern interfacial science.

EQCM-D in Action: Methodologies and Real-World Applications in Redox Research

Electrochemical Quartz Crystal Microbalance with Dissipation monitoring (EQCM-D) is a powerful analytical technique that combines the mass sensitivity of a quartz crystal microbalance with the controlled perturbation of electrochemistry. This combination allows researchers to simultaneously monitor current, potential, mass changes, and viscoelastic properties at an electrode-electrolyte interface in real-time [24]. For redox studies, this provides unparalleled insights into reaction mechanisms, ion transport phenomena, and structural changes occurring during electrochemical processes. This application note details the configuration, calibration, and implementation of an EQCM-D system specifically optimized for investigating redox processes, with practical protocols for researchers in materials science and electrochemistry.

EQCM-D Fundamental Principles

The EQCM-D technique builds upon the inverse piezoelectric effect, where an oscillating quartz crystal resonator serves as the working electrode in an electrochemical cell. The technology measures two fundamental parameters: the resonance frequency (f) and the energy dissipation (D) [24].

- Frequency Shift (Δf): Primarily relates to mass changes at the sensor surface according to the Sauerbrey equation, where a decrease in frequency indicates mass accumulation, and an increase indicates mass loss [24] [25].

- Dissipation Shift (ΔD): Quantifies the energy losses in the system and provides information about the viscoelastic character of the adhered layer [24] [26]. An increase in dissipation indicates a more soft, viscoelastic film, while little to no change suggests rigid, well-coupled layers.

Measurement Approaches: QCM-D vs. QCM-I

Two primary technical methods exist for monitoring these energy losses:

Table 1: Comparison of QCM Measurement Techniques

| Feature | QCM-D (Decay-based) | QCM-I (Impedance-based) |

|---|---|---|

| Measurement Principle | Measures oscillation decay time after excitation ("pinging") [27] | Analyzes impedance spectrum across resonance frequency [27] |

| Time Resolution | High (fast measurement) [27] | Lower (slower frequency sweeps) [27] |

| Key Advantage | Insensitive to shunt capacitance; stable measurement [27] | Full characterization of equivalent circuit [27] |

| Suitability for Redox Studies | Excellent for fast kinetics | Suitable for slower processes |

For most redox applications involving dynamic processes, the high time resolution of decay-based QCM-D is advantageous [27].

System Configuration

Core Hardware Components

A complete EQCM-D system for redox studies requires integration of electronic instrumentation, fluidics, and an electrochemical cell.

Table 2: Essential System Components for EQCM-D Redox Studies

| Component | Function | Typical Specifications/Examples |

|---|---|---|

| QCM-D Instrument | Drives the sensor, monitors f and D | QSense EQCM-D, openQCM [24] [23] |

| Quartz Crystal Sensor | Acts as piezoelectric resonator and working electrode | AT-cut crystal (5 MHz); Gold electrode surface [24] [28] |

| Electrochemical Cell | Houses the sensor and electrodes for controlled electrochemistry | Flow cell with temperature control [24] |

| Potentiostat/Galvanostat | Controls electrochemical potential/current | Integrated or external system [24] |

| Fluid Handling System | Introduces and exchanges electrolytes | Peristaltic or syringe pump [26] |

The Three-Electrode Electrochemical Configuration

A critical aspect of the setup is the integration of a standard three-electrode electrochemical cell, where the QCM-D sensor itself functions as the working electrode [24].

Three-Electrode EQCM-D Cell Setup. The QCM sensor acts as the Working Electrode (WE). The Potentiostat applies a potential between the WE and the Counter Electrode (CE), measured against the stable Reference Electrode (RE). The QCM-D instrument simultaneously monitors mass and viscoelastic changes.

- Working Electrode (WE): The quartz crystal sensor, typically coated with a conductive material such as gold, serves as the surface where the redox reaction and mass changes occur [24].

- Reference Electrode (RE): Provides a stable, known potential against which the WE is measured (e.g., Ag/AgCl) [24].

- Counter Electrode (CE): Completes the electrical circuit, typically made of an inert material like platinum [24].

This configuration allows for precise control of the electrode potential while simultaneously monitoring the resultant mass and viscoelastic changes.

Experimental Protocol: Copper Redox Cycling

The following detailed protocol uses the electrodeposition and stripping of copper as a model redox system to demonstrate EQCM-D capabilities [3].

Research Reagent Solutions

Table 3: Essential Reagents for Copper Redox Experiment

| Reagent | Specification | Function in Experiment |

|---|---|---|

| Copper Sulfate (CuSO₄) | 10 mM in electrolyte [3] | Source of Cu²⁺ ions for reduction to metallic copper |

| Sulfuric Acid (H₂SO₄) | 0.1 M [3] | Provides conductive electrolyte and low pH |

| Deionized Water | High purity (e.g., 18.2 MΩ·cm) | Solvent for electrolyte preparation |

| Quartz Crystal Sensors | Au-coated, cleaned | Substrate for electrodeposition and QCM signal transduction |

| Cleaning Solutions | Piranha solution, oxygen plasma, etc. [28] | Ensure contaminant-free sensor surface |

Step-by-Step Procedure

- Sensor Preparation: Clean the gold-coated quartz crystal sensor. A standard protocol involves rinsing with ethanol and subsequent oxygen plasma treatment for 5 minutes to ensure a pristine, hydrophilic surface [28].

- System Assembly: Mount the clean sensor in the EQCM-D electrochemical flow module. Connect the potentiostat leads to establish the three-electrode configuration with the sensor as the WE [24].

- Baseline Establishment: Flow the supporting electrolyte (0.1 M H₂SO₄) into the cell at a constant rate (e.g., 100 μL/min). Monitor the frequency (f) and dissipation (D) signals until stable baselines are achieved across multiple overtones (e.g., 3rd, 5th, 7th) [3] [26].

- Analyte Introduction: Introduce the copper sulfate solution (10 mM CuSO₄ in 0.1 M H₂SO₄) into the cell while continuing to monitor f and D [3].

- Electrochemical Cycling:

- Initiate Cyclic Voltammetry (CV) on the potentiostat. A typical method is to scan the potential from a starting point of +0.3 V, down to -0.5 V (to reduce Cu²⁺ to Cu⁰), then back to +0.5 V (to oxidize Cu⁰ back to Cu²⁺), and finally return to the start potential [3].

- Set an appropriate scan rate, such as 50 mV/s, and perform multiple cycles (e.g., 5 cycles) [3].

- Simultaneous Data Acquisition: Ensure the QCM-D software and potentiostat are synchronized to simultaneously collect current (I) vs. potential (E) from the CV, and frequency (Δf) and dissipation (ΔD) vs. time from the QCM-D [24] [3].

- Rinsing and Recovery: After the final cycle, flush the cell with the supporting electrolyte (0.1 M H₂SO₄) to remove copper ions from the bulk solution.

Data Interpretation and Analysis

The simultaneous data streams provide a comprehensive view of the redox process.

Interpreting Copper Redox Data. The electrochemical stimulus (Cyclic Voltammogram) induces redox reactions. Reduction causes mass gain on the sensor, detected by a frequency decrease. Oxidation causes mass loss, detected by a frequency increase. Correlating current peaks with mass changes confirms the reaction mechanism.

- During Reduction (Cu²⁺ + 2e⁻ → Cu⁰): A significant negative frequency shift (Δf down to -500 Hz or more) confirms mass accumulation due to copper deposition. The minimal dissipation change indicates the formation of a rigid, well-adhered metallic layer, validating the use of the Sauerbrey equation for quantitative mass calculation [3].

- During Oxidation (Cu⁰ → Cu²⁺ + 2e⁻): A positive frequency shift back toward the original baseline confirms mass loss as copper is stripped from the surface [3].

- Hysteresis and Non-Idealities: Differences in deposition and stripping profiles in either the current or mass signal can reveal information about nucleation mechanisms, kinetic limitations, or film morphology changes.

Advanced Applications in Redox Research

The EQCM-D technique provides critical insights for various advanced research areas:

- Battery Electrode Materials: EQCM-D can elucidate charge storage mechanisms by distinguishing between capacitive behavior (fast, minimal mass change) and battery-type behavior (significant mass change from ion insertion/expulsion). It is also crucial for studying the formation and viscoelastic evolution of the Solid Electrolyte Interphase (SEI) [24] [29] [30].

- Conducting Polymer Redox Switching: During the electropolymerization and subsequent redox cycling of polymers like polypyrrole, EQCM-D can track mass uptake associated with ion and solvent movement and correlate it with the polymer's changing viscoelastic properties, which is vital for applications in supercapacitors and biosensors [31].

- Corrosion Studies: The technique allows for in-situ monitoring of both mass changes (from oxide formation or metal dissolution) and the mechanical properties of passivating layers during corrosion processes [24].

Troubleshooting and Best Practices

- Sensor Cleaning: Contamination is a major source of noise and poor adhesion. Consistent, rigorous sensor cleaning before each experiment is paramount [28].

- Viscoelastic vs. Gravimetric Regime: If the dissipation shift (ΔD) is significant, the adsorbed layer is soft and viscoelastic. In these cases, the Sauerbrey equation is invalid, and a viscoelastic model applied to multiple overtone data is required for accurate mass determination [24] [30].

- Electrochemical Artifacts: Be aware that bubbles in the cell can cause severe signal instability. Ensure the reference electrode is stable and properly positioned. The use of a faraday cage can help reduce electronic noise.

- Data Correlation: Always correlate features in the electrochemical data (current peaks) directly with the QCM-D data (mass changes). The timing and magnitude of these correlated events are key to a valid interpretation [3].

Electrochemical Quartz Crystal Microbalance with Dissipation monitoring (EQCM-D) is a powerful analytical technique that synergistically combines the mass and viscoelastic sensing capabilities of a quartz crystal microbalance with the reaction control and monitoring features of electrochemistry [32] [24]. This integration allows researchers to simultaneously monitor electrochemical reactions and corresponding changes in mass and viscoelastic properties at the sensor surface in real-time [32]. The technique provides unique insights into interfacial processes that cannot be obtained by either method independently, enabling direct correlation between electrochemical data (current and potential) and gravimetric/mechanical properties (mass changes and dissipation) [32] [24]. EQCM-D has become an indispensable tool in advanced research fields including battery technology, fuel cell development, electrometallurgy, biomolecular interactions, and corrosion studies [32] [24].

The fundamental principle of QCM-D relies on the piezoelectric properties of an AT-cut quartz crystal, which oscillates at a characteristic resonant frequency when an alternating current is applied [33]. When mass is added to or removed from the crystal surface, the resonant frequency shifts according to the Sauerbrey equation, which relates the frequency change (Δf) to mass change per unit area (Δm) [33]. The energy dissipation factor (D) provides additional information about the viscoelastic properties of the surface layer, distinguishing between rigid and soft films [24]. In electrochemical applications, the quartz sensor itself serves as the working electrode, enabling simultaneous stimulation and monitoring of electrochemical reactions alongside mass and viscoelastic changes with nano-level sensitivity [24].

Core Electrochemical Methods in EQCM-D

Cyclic Voltammetry (CV) with QCM-D

Cyclic Voltammetry (CV) is the most commonly employed electrochemical technique in EQCM-D studies, particularly for investigating redox reactions and deposition processes [32] [19]. In CV, the potential of the working electrode is cycled linearly between designated voltage limits while measuring the resulting current [19]. When combined with QCM-D, this technique simultaneously tracks mass changes and viscoelastic properties alongside faradaic currents, providing a comprehensive view of electrochemical processes [32].

The experimental setup for CV-QCM-D employs a standard three-electrode configuration where the quartz crystal with a conductive coating (typically gold) serves as the working electrode [24] [19]. A typical protocol involves:

- Electrode Setup: Quartz crystal sensor (working electrode), reference electrode (e.g., Ag/AgCl), and counter electrode (e.g., platinum wire) [19]

- Potential Scanning: Linear potential sweep between predetermined upper and lower limits [19]

- Simultaneous Monitoring: Current response, frequency shifts (Δf), and dissipation changes (ΔD) [32] [19]

A representative application is the study of copper deposition and stripping, where CV-QCM-D reveals a negative frequency shift of 500-600 Hz during copper reduction (deposition) and a positive shift during oxidation (stripping) [32]. The small dissipation shifts observed indicate rigid deposition at the surface [32]. Another common application is investigating electroactive polymer films such as polypyrrole, where CV-QCM-D can monitor doping processes through anion insertion/deinsertion during oxidation and reduction cycles [19]. During polymer oxidation, electrolyte anions insert into the film to maintain electroneutrality, resulting in a mass increase (frequency decrease), while during reduction, anions are expelled, decreasing the mass (frequency increase) [19].

Table 1: Key Parameters for Cyclic Voltammetry in EQCM-D

| Parameter | Typical Range | Application Example | Measured Outputs |

|---|---|---|---|

| Scan Rate | 10-100 mV/s [19] | Polymer film growth | Current (I) vs. Potential (E) |

| Potential Range | Variable (e.g., -0.5 to +0.5 V for Cu deposition) [32] | Metal deposition/stripping | Frequency shift (Δf) |

| Number of Cycles | 5-20 cycles [32] [19] | Redox process reversibility | Dissipation shift (ΔD) |

| Mass Sensitivity | ng/cm² range [33] | Surface adsorption | Mass change (Δm) |

Galvanostatic Cycling with QCM-D